Syllabus UNIT-I : BASICS OF IC ENGINES (5) Heat Engines, IC and EC engines, IC engines construction-...

-

Upload

paul-martin -

Category

Documents

-

view

283 -

download

13

Transcript of Syllabus UNIT-I : BASICS OF IC ENGINES (5) Heat Engines, IC and EC engines, IC engines construction-...

Unit –IBasics of IC Engines

andFuel-Air & Actual Cycles

Syllabus

UNIT-I : BASICS OF IC ENGINES (5)Heat Engines, IC and EC engines, IC engines construction- components and materials, engine nomenclature, valve diagrams,intake and exhaust systems, engine classification, applications STANDARD CYCLES & FUEL-AIR CYCLES (5)Fuel-air cycle, assumptions, comparison with air standard cycle, effect of variables on performance, actual engine cycle and various losses

Unit I [10 hrs]Basics of IC Engines, Fuel Air cycles and actual cycles Part A] Basics of ICE [5 hrs]- What is meant by engine and heat engine- Difference between IC & EC engine with examples- Construction: Different components of I. C. Engines and names of the materials used for different components (Spark plug, engine block, crank case, intake, exhaust manifold etc) there function, location.- Nomenclature: (TDC, BDC, Stroke, Swept vol, CC etc.)- Working of 4 stroke I. C. Engine –SI and CI, Difference between SI & CI engine- Working of 2 stroke IC Engine (Petrol)

- Difference between two-stroke and four stroke engine.- Classification of I. C. Engines (Inline, radial, V-type, SI & CI, two- stroke & four stroke etc.)- Applications of IC Engines-Theoretical and actual valve timing diagrams.- Intake and Exhaust Systems (Manifolds and their requirements)

Part B] Fuel air cycle and actual cycle [05 hrs]Give reference of air standard cycle and start the topic- What is Fuel air cycle, its assumptions- Comparison with air standard cycle- Factors affecting fuel air cycle analysis (Composition of cylinder gases, specific heat variation, dissociation and molecular change)- Effect of operating variables (CR, AF ratio) on cycle analysis performance - Actual cycle and various losses.

Unit I [10 hrs]

Online exam (Compulsory weight age 13 marks): - Only theoretical treatment.- No numerical would be asked on unit 1 for online exam.

- Offline exam (Compulsory weight age 6 marks): - Q 1 a or Q 2a (6 marks). - Only theoretical question for 6 marks for offline exam.- No mathematical treatment.

- Total weight age (out of 100 marks): 19 marks.

Lecture No 1

Learning Objectives: • To learn basics of heat engines, IC and EC engines, IC engines

construction- components and materials

Introduction to Engines

Difference between IC and EC Engines

Engine Components

Parts of an Engine

Engines Components & Materials

1. Cylinder block/ Crank case: • For holding major components like crankshaft, cylinder head, liners, gears, pumps etc. • Cooling jackets, oil passages, passages for push rods etc• Grey CI, Al alloy2.Cylinder head:• For fitment of SP/ injectors, valve openings, comb chamber, valves & valve operating mechanism• CI , Al alloy3. Oil pan:• Oil sump• Pressed steel sheet, Al alloy

Engines Components & Materials

4. Manifolds: • Inlet & exhaust tubing for AF intake & exhaust• CI

5. Gaskets:• For leak proof sealing between two components• Embossed steel, cork, special rubber

Engines Components & Materials

7. Piston: • For transmission of force, light weight, high thermal k, low thermal coeff of expansion• Al alloy8. Piston rings:• For high pr leak proof sealing between piston & cylinder.• Alloy CI with Si, Mn with chromium plating

9. Connecting rod:• For transmitting force on piston to crankshaft• I-section, drop forged from steel• Axial and bending stresses

Engines Components & Materials

10. Piston pin/Gudgeon Pin: • For connecting piston to small end of connecting rod• Case hardened steel11. Crankshaft:• For converting reciprocketing motion of piston to rotary motion of crankshaft by connecting rod, vibration damper and fly wheel fitted• Forged from spheroidal graphite iron

12. Main & Big end bearings:• For facilitating holding & friction free rotation of crankshaft• Babbitt material- alloy steel

