IC engines course outline.docx

-

Upload

ratchagaraja -

Category

Documents

-

view

231 -

download

0

Transcript of IC engines course outline.docx

-

8/14/2019 IC engines course outline.docx

1/16

1

AKSUM UNIVERSITYDepartment of mechanical engineeringCollege of Engineering & Technology

Course code MENG 4807

Course Title I.C. Engines and Recip. Machines

Degree Program BSc. in Mechanical Engineering

Lecturer RatchagarajaCredits 4

Pre-requisites MENG 2308, MENG 3611

Semester Year IV, Semester I

Course Objectives To analyze the behavior of solid bodies subjected to various types of loading, such as axially

loaded members, shafts in torsion, beams, and columns, as well as structures that areassemblies of these components.

To provide the students with the foundation of design analysis

Upon completion of the course, students would have:

Sufficient knowledge on IC Engines, Sufficient knowledge on assembly of vehicles, Sufficient knowledge on engine selection and Maintenance.

CHAPTER ONE-- ENGINE TYPES AND CLASSIFICATION

1.1 Introduction1.2 Spark ignition ( SI ) engines1.3 Compression ignition ( CI ) engines1.4 Four Stroke Diesel & Petrol Engine1.4 Two Stroke Diesel & Petrol Engine

CHAPTER TWO-- THERMODYNAMIC CYCLE

2.1 Otto cycle

2.2 Diesel Cycle2.3 Dual Cycle2.4 Problems in Otto, Diesel, Dual Cycles

CHAPTER THREE--PERFORMANCE EQUATION AND ENGINE CHARACTERISTICS

3.1 Brake torque and power3.2 Indicated work per cycle3.3 Mechanical Efficiency3.4 Mean Effective pressure3.5 Specific Fuel Consumption and Efficeincy3.6 Volumetric Efficiency3.7 Engine Specific weight and specific volume

3.8 3.9 Relationship between performance parameters

CHAPTER FOURFUELS AND COMBUSTION4.1. Fuels4.2. Alternate fuels4.3. SI Engine Combustion Chamber Design4.4. Mixture Formation4.5. Forces and turning effort4.6. Valve timing diagram4.7. Port timing diagramCHAPTER FIVE..COOLING AND LUBRICATION SYSTEMS5.1 Splash lubricating system5.2 Full Force feed lubricating system

5.3 Force feed and splash lubricating system5.4 .Air cooling system5.5 Water cooling system

-

8/14/2019 IC engines course outline.docx

2/16

2

Teaching & LearningMethods

Lectures Tutorials and laboratory exercises Assignments

Assessment/Evaluation

& Grading System

Assessment:

Continuous assessment--30%Assignment and Projects-------20%Final examination ---------50%

AttendanceRequirements

Minimum of 80% attendance during lecture hours, and 100% attendanceduring practical work sessions, except for some unprecedented mishaps.

Text Books 1. Obert: Internal Combustion Engines

2. Hey Wood: Internal combustion Engines

References 1. Willard. W . Pulkrabek, Engineering Fundamentals of the InternalCombuction engine, :Prentice Hall2. R.K .Rajput.Engineering Thermodynamics Third Edition SI unitsversion

-

8/14/2019 IC engines course outline.docx

3/16

3

CHAPTER ONE-- ENGINE TYPES AND CLASSIFICATION

1.1 Introduction

The internal combustion engineis anengine in which thecombustion of afuel (normally afossil

fuel) occurs with an oxidizer (usually air) in acombustion chamber that is an integral part of theworking fluid flow circuit. The terminternal combustion engine usually refers to an engine in whichcombustion is intermittent, such as the more familiarfour-stroke andtwo-stroke piston engines, alongwith variants, such as thesix-stroke piston engine and theWankel rotary engine

Heat Engines

Any type of engine or machine which derives heat energy from the combustion of fuel or

any other source and converts this energy into mechanical work is termed as a heat engine.

