PEI-QHSE-001-QHSE System V2.docx

-

Upload

jacob-keemink -

Category

Documents

-

view

62 -

download

20

Transcript of PEI-QHSE-001-QHSE System V2.docx

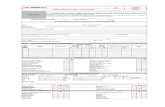

QHSE MANUALDocument Control No.

QHSE MANAGEMENTPEI-QHSE-001

Revision : 1

Date Issued: 03/20/2015

HEALTH, SAFETY AND ENVIRONMENTAL MANAGEMENT SYSTEM

QHSE MANAGEMENT SYSTEM

PEI-QHSE-001

REVISIONS:

DateRevisionDescriptionBySignature

03/20/20151New DocumentJK

The long-term business success of Prowell Energi depends on our ability to continually improve the quality of our services and products while protecting people and the environment. Prowell Energis emphasizes the protection of human health, enhance operational safety, protection of the environment and enhancement of quality, to further the best interests of our customers, our employees and contractors, our stockholders.Prowell Energi requires the active commitment to and accountability for QHSE from all employees and contractors. Line management has a leadership role in the communication, implementation of, and ensuring compliance with, QHSE policies and standards. Prowell Energi is committed to: Protect, and strive for improvement of the health, safety and security of our people at all times; Eliminate HSE accidents; Ensure continuous customer satisfaction by meeting customer requirements; Set HSE performance objectives, measure results, assess and continually improve processes, services and product quality, through the use of an effective management system; Plan for, respond to and recover from any emergency, crisis and business disruption; Minimize our impact on the environment through pollution prevention, reduction of the consumption of natural resources and emissions, and the reduction waste. Apply HSE aspects in the design and engineering of all our services and products; This Policy shall be regularly reviewed to ensure ongoing suitability. The commitments listed are in addition to our basic obligation to comply with Prowell Energis standards as well as all applicable laws and regulations where we operate.

_________________________________________________________________________President DirectorChief Operating Officer

TABLE OF CONTENT

1.0 MISSION, VISION AND POLICY32.0 REFERENCES3

3.0 RESPONSIBILITIES3

4.0 TRAINING PROGRAMS7

5.0 MEETINGS AND COMMITTEES96.0 SELECTION AND CONTROL OF SUB CONTRACTORS10

7.0 SAFETY AUDIT11

8.0 JSA119.0 ACCIDENTS AND INCIDENTS11

10.0 FIRST AID12

11.0 EMERGENCY PROCEDURES12

12.0 PERMIT PROCEDURES14

13.0 SAFETY EDUCATION14

14.0GENERAL SITE RULES15

15.0OCCCUPATIONAL HEALTH18

16.0GRIEVANCE PROCEDURE20

17.0DISCIPLINARY PROCEDURE21

18.0APPENDIX A - QHSE PROCEDURES

1.0VISION, MISSION, CULTURE AND STRATEGY

QHSE VISIONTo establish and maintain a QHSE culture that exceeds customer expectations and requirements by actively involving and empowering all our employees to continuously improve our health, safety and environmental processes and procedures so we will: Proactively respond and react to customer expectations, standards and procedures Proactively adapt to changing laws, regulations and market conditions. Be the leader in QHSE in the oil and gas industry.

QHSE MISSIONOur mission is to ensure that health, safety and environmental considerations are, and always will be, the first priority for our management and employees. Prevention of accidents, incidents and damage to the environment, and the continuous improvement of our standards, are an integral part of our management culture.

QHSE CULTURE

QHSE STRATEGYTo strive for a corporate culture that eliminates incidents, accidents and environmental impact. No accidents No health related incidents. No spills and impact on the environment

EVERY ONE GOES HOME SAFELY

2.0QHSE MANAGEMENT SYSTEM

A QHSE Management System is defined as a series action steps, controls and mechanisms which interact to enable a process to be efficiently carried out, in order to meet HSE expectations

The essential steps for effective management;

Policy Statement to demonstrate commitment from the top of the company for values which involve the entire workforce Organization Structure to develop a health, safety and environmental protection culture throughout a high quality service. Roles and Responsibility to ensure clarity on who is doing what within the organization structure for smooth interaction Clear objectives to identify and set targets that are measurable, achievable and realistic within budgets and resource capability. Measurement to enable our performance to be monitored and progress identified - for continual improvement Review to ensure preventive and corrective actions are maintained with appropriate follow up

3.0Policy statementsPT Prowell-Energy policy statements highlight the accountability of all employees according to clear line management responsibility. These policies are; Health Safety and Environment (HSE) Policy Quality Policy Drug and Alcohol Policy Driving Policy

The statements emphasize the total commitment from the very top to comply with all applicable legislation, to set industry standards and promote continual improvement throughout PT Prowell-Energy. These policies will be reviewed annually by top Management.3.1HSE (Health Safety and Environment) PolicyIt is Prowell Energys policy to conduct its business and operation in a manner that protects the safety and health of the public, employees & contractors, and prevent damage or loss to physical assets. Further, the Company will conduct its business in a manner that is compatible with the balanced environmental and economic needs of the communities in which we operate.

