QHSE Bulletin 51

Transcript of QHSE Bulletin 51

-

8/9/2019 QHSE Bulletin 51

1/3

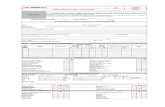

QHSE BulletinDESCON ENGINEERING LIMITED

Safe Sub-Contractor of the Month:

Technip once again awarded Descon as a Safe Sub-

Contractor for the month (January, 2009) at Olefin Project

Qatar. Our HSE team has received this award

5th time at Olefin Project. We

congratulate our project team on

achieving this award.

One hundred thousand Man-

Hours with out LTI at TRL

Project (P#1129):

Our Project HSE team has

achieved LTI free One hundred

thousand Man-hours at TRL Project

(P#1129). We congratulate our Project

Team on reaching this milestone

successfully. Achievement of this milestone is

the result of joint effort of HSE & Execution Team. Wewish them good luck and hope that they will complete this

project without LTI.

Eight Million Man-hours without LTI at Pearl GTL

Project:

On 11th February, 2009 our Project HSE team at Pearl GTL

has completed Eight Million Man-hours without any OHSA

Recordable Injury. We congratulate our project team on

achieving this milestone and hope that same stride will befollowed by the end of project.

Issue No. 51 \\\\ Jan, Feb 2009

Protect Yourself from

Pollution

If you can't live in a smog-free

environment, at least avoid

smoke-filled rooms, high traffic

areas, breathing in highway

fumes and exercising near

busy thoroughfares.

Exercise outside when

the smog rating is low.Exercise indoors in air

conditioning when air

quality is good. Plant

lots of shrubbery in

your yard.Thought for the day:

'Smoke gets in your

eyes'and your mouth, and

your nose and your lungs as do

pollutants.hum the tune daily.

TIP of

THE MONTHNewsCORNERQHSE

FAITH AND BELIEF

Only the person who has

faith in himself is able to be

faithful to others.

Erich Fromm

QHSE Monthly Bulletin 01

-

8/9/2019 QHSE Bulletin 51

2/3

Welding is the joining of multiple pieces of metal by the use ofheat and or pressure. A union of the parts is created by fusion orre-crystallization across the metal interface. Welding can involvethe use of filler material, or it can involve no filler.

There are many types of welding processes out of that one is GasTungsten Arc Welding also called TIG Welding process.

GTAW uses a non-consumable tungsten electrode which must beshielded with an inert gas. The arc is initiated between the tip ofthe electrode and work to melt the metal being welded, as well asthe filler metal, when used. A gas shield protects the electrode andthe molten weld pool, and provides the arc characteristics.

GTAW tools and equipments:

Welding Torch

Tungsten Electrode Inert Gas Pressure regulators and flow meters Welding face shield Protective clothing Gas Nozzle on gun A source of shielding gas. Power Source (8KW to 30 KW) Current range (200A to

500A) High Frequency Oscillator Welding wire

Advantages:

Welds with or without filler metal Precise control of welding variables Low distortion Higher quality root pass. Accommodate wide range of thickness, positions and

geometries. Portable Equipment Combination with GMAW or SMAW (Shielded Metal Arc

Welding) produces good resultsfor pipe welding.

Limitations:

More training time required as GMAW & SMAW. More expensive than SMAW Requires greater welder dexterity than MIG or stick welding Lower deposition rate More costly for welding thick sections

Applications:

Most commonly used for Aluminum, Steel and Stainless steel.Except for thin sections or where very high quality is needed.

Common Defects:

Porosity Incomplete Fusions Inadequate joint penetration. Cracks

QHSE Monthly Bulletin 02

GAS TUNGSTEN ARC WELDING IS ONE OF

THE WELDING PROCESS TYPE AND ITS

ALSO CALLED TIG WELDING PROCESS

Gas Tungsten Arc Welding (GTAW)QUALITY

The arc is initiatedbetween the tip of the

electrode and work to meltthe metal being welded, as

well as the filler metal,when used. A gas shield

protects the electrode and

the molten weld pool, andprovides the arccharacteristics.

Issue No. 51 \\\\ Jan, Feb 2009

TIG/GTAW butt weld in 3/8-in.

thick 4140 aluminum alloy usingAlumaxx Plus gas.