Heat engines may be classified into two main classes as follows :

1. External Combustion Engine.

2. Internal Combustion Engine.

1. External Combustion Engines (E.C. Engines)

In this case, combustion of fuel takes place outside the cylinder as in case of steam

engines where the heat of combustion is employed to generate steam which is used to move a

piston in a cylinder. Other examples of external combustion engines are hot air engines, steam

turbine and closed cycle gas turbine. These engines are generally needed for driving

locomotives, ships, generation of electric power etc.

2. Internal Combustion Engines (I.C. Engines)

In this case combustion of the fuel with oxygen of the air occurs within the cylinder of the

engine. The internal combustion engines group includes engines employing mixtures of combusti-

ble gases and air, known as gas engines, those using lighter liquid fuel or spirit known as petrol

engines and those using heavier liquid fuels, known as oil compression ignition or diesel

engines.

Development of I.C. Engines

Many experimental engines were constructed around 1878. The first really successful engine

did not appear, however until 1879, when a German engineer Dr. Otto built his famous Otto gas

engine. The operating cycle of this engine was based upon principles first laid down in 1860 by a

French engineer named Bea de Rochas. The majority of modern I.C. engines operate according

to

these principles.

The development of the well known Diesel engine began about 1883 by Rudoff Diesel.

Although this differs in many important respects from the otto engine, the operating cycle of

modern high speed Diesel engines is thermodynamically very similar to the Otto cycle.

Different parts of I.C. Engines

A cross-section of an air-cooled I.C. engines with principal parts is shown in Fig

A. Parts common to both petrol and diesel engines

1. Cylinder 2. Cylinder head 3. Piston

4. Piston rings 5. Gudgeon pin 6. Connecting rod

7. Crankshaft 8. Crank 9. Engine bearing

10. Crank case 11. Flywheel 12. Governor

13. Valves and valve operating mechanism.

B. Parts for petrol engines only

1. Spark plugs 2. Carburettor 3. Fuel pump.

C. Parts for Diesel engine only1. Fuel pump. 2. Injector.

http://en.wikipedia.org/wiki/Enginehttp://en.wikipedia.org/wiki/Combustionhttp://en.wikipedia.org/wiki/Fuelhttp://en.wikipedia.org/wiki/Fossil_fuelhttp://en.wikipedia.org/wiki/Fossil_fuelhttp://en.wikipedia.org/wiki/Combustion_chamberhttp://en.wiktionary.org/wiki/internal_combustion_enginehttp://en.wikipedia.org/wiki/Four-strokehttp://en.wikipedia.org/wiki/Two-strokehttp://en.wikipedia.org/wiki/Six-stroke_enginehttp://en.wikipedia.org/wiki/Wankel_enginehttp://en.wikipedia.org/wiki/Wankel_enginehttp://en.wikipedia.org/wiki/Six-stroke_enginehttp://en.wikipedia.org/wiki/Two-strokehttp://en.wikipedia.org/wiki/Four-strokehttp://en.wiktionary.org/wiki/internal_combustion_enginehttp://en.wikipedia.org/wiki/Combustion_chamberhttp://en.wikipedia.org/wiki/Fossil_fuelhttp://en.wikipedia.org/wiki/Fossil_fuelhttp://en.wikipedia.org/wiki/Fuelhttp://en.wikipedia.org/wiki/Combustionhttp://en.wikipedia.org/wiki/Engine -

8/14/2019 IC engines course outline.docx

4/16

4

Classification of IC engine:

Normally IC engines are classified into

1.C.I engines and

2.S.I engines

Some of the important classifications are given below,

1. Number of strokes

-two stroke and four stroke

2. Working Cycles

-Otto ,Diesel, Dual cycle

3. Cylinder arrangement

-In-line, V-type, Opposed, Radial

4. Valve Arrangement

-T-head, F-head, L-head, I-head

5. Fuel Used

-Petrol, Diesel, Gas

6. Combustion chamber design

-Open, divided

7. Cooling System

-Water and air cooling

8. According to the number of cylinders

-Single and Multi

9. According to the speed

-Slow, medium, and high speed engines

10. According to the application

-Stationary, Automotive, Marine, Locomotive, Aircraft etc.,

-

8/14/2019 IC engines course outline.docx

5/16

5

Components of I.C engine

1.Cylinder block:

The cylinder block is the main body of the engine, the structure that supports all the

other components of the engine. In the case of the single cylinder engine the cylinder block

houses the cylinder, while in the case of multi-cylinder engine the number of cylinders are cast

together to form the cylinder block. The cylinder head is mounted at the top of the cylinderblock.

When the vehicle runs, large amounts of heat are generated within the cylinder block. To

remove this heat the cylinder block and the cylinder head are cooled by water flowing through the

water jackets within larger engines such as those found in cars and trucks. For smaller vehicles like

motorcycles, fins are provided on the cylinder block and on the cylinder head to cool them. The

bottom portion of the cylinder block is called a crankcase. Within the crankcase is where

lubricating oil, which is used for lubricating various moving parts of the engine, is stored.

2) Cylinder:

As the name suggests it is a cylindrical shaped vessel fitted in the cylinder block. This

cylinder can be removed from the cylinder block and machined whenever required to. It is also called

a liner or sleeve. Inside the cylinder the piston moves up and down, which is called the reciprocating

motion of the piston. Burning of fuel occurs at the top of the cylinder, due to which the reciprocating

motion of the piston is produced. The surface of the cylinder is finished to a high finish, so that there

is minimal friction between the piston and the cylinder.

3) Piston:

The piston is the round cylindrical component that performs a reciprocating motion inside

the cylinder. While the cylinder itself is the female part, the piston is the male part. The piston

fits perfectly inside the cylinder. Piston rings are fitted over the piston. The gap between the

piston and the cylinder is filled by the piston rings and lubricating oil. The piston is usually made

up of aluminum.

4) Piston rings:

The piston rings are thin rings fitted in the slots made along the surface of the piston. It

provides a tight seal between the piston and the cylinder walls that prevents leaking of the

combustion gases from one side to the other. This ensures that that motion of the piston produces as

close as to the power generated from inside the cylinder.

5) Combustion chamber:

It is in the combustion chamber where the actual burning of fuel occurs. It is the

uppermost portion of the cylinder enclosed by the cylinder head and the piston. When the fuel is

burnt, much thermal energy is produced which generates excessively high pressures causing the

reciprocating motion of the piston.

6) Inlet manifold:

Through the inlet manifold the air or air-fuel mixture is drawn into the cylinder.7) Exhaust manifold:

All the exhaust gases generated inside the cylinder after burning of fuel are discharged

through the exhaust manifold into the atmosphere.

8) Inlet and exhaust valves:

The inlet and the exhaust valves are placed at the top of the cylinder in the cylinder head.

The inlet valve allows the intake of the fuel during suction stroke of the piston and to close

thereafter. During the exhaust stroke of the piston the exhaust valves open allowing the exhaust

gases to release to the atmosphere. Both these valves allow the flow of fuel and gases in single

direction only.

9) Spark plug:

The spark plug is a device that produces a small spark that causes the instant burning of thepressurized fuel.

-

8/14/2019 IC engines course outline.docx

6/16

6

10) Connecting rod:

It is the connecting link between the piston and the crankshaft that performs the rotary

motion. There are two ends of the connecting rod called the small end and big end. The small

end of the connecting rod is connected to the piston by gudgeon pin, while the big end is

connected to crankshaft by crank pin.

11) Crankshaft:

The crankshaft performs the rotary motion. It is connected to the axle of the wheels which

move as the crankshaft rotates. The reciprocating motion of the piston is converted into the rotary

motion of the crankshaft with the help of connecting rod. The crankshaft is located in the crankcase

and it rotates in the bushings.