Prowell Energy strives to prevent all accidents, injuries and occupational illnesses through the active participation of every employee, and is committed to continuous-efforts in identifying and managing safety and health risks associated with its activities, as well as to improve environmental performance throughout its operations.

Accordingly, the Company will:

Furnish and maintain its work places free from recognized hazards, which are likely to cause death, injury, and / or illness. Establish an integrated management system, provide training and conduct operations in a manner that safeguards people, the environment and properties. Identify and evaluate safety, health and environmental risks related to its operations and implement programs and appropriate protective measures to control such risks. Respond quickly, effectively and with care to incidents resulting from its operations by co-operating with the clients, community, industry and government. Comply with all applicable laws and regulations, and undertake appropriate reviews and evaluations of its operations to measure progress and to ensure compliance with the policy Stress to all employees and contractors about their responsibility for safe performance on the job and encourage safe behaviour on and off the job. Determine at the time of employment and thereafter as appropriate, the medical fitness of employees to do their work without undue risk to themselves or others. Provide or arrange for reasonable medical coverage necessary for the treatment of employee health occupational illness or injury and for handling medical emergencies. Encourage concern for the environment and emphasise every employees responsibility in environmental performance Communicate with the public and the industry on the Safety , Health, and Environmental matters and share its experiences to facilitate improvement in industry performance.

3.2QUALITY POLICYManagement and Staff Prowell Energy will provide products and services that are useful and safe and, exceed our customer expectations. We are committed to be a socially responsible party by safeguarding our staffs and visitors health and safetyWe are committed to: Achieve our goals by fulfilling our duties with greater effectiveness and efficiency Have a safe and stable operations and observe the Principle of Responsible Care Minimize hazards and risks associated with handling, fabrication and carrying out wireline operations. Continually improve our Health and Safety performance via a framework for setting and periodically reviewing of our occupational Health and Safety targets The prevention of ill-health and death and damage to property Comply with relevant occupational health and safety legislation and regulations and with other requirements to which our organization subscribes Periodically review our QHSE policy to ensure that it remains relevant and appropriate to our organization

3.3DRUG AND ALCOHOL POLICYOperations performed by PT Prowell Energy personnel in the Energy Industry and particularly in the field of hydrocarbon exploration and production are recognized as an integral part of industry safe working practices. Our control measures are designed to ensure that risk is as low as reasonably practicable. PT Prowell Energy understands that the health and operational capacity of its staff are paramount in maintaining a safe working environment for PT Prowell Energy, Clients and third party personnel.Within the spirit of laws, regulations and standards applicable in the geographically diffuse areas of the Company's operations, PT Prowell Energy requires that: Alcohol is prohibited on all PT Prowell Energy premises and Client facilities. All personnel shall be periodically controlled by a recognized medical authority in order to establish their functional aptitude for the post. All personnel shall conform to relevant drug and alcohol policies applicable at the work-site. Any individual under medical treatment shall clearly identify controlled drugs, narcotics or tranquillizers that may have an adverse effect on his capability to maintain an alert, sleep-free work attitude. This with a view to his replacement during treatment, on approval of the relevant competent medical authority, for duties requiring special attention. It is strictly forbidden for PT Prowell Energy personnel to perform work, services or undertake company duties whilst under the influence of alcohol or narcotic substance.

Any infringement to this policy will be considered as a serious offence and can result in a dismissal from the company. PT Prowell Energy reserves the right to inform the relevant authorities of any suspected illegal alcohol and/or drug abuse in premises owned or controlled by the Company.3.4DRIVING POLICYProwell-Energy, a leading oil & gas service company in providing wireline equipment and services is committed to delivering the highest level of competent technical solutions to meet the demands of the clients in the petroleum industry. Health, Safety, Environment and Quality are all integral parts of our management system.As part of their job, our personnel are frequently required to drive in diverse geographic and climatic conditions. All drivers must understand that it is their direct responsibility to safeguard the life of our personnel and of third parties, before and during any trip. Prowell requires that: The drivers (including any contractors providing transportation services) must be authorized, licensed and competent to drive. They must comply with all relevant local legislative, health and insurance prerequisites. They must adhere to local traffic control measures and in particular, all speed restrictions. These should be considered as guidelines, lower limits must be used if abnormal conditions prevail. They must be medically fit and not under the influence of any substance or fatigue which could adversely affect their safe driving capability. Nobody must drive when in an unfit state due to tiredness, stress or a similar condition They must only carry authorized passengers. The driver and all passengers must wear a seatbelt throughout every journey. All loads and luggage must be secured in the appropriate compartment. Journey management - when applicable - must be strictly adhered to. The roadworthiness of the vehicle must be checked by the driver before a journey. When appropriate, in compliance with local laws, they must carry all relevant documentation and essential emergency / communication equipment. (e.g. First Aid Box / Cell, Mobile or Satellite phone, warning triangle, reflective clothing etc.) The use of mobile phones, for calls, messaging or any other purpose, except for use as GPS, is strictly forbidden. Whenever possible, driving during darkness or in restricted visibility must be avoided All vehicle incidents and accidents are fully recorded and reported using our Accident Report Form. Near miss reports provide proactive information The wearing of an approved safety helmet is compulsory for all motorcyclists (rider and passenger)Driving is still the most significant source of accidents in the oil industry. All employees must adhere to procedures and be fully involved with a proactive attitude.This Driving Policy clarifies Prowell Energy firm belief in applying the highest practical standards through common sense and respect for others to protect and preserve life. These requirements simply outline a safe and responsible attitude to driving anywhere in the world. Any employee who openly disregards these driving requirements will be subject to disciplinary action.

