Company Announcements Office Australian Securities ... · board (PCB) technologies that make use of...

Transcript of Company Announcements Office Australian Securities ... · board (PCB) technologies that make use of...

Strategic Elements Ltd

ABN 47 122 437 503

Suite 6/27 Railway Road

Subiaco WA 6008

Australia

Phone: +61 8 9278 2788

Fax: +61 8 9288 4400

16 May 2016

Company Announcements Office

Australian Securities Exchange

20 Bridge Street

SYDNEY NSW 2000

Dear Sir/Madam

PRINTED ELECTRONICS SECTOR

Please find an attached presentation from the Company in relation to its activities in the Printed

Electronics sector.

Strategic Elements Ltd

Phone: +61 8 9278 2788

Fax: +61 8 9288 4400

www.strategicelements.com.au

For

per

sona

l use

onl

y

+

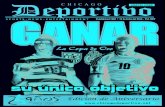

printed electronics industry ASX:SOR

The global interest in the technology is booming… Almost every sector of our economy already is or will be affected, if not revolutionized, by printed electronics….

ORGANIC AND PRINTED ELECTRONICS 29

The wafer level technology includes batch pro-cessing, typically film substrates on a carrier. An adapted semiconductor line is used for process-ing. High resolution can be achieved by vacuum deposition and/or spin coating followed by pho-tolithography and wet or dry etching. The pro-duction cost is relatively high and the process is not compatible for conversion to in-line sheet to sheet or reel-to-reel processes.

Under hybrid technologies, we summarize com-binations of processes including large area pho-tolithography, screen printing or printed circuit board (PCB) technologies that make use of flexi-ble substrates (e.g. polymer films or paper). Depo-sition of materials happens by spin coating, blade coating or large area vacuum deposition, in some cases also partly by printing. Ink-jet print-ing and laser patterning are further technologies that are grouped in the hybrids and enable pro-duction at a medium cost level. At the moment hybrid appears to be possibly the most promising technology for further market penetration in the next few years, and it could also be combined with some amount of silicon for specific func-tions in hybrid systems.

Fully printed means continuous, automated mass-production compatible printing and coat-ing techniques (flexo, gravure, offset, slot-die,

from a large area unpatterned film, while others are additive, i. e. they only deposit material where it is wanted, e.g. by fusing a shadow mask.

There are no single standard processes in exist-ence today. Deciding which printing or other pat-terning process is used depends on the specific requirements of a particular device. In general, different processes have to be used for subse-quent steps of a multilayer device in order to optimize each process step. In an integrated product there may also be some steps in which printing processes are used at standard levels, e.g. for graphics or adhesives, and other critical ones where the highest quality standards need to be applied, e.g. for functional layers and small features. The above mentioned processes differ strongly with regard to, e.g., resolution and throughput and the feature size and throughput for some important processes at the highest quality level are shown in Figure 20.

Process Technology LevelsThe technologies that are used in organic elec-tronics range from batch, clean-room, etching based processes to mass printing processes that are capable of deposition of square meters of substrates per second. Here is a rough classifica-tion of the technologies in three different tech-nology levels:

Figure 21: Reel-to-reel printing of electronic devices. (Source: OE-A)

LOPEC is the industry event for printed electronics that success-fully combines technology and business. As a leading inter- national platform, LOPEC gives participants a broad overview of everything that this technology has to offer—from applications to research. It unites, inspires and realizes. Today and tomorrow. LOPEC makes printed electronics a stimulating experience.

The LOPEC conference compliments the exhibition perfectly and is the world’s leading conference for printed electronics. Care- fully chosen speakers present the latest applications, current busi- ness models and recent research results. A transfer of know- ledge at its finest.

Exhibitors and visitors give LOPEC and its content outstanding ratings. The results of our participant survey are available here: lopec.com/participantsurvey

LOPEC—the success story

133 exhibitors from 19 countries

More than 2,300 visitors from 42 countries

199 conference presentations from 28 countries

96% of participants feel that LOPEC’s importance is stable and/or growing.

Performance figures for LOPEC 2015:

Application sectors for printed electronics

Automotive

Lighting

Printing and graphic arts

Energy

Building and architecture

Logistics

Medical and pharmaceutical

Textiles

Consumer electronics

Packaging

White goods

2

Conveniently order your ticket to LOPEC 2016 online: lopec.com/tickets

For

per

sona

l use

onl

y

+sector involvement

SOR recently announced an intended expansion of its involvement in the Printed and Flexible Electronics sector.