12) Camshaft:

It takes driving force from crankshaft through gear train or chain and operates the inlet

valve as well as exhaust valve with the help of cam followers, push rod and rocker arms.

Theoretical and actual valve timing diagram of four stroke engine:

Valve timing diagram of a four stroke engine gives a clear idea about the actual position of the

piston during the opening & closing of inlet & exhaust valves. In practice, the events of the four-stroke

cycle do not start and finish exactly at the two ends of the strokes - to improve the breathing and

exhausting, the inlet valve is arranged to open before TDC and to close after BDC and the exhaust

valve opens before BDC and closes after TDC. These early and late opening and closing events can

be shown on a valve timing diagram such as Fig

-

8/14/2019 IC engines course outline.docx

7/16

7

Simple Carburetor:

The function of a carburetor is to vaporize the petrol (gasoline) by means of engine suctionand to supply the required air and fuel (petrol) mixture to the engine cylinder. During the suctionstroke, air flows from atmosphere into the cylinder. As the air passes through the enture, velocityof air increases and its pressure falls below the atmosphere. The pressure at the nozzle tip is alsobelow the atmospheric pressure. The pressure on the fuel surface of the fuel tank is atmospheric.Due to which a pressure difference is created, which causes the flow of fuelthrough the fuel jet into the air stream. As the fuel and air pass ahead of the venture, the fuel getsvaporized and required uniform mixture is supplied to the engine.

The quantity of fuel supplied to the engine depends upon the opening of throttle valvewhich is governed by the governor.

The main parts of a simple carburetor are:

Float chamber: The level of fuel in the float chamber is maintained slightly below the tip of the

nozzle. If the level of petrol is above then the petrol will run from the nozzle and drip from thecarburetor. If the petrol level is kept low than the tip of the nozzle then part of pressure head is lost inlifting the petrol up to the tip of nozzle. Generally it is kept at 5mm from the level of petrol in the floatchamber. The level of the fuel is kept constant with the help of float and needle valve. The needlevalve closes the inlet supply from main tank if the level rises above the

required level. If the level of fuel decreases then the needle valve opens the supply. Generally the

fuel level is kept 5mm below the nozzle tip.

Venturi:When the mixture passes through the narrowest section its velocity increases andpressure falls below the atmospheric. As it passes through the divergent section, pressureincreases again.

Throttle valve: It controls the quantity of air and fuel mixture supplied to the engine throughintake manifold and also the head under which the fuel flows.

Choke: It provides an extra rich mixture during to the engine starting and in cold weather towarm up the engine. The choke valve is nearly closed during clod starting and warming. Itcreates a high vacuum near the fuel jet which causes flow of more fuel from the jet.

-

8/14/2019 IC engines course outline.docx

8/16

8

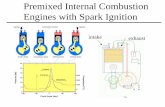

1.2 Spark ignition ( SI ) engines

These engines may work on either four stroke cycle or two stroke cycle, majority of them, of

course, operate on four stroke cycle.

1.3 Compression ignition ( CI ) engines

The operation of C.I. engines (or diesel engines) is practically the same as those of S.I.engines. The cycle in both the types, consists of suction, compression, ignition, expansion andexhaust. However, the combustion process in a C.I. engine is different from that of a S.I. engine

asgiven below :

In C.I. engine, only air is sucked during the stroke and the fuel is injected in the cylindernear the end of the compression stroke. Since the compression ratio is very high (between 14 : 1to

22 : 1), the temperature of the air after compression is quite high. So when fuel is injected in theform of a spray at this stage, it ignites and burns almost as soon as it is introduced. The burnt

gases are expanded and exhausted in the same way as is done in a S.I. engine.