4.0QHSE Prowell Energis philosophy is to approach QHSE as a system where continuous monitoring, analyzing and improvement is used to make safety an integral part of every employees daily activities and where not only personal safety is important but they safety, and concern for the environment, of everyone in the work environment becomes an integral part of each and every employee.

A mayor tool to achieve total safety awareness is to investigate, analyze and share the results to avoid similar incidents in the future.

5.0ORGANIZATION

The mission of the organization is to provide efficient, accurate, cost effective wireline engineering, procurement, fabrication, and services, The Prowell-Energy organization structure is flexibly designed to accommodate ever changing opportunities in Indonesia.

While the basic organization is fixed, the operational organizations can be expanded depending upon the nature of captured business opportunities. 6.0ROLES AND RESPONSIBILITIES

6.1DIRECTORS Establish corporate policies that states its intentions and principles in relation to its overall quality, health and safety performance which provides a framework for action and for the setting of its QHSE objectives and targets Responsible for formulating policies Ensure that departmental objectives are established Responsible for the organization business profitability Responsible for formulating appropriate business strategy / plan for each fiscal year to expand the business and improve the turnover Oversee the organization operational processes effectiveness in meeting both customer requirements and applicable statutory and regulatory requirements Ensure the appropriate handling of all customer feedback on the organizations products / services, including timely response to their queries and complaints Responsible to ensure that the relevant permit or; letter of consent or approval is granted by the relevant regulatory bodies e.g. Fire Safety Bureau; Ministry of Manpower (Factory Inspectorate); Building Construction Authority (BCA) - for the facility that has a change of use Responsible to ensure that the relevant regulatory body has issue the relevant permit or; letter of consent or approval on the modification of the building or facility

6.2QHSE MANAGER He is the appointed corporate QHS Management Representative. Nevertheless, he may also be appointed as QHS Management Representative at the divisional / subsidiary level(s), where assigned by the Director He is responsible to ensure that the requirements of the QHS Management System are implemented and maintained. Irrespective of other functional duties, he has the following responsibilities: Custodian of the corporate QHS Management System Manual integrated management system manual - and the implementation of the QHS Management System / integrated management system. Promulgate and implement new procedures as and when necessary to improve the corporate QHS Management System / integrated management system. Plan and schedule Internal Audit of the corporate QHS Management System / integrated management system. Ensure suitability and effectiveness of the corporate QHS Management System / integrated management system. Represent the corporate in QHSE concerns / issues. Report on the performance of the corporate QHS Management System / integrated management system to the management for review on the improvement to the corporate QHS Management System / integrated management system. Ensure compliance with QHS policy and applicable HSE regulations and legislation in the corporate logistic activities and processes Ensure appropriate (corrective / preventive) actions on reported accident; incident or non-conformance Ensure that infrastructure is appropriately maintained at specified interval in compliance with corporate QHS policy and applicable HS regulations and legislation

6.3SAFETY OFFICER Exercise supervision on the observance of the applicable provisions of the Factories Act (Cap 104) in the corporate activities and processes Carry out monthly inspections with assigned corporate HS team to review HSE practices and conditions at the work-site and propose potential improvements in corporate HSE performance Oversee the safe work conditions and practices at the divisional level, fabrication, sub-contractors and client locations. Chair internal safety meetings. Conduct safety briefings for visitors. Liaise with Client safety officers regarding HSE procedures to be followed at client facilities. Assist the QHSE Manager in the implementation of the company QHSE management system, procedures and reporting. Compile monthly QHSE statistics.

6.4DIVISION MANAGERS Report to top management concerning status of projects and associated issues and concerns. Supervise and monitor the required works for each division and ensure that it complies with the customers stated requirements and corporate QHSE Policy and Objectives. Conduct regular HS and Toolbox meetings with staff at the workshop. To ensure the smooth running of the workshop and that all required resources to complete projects are provided for. To conduct regular HS and Operations Inspections to ensure that the workshop and staff are in compliance with corporate QHS Policy and Objectives. Supervise employees to ensure that they comply with established corporate work instructions Supervise and monitor the employees to ensure that they observe HS procedures.