Engines Components & Materials

13. Engine Valves: • Inlet –for air/AF intake; Silicon-chrome steel (C+Ni +Mn+Si)• Exhaust- for exiting burnt gases (C+Ni+Mn+Si+Mb)14. Camshaft:• For operating valves (rotates at half speed of C/S)• Forged alloy steel

15. Silencer/ Mufler:• For reducing exhaust/comb sound• Metal sheet

Parts of an IC Engine

CROSS SECTION OF OVERHEAD VALVE FOUR STROKE SI ENGINE

Name as manyparts as you can

Parts of an IC Engine

Air cleaner

Choke

Throttle

Intake manifold

Exhaust manifold

Piston ringsPiston

Wrist pinCylinder blockConnecting rod

Oil gallery to pistonOil gallery to head

Crankcase

Crankpin

Crankshaft

Cylinder head

Breather cap

Rocker armValve spring

Valve guidePushrod

Sparkplug

Combustion chamber

TappetDipstickCam

CamshaftWater jacketWet liner

Connecting rod bearing

Main bearing

Oil pan or sump

If you scored:25 – 32- Excellent15 – 24- Good10 – 14- OK<10- Change your lubricating oil

Naming Engine Components

Cylinder Block, Cylinder Head, Rocker Arms, Rocker Shaft, Push Rods, Engine Valves, Inlet & Outlet Manifolds, Carburetor, Air Filter, Tappet CoverPiston, Piston Rings, Connecting Rod, Cylinder/ Cylinder Liners, Gudgeon/Piston Pin, Crank Shaft,Big end Bearings, Main/Journal Bearings, Cam Shaft,Cam Followers, Oil Pan, Oil Pump, Oil Filter, WaterPump, Fan Belt, Radiator/HE, Fuel Injector, FuelPump, Governor, Spark Plug, Distributor, IgnitionCoil, Battery, Dynamo/Alternator, Flywheel, Vibration Damper, Muffler/Silencer, Gaskets, Thermostat, Aux Gears, Super Charger/ Turbo Charger, Fuel TankFuel Lines, Fuel Filter, HT & LT Wires/Cables etc

Lecture No 2

Learning Objectives:•To understand working of 4-stroke SI and CI engines and 2-stroke SI engines

Spark plug

Inlet valve

Exhaust valve

Cylinder

Piston

The four-stroke engine

Inlet valve opens

INDUCTION STROKE

The four-stroke engine

Inlet valve open

Piston downINDUCTION STROKE

The four-stroke engine

Inlet valve open

Piston down

INDUCTION STROKE

The four-stroke engine

Air/Fuel Mixture In

Inlet valve closes

COMPRESSION STROKE

The four-stroke engine

Piston up

Inlet valve closed

COMPRESSION STROKE

The four-stroke engine

Piston up

Inlet valve closed

POWER STROKE

The four-stroke engine

BANG

Inlet valve closed

POWER STROKE

The four-stroke engine

Piston downpowerfully

Inlet valve closed

POWER STROKE

The four-stroke engine

Piston downpowerfully

Inlet valve closed

POWER STROKE

The four-stroke engine

Inlet valve closed

EXHAUST STROKE

The four-stroke engine

Exhaust valve open

Inlet valve closed

EXHAUST STROKE

The four-stroke engine

Exhaust valve open

Piston up

Exhaust gasesout

Inlet valve closed

EXHAUST STROKE

The four-stroke engine

Exhaust valve open

Piston up

Exhaust gasesout

Inlet valve opens

INDUCTION STROKE

The four-stroke engine

Exhaust valve closed

And so the cycle

continues!!

The four-stroke cycle

The four stroke combustion cycle consists of:– 1. Intake– 2. Compression– 3. Combustion– 4. Exhaust

The four-stroke cycle

The piston starts at the top, the intake valve opens and the piston moves down to let the engine take in a full cylinder of air and gasoline during the intake stroke

The piston then moves up to compress the air/gasoline mixture. This makes the explosion more powerful.

The four-stroke cycle

• When the piston reaches the top, the spark plug emits a spark to ignite the gasoline/air mixture.

