Wheel Dozer 844

-

Upload

christian-kari -

Category

Documents

-

view

223 -

download

0

Transcript of Wheel Dozer 844

-

8/13/2019 Wheel Dozer 844

1/20

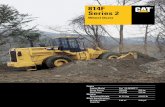

844Wheel Dozer

Blade Capacities 15.9 to 30.7 m3 20.7 to 40.2

Operating Weight 69 227 kg 152,619

Cat 3412E HEUI Engine

Gross Power 503 kW 675

Flywheel Power 466 kW 625

-

8/13/2019 Wheel Dozer 844

2/202

844 Wheel DozerStrong power train combined with a heavy-duty front frame provides long life and

economical operation.

EngineThe Caterpillar 3412E Hydraulic

Electronic Unit Injection (HEUI) engine

delivers power and efficiency in the

most demanding applications. Engine

performance and decreased fuelconsumption are achieved through the

HEUI fuel system. pg. 4

Power Train

The Caterpillar planetary power shift

transmission and Impeller Clutch

Torque Converter with lockup clutch

provide smooth, consistent shifting with

rimpull control and direct driveefficiency. pg. 4-5

Structures

The 844 features a box-section rear

frame and four-plate front frame

providing strength and stability.

Together they provide resistance to

dozing shocks and stresses whileabsorbing shock loads and twisting

forces. pg. 6

Engineered for demanding work in largedozing applications. The 844 Wheel Dozerjoins the Caterpillar wheel dozer line-up

as an ideal match for power generating

utilities, smaller scale mines and thegeneral contracting industry.

-

8/13/2019 Wheel Dozer 844

3/20

Blades and Blade Control

Choose between 21 and 40 yd3 sem

heavy-duty semi-U and coal blades

Replaceable bolt-on cutting edges a

bottom wear plates help extend blad

life. A single lever is used tohydraulically control all blade

operations. pg. 10-11

Hydraulics

Two, independent hydraulic systems

and load-sensing steering are the

invisible force behind the mobility and

versatility of the 844.

pg. 7

Operator Station

Experience a high level of efficiency

and comfort with one-hand operation

provided by the STIC controller and a

state-of-the-art cab. Operator

productivity is also increased withimproved range of viewing, reduced

sound levels, improved ventilation and

easy entry and exit.

pg. 8-9

ServiceabilityLarge engine doors, rear access stai

and convenient service platform wi

large doors enhance the serviceabil

of the 844. pg. 12

-

8/13/2019 Wheel Dozer 844

4/204

Power Train844 power train components deliver dependable, reliable performance customers expect

from Cat wheel dozers.

The Caterpillar 3412E HydraulicElectronic Unit Injection engine is ratedat 466 kW Net (625 hp) at 2000 rpm.

HEUI fuel system and Electronic

Control Module (ECM) deliver power

and efficiency in the most demanding

applications. Electronic control

provides many benefits:

Automatic altitude deration

Elevated low idle

Cold weather starting mode

Acceleration delay on startup to

reduce engine wear

Advanced diagnostic capabilities

Automatic control of ether aid

Complete control of injection timingwithout concern for cam profile

limitations. Complete control of

engine speed provides advantages in

lower emissions, quieter operation,

reduced smoke, improved hot or cold

starting, white smoke cleanup and

high altitude operation.

Complete control of injectionduration. The HEUI system willdecrease proportionately with engine

speed but can also electronically

control the oil supply pressure. This

provides improved engine

performance and decreased fuel

consumption.

Injection rate shaping reduces nitrousoxide (NOx) emissions and reduces

engine combustion noise.

1 Aftercooler lowers inlet chargetemperature. Reduces thermal stresses

that can cause premature wear of

pistons, rings and liners.

2 High injection pressures,

independent of engine speed,decrease smoke and emissions while

improving response.

3 Oil-cooled pistons and full-length,water-cooled cylinder liners providemaximum heat transfer for longer

component life.

4 Engine oil cooler maintains optimumoil temperature for proper cooling

and lubrication.

Engine cooling provided by Multi-

Row Modular radiator. Hydrostatic

fan drive gives the standard coolingpackage 110F ambient capability.

4

3

2

1

-

8/13/2019 Wheel Dozer 844

5/20

3 533 mm (21") planetary, electronic,power shift transmission. This is thesame transmission found in the 990

Series II wheel loader. Electronic

shifting provides smooth consistent

shifts with finger tip controls housed

in the STIC controller. The

transmission is built around a center

shaft with a gear set cluster stacked

end-to-end to distribute load,

conserve space and transfer energy

efficiently. Large diameter perimeter

clutches coupled with high contactplanetary gear sets provide high

torque carrying capacity for long,

trouble-free life.

Axle-shaft, oil-disc brakes are fullyhydraulic, completely sealed and ne

need adjustment. Disc face grooves

provide cooling even when brakes a

applied for a long, fade resistant life

This design provides larger cooli

oil reservoir and thicker separato

plates than conventional brake

designs. This gives the brake high

heat dissipation rates giving it hig

capacity than conventional oil-di

brakes.

The location of the brake reduces

service time. Conventional brake

require final drive disassembly. T

axle-shaft brake design allows br

service while leaving the final dri

intact. Reduced service time and

machine downtime keeps operati

costs low.

Bevel gear sets and differentials a

common with the 990 Series II w

loader.