6.5EMPLOYEES Aware of corporate QHS policy and, where applicable, divisional / subsidiary QHS policy and, objectives and targets. Aware of their roles and responsibilities in achieving conformance with: corporate QHS policy where applicable, divisional / subsidiary QHS policy, objectives and targets, applicable HS regulations and legislation, relevant procedures and requirements of QHS management system / integrated management system. Propose improvement to HS performance to corporate QHS committee for review and implementation

6.6SUPPLIERS AND CONTRACTORS Aware of corporate QHS policy and, where applicable, divisional / subsidiary QHS policy and, objectives and targets. Aware of their roles and responsibilities in achieving conformance with: corporate QHS policy where applicable, divisional / subsidiary QHS policy, objectives and targets, applicable HS regulations and legislation, relevant procedures and requirements of QHS management system / integrated management system.

6.7Human Resource Develop training plan for identified training needs by the division and subsidaries Arrange for the training of the nominated personnel / staff Maintain staff training records

7.0 TRAINING PROGRAMSPT. Prowell Energi Indonesia is committed to training as the best means of ensuring its staff and employees are capable of doing their assigned jobs as good as possible and to conduct their activities according to PT. Prowell Energi Indonesias objectives.

It is PT. Prowell Energi Indonesias policy that all supervisors are to be trained in employee management skills and understand the companys commitment to health and safety.

8.0QHSE PROCEDURESSafe working procedures have been established, it is the duty of each and every employee to familiarize themselves with the relevant procedures before carrying out any task.

All employees are encouraged to suggest improvements to the procedures and to report any shortcomings or errors.

9.0 SAFETY INDUCTIONS

9.1 Induction for VisitorsVisitors to all Prowell Energis offices will be given a safety briefing detailing: Emergency evacuation routes. What to do in case of fire and earthquakes Responsible safety officers and floor wardens.Visitors to Prowell Energis workshops and bases will, in addition to the above, be given instructions in: Type of facility and activities carried out. Dangers associated with the activities. Where and where not access is allowed in the facility. The proper use of the, Prowell Energi provided, PPE.

9.2 Induction for new employeesEvery new PT. Prowell Energi Indonesias employee will be given an induction course which shall include: Evacuation routes What to do in case of fire or earthquakes. Safety officers and Wardens and their duties and responsibilities. Prowell Energis QHSE philosophy and objectives. Introduction to Prowell Energis QHSE Procedures.Employees shall be required to attend a refresher course at any time during his/her employment if a persons action indicates that they are not maintaining the policies and objectives of the Prowell Energis QHSE.

10.0 SAFETY COMMITTEEA Safety Committee shall be established to consider items such as: statistics on accident records, ill health, sickness absence; accident investigations and subsequent action; inspections of the workplace by enforcing authorities, management or employee health and safety representatives; risk assessments; health and safety training; emergency procedures; and changes in the workplace affecting the health, safety and welfare of employees. If the health and safety committee is discussing accidents, the aim is to stop them happening again, not to give blame. Committees should: look at the facts in an impartial way consider what precautions might be taken recommend appropriate actions monitor progress with implementing the health and safety interventions.

The Safety Committee is composed as follows: Chief Operating Officer QHSE Manager QHSE Safety Officer Operations Manager Geothermal Manager

Additional and/or alternative members of the commit can be appointed from time to time as conditions requires.11.0 SAFETY MEETINGS

11.1Toolbox MeetingsSupervisors are required each morning to gather personnel together on the worksite to discuss some aspects of safety in a discussion mode for 5 minute toolbox meetings. Subjects can vary considerably, but would include, items such as wearing safety gear, housekeeping, safety procedures or any matter of health and safety nature.

11.2Safety MeetingsSafety Meetings shall be scheduled on a regular basis for the head office, Balikpapan Base, Cepu Base and Workshop, for all personnel assigned to these facilities.

12.0 SELECTION AND CONTROL OF SUBCONTRCTORSProwell Energi Indonesia may elect to audit subcontractors operations prior to acceptance of any tender to satisfy itself of a subcontractors ability to perform as required as per PEI-QHSE-005.

12.1 Information to be ProvidedThe Subcontractor shall, if requested, provide Prowell Energi Indonesia with the following documents and information prior to commencement of the contract.

a) Subcontractor safety Policy Statements and Procedures.b) Details of cumulative safety records for the past five yearsc) Methods used for investigating and reporting accidents and incidents.d) Details of health and safety training to Managers, Supervisors and employees.e) Advise if any person associated with the company has been served an improvement notice or prohibition notice or the subcontractor itself has been served with any infringement or prohibition notices. If so, details shall be provided.f) Allow Prowell Energi Indonesia safety personnel access to plant, equipment, personnel and records to substantiate any noted records.

12.2 Responsibilities of SubcontractorProwell Energi Indonesia and Subcontractor shall define in detail the scope and responsibilities of each party in the administration of health and safety matters.

Responsible PersonThe appointed person must be made readily available to attend any meeting Prowell Energi Indonesia wishes to convene and have sufficient knowledge of health and safety requirements to actively participate in such meetings.

Training Each Subcontractor is responsible to ensure that any persons nominated to work on the Project is adequately trained and experienced to carry out their work safely. All Subcontractor personnel must attend a Prowell Energi Indonesia induction session prior to starting work on the Project.

12.3 Improvement and Prohibition NoticesIn the event of an improvement or prohibition notice or any Government notices being served, Prowell Energy Indonesia must be notified immediately.