• The gasoline/air mixture explodes driving the piston down.

• The piston reaches the bottom of its stroke, the exhaust valve opens and the exhaust leaves out of the tailpipe.

• The engine is ready for another cycle.

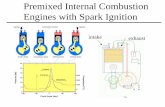

4 Processes Cycle

Intake StrokeIntake valve opens, admitting fuel and air. Exhaust valve closed for most of

stroke

Compression StrokeBoth valves closed,Fuel/air mixture is

compressed by rising piston. Spark ignites mixture near end of

stroke.

IntakeManifold

Spark Plug

Cylinder

Piston

Connecting Rod Crank

Power StrokeFuel-air mixture burns,

increasing temp and pressure, expansion of

combustion gases drives piston down. Both

valves closed, exhaust valve opens near end of stroke

1 2 3 4

Exhaust StrokeExhaust valve open,

exhaust products aredisplaced from

cylinder. Intake valve opens near end of

stroke.

Crankcase

ExhaustManifold

Exhaust ValveIntake Valve

Working of a

4 StrokeSI Engine

Working of a

2 StrokeSI Engine

Lecture No 3

Learning Objectives: • To understand engine terminology• To learn about classification of engines• To learn about theoretical and actual valve timings of SI and CI engines• To learn about engine induction and exhaust systems

Engine Terminology

TDC, BDC

Stroke/Swept /Displacement Volume (Vs)

Clearance Volume (Vc)

Compression Ratio CR (r)

Engine Terminology

More Terminology

Terminology

• Bore = d• Stroke = s• Displacement volume =Vs =• Clearance volume = Vc • Compression ratio = r

4

ds

2

TDC

BDC

V

Vr = Vs + Vc

Vc

Classification of IC Engines

Based on No of stroke per cycle:• Four stroke• Two stroke

Based on thermodynamic cycle:• Otto/Constant volume cycle• Diesel/Constant pressure cycle• Dual Cycle

Based on No of cylinders:• Single cylinder• Multi-cylinders

Classification of IC Engines

Based on arrangement of cylinders:• Inline engines• V – engines• Radial engines• Opposed cylinders engines• Opposed pistons enginesBased on ignition systems:• SI engines• CI enginesBased on cooling system:• Air cooled• Liquid cooled

4. - Cylinder Orientation

There is no limit on the number of cylinders that a small engines can have, but it is usually 1 or 2.

Vertical

HorizontalSlanted Multi position

4. - Cylinder Orientation—cont.

VHorizontally opposed

In-line

Three common cylinder configuration in multiple cylinder engines:

Horizontal

Vertical

S m a l l g a s e n g i n e s u s e t h r e e c r a n k s h a ft o r i e n t a ti o n s :

5. Crankshaft Orientation

Multi-position

Classification of IC Engines

Based on fuel used:• Petrol engines• Diesel engines• Gas engines• Bi-fuel enginesBased on fuel supply systems:• Carburetor engines• Solid injection engines

Based on lubrication system:• Wet sump lubrication• Dry sump lubrication• Mist lubrication

Actual Valve Timings : 4 Stroke SI Engine

IVO

IVC

TDC

BDC

EVC

EVO

Suction Stroke

Power/ ExpansionStrokeExhaust

Stroke

Compression Stroke10°

20°

25°20°

Ign Adv

Actual Valve Timings : 4 Stroke CI Engine

IVO

IVC

TDC

BDC

EVC

EVO

Suction Stroke

Power/ ExpansionStroke

Exhaust Stroke

Compression Stroke10°- 25°

10°-15°

45°20°- 30°

FICFIS15° 25°

EngineIntake & Exhaust

Systems

Engine Intake System

Carburetor Intake Manifolds

Air Filter

Engine

A/F Mixture

Engine Manifolds

• Manifolds are conduits, which are connected to engine cylinder head; one per cylinder• Inlet manifolds are used to carry air-fuel mixture from carburetor/ air from air filter to cylinders through intake valve(s) in SI engs; air from air filter to cylinders in CI engines

• Exhaust manifolds carry burnt/flue gases from cylinder through exhaust valve(s) to silencer/ muffler and ultimately to atmosphere