!!! ! ! ! ! ! ! ! ! !!!!!!!!!!!!!!!! !! ! ! ! ! ! ! ! ! ! ! !!"#!$%&!'#"(!

)*%+!,-%+*-./0*+1!

!

2! %3! 4/*%5*0! 6.! .77*+! &.8! %! /9396*0! .44.+68:96&! 6.! 48+;-%5*! :*<! 5-%+*5! %6! %! !"#$%&'(! 6.! 6-*! =*;.+0! )%6*! 9:!

,6+%6*>9;!?/*3*:65!@9396*0!A ,B= C!)*"%*+(%+(,-+'-.(+),/#-+.7!4.6*:69%/!0*D*/.43*:65! 9:!6-*!E%:.;8F*!$*3.+&!

6*;-:./.>&!%:0!.6-*+!4+.G*;65H!

!

I5!&.8!%+*!%!;8++*:6!5-%+*-./0*+1!&.8!%+*!*/9>9F/*!6.!%;J89+*!!"#$%&'(-!+#,/*-#!8:0*+!.8+!,-%+*!K8+;-%5*!K/%:!

! !8:0*+!6-*!L*+35!%:0!M.:0969.:5!5*6!.86!9:!6-95!0.;83*:6H!!!

!

! N.8!;%:!48+;-%5*!5-%+*5!%6!0012+$-'(#!<-9/56!6-*!4+9;*!%5!%6!6-*!=*;.+0!)%6*!<%5!"O!;*:65!F*9:>!%:!034+!"#$%&'(!6.!6-*!;/.59:>!4+9;*!.7!5-%+*5!.:!6-*!=*;.+0!)%6*H!

!

! N.8!;%:!48+;-%5*!%!39:9383!.7!P"1###!%:0!%!3%Q9383!.7!P"R1###!.7!5-%+*5H!

!

! L-*!K/%:! 95!$/))-!+ 6.!%!6.6%/!.7!P"1###1###!%:0!%44/9;%69.:5!<9//!F*!%;;*46*0!.:!%! 5"*#(+*-$-"6-!!F%595!

6.+&!

+*J89+*3*:65CH!!!

!

! L-*!K/%:!95!5*6!6.!;/.5*!S"!$%&!'#"(!-.<*D*+!6-95!3%&!F*!%/6*+*0!%6!6-*!)9+*;6.+5!095;+*69.:H!

!

! L-*+*!95!:.!:**0+6.!79//!.86!%:0!4.56!6-*!%44/9;%69.:+7.+3+ 97!&.8!*/*;6!6.!4%&!F&+789:H!N.8+!%44/9;%69.:!95!

+*;*9D*0!";;-!"/(-<=+.:!6-*!0%6*!&.8+!789:!4%&3*:6!95!+*;*9D*0H!!K/*%5*!85*!6-*!+*7*+*:;*!;.0*!4+9:6*0!

.:!6-*!%66%;-*0!%44/9;%69.:!7.+3H!

!

!"#$%#& '()#*& +,#& -(./$'0& "$%)& 1('231)#2& $& 4,$5#& !351,$%#& !"$'& 6$"%(& 1$//#2& $'2& (77#5#2& ('& $& 785%)& 5#1#89#2&:$%8%;& 8'& <$0& =>?@A& & B3'2%& 75(.& ),$)& ,#$98"0& (9#5%3:%158:#2& 5$8%8'C& D#5#& /58(58)8%#2& )(D$52%& $1E38%8)8('& $'2&1(..#'1#.#')&(7&D(5F&('&),#&G$'(13:#&<#.(50&)#1,'("(C0A&!

N.8+! ;8++*:6! .44.+68:96&! ;.3*5! %6! %! 4%+69;8/%+/&! 1! <96-! 6-*! +%490!

0*D*/.43*:6! .7! 6-*! E%:.;8F*! $*3.+&! 6*;-:./.>&H! L-*! 4+.;**05! .7! 6-*! K/%:! <9//! F*! 85*0! 6.! 78+6-*+! 4+.>+*55!

9:D*563*:65!%:0!5844/*3*:6!<.+T9:>!;%496%/!9:;/809:>U!

!