13.0SAFETY AUDIT PROCEDURE The Safety Officer(s) are required to conduct regular safety inspections of the Fabrication Shop, Balikpapan Base, Cepu Base and Project Sites consisting of at least a formal audit of the site or project every six (6) months. In addition, the QHSE Manager shall conduct a safety audit once every year or once during the Project execution if the duration is less than one year.

The audit program nominates members of the audit team who shall publish details of their findings for review by Prowell Energi Indonesia Management. The audits are intended to identify any discrepancies or failings in the process or site area audited.

Refer to PEI-QHSE-010 for details.

14.0 JOB SAFETY (HAZARD) ANALYSIS It is Prowell Energi Indonesias policy that Job Safety Analysis (JSA) shall be prepared for proposed job or work processes that have been identified as containing inherent risks prior to commencement of the work activity. Where a JSA has been prepared all personnel concerned with the job shall be made aware of the safety requirements and the steps contained prior to commencing work. This may be done in the form of a Toolbox Meeting o special gathering. Approved JSAs shall be retained by those supervisors associated the the work activity covered by the analysis. The Project Manager shall hold a copy off all JSAs completed on the Project. Prowell Energi Indonesia has, for the purpose of the Project, developed hazard avoidance plans in the form of JSAs outlining the tasks, hazards and control methods of the three greatest considered safety hazards.

Refer to PEI-QHSE-002 for Hazard Identification and Risk Analysis

15.0 ACCIDENTS AND INCIDENTSPT. Prowell Energi Indonesias Safety Procedure PEI-QHSE-002 details the method to be adopted in the event of an accident or incident occurring on the site. a) The initial investigation of any accident or incident will be the responsibility of Powell Energi Indonesias line management including supervisors and foremen.b) The line management must carry out a full investigation of the accident or incident on site and forward the completed report form for close out comments by Senior Management.

For events involving injury to personnel, the Client investigation forms shall be completed and submitted through Prowell Energi Indonesias investigation format before passing into Clients accident review system.

Incidents shall be reported and investigated as per PEI-QHSE-003

16.0 FIRST AID / REHABILITATION

16.1 First Aid / Injury TreatmentFully equipped first aid boxes shall be located onsite for the treatment of minor injuries and for first aid provisions for serious occurrences. The Clients medical center, if any, shall be available for treatment of any serious injuries or sickness.

Refer to PEI-QHSE-012 for First Aid Procedures.

16.2 RehabilitationProwell Energi Indonesia shall ensure that injured personnel are assisted to remain in productive work as part of the rehabilitation initiative.

17.0 EMERGENCY PROCEDURES

17.1 IntroductionProwell Energi Indonesias QHSE Manager is responsible for ensuring emergency response procedures are described for all operations and activities where there is potential for any event which involves risk to personnel or the Project.

Prowell Energi Indonesias QHSE Manager shall ensure the emergency response to any situation to all personnel likely to become involved in a emergency. He shall ensure that personnel designated to are in charge or control any emergency are best suited for the duty and properly trained to perform the duties.

In the event of an emergency within Client facilities, Prowell Energi Indonesia employees and contractors will follow Client emergency response procedures. The Project Manager shall ensure that Prowell Energi Indonesias emergency response procedures are compatible with Client procedures.

Refer to PEI-QHSE-011 for detailed Emergency Response Procedures.

17.2 Nature and Types of EmergenciesAn incident shall be classified as an emergency if it has the potential for affecting the safety, health and welfare of persons on or off the Project site or the environment. These may fall within, but are not limited to, the following categories.

a) Chemical/gas/oil leakages or firesb) Natural disasters such as earthquakes, floods, storms etc.c) Vehicle / transport accidentsd) Aircraft accident.

17.3 Site Management and AuthorityFull authority and management of any Prowell Energi site emergency rests with the QHSE Manager. In absence of the QHSE Manager, his authorized Representative / replacement shall assume this role.

On client locations, facilities and sites the senior Client Representative has full authority and shall manage the emergency. Prowell Energi personnel shall follow any and all instructions from the Senior Client Representative on site.

17.4 Alarms and Communications SignalsWhen a dangerous or potentially dangerous situation has been devised either within or outside the site, Client management shall be notified and if they consider it necessary to inform or warn all persons of the danger, will sound alarm or take other appropriate Acton.

17.5 Muster Points All personnel shall assemble at designated muster points and conform to Client control and communication systems. Client shall nominate and area for mobile fleet to assemble if an emergency occurs. Prowell Energi Indonesias Supervisor will conduct personnel accounting of all his employees and advise Client emergency personnel of any discrepancy. Personnel are to stay at Muster points (or parking locations) until instructed by their Supervisor who will instruct and./or direct the exit from the site if further evacuation action is deemed necessary by Client.

17.6 CommunicationsGeneral communications within the Project area shall be by radio. All equipment shall conform intrinsically safe requirements and be approved for use on the Project by Client.

17.7 Command PostThe Site Manager is the focal point for all subsequent incoming and outgoing information relative to any emergency and for making decisions relative to that information.