• Manifolds are manufactured by casting process of cast iron/ by die-casting of aluminum alloy

Intake Manifolds

• Intake manifolds should cause minimum pressure loss thus ensuring max volumetric efficiency

• Should distribute A/F mixture uniformly to each cylinder over wide range of speeds and loads (equal length to each cylinder)

• Should assist vaporization of fuel and mixing with air while passing through it

• Shape and size should be to prevent condensation of fuel without restricting air flow

For 4 Cylinder Engine

Cylinder Head

Exhaust System

ExhaustManifolds

Silencer/Muffler

Exhaust PipeExhaust/Tail Pipe Open to Atm

Engine

Exhaust Manifolds

• After power stroke, flue/ burnt gases are required to be removed from engine cylinders

• Exhaust manifolds collect the burnt gases from each cylinder and through silencer, pass them to atm

Requirements:• Minimum back pressure to reduce power loss (Increase in back pressure by 0.1 bar results in decrease in power output by about 1.5%)• Reduction in combustion noise as exiting gases will expand suddenly in atmosphere making lot of noise • Transfer of minimum possible heat to system (Vehicle)• Reduce emissions going to atmosphere (exhaust treatment like using Catalytic Converter)

Silencer/ Muffler

• After the power stroke, burnt gases, which are at higher pressure, if exhausted to atmosphere directly, make unpleasant loud sound due to difference in exhaust pressure and atmospheric pressure

• Muffler allows the gases to expand in it so that pressure pulsations die down with the result, burnt gases are discharged to atmosphere quietly

Assignments

Q1. Explain working of 4-stroke CI engine and compare with 4 -stroke SI engine in every aspect

Q2.Compare diesel and petrol engines

Q3.Compare 2 stroke and 4 stroke engines

Lecture No 4

Learning Objectives: • To highlight certain aspects of Air Standard Cycles

Ideal or Air Standard Cycles

Air standard cycles are defined as cycles using a perfect gas as the working fluid/ medium.

• Working medium is AIR and behaves like ideal/ perfect gas throughout ( follows the Law pV=mRT )• Working fluid is a fixed mass of air either contained in a closed system or flowing at a constant rate round a closed circuit

Air is invariably used as the working fluid in IC Enginesand assumed to behave as a perfect gas

Following simplifying assumptions are made in the analysis of air standard cycles:

Assumptions of Ideal or Air Standard Cycles

• Working medium has constant specific heats• Heat addition & rejection processes take place in reversible manner and if required, instantaneously (at constant volume)• Compression & Expansion processes are reversible adiabatic (Isentropic); (no heat transfer)

• All dissipative effects like friction, viscosity etc, are neglected

• Kinetic & PE of the working fluid are neglected

• Physical constants of working medium are the same as that of air at standard atmospheric conditions; Cp=1.005, Cv=0.718 & γ=1.4

Useful Thermodynamic Relations (Perfect Gas)• pV = mRT or pv = RT and p1V1/T1 = p2V2/T2

• Cp – Cv = R

• For reversible adiabatic process : pVγ = Const

• For Const Volume(Isochoric) process: p/T = Const (Gay Lussac Law)• For Const Pressure (Isobaric) process : V/T = Const (Charle’s Law)• For Const Temp (Isothermal) process: pV = Const (Boyle’s Law)

• In Compression process, if p1, V1 and T1 represent initial conditions & p2, V2 and T2 the final conditions;

n

nn

p

p

V

V

T

T1

1

2

1

2

1

1

2

Where n=γ for reversibleadiabatic (isentropic) process

Some Useful Standard Values for Perfect Gas/Air

Specific Heat at Const Pressure Cp=1.005 kJ/kgK

Specific Heat at Const Volume Cv=0.718 kJ/kgK

Gas Constant R=0.287 kJ/kgK

Ratio of Cp/Cv=γ=1.4 (Constant)

Pascal Pa=N/m2

1 bar = 105 Pa =105 N/m2 =100 kPa =1.03 kg/cm2 1 MPa = 106 Pa = 10 bar

Pressure:

Volume:1 lit = 1000cc = 10-3m3

Important Cycles for Piston Engines

1. Constant Volume or Otto Cycle

2. Constant Pressure or Diesel Cycle

3. Dual Combustion or Limited Pressure Cycle

p

V

1

2

3

4

Idealized Otto /Const Volume Cycle

0

1-2 : Adiabatic Compression2-3 : Const Volume Heat Addition 3-4 : Adiabatic Expansion4-1 : Const Volume Heat Rejection

V1/V4V2/V3

1

11

r

Air Standard Efficiency of Otto Cycle

Ideal Diesel /Constant Pressure Cycle

1

111

1

r

Some Important Aspects of Diesel Cycle

• During heat addition at constant pressure, air expands from volume V2 to V3 doing some work as fuel injection commences at V2 and cuts off at V3 , called Cut Off Point • In actual engine, heat addition takes place in the form of injection of fuel, which self-ignites due to high temp caused by high CR and burns at constant pressure as piston moves down• The volume ratio V3/V2 is called cut off ratio and is denoted by ρ

• Compression Ratio and Expansion Ratio are not equal in diesel cycle (unlike in Otto Cycle)

Air Standard Efficiencies : Otto & Diesel Cycles

1

111

1

r

1

11

rOtto Cycle:Diesel Cycle:

• In Diesel Cycle, bracketed term is always > 1, hence η for diesel cycle will always be lower than Otto for same CR • With increase in CR, η initially increases at faster rate• Diesel engs operate at much higher CR as compared to petrol engs, hence η for diesel eng is actually higher• η decreases as Cut off ρ increases

Dual Combustion or Limited Pressure Cycle

p

V

0 1

2

3 4

5

1-2 : Adiabatic Compression2-3 : Heat Addition at Const Volume3-4 : Heat Addition at Const Pressure4-5 : Adiabatic Expansion5-1 : Heat Rejection at Const Volume

1.1

1.11

1

r

Theoretical/ Air Std Efficiencies

Otto Cycle: 1

11

r

Diesel Cycle:

1

111

1

r

Dual Cycle:

1.1

1.11

1

r

Q. An engine working on Otto Cycle has a clearancevolume of 17% of the total volume. Find (i) air std efficiency of the cycle (ii) Relative efficiencyif actual efficiency is 26.85%.

Solution:

c

csStdair V

VVr

r

;

11

1

Now Vc=0.17V1=0.17(Vs+Vc)

88.517.0 1

1 V

Vr

%76.505076.088.5

11

14.1or

%9.5210076.50

85.26 x

efficiencystdAir

EfficiencyActualr

Lecture No 5

Learning Objectives: • To learn theoretical Fuel-Air Cycles

Theoretical Fuel-Air Cycles

Cycles, which take in to account the variations of specific heats, effects of molecular structure, effects of composition of mixture of fuel, air & residual gases approximating to working substance, are called Fuel-Air Cycles

Fuel-air cycles largely take the following in to consideration:• Actual composition of cylinder gases i,e. fuel, air, water vapor and residual gases

• Variation (increase) of specific heats with temp Specific heats vary (increase) with increase in temp (hence γ = Cp/Cv ↓with ↑T) Cp = a + bT + cT2 + dT3

Cv = a1 + bT + cT2 + dT3; a1 > a

Theoretical Fuel-Air Cycle

• After combustion process, mixture is in chemical equilibrium (No dissociation )

• Intake and exhaust processes take place at atmospheric pressure

• Compression & expansion processes are adiabatic without friction

• In case of Otto Cycle, mixture of air & fuel is homogenous and it burns at constant volume

• Change in KE is negligible

• No heat exchange between gases and cylinder walls

• Mixture of fuel & air (A/F ratio)

Theoretical Fuel-Air Cycle

1. Effect of Composition of Fuel and Air (A/F Ratio):• Leaner mixture has higher thermal efficiency• Richer mixture will have lower efficiency as unburnt fuel will go to exhaust

• Efficiency increases with CR

1

111

11

1

1

r

ORr

diesel

otto

V

p

1

2

3

42’

3’

4’4’’

Actual Cycle 1-2’-3’-4’’