9&#(*/<"/'+ 9!6/'$-!+ >/(-*"/<#+ 8(=+ ?(!+ @99>AB! "##V! .<:*0! II$! 95! ;.:69:89:>! 6.! 0*D*/.4! 6-*!

E%:.;8F*! $*3.+&! 6*;-:./.>&! 8:0*+! /9;*:;*! 7+.3! 6-*! W:9D*+596&! .7! E*<! ,.86-! X%/*5H! L-*! E%:.;8F*!

$*3.+&!6*;-:./.>&!95!0*D*/.49:>!+%490/&H!,8;;*55!9:! 9::.D%69D*!:*<!5*;6.+5!58;-!%5!K+9:6*0!?/*;6+.:9;5!

+*J89+*5!4%+6:*+5-94H!Y.9:>!7.+<%+01!%!4+9.+96&!7.;85!.7!6-*!M.34%:&!<9//!F*!.:!0*D*/.43*:6!%:0!%;69D969*5!

+*/%6*0!6.!4%+6:*+9:>H!!

!

9&#(*/<"/'+8*"'(-!+/'!+C<-."D<-+E<-$(*%'"$#+F-$(%*B!L-*!5*;6.+!95!*Q4%:09:>!>/.F%//&1!-.<*D*+!I856+%/9%!

95!.:/&!G856!F*>9::9:>!6.!8:0*+56%:0!6-*!.44.+68:96&H!I5!%!79+56!3.D*+!9:!I856+%/9%!A%:0!K../*0!)*D*/.43*:6!

Z8:0! 56%685C1! ,B=! -%5! 56+.:>! 4.6*:69%/! 6.! F*! %! 0.39:%:6! 4/%&*+H! ,B=! <9//! <.+T! <96-! +*5*%+;-*+5! %:0!

9:D*:6.+5!%;+.55!I856+%/9%!6.!9:;+*%5*!0*D*/.43*:6!.7!6-*!5*;6.+!%:0!>*:*+%6*!6*;-:./.>&!%;J895969.:!%:0!

%55956!6-*5*!%;69D969*5H!!!

!

F(*/(-G"$+>/(-*"/<#+8(=+?(!+@F>?AB!L-*!-9>-[>+%0*!Y./0*:!\/.;T5!4*+396!95!F*9:>!3%9:6%9:*0H!M.+4.+%6*!

56+%6*>9*5! 9:;/80

%>+**0!4+.4.+69.:!6.!6-*!:83F*+!,B=!5-%+*5!6-*&!-./0C!%+*!F*9:>!%55*55*0H!26!95! 9:6*:0*0!6-*!M.34%:&!

%:0].+!965!5-%+*-./0*+5!<9//!+*6%9:!;.:6+./!.7!6-*!>./0!%55*65!<96-9:!,$@H!

!

!

Why is this very good timing ?...

1. Both poliAcal parAes have announced a surge in innovaAon funding and benefits for innovaAve sectors.

2. SOR has an extra advantage of being a Pooled Development Fund with generous tax concession for our shareholders.

3. Global Printed Electronics sector being ignored by Australian industry. F

or p

erso

nal u

se o

nly

+national focus on innovation

Surging na-onal focus on innova-on in Australia… n AddiAonal $1.1b in new funding

n R&D Tax IncenAve Program

n Australian Research Council funding

n Tax incenAves for investors

n Tax breaks for start-‐ups

n $127m of University collaboraAon

n $200 funding for CSIRO for Uni start-‐ups

However SOR has access to one more Federal Government benefit that provides

a significant advantage over other ASX listed companies….

SOR will leverage these new programs to benefit

shareholders…

For

per

sona

l use

onl

y

+pooled development fund

§ SOR operates under the Pooled Development Fund program, an Australian Federal Government program designed to increase investment in Australian SME’s.

§ Designed by Federal Government to in part drive investment into Australian innovaAon.

§ Under this Ausindustry Venture Capital Program our shareholders can pay no capital gains tax on the sale of their ASX listed shares.

§ Other benefits for shareholders include paying no tax on dividends received.

§ SOR as a Company also pays just 15% corporate tax rate on returns from backing Australian SME’s.

§ Over $1bn invested by the PDF program.

Australian Innovation

Entrepreneurs and researchers

*Shareholders should seek their own independent tax advice.

For

per

sona

l use

onl

y

+printed electronics

§ PE can create flexible, transparent electronics which current semiconductors cannot.