1.4 Four Stroke Diesel & Petrol Engine

1.4 Two Stroke Diesel & Petrol Engine

Two Stroke cycle Petrol Engines

-

8/14/2019 IC engines course outline.docx

9/16

9

Construction : A piston reciprocates inside the cylinder

It is connected to the crankshaft by means of connecting rod and crank There are no valves in two stroke engines, instead of valves ports are cut on the

cylinder walls. There are three ports, namely inlet, exhaust and transfer ports. The closing and opening of the ports are obtained by the movement of piston. The

crown of piston is made in to a shape to perform this. A spark plug is also provided.

First Stroke : (Compression, ignition and inductance) (Upward stroke of piston)(a) compression: The piston moves up from Bottom Dead Centre (BDC)to Top Dead Centre (TDC)

Both transfer and exhaust ports are coveredby the piston. Air fuel mixture which is transferredalready into the engine cylinder is compressedby moving piston. The pressure and temperature increases

at the end of compression.First Stroke : (Compression, ignition and inductance) (Upward stroke of piston)(b) Ignition and Inductance:

Piston almost reaches the top dead centre The air fuel mixture inside the cylinder is ignited by means of an electric spark

produced by aspark plug

At the same time, the inlet port isuncovered by the plane.

Fresh air fuel mixture enters thecrankcase through the inlet port.Second Stroke: (Downward Stroke of the engine) :(c)Expansion and Crankcase compression

The burning gases expand in the cylinder The burning gases force the piston to move down. Thus useful work is obtained. When the piston moves down, the

air fuel mixture in the crankcaseis partially compressed.This compression is known asCrank case comp ression.Second Stroke: (Downward Stroke of the engine) :(d) Exhaust and transfer:

At the end of expansion, exhaust port is uncovered. Burnt gases escape to the atmosphere. Transfer port is also opened. The partially compressed air fuel mixture enters the

cylinder through the transfer port.

The crown of the piston is made of adeflected shape. So the fresh chargeentering the cylinder is deflectedupwards in the cylinder.

Thus the escape of fresh chargealong with the exhaust gases is reduced.

CHAPTER TWO-- THERMODYNAMIC CYCLE

2.1 Otto cycle

-

8/14/2019 IC engines course outline.docx

10/16

10

CHAPTER THREE--PERFORMANCE EQUATION AND ENGINE CHARACTERISTICS

3.1 Brake torque and power

3.2 Indicated work per cycle

-

8/14/2019 IC engines course outline.docx

11/16

11

3.3 Mechanical Efficiency

3.4 Mean Effective pressure

3.5 Specific Fuel Consumption and Efficeincy

3.6 Volumetric Efficiency

3.7 Engine Specific weight and specific volume

3.8 3.9 Relationship between performance parameters

CHAPTER FOURFUELS AND COMBUSTION4.1. Fuels

4.2. Alternate fuels

4.3. SI Engine Combustion Chamber Design

4.4. Mixture Formation

4.5. Forces and turning effort

4.6. Valve timing diagram

4.7. Port timing diagram

CHAPTER FIVE.. COOLING AND LUBRICATION SYSTEMS

5.1 Splash lubricating system

-

8/14/2019 IC engines course outline.docx

12/16

12

The splash system is no longer used in automotive engines. It is widely used in small four-cycle

engines for lawn mowers, outboard marine operation, and so on.

In the splash lubricating system , oil is splashed up from the oil pan or oil trays in the lower part of

the crankcase. The oil is thrown upward as droplets or fine mist and provides adequate

lubrication to valve mechanisms, piston pins, cylinder walls, and piston rings.

In the engine, dippers on the connecting-rod bearing caps enter the oil pan with each crankshaft

revolution to produce the oil splash. A passage is drilled in each connecting rod from the dipper to

the bearing to ensure lubrication.

This system is too uncertain for automotive applications. One reason is that the level of oil in the

crankcase will vary greatly the amount of lubrication received by the engine. A high level results in

excess lubrication and oil consumption and a slightly low level results in inadequatelubrication and failure of the engine.