2. Effect of Variation Specific Heats :

Ideal Otto Cycle 1-2-3-4

Theoretical Fuel-Air Cycle

2. Effect of Variation Specific Heats :• Cp=a+bT+cT2 & Cv=a1+bT+cT2

• During adiabatic compn process 1-2, as the temp increases, Cp & Cv increase and γ decreases

', 2

1

2

112 Ttemptodowncomes

V

VTTtempTherefore

• During process 2-3, for a given heat supplied Qs, temp T3 will lower down to T3’ as per the expression Qs=mCv(T3-T2’)

Qs

Theoretical Fuel-Air Cycle

2. Effect of Variation Specific Heats (Contd) :• And, therefore, process 3-4 will now become 3’-4’

• But process 3’-4’ represents process with const γ. Since eng is in expansion stroke, the temp of gases decreases, Cp & Cv decrease and hence γ increases

'''

''' 413

1

1

23

1

4

334 Ttodecreases

r

T

V

VT

V

VTTTemp

• Hence, actual process becomes 3’-4’’ from 3’-4’

• Therefore, actual cycle becomes 1-2’-3’-4’’ although ideal Otto Cycle was 1-2-3-4

Theoretical Fuel-Air Cycle3. Effect of Molecular Structure :

• Pressure of gases in comb chamber is proportional to number of moles for given temp and volume by the relation pV=nR˚T; where n is the no of moles

• If the no of moles before and after combustion are different, pressure will change accordingly

• Take example of combustion :

C + O2 = CO2

1 mole 1 mole 1 mole

2H2 + O2 = 2H2O2 moles 1 mole 2 moles

MolecularContraction

C8H18 + 12.5O2 = 8CO2 + 9H2O1 mole 12.5 moles 8 moles 9 moles

MolecularExpansion

Theoretical Fuel-Air Cycle

• From the foregoing, it is clear that no of moles may be more or less after the combustion

• This phenomenon is called molecular contraction or molecular expansion

• Therefore, actual pressure in combustion chamber will be different compared to theoretical cycle

• Actual pressure in combustion chamber shall be more in case of molecular expansion and lesser in case of molecular contraction compared to theoretical cycle

Theoretical Fuel-Air Cycle

4. Dissociation Losses:• Products of combustion dissociate in to its constituents at higher temp beyond 1000˚C• Rate of dissociation increases with increase in temp

• Dissociation process absorbs heat energy from comb gases being chemically endothermic reaction and association releases energy being exothermic reaction

2CO2=2CO+O2 : (Dissociation) Endothermic Reaction

2CO+O2=2CO2 : (Association) Exothermic Reaction

Theoretical Fuel-Air Cycle

• This results in lowering of temp and hence pressure which in turn reduces power output and thermal efficiency

• However, at the end of expansion stroke, temperatures become low and dissociated gases start combining releasing heat energy.

• But, it is too late as most of this heat energy is carried away by exhaust gases. This loss of power is called dissociation loss

• Dissociation losses have been shown in Fig

Lecture No 6

Learning Objectives: • To compare air standard cycle with theoretical Fuel-Air Cycles• To learn actual fuel-air cycle

Comparison of Fuel-Air Cycles with Air Standard Cycle

• Air std cycle has highly simplified approximations• Therefore, estimate of engine performance is much higher than the actual performance• For example, actual indicated thermal efficiency of a petrol engine for CR 7, is around 30% whereas air std efficiency is around 55%.

• This large difference is due to non-instantaneous burning of charge, incomplete combustion and largely over simplifications in using values of properties of working fluid for analysis

• In air std cycle, it was assumed that working fluid was air, which behaves like perfect gas and had constant specific heats

• In actual engine , working fluid is not air but a mixture of air, fuel and residual gases

• Also, specific heats of working fluid are not constant but increase as the temp rises

• And, products of combustion are subjected to dissociation at high temperatures

• Engine operation is not frictionless

Comparison of Fuel-Air Cycles with Air Standard Cycle

Actual/Real Fuel-Air Cycles

Actual cycle efficiency is much lower than the air std efficiency due to various losses occurring in actualengine operation. These are:1. Losses due to variation of specific heats with temp

