NEIL WALKER - Boeing: Boeing UK - Home...(projection) Doubled 2011-2014 Boeing sites in the UK...

Transcript of NEIL WALKER - Boeing: Boeing UK - Home...(projection) Doubled 2011-2014 Boeing sites in the UK...

“My older brother was a pilot in the Air Force and he used to take me to the stations from time to time and I could go around the squadrons and look at the aeroplanes. I found them fascinating. The two things seemed to blend together very well. So at 18, I found myself joining the Royal Air Force to undertake training in the engineering branch. And from there, I’ve never looked back.”

Now, a team of 12 looks up to Neil. Together they share the lofty responsibility as the first point of contact for Boeing 787 Dreamliners. Today is no different.

“We affectionately call our workspace the Goldfish Bowl. It’s the heart of the operation. We manage all aspects of maintenance for Boeing 787 Dreamliners.”

Through the giant, clear wall of the aptly named “Goldfish Bowl,” one can see a 24-hour, 365-days-a-year Boeing Dreamliner hub in action. Monitors that display anything from health information to flight trackers fill a wall like tapestries taken out of a science fiction novel. Neil and his team keep close watch.

“If anything happens, we in the Goldfish Bowl know about it first.”

Pilots and passengers aren’t the only people benefiting from Neil making a living out of his passion. Toward the end of his shift, Neil elaborates as he polishes off the last of his tea.

“Aviation is a significant industry in the UK and Boeing’s presence here is important, investing almost two billion pounds a year. We have great plans for expansion and development of the business. We’ve got a lot of exciting times to look forward to.”

For now, Neil looks forward to showing up tomorrow at the same time. Fortunately, he has the luxury of travelling from rented flat five minutes away for the rest of this week—although he probably wouldn’t mind making the trek from Yarm again.

“One of the most rewarding aspects is to be able to leave the office on an evening knowing that everything has flown on time and safely. Take it from me, you don’t travel 285 miles to work unless you’re doing something special.”

The alarm goes off again. It’s 3:15 A.M. Neil Walker knows he has reached his allotment of “snoozes” for the morning, so he rolls out of bed and splashes his face—he’s got a 285-mile trip ahead.

To work.

Yes, you read that correctly. Not for holiday. Not to reconnect with an estranged family member. Not to satisfy that innate human thirst of exploration.

To work.

To some, it’s perplexing. Not to Mr. Walker, a Lead Technical Control Engineer for Boeing.

“I live in a small market town in the Northeast called Yarm. I feel very lucky to live in that area. I travel 285 miles each way to get to work, but it’s well worth the drive. I don’t need to move any closer.”

Neil’s weekly haul takes him through the countryside of the Northeast which by any account—especially his own—is stunning. Surely, that’s part of the reason he refuses to move closer to his office, southwest of London. But you can tell by the way his eyes grow a bit softer when asked about what he does for a living that there’s a deeper reason.

Fortunately, Neil is feeling reflective on this particular trip. He opens up about a passion that started at the impressionable age of 12. A passion that began by tinkering with motorcycle engines.

“For the first couple of years I was really great at taking apart pieces, but I wasn’t so clever at putting them back together again.”

Okay, so no engineer starts out building rocket ships, but it started the itch. Turns out that itch runs in the family.

“My father was an accomplished engineer in his own right and coached me and explained the right way of doing things. Eventually, I was putting [the motorcycles] back together and they’d actually run. And what was even better was that I didn’t have any pieces left at the end of the job.”

But engineering is just a half of what makes Neil so passionate about the job he’s willing to travel four and half hours, twice a week, for. Upon finally arriving onsite, Neil offers more insight on his childhood as he routinely picks up the bottles of milk outside the office door.

“One of the most rewarding

aspects is to be able to leave the office on an evening knowing that everything has flown on time and safely. Take it from me, you don’t travel 285 miles to work unless you’re doing something special.

”

NEIL WALKERBOEING LEAD TECHNICAL OPERATIONS ENGINEER

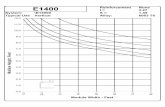

The £1.8 billion UK-Boeing partnership

12,700indirect supply chain employees

Employment in Boeing’s supply chain companies up 38% in 2 years

more than2,000direct

employees

5,000+Young people engaged in Boeing’s UK community projects

UK university partners6

Boeing products in UK Armed Forces

service

140+250 Boeing aircraft

UK airlinesusing13

Boeing direct employment in the UK3000

2500

2000

1500

1000

500

02007 2009 2011 2013 2015 2017

(projection)

Doubled 2011-2014

Boeing sites in the UK

Employment stimulated by supply chain spending14000

12000

10000

8000

6000

4000

2000

02012 2014

Increased by 38% 2012-2014

Sources: Boeing figures and research by Oxford Economics in Q4 2015. More at www.boeing.co.uk/value

Boeing supply chain spending in the UK2bn

1.5bn

1bn

0.5bn

02012 2013 2014 2015

More than doubled since 2012

£

www.boeing.co.ukFollow us on Twitter @BoeingUK

The £1.8 billion UK-Boeing partnership

12,700indirect supply chain employees

Employment in Boeing’s supply chain companies up 38% in 2 years

more than2,000direct

employees

5,000+Young people engaged in Boeing’s UK community projects

UK university partners6

Boeing products in UK Armed Forces

service

140+250 Boeing aircraft

UK airlinesusing13

Boeing direct employment in the UK3000

2500

2000

1500

1000

500

02007 2009 2011 2013 2015 2017

(projection)

Doubled 2011-2014

Boeing sites in the UK

Employment stimulated by supply chain spending14000

12000

10000

8000

6000

4000

2000

02012 2014

Increased by 38% 2012-2014

Sources: Boeing figures and research by Oxford Economics in Q4 2015. More at www.boeing.co.uk/value

Boeing supply chain spending in the UK2bn

1.5bn

1bn

0.5bn

02012 2013 2014 2015

More than doubled since 2012

£

www.boeing.co.ukFollow us on Twitter @BoeingUK