17.8 General Action Plans / Procedures

17.8.1 NotificationImmediately upon receipt of a message or advise of an impending or aggravating dangerous situation, the recipient (regardless of who) shall immediately contact the Project manager to inform him of the situation.

Appropriate alarm or warning to Client and within Prowell Energi Indonesia shall be raised at the direction of the QHSE and/or Operations Manager.

Where appropriate, practical and deemed necessary, subcontractors will report to the QHSE Manager for advise and instruction.

17.8.2 EvacuationWhen evacuation of personnel from the site is necessary, subcontractors shall be advised in accordance with Prowell Energi Indonesia and Client Emergency Programs.

17.8.3 Personnel AccountingSupervisors shall check their areas of responsibility and conform their employee numbers to ensure that all personnel have left the site and assembled in the designated area after an emergency or evacuation signal has been given.

17.9 Emergency Procedures for Fire or Serious Personal Injury

17.9.1 FireOn discovery of a fire, Prowell Energi Indonesias personnel shall:a) Advise all persons in the area of the fire hazard and raise the alarm.b) Alert Client fire personnel either by delegation or doing so themselves.c) If possible, without any personnel being exposed to hazard, action must be taken to extinguish the fire immediately by Prowell Energi Indonesia trained employees working in the area using fire extinguishers provided.d) The supervisor should post a person at entrances or roads to direct Client fire fighting personnel or others to the fire.e) Temporary generators and other power to the affected area shall be shut down at the direction of the senior person on site.f) On arrival of Client fire fighting or others, the Site Manager or his representative shall liaise with Client Fire Brigade Commander who will then take charge of the incident.

17.9.2 Accidenta) Inform Prowell Energi Indonesia and Client medical personnel; immediately (whichever is closest). It is important that correct information is given as to exact details of the accident and the location of victims.b) A Prowell Energi Indonesias Site Manager shall post personnel at the entrances or roads lading to the location to direct ambulance and first aid workers to the site.c) Client doctor should then take charge on arrival for the safe treatment and safe patient evaluation.

18.0 PERMIT PROCEDURES

18.1 Personal Danger Tags and Out of Service TagsAll danger tags and isolation tags shall be used in conformation and compliance with Client systems.

18.2 Permit ProcedureAll permits associated with Client plant or equipment shall be authorized by Client designated responsible officer(s). The Prowell Energi Indonesia supervisor named on the permit shall be responsible for conformation to al procedures nominated on the permit by Client.

19.0 SAFETY EDUCATION Throughout the term of the contract, Prowell Energi Indonesia shall display general safety information in the form of safety posters, accident reports and statistical information on notice board to highlight Project safety items. Toolbox talks will emphasize site safety requirements as well as highlight training / education subjects relative to the Project.

20.0 GENERAL SITE RULES

20.1 Plant Materials and Equipment (General)All plant, materials and equipment used on the Project must be of good construction, sound material, adequate strength, free from patent defects, properly maintained, comply with all statutory regulations and be operated by competent persons. All purchases shall be made from reputable companies.

20.2 PlantAll plant and equipment must be safe and fully efficient to use, guarded and equipped with appropriate safety devices wherever required and tested in accordance with Dit. Jen Migas Regulations. Copies of test certificates for any equipment used on site shall be available for inspection with Prowell Energi Indoneisas safety representative.

Cranes and other nominated equipment shall be inspected by Client and approved for use on the Project.

20.3 MaterialsAll material, whether permanent or temporarily, supplied to the Project. Are to be properly used and any manufacturers caution or known hazard relating to the use, handling or storage, made known to all users. Material Safety Data Sheets shall be supplied for all necessary materials held by Prowell Energi Indonesia and its Subcontractors.

20.4 EquipmentAll equipment supplied to the Project must be provided safe to use and every operator properly trained and competent in its use.

20.5 Safety Equipment and Clothing.All persons working on site shall be provided with all necessary safety clothing and equipment including safety helmets, hearing protection, eye protection, footwear, respiratory protection etc.

All personal issue of safety equipment shall be recorded.

In the event of a Subcontractor failing to supply protective equipment as required, Prowell Energi Indonesia may supply from its own stock at the expense of the Subcontractor or may require the person(s) to leave the site until suitable equipment is provided by the Subcontractor.

20.6 Safety Helmets, Footwear and Eye Protection.It is a requirement that suitable and approved safety helmets, safety footwear and eye protection shall be worn at all times by persons working at or visiting the Project. The only exemptions are whilst in site offices, welfare facilities, crib rooms or site toilets and accommodations areas. Suitable signs are to be placed warning persons entering the working area of the safety requirements.

20.7 Site SupervisionProwell Energi Indonesia and Subcontractors shall ensure that a person of suitable seniority and authority is always present on site during the course of contract work to supervise and direct those works and to receive and implement instructions from Client Safety personnel or Authorized representatives.

20.8Permit to WorkWhere Client operates a permit to work system, or has advised it requires a permit to work system to be used, Prowell Energi Indonesia will operate incompliance to that system.