2. Dissociation or chemical in-equilibrium losses3. Time losses

4. Incomplete combustion losses

5. Direct heat losses from comb gases to surroundings

6. Exhaust blow-down losses

7. Pumping losses

8. Friction losses

Actual/Real Fuel-Air Cycle• Working substance is mixture of fuel, air & residual gases (not air or perfect gases)

• Specific heats vary (increase) with temp (hence γ = Cp/Cv ↓with ↑T) Cp = a + bT + cT2 + dT3

Cv = a1 + bT + cT2 + dT3; a1 > a • Effect of molecular structure due to comb of fuel. (Beyond 1000°C, products of comb dissociate & absorb heat energy, thus lowering comb temp and hence the power)• Comb is not instantaneous (at const volume) as piston continuously keeps moving resulting in time losses

• Heat addition is not from reservoir but due to comb of fuel, which alters composition of working fluid

Actual/Real Fuel-Air Cycle• Compression & Expansion processes are polytropic due to direct heat transfer to surroundings• Opening and closing of valves are not instantaneous. All 4 strokes do not take place in 180° crank rotation. Early opening of exhaust valve causes blow down losses

• Suction stroke takes place below atmospheric pressure and exhaust stroke above atm pressure (Pumping losses)

• Thus, work developed in actual cycle is much less than the theoretical cycle

• Friction losses also take place

Losses In Actual Cycle Other Than Fuel-Air Cycle

1. Time Losses:

• Work developed in actual cycle is much less than theoretical cycle as shown in Fig (Area enclosed by Blue Curve)

• Due to this time lag, actual max pr in comb chamber lowers down to point x.

• In ideal cycles, heat addition is assumed at constant volume but actually, combustion takes some finite time while piston continues to move (30-40˚rotation of crank shaft)

• Loss of work represents time losses

Losses In Actual Cycle Other Than Fuel-Air Cycle

2. Heat Losses:

• Due to this, lot of work is lost

• There is considerable quantity of heat loss during combustion and expansion processes

• Ideal Compression and Expansion processes are assumed to be adiabatic but in actual processes, heat transfer does take place from working fluid to cylinder walls

• These work losses are called Heat Losses

Losses In Actual Cycle Other Than Fuel-Air Cycle

3. Exhaust Blow-down Losses:

• But due to this, lot of heat energy is carried away by exhaust gases resulting in to loss of work

• In ideal cycle, exhaust valve is assumed to open at BDC, when exhaust stroke starts but in actual cycle, it opens 30 to 40˚ before BDC in power stroke itself

• This helps in reducing pressure in the cylinder during exhaust stroke, so that work required to push out exhaust gases, reduces

• This work losses are called Exhaust Blow-down Losses

Losses In Actual Cycle Other Than Fuel-Air Cycle

4. Pumping Losses:• In ideal cycle, suction and exhaust processes are assumed to be taking place at atmospheric pressure

• But in actual cycle, suction is carried out below and exhaust above atm pressures and for these operations, work is required to be done on gases which comes from actual work developed, thus reducing over all power output

• These work losses are called Pumping losses (shown in pink in Fig)

Losses In Actual Cycle Other Than Fuel-Air Cycle

5. Friction Losses:

• All this comes from power developed by the engine, thus reducing actual power out put

• In ideal cycle, engine operation is considered frictionless but in actual it is not so.

• Friction losses do occur between sliding or rotating components like piston rings and cylinder walls, bearings etc and it increases rapidly with speed of the engine. Also, power is required to run various auxiliary equipment like fans, pumps etc

• These power losses are called Friction Losses

Real/Actual

Otto Cycle

Latest Developments

Recent Trends in Engine Development

• Compact Size

• Fuel Economy (VCR, VVT, MPFI, Stratified Charge, HCCI)

• More Power

• Reduced Emissions/ Hybrid/ Electric vehicles

• Cheaper Fuel – Low Cetane / Octane No

• Lighter engines/ better materials for eng components

• DI combustion chambers; IDI being phased out

• Two stage boosting

• Increase in specific power output-90kW/Litre

ENGINE ANIMATIONS

End of Unit I