§ PE can also be manufactured using cheap prinAng methods unlike current electronics made in expensive fabricaAon plants.

Printed electronics manufacturing facili;es cost 1/100th of tradi;onal semiconductor fabrica;on plants.

n InnovaAon on prinAng techniques and conducAve materials makes high throughput and volume producAon of electronics possible at low cost on flexible plasAc, paper, or texAle substrates.

n This flexibility enables integraAon of printed and flexible electronics into everyday items and places we had only dreamed of before.

This allows device manufacturers to place electronics in places and on products that have never been able to use electronics before.

ORGANIC AND PRINTED ELECTRONICS 29

The wafer level technology includes batch pro-cessing, typically film substrates on a carrier. An adapted semiconductor line is used for process-ing. High resolution can be achieved by vacuum deposition and/or spin coating followed by pho-tolithography and wet or dry etching. The pro-duction cost is relatively high and the process is not compatible for conversion to in-line sheet to sheet or reel-to-reel processes.

Under hybrid technologies, we summarize com-binations of processes including large area pho-tolithography, screen printing or printed circuit board (PCB) technologies that make use of flexi-ble substrates (e.g. polymer films or paper). Depo-sition of materials happens by spin coating, blade coating or large area vacuum deposition, in some cases also partly by printing. Ink-jet print-ing and laser patterning are further technologies that are grouped in the hybrids and enable pro-duction at a medium cost level. At the moment hybrid appears to be possibly the most promising technology for further market penetration in the next few years, and it could also be combined with some amount of silicon for specific func-tions in hybrid systems.

Fully printed means continuous, automated mass-production compatible printing and coat-ing techniques (flexo, gravure, offset, slot-die,

from a large area unpatterned film, while others are additive, i. e. they only deposit material where it is wanted, e.g. by fusing a shadow mask.

There are no single standard processes in exist-ence today. Deciding which printing or other pat-terning process is used depends on the specific requirements of a particular device. In general, different processes have to be used for subse-quent steps of a multilayer device in order to optimize each process step. In an integrated product there may also be some steps in which printing processes are used at standard levels, e.g. for graphics or adhesives, and other critical ones where the highest quality standards need to be applied, e.g. for functional layers and small features. The above mentioned processes differ strongly with regard to, e.g., resolution and throughput and the feature size and throughput for some important processes at the highest quality level are shown in Figure 20.

Process Technology LevelsThe technologies that are used in organic elec-tronics range from batch, clean-room, etching based processes to mass printing processes that are capable of deposition of square meters of substrates per second. Here is a rough classifica-tion of the technologies in three different tech-nology levels:

Figure 21: Reel-to-reel printing of electronic devices. (Source: OE-A)

For

per

sona

l use

onl

y

+market information

This is only the beginning.. the global market is expected to reach $340 Billion by 2030.

Printed and flexible electronics are already in the market. The global interest in the technology is booming. Almost every sector of our economy already is or will be affected, if not revoluAonized, by printed electronics.

According to research firm IDTechEx, the global market for printed and potenAally printable electronics, will rise from about USD 24 billion in 2014 to $70.4 billion in 2024, with a compound annual growth rate of 40 per cent. Those amounts jump dramaAcally when you include the total market value of the products that do, and could, incorporate PE components.

All informa;on from the Canadian Printable Electronics Industry Associa;on

For

per

sona

l use

onl

y

+sector activities

ORGANIC AND PRINTED ELECTRONICS 21

regard to the trend from health care at clinics and hospitals to health care at home. To some extent, the future is already here, since organic and printed electronics already enables products on the health care market, such as glucose test strips, lab-on-chip products and smart blister package for pharmaceuticals.

