WS-9000T HYDRAULIC HITCH OWNER’S MANUAL...8 ws1-006 drawbar plate - top 1 9 ws1-007 drawbar plate...

Transcript of WS-9000T HYDRAULIC HITCH OWNER’S MANUAL...8 ws1-006 drawbar plate - top 1 9 ws1-007 drawbar plate...

REV 1

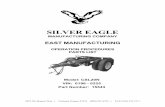

WS-9000T HYDRAULIC HITCH

OWNER’S MANUAL

Page2

REV 1 www.proTrakker.com

Page3

REV 1 www.proTrakker.com

Table of Contents

Specifications ........................................................................4 Contacting the Company ......................................................4

Safety Instructions ................................................................5 Maintenance .........................................................................6 Troubleshooting ....................................................................7

Installation Instructions .........................................................8 Parts Diagram: WS-9000T ASSEMBLY .............................. 17

Parts Diagram: HOSE ASSEMBLIES ................................. 19 Parts Diagram: ANGLE SENSOR ASSEMBLY ................... 21 Parts Diagram: ZERK MOUNT PLATE ............................... 23

Page4

REV 1 www.proTrakker.com

Specifications

Hydraulic Requirements: Single Hydraulic Outlet, Continuous Duty Flow Rate: 1.5 gpm Pressure Range: 2250-3000 psi Electrical Requirements: Maximum Current: 3.5 amps Voltage Range: 9-16 Volts DC Standards and Limitations: Not for use with PTO drive-line powered equipment

Contacting the Company MBW 122 North Des Moines Street Odebolt, Iowa 51458 U.S.A. Toll Free: 877.568.4240 (Monday – Friday, 7:30AM – 5:30PM U.S. CST, Saturday 7:30AM – 12:00PM U.S. CST) Local/International Phone: 1.712.668.4240 Fax: 1.712.668.2311 (24 hours, 7 days/week) Email:[email protected] Website:www.proTrakker.com or www.mbwproducts.com

Page5

REV 1 www.proTrakker.com

Safety Instructions

Read and understand the information in this manual before installing or operating this system.

Installation of this equipment requires jacks and hoists that can safely lift and hold the components. Do not attempt to install the equipment without properly rated and operating tools.

Inspect this system for damage and/or wear before every operation. Replace any damaged or worn components before using.

Never work alone. Never operate this system with guarding removed. When preparing to install or maintain this system, the

tractor wheels need to be blocked to prevent movement and any jacks or lifts used should be appropriate for the weight to be lifted, stable and in good condition.

Hydraulic lines should be inspected for wear and cracks. Any indication of damage to these lines should be immediate grounds for replacement of the line.

Caution should be taken when working on hydraulic systems. Ensure all pressure in the system is relieved properly and that the fluid is cool before loosening any fittings or removing lines.

Use appropriate personal protective equipment (PPE) when performing maintenance on hydraulic systems, such as safety glasses with approved side shields, heavy leather work gloves, and coveralls or an apron.

Page6

REV 1 www.proTrakker.com

Maintenance

Initial Installation: After the first few hours of operations, check the tightness of all hardware. Substantial wear will occur to the product and implement if fasteners and hardware are not properly secured. Grease Fittings:Proper lubrication of the 4 grease spots will dramatically prolong the life of the product. The grease spots are located on each of the rod ends of the cylinders and on each of the butt ends of the cylinders fed by a grease line which is mounted at a convenient location. Bolts: Periodic tightening of the bolts is important. If the M20 bolts become loose for any reason, they must be tightened to 450 ft-lbs. If the 1" x 4" set screws should be tightened to 680 ft-lbs. Note:Optional adjustable restrictor is available for dampening, if you desire to use the WS9000T in manual/float mode.

Page7

REV 1 www.proTrakker.com

Troubleshooting (ProTrakker Controlled)

Problem: The hydraulic hitch does not move

The tractor hydraulics are not active.