-

8/9/2019 QHSE Bulletin 51

3/3

IT IS VERY IMPORTANT TO KNOW THAT

ON WHICH POINTS TO BE

FOCUSED TO ACHIEVE

SUCCESSFUL SAFETY SYSTEM

What Does SafetySuccess Look Like?SAFETY

Safety is a condition of

operations that has certain

qualities. When you

achieve the qualities, the

numbers follow. If you

think of safety as a vacuum

in which accidents have all

been sucked out, you fall in

to the trap of avoiding

failure and your efforts

become negative and

ineffective. It is very

important to know that on

which points to be focus to

achieve successful safety

system.

Following areas to be focused to achieve successful safety system:

1. Proactive

Truly successful safety efforts have begun to max out traditional

reactive safety and go well beyond these minimal efforts to getahead of the curve in safety efforts. Success in reactive safety

generates the necessity for proactive safety. When you use

accident investigation data to improve safety, the more you

succeed, the less data you have. Before the accident data

disappears it does another nasty trick: it loses its statistical

significance that last bit of accident data tells you that you are not

perfect; but it doesnt tell you how to get better.

2. Focused

Truly successful safety efforts generate a focus on the most

important dangers and the precautions that can best avoid them.The narrow focus needs to be communicated relentlessly until

workers actually memorize the list.

Many sites create acronyms or other mnemonics to aid the

learning and retention of the focus list then they reinforce the list

until it becomes second nature or even habitual. Once workers

automatically take the most critical precautions, the accidents

rate go down and stay down. FOCUS is an acronym for Forming

One Common Understanding of Safety.

3. Transformation

Precautions that can potentially have a significant impact onaccidents are called transformation precautions. Truly excellent

safety efforts are not striving for modest gains, but working

toward goals that can truly transform the accident rates with a

minimal effort.

4. Involves Workers

Management efforts to improve

safety can be highly effective, but

almost inevitably are limited if

worker involvement is not

increased. Deming said that you

should always involve the people

who know the most when solving

organizational problems. Truly excellent safety efforts attack risks

on two fronts: the management front and the cultural (or worker-

involved) front. Managers should dictate compliance with laws

and company policies as a condition of employment and enforce

them accordingly. Workers should identify precautions that go

beyond compliance and tap into worker discretional efforts to

further move safety efforts toward excellence.

5. Clearly Communicated

Effective communication is a trademark of safety success. Both

the quantity and quality of safety communication are critical to

safety success. When managers and supervisors talk about

productivity much more often than safety, this tends to create the

perception that productivity is important and safety is a lesser

goal. Because of changing priorities and changing perceptions,

many have suggested that safety should be a value and not a

priority. If this goal is to be accomplished, it will require a steady

flow of communication that does not waiver or bend and

management decisions that demonstrate the commitment.

Everyone in the organization should self-monitor their level of

safety communication in both word and deed to determine if

safety is truly clearly communicated.

6. Results Oriented

Processes that do not produce downstream results are not

working and should be revised or scrapped. The true value of

process metrics is to determine if the process is being worked and

if the process is working. Profound knowledge of safety is neither

process or result metrics; it includes knowledge of the process

and result metrics as well as having an understanding of the

relationship between the two. Many safety programs and

processes create a process mentality.

7. Multi-dimensional

The safety world is full of subject-matter experts trying to disguise

science as technology. We constantly are being exposed to new or

revised processes that are largely one-dimensional, one-science

approaches to one symptom of safety failure.

8. Integrated

Truly successful safety efforts are not something else you do; theyare the way you do everything. The more apart safety efforts are

from day-to-day functions, the less successful they are. If your

organization practices Six Sigma, your safety processes should

parallel or even piggy-back on these methods and efforts. Safety is

a quality issue and a staffing issue. When we integrate safety into

everything else, we can truly make it a value and not just a

changeable value.

9. Practical

Safety success can be advanced by theories, but it ultimately is not

a theory. Safety success is impossible if it does not fit the cultural,procedural and conditional realities of the workplace.

10. Humanistic

Ultimately, the reason for working on safety is as important as

how you work on it. If your goals are all financial and bench

marking in their orientation, you will not win the hearts of the

people who can make you successful.

Issue No. 51 \\\\ Jan, Feb 2009

All truly successful safety

efforts have all or most of

the following qualities in

common. The more of these

qualities, the moresuccessful the effort.

Send your comments and suggestions [email protected]

We welcome all useful informationregarding Quality, Health, Safety, &

Environment for inclusion in theforthcoming Issues.

QHSE Monthly Bulletin

03