Impeller Clutch Torque Converter

allows the operator to modulate rimpull

from 100 percent to 20 percent of

maximum rimpull. After 20 percent of

maximum rimpull is achieved, further

pedal travel applies the brake. The

torque converter is equipped with a

lockup clutch for direct drive efficiency.

1 Impeller clutch. Locked in fullyengaged position for maximum

engine power transfer.

2 Lockup clutch. Provides direct driveefficiency in all three gears with

higher speeds and improved fuel

economy on long distance dozing.

2 1 3

-

8/13/2019 Wheel Dozer 844

6/206

StructuresAdvanced design and materials provide superior strength.

Structures on the 844 are more than 90percent robotically welded. Thisprovides highly consistent welds with

deep plate penetration and excellent

plate fusion. The benefit is greater

fatigue strength and longer life than

with conventional welding methods.

Castings in the engine end-frame areused in critical high-stress areas to help

spread the load and reduce the number

of parts. The casting for the rear

trunnion mount also serves as an enginemount, which provides a load path for

the weight and torque of the engine to

travel down to the trunnion and then on

through to the axle. Other castings used

in the engine-end frame include: front

trunnion mounts, steering cylinder

brackets, articulation stops and lock

link.

1 Box-section rear frame absorbs shockloads and torsional forces, solidly

maintaining alignment for hitch pins

and driveline.

2 Four-plate front frame providesmaximum structural strength to resist

twisting loads during dozing

applications.

3 Upper and lower hitch pins pivot ondouble-tapered roller bearings and are

shaped to direct stress away from theend of the weld, resulting in a

smoother transition of stress loads.

4 Spread-hitch design helps square upthe frame and provides more

clearance for hydraulic lines. Double

tapered roller bearings and hardened

pins resist both horizontal and

vertical loads to increase life. The

spread hitch also makes service

access easier.

Engine and transmission mounts aredesigned to use mushroom and cup-

shaped ISO mounts, reducing

component vibration and sound levels.

The engine mounts directly to the rear

cross member, simplifying and

improving load transfer structure.

1

2

3

4

-

8/13/2019 Wheel Dozer 844

7/20

1 Two separate, hydraulic systems.One system is for implements and

brakes while the other is for steering

and hydraulically-driven engine

cooling fan. The benefits of the

separate hydraulic systems are

increased cooling and elimination of

cross-contamination. If one system

runs hot or is contaminated, the otherwill be unaffected.

2 Blade control. Armrest-mountedcontrol lever sends signals to a pilot

valve for tilt/tip control and to a main

valve for lift control.

Tandem vane pumps providehydraulic flow for the lift, tilt and tip

functions. The circuit is well balanced

to provide control when all functions

are used simultaneously.

Well-proven pumps, valves and

cylinders are common with thoseused on large, Caterpillar track-type

tractors.

For improved serviceability, allhydraulic pumps are mounted on a

single pump drive.

3 Load Sensing Steering with STICControl System is a revolutionary

system that integrates steering and

transmission into a single controller.

The variable displacement pump

maximizes machine performance by

directing power through the steering

system only when needed. More

efficient use of power results indecreased fuel consumption and

higher production.

Simple side-to-side motions of the

operators left arm turn the machine

right or left.

Transmission shifting forward,

neutral, or reverse is controlled by the

operators fingers, and gear selection

is controlled by the operators thumb.

Caterpillars XT-3 and XT-5 hose, O-ringface seals and large-bore lift and tilt

cylinders top off the hydraulic system,delivering the performance and

durability owners expect. Reliable

components reduce leaks and help

protect the environment.

Hydrostatic cooling fan is used forengine, transmission and hydraulic

cooling. A variable displacement pu

drives the fans hydraulic motor so

fan speed varies with rpm. The fan

draws only the power needed for

cooling, reducing fuel consumption

increasing efficiency.

1

3

2

HydraulicsWell-balanced hydraulics deliver precise low-effort control and trouble-free operation.

2

-

8/13/2019 Wheel Dozer 844

8/208

6

2

3

1

Operator StationComfort and control top quality operator station will help maximize productivity.

-

8/13/2019 Wheel Dozer 844

9/20

Spacious cab design, incorporatinginnovations for operator comfort and

productivity, include excellent viewing

area, interior sound levels below 75

dB(A), Caterpillar Contour Series seat,

standard coat hook, cup holder, storage

bin, sun visor, intermittent wet-arm

wipers, and is radio-ready for two-way

radios.

1 STIC Control System is arevolutionary system that integrates

steering and transmission into a

single controller. Simple side-to-side

motions of the operators left arm

turn the machine right or left.

Transmission shifting forward,

neutral or reverse is controlled by the

operators fingers, and gear selection

is controlled by the operatorsthumb. These factors combine to

produce a fluid motion that reduces

effort and allows the operator to

work the machine for long periods of

time with little or no fatigue.

2 Left foot pedal operates ImpellerClutch Torque Converter for about

the first inch of travel, then engages

the brakes. Within the first inch of

pedal travel, rimpull can be

controlled from 100 percent to 20

percent.

3 Contour Series seat with airsuspension and retractable seat belt

is designed for comfort and support.

Seat cushions reduce pressure on the

lower back and thighs while

allowing unrestricted arm and leg

movement. The seat has three height

levels. The retractable seat belt

remains off