20.9 Overhead / Underground ServicesAny work activity or operations in locations where underground or overhead services exist, adequate steps must be taken to located and identify such services. Relevant precautions must then be taken to prevent injuries or damage to persons and property. Any excavation exceeding fifty (50) centimeters in depth can only be made under the authority of an excavation permit issued under the authority of Client Production Superintendent.

20.10 NoisePT. Prowell Energi Indonesia, and its Subcontractors, shall ensure that the noise levels to which personnel are exposed are reduced as much as practicable.

Noise levels exceeding, or likely toe exceed, 140 Db (LIN) peak or Leq. (8HR) 85 dB (Action Levels), shall be identified and either;a) exposure reduced by controlling the length of time a person is exposed, or;b) hearing protection is issued and worn which reduce the noise exposure to below Leq (8HR) 85 dB (A).

20.11 Explosives or Radioactive MaterialsUnder no circumstances will explosives, explosive devices or sources of ionizing radiation be allowed on site without prior written consent of Client.

20.12 Operation of PlantNo person employed on the Project may operate any item of equipment unless he/she has been adequately trained and is competent in its use and operation.

No person may operate another Companys plant without authorization by its owner and approval of the persons supervisor.

20.13 Explosive Powered ToolsNo person shall be permitted to operate a cartridge operated fixing tool unless he/she has been trained in its use and if required hold a certificate of training or competence.

20.14 Disc Operated Grinding Tools.No persons may operate such tools unless he/she has been properly trained in their use.

20.15 ContaminantsShould any contaminants, or any material beloved to be contaminant, be discovered on site, work on that task and work in the immediate vicinity shall cease and the Project manager must be informed immediately. Appropriate containment and handling procedures will be developed immediately in consultation with Client to control the hazard after proper identification and assessment of exposure levels and risks,

20.16 ElectricalAll electrical equipment brought to site will be tested and maintained on a regular three month basis with a record of all equipment on site in accordance with PT. Prowell Energi Indonesias electrical equipment testing program. All equipment must arrive at Project site carrying current certification.

20.17 Cranes, Rigging, Scaffolding, Aerial Work Platforms

20.17.1 Crane Operation All cranes on the Project under PT. Prowell Energi Indonesia direct or indirect control are to be registered and certified by Dit. Jend. Migas and all crane operators and drives shall hold a current valid certificate to operate that particular model / type of crane. All cranes shall be in compliance with appropriate and applicable Government Statues. Copies of current crane certificates and crane operator certificate of competence are to be produced to the Project Quality Representative and copied to Client under transmittal advice. Any person who slings or directs the movement of loads handled by a crane on the Project is required to hold a certificate of competency as a Dogman or Rigger issued by the Dept. of Manpower.

20.17.2 Rigging The names of all certified Riggers and copies of their certificates of Competency hall be noted by the Quality representative prior to commencing rigging work on the Project. Only persons with a Certificate of Competency as Rigger issued by the appropriate authority shall be permitted to directly supervise rigging work and shall not be caused to supervise ore than 4 (four) trainee riggers at any one time.

20.17.3 Rigging GearAll rigging gear and equipment to be used on the Project shall be of a type approved by the appropriate authority.

A register for all rigging gear shall be kept to record:a) gear on siteb) condition of gear

All rigging gear shall be maintained by a person authorized and appointed by Prowell Energi Indonesia.

20.17.4 Scaffolding All scaffolding and associated component for the Project shall either be property of Prowell Energi Indonesia or hired from a selected reputable scaffolding supply group. All items taken to the Project shall be inspected by the Quality representative or authorized person prior to acceptance for use. An area of the site, agreed to by Client, shall be allocated for the safe storage of scaffolding gear. All scaffolding erection shall be done under the supervision of a person holding a certificate of competence issued by the Dept. of Manpower. All scaffolding equipment shall comply with requirements of Prowell Energi Indonesia and shall only be used in accordance with approved scaffolding procedures. The method of ensuring controlled use of the scaffold on the Project shall be the SCAFFTAG system if no other system specified by Client. The Quality representative shall ensure sufficient tags, holders etc. are available for the Project.

20.18 Fall ProtectionOnly full body harnesses can be worn on the Project. A safety harness must be worn when there is the possibility, however remote, of a person falling from height. Safety lines must be secured to positive anchorage and the wearers possible fall limited to 60 cm (two feet) maximum.

20.19 Tidiness and HousekeepingIt is essential that all personnel shall ensure that their work areas are kept clean and tidy and checked regularly. All waste material shall be removed and disposed of in approved containers immediately or at the end of the work day or shift, whichever comes first. Areas not maintained to a sufficient standard by Subcontractors will be cleaned by Prowell Energi Indonesia at Subcontractors sole cost.

21.0 OCCUPATIONAL HEALTH

21.1 Chemicals

Material Safety Sheets Prowell Energi Indonesia shall ensure that Material Safety Data Sheets (MSDS) are provided by the supplier of all nominated products and any chemicals used during works on the Project. MSDS are to be kept in a central register of chemicals by the Site Manager and a copy of the register(s) shall be located at a agreed point on the Project accessible to all personnel. Any items not supplied with a MSDS shall be informed to the QHSE Manager who will arrange for a copy for the central register.