Make sure the hydraulic hoses are hooked up correctly (line labeled pressure; the other line return).

Poor electrical connection.

Check Indictor lights on the hydraulic block coil connectors. If no light, check cable connections. If lights show, then replace the coil.

Error codes. 1 – CONTROLLER 2 – HUB 3 – POSITION 4 – VALVE 5 – TILT

An error code is a number flashing in the gain window and lights traveling continuously across the light bar. The number flashing tells us where the error is. An error code could be a component failure or a simple connection issue. Be sure to check all connections before replacing components.

Problem: The hydraulic hitch moves the wrong direction

The tractor hydraulics are reversed

Make sure the hydraulic hoses are hooked up correctly (line labeled pressure; the other line return).

Problem: The hydraulic hitch seems very “jerky” and seems to “hunt” when the tractor is at a standstill

The hydraulic flow is too fast

Turn the oil flow way down. The slower the hitch moves, the better it will perform. If you tractor hydraulics will not turn down far enough, ProTrakker offers a needle valve to put inline.

Too much 3-point movement

Tighten up drawbar and/or 3-point slap. When the hitch stops it will sense any looseness or slop and a chain reaction will occur.

Page8

REV 1 www.proTrakker.com

Installation Instructions

Tractor Preparation

Before installing the WS-9000T, park the tractor on a smooth level floor with adequate clearance to work around the drawbar area. Installation of the system requires access under the tractor and removal and re-installation of the tractor drawbar.

Remove the Hitch Stop Plates

Remove the two side stop plates from the rear hitch.

Remove the Front Drawbar Pin

Remove the two bolts that hold the front drawbar pin. The pin is positioned under the tractor near the center.

Side Stop Plates

Drawbar Pin Bolts

Drawbar Pin

Page9

REV 1 www.proTrakker.com

Remove the Drawbar

Use a floor jack under the drawbar to allow it to slide out the rear of the tractor. Place blocks or jacks under the drawbar to safely support the drawbar during the rest of the installation.

Install Sensor/Valve Assembly

Install the sensor/valve assembly using the two 5/16 hex head bolts provided.

Valve/Sensor Assembly

Page10

REV 1 www.proTrakker.com

Install Bolts Through Frame & Cylinders

Mount the cylinders to the main frame using the two 1 ¼ hex head bolts and nuts provided.

Install Hydraulic Hitch

Use floor jacks to position the hydraulic hitch under the tractor. Route the hydraulic lines around the outside of the frame clamps. Line up the 4 holes in the tractor chassis. Install the 4 M20 bolts and tighten.

Frame Clamps

Hydraulic Cylinders

M20 Bolts

1 ¼ Bolts

Page11

REV 1 www.proTrakker.com

Tighten Frame Clamp Set Screws

Tighten the 4 set screws to the tractor frame using a 9/16" hex socket. Once set screws are torqued, tighten set nuts.

Reinstall the Tractor Drawbar

Use a jack or hoist to slide the drawbar back into the tractor. The drawbar should slide through the hydraulic hitch frame. Reinstall the front drawbar pin and bolts.

Mount the Sensor Arm Bracket

Mount the angle sensor bracket to the top of the drawbar. Be sure the sensor bracket stud is attached to the angle sensor link. Flat washers may or may not be used depending on drawbar thickness.

Set Screws

Set Nuts

Sensor Arm Bracket

Angle Sensor Link

Page12

REV 1 www.proTrakker.com

Mount the Drawbar Plates

The drawbar plates are mounted to the top and bottom of the drawbar 35” from the frame plates as shown.

35

Page13

REV 1 www.proTrakker.com

The top bracket has tabs that hold the bolt’s wrench flats. A 5/16 spacer is provided (top and bottom) if your drawbar thickness does not allow the cylinder ends to clear the plates.

Bottom Bracket

Top Bracket with Tabs

¾ Bolts

1-1/4 Bolts

Spacer

Page14

REV 1 www.proTrakker.com

Attach Front Drawbar Bracket to the Cylinders

Install the rod end of the cylinder using the 1-1/4"x 6"

bolts provided and tighten. The top plate has a welded tab to match the wrench flats of the bolt. You may need to install the stop plates that came with the tractor. This will allow you to ‘nudge’ the cylinder positions without moving the drawbar to align the cylinder rod-end holes.

WARNING

STAY CLEAR OF ALL MOVING PARTS WHEN OPERATING THE HYDRAULICS

WARNING BE SURE THE RETORQUE ALL FRAME BOLTS AND SET SCREWS PERIODICALLY

Page15

REV 1 www.proTrakker.com

Route hydraulic hoses and Grease Lines

Route the hydraulic hoses and grease lines along the inside of the right side tractor frame along with the tractor’s harnesses and hydraulic lines.

Page16

REV 1 www.proTrakker.com

Attach Grease Lines

Install the grease zerk bracket and attach the grease lines as shown.

Secure all lines with zip ties and inspect to be sure the lines do not contact any moving components through the entire stroke of the hitch.

Page17

REV 1 www.proTrakker.com

Parts Diagram: WS-9000T ASSEMBLY

Page18

REV 1 www.proTrakker.com

ITEM PART # DESCRIPTION QTY

1 BLT1-1_4X6 BOLT 1-1/4X6 4

2 BLT3_4X6 BOLT 3/4X6 10

3 BLTM20X18 BOLT M20X18X2.5 4

4 N5 1IN JAM NUT 4

5 N8 3/4 FLANGE HEX LOCKNUT 10

6 RHN021 LOCKNUT 1 1/4 4

7 SET129129 SET SCREW 1IN X 4IN 4

8 WS1-006 DRAWBAR PLATE - TOP 1

9 WS1-007 DRAWBAR PLATE BOTTOM 1

10 WS1-117 WIDE SWING SPACER 1

11 WS1-CYLINDER WIDE SWING CYLINDER 2

12 WS1-FRAME WIDE SWING FRAME WELDMENT 1

13 WS4 3/4 NR G8 WASHER 24

Page19

REV 1 www.proTrakker.com

Parts Diagram: HOSE ASSEMBLIES

Page20

REV 1 www.proTrakker.com

Page21

REV 1 www.proTrakker.com

Parts Diagram: ANGLE SENSOR ASSEMBLY

Page22

REV 1 www.proTrakker.com

ITEM PART # DESCRIPTION QTY

1 BEIDS_WS POSITION SENSOR 1

2 FT1 9/16 ORB T-FITTING 2

3 FT2 9/16 ORB 90 DEG ELBOW FITTING 2

4 HEXBOLT-3_8-16X3_75 HEX BOLT 3/8-16 X 3 3/4 4

5 HEXBOLT-5_16-18X1_25 HEX BOLT 5/16 X 1 1/4 2

6 HEXNUT-3_8-16 HEX NUT 3/8-16 4

7A HV1 BLACK & WHITE VALVE (ProTrakker Controlled) 1

7B HV2 PROPORTIONAL VALVE (Trimble Ready) 1

8 HV3 ALUMINUM MANIFOLD 1

9 PSN1 POSITION SENSOR CABLE 1

10 WS1-113 SENSOR BRACKET 1

11 WS1-114 SENSOR SWING BRACKET 1

12 WS1-114W WIDE SWING DRAWBER SENSOR BRACKET 1

13 3/8” WASHER 16

Page23

REV 1 www.proTrakker.com

Parts Diagram: ZERK MOUNT PLATE

ITEM PART # DESCRIPTION QTY

1 FT1 ZERK HOSE ADAPTER 2

2 WS1-110 ZERK BRACKET 1

3 ZERK-025 ZERK 1/4-28 STRAIGHT GREASE

2