5.2 Force feed lubricating system

A somewhat more complete pressurization of lubrication is achieved in the force-feed lubrication

system . Oil is forced by the oil pump from the crankcase to the main bearings and the camshaft

bearings. Unlike the combination system the connecting-rod bearings are also fed oil under

pressure from the pump.

-

8/14/2019 IC engines course outline.docx

13/16

13

Oil passages are drilled in the crankshaft to lead oil to the connecting-rodbearings. The passages

deliver oil from the main bearing journals to the rod bearing journals. In some engines, these

opening are holes that line up once for every crankshaft revolution. In other engines, there are

annular grooves in the main bearings through which oil can feed constantly into the hole in the

crankshaft.

The pressurized oil that lubricates the connecting-rod bearings goes on to lubricate the pistons and

walls by squirting out through strategically drilled holes. This lubrication system is used in virtually

all engines that are equipped with semifloating piston pins.

5.3 Force feed and splash lubricating system

In a combination splash and force feed , oil is delivered to some parts by means of splashing and

other parts through oil passages under pressure from the oil pump.

The oil from the pump enters the oil galleries. From the oil galleries, it flows to the main

bearings and camshaft bearings. The main bearings have oil-feed holes or grooves that feed oil

into drilled passages in the crankshaft. The oil flows through these passages to the connecting rod

bearings. From there, on some engines, it flows through holes drilled in the connecting rods to the

piston-pin bearings.

Cylinder walls are lubricated by splashing oil thrown off from the connecting-rod bearings. Some

engines use small troughs under each connecting rod that are kept full by small nozzles which

deliver oil under pressure from the oil pump. These oil nozzles deliver an increasingly heavy

stream as speed increases.

At very high speeds these oil streams are powerful enough to strike the dippers directly. This

causes a much heavier splash so that adequate lubrication of the pistons and the connecting-rodbearings is provided at higher speeds.

-

8/14/2019 IC engines course outline.docx

14/16

14

If a combination system is used on an overhead valve engine, the upper valve train is lubricated by

pressure from the pump.

5.4 .Air cooling system

Air cooled system is generally used in small engines say up to 15-20 Kw and in aero plane

engines. In this system fins or extended surfaces are provided on the cylinder walls, cylinder

head, etc. Heat generated due to combustion in the engine cylinder will be conducted to the

fins and when the air f lows over the fins, heat will be dissipated to air.

The amount of heat dissipated to air depends upon :

(a) Amount of air flowing through the fins.

(b) Fin surface area.

I Thermal conductivity of metal used for fins.

Advantages of Air Cooled System

Following are the advantages of air cooled system :

(a) Radiator/pump is absent hence the system is light.

(b) In case of water cooling system there are leakages, but in this case

there are no leakages.

(c) Coolant and antifreeze solutions are not required.

(d) This system can be used in cold climates, where if water is used it

may freeze.

Disadvantages of Air Cooled System

(a) Comparatively it is less efficient.

(b) It is used only in aero planes and motorcycle engines where the engines are exposed to airdirectly.

Water Cooling System:

In this method, cooling water jackets are provided around the cylinder, cylinder head, valve seats

etc. The water when circulated through the jackets, it absorbs heat of combustion. This hot water

will then be cooling in the radiator partially by a fan and partially by the flow developed by the

forward motion of the vehicle. The cooled water is again recirculated through the water jackets

5.5 Water cooling system

-

8/14/2019 IC engines course outline.docx

15/16

15

There are two types of water cooling system :

Thermo Siphon System

In this system the circulation of water is due to difference in temperature (i.e. difference in

densities) of water. So in this system pump is not required but water is circulated because ofdensity difference only.

Pump Circulation System

In this system circulation of water is obtained by a pump. This pump is driven by means of engineoutput shaft through V-belts.

-

8/14/2019 IC engines course outline.docx

16/16

16