While we focus on clusters of applications based on functions, organic electronics contributes to innovation in different industrial sectors such as automotive or health care, with products cover-ing a range of functions. For this reason, OE-A has also begun to look at these market segments, and there have already been intensive discus-sions about how organic electronics may contrib-ute to the future of health care, especially with

Primary batteries, memory for brand protection,ITO-free transparent conductive films and touch sensors

Garments with integrated sensors,anti-theft/forgery labels, temperature sensor smart labels, printed sensors and test strips

Rechargeable batteries, transparent touch sensors, reflective display elements,flexible & large area ITO-free touch sensors

NFC enabled sensor labels, intelligent packaging, integrated systems on garment

Multi-cell batteries, wireless readable memory, printed logic chips, bendable ITO-free touch & gesture sensors

Directly printed batteries, smart objects integrating actives and passive devices, fully integrated touch & gesture sensors

Multi-cell batteries, wireless readable memory, printed logic chips, bendable ITO-free touch & gesture sensors

OLED on textile, disposable health monitoring systems, wireless sensors for smart buildings

OE-A Roadmap for Organic and Printed Electronics Applications 2015

Electronics & Components

Integrated Smart

Systems

Existing until 2015

Short term 2016–2018

Medium term 2019–2022

Longer term 2023+© OE-A 2015

! ! !

Rigid modules for design driven luminaires B2B and B2C

Flexible lighting for design driven applications

Mass-produced flexible lighting

General lighting

Curved OLED TVs, flexible OLED displays, mobile OLED displays, e-reader, wearables

In-moulded displays, (semi-) transparent bendable display, OLED monitors and TVs

Portable foldableOLED displays, (semi-) transparent rollable display

Stretchable display, rollable OLED TV, rollable consumer electronics

Consumer electronic chargers, solar lamps, architectual installations

Consumer electronics, mobile power, energy harvesting, specialized BIPV and BAPV

Mobile power, Internet of Everything energy harvesting, building integration, medium size off-grid

Large volume BIPV integration, large and industrial off-grid, grid-connected PV

Organic Photovoltaics

Flexible andOLED Display

ELO DLighting

Figure 13: 6th Edition of the OE-A Roadmap for organic and printed electronics, with forecast for the market entry in large volumes (general availability) for the different applications. The table is a further development of and update to the fifth version of the OE-A roadmap presented in 2013.

Australian Innovation

Entrepreneurs and researchers

SOR will seek to idenAfy and assess Australian Printed Electronics technologies and Companies for potenAal licensing and acquisiAon opportuniAes.

For

per

sona

l use

onl

y

+commercialisation strategy

The secret to Printed Electronics growth is collaboration - Dupont

§ IdenAfy potenAal partners from Industrial InnovaAon Centres, InnovaAon Clusters and Companies across the Printed Electronics supply chain.

§ Leverage partners global network and experAse in many areas. § Develop products faster and launching them earlier. § Gain be`er access to the target market.

Our strategy is to specifically focus technical research and development on those tasks that enable partnerships to be formed.

For

per

sona

l use

onl

y

+what do others think?

“These prinAng, materials, paper and chemical companies of today will be the new electronic giants tomorrow” – IDTechEx “The demand for low-‐cost, non convenAonal electronic soluAons is real and its growing” – Xerox “Investors are increasingly drawn to the printed electronics market due to its low cost of entry and technological knowhow of convenAonal prinAng. The convenAonal prinAng methods are already mastered and this reduces the chances of any anomaly with the process” – Frost and Sullivan “Technologies for flexible electronics manufacturing will be major differenAators in the next generaAon of consumer and compuAng devices”– President’s Council of Advisors on Science and Technology “Flexible Hybrid Electronics has the potenAal to re-‐shape enAre industries, from the electronic wearable devices market, to medical health monitoring systems, to the ubiquitous sensing of the world around us – also known as the Internet of Things” -‐US Department of Defense “Printed Electronics.. the Holy Grail of low cost, high volume manufacturing. Follow the money” -‐ DuPont

For

per

sona

l use

onl

y

+psst..

The current memory capacity of printed electronics and smart systems is limited. As memory capacity increases applica;ons will be able to expand their func;onality -‐ IDC

Memory is at the heart of electronics…

For

per

sona

l use

onl

y

![[Ge(TenBu)4] – a single source precursor for the …Chemical vapour deposition (CVD) is a widely used depo-sition technique for thin films and coatings, with its relatively low cost](https://static.fdocuments.in/doc/165x107/5f1411948426f939003143d8/getenbu4-a-a-single-source-precursor-for-the-chemical-vapour-deposition-cvd.jpg)

![Platinum electroless depo sition on Nafion membrane for ... · The optimum condition was found at electroless time of 60 min and Pt ... [Park et al., 2005]. The best electrocatalyst](https://static.fdocuments.in/doc/165x107/606282127ea3527cc20e3ae7/platinum-electroless-depo-sition-on-nafion-membrane-for-the-optimum-condition.jpg)