Personal Protection Equipment All persons handling or coming into contact with chemicals must wear protective equipment which is to be stated on the MSDS. The minimum eye protection for use with flammable liquids, solvents, oxidizing agents and corrosive chemicals shall be chemical safety goggles. The CSO shall ensure adequate supplies of appropriate personal protection equipment shall be available at all times.

Solvents

Solvents shall not be used with atomizing spray equipment.

New ProductsNew chemical products are to be brought on site without the clearance of the Project Manager.

21.2 PaintsWhenever possible, painting activities will be conducted prior to material entering the Project. If this is not possible painting shall be carried out on a Client allocated pad, clear of the main work site.

Whenever it is necessary for painting to be conducted on the worksite the persons in charge of the work shall:a) Notify the Safety officer of the type of paint and the area of use.b) Ensure suitable protective equipment is supplied and used by the painters.c) Ensure adequate ventilation arrangements are made.d) Ensue flameproof lights and fittings are used in the area of painting (if required).e) Provide suitable warning signs and barricades.f) Have available the MSDS for the paint used.g) Store the paint in a proper paint store nominated for the purpose and in compliance with Prowell Energi Indonesias and Client regulations.h) Transfer to the worksite only sufficient paint for one day of operation.i) Ensure weather conditions are suitable for spraying operations/painting activities particularly with regard to preventing overspray.j) Shall work in accordance with Prowell energis General Specifications for Painting.

21.3 VentilationAir operated and electrically operated exhaust / ventilation units shall be available on the Project and shall be used to provide for removal of any fumes, exhaust fumes, paint fumes and any other dust or fumes from work areas.

21.4 Ionizing Radiation and LasersThe Safety officer will coordinate communication between the Project and appropriate Authorities to ensure correct registration of equipment and conformity with usage regulations.

22.0 GRIEVANCE PROCEDUREIt is the intention of this procedure to resolve safety issues whilst whenever possible maintaining productive work. It is emphasized that at all times personnel must accept responsibility for their own safety.a) An employee shall first raise an issue relating to Occupational Health, Safety and Welfare with their Foreman or Supervisor. When an employee encounters what he/she believes to be a safety hazard, the employee shall immediately advise the foreman or Supervisor and that work shall be suspended and not carried out until such time that the matter is resolved, provided the work may continue on conditions agreed to between the parties. The aim should be to resolve the matter as soon as possible.b) Should the safety issue remain unsolved, the Supervisor and the Safety Officer shall meet and inspect the work with a view to resolving the issue.c) Should the issue remain unsolved the parties described in paragraph (b) shall meet with the QHSE Manager and Client Safety personnel to resolve the issue.

Nothing herein diminishes an employees rights to refuse to work in an area where he/she has reasonable grounds to believe that to continue work would expose him/her or any other person to a risk of imminent and serious injury or imminent serious harm to his/her health.

23.0 DISCIPLINARY PROCEDUREA consultative approach to discipline shall be maintained as much as possible. Persons who ignore safety rules or procedures or through a deliberate action, place the health and safety of themselves or others at risk may be subject to disciplinary action including dismissal.

QHSE PROCEDURES INDEX

PEI-QHSE-001QHSE POLICYPEI-QHSE-002HAZARD IDENTIFICATIONPEI-QHSE-003ACCIDENT & INCIDENT REPORTINGPEI-QHSE-004HSE STATISTICSPEI-QHSE-005CONTRACTOR MANAGEMENT

PEI-QHSE-006TRAINING AND COMPETENCE

PEI-QHSE-007QHSE DOCUMENT CONTROL

PEI-QHSE-008HEALTH PROCEDURE

PEI-QHSE-009ENVIRONMENTAL PROCEDURE

PEI-QHSE-010QHSE AUDIT

PEI-QHSE-011EMERGENCY RESPONSE

PEI-QHSE-012FIRST AID PROCEDURE

PEI-QHSE-013PPE

PEI-QHSE-014WIRELINE SAFETY AND H2S

PEI-QHSE-015HSE MEETINGS

PEI-QHSE-016CONFINED SPACES

PEI-QHSE-017CRANES AND RIGGING

PEI-QHSE-018SCAFFOLDING AND LADDERS

PEI-QHSE-019LIFTING AND SLINGING

PEI-QHSE-020LIFTING GEAR DATA

PEI-QHSE-021HAND TOOLS

PEI-QHSE-022FORKLIFT OPERATIONS

PEI-QHSE-023ELECTRICAL SAFETY

PEI-QHSE-024HOUSEKEEPING

PEI-QHSE-025WELDING AND CUTTING

PEI-QHSE-026ABRASSIVE WHEELS

PEI-QHSE-027DRIVING AND JOURNEY MANAGEMENT

PEI-QHSE-028PRESSURE TESTING

PEI-QHSE-029CHEMICAL SAFETY

@ Prowell Energi Indonesia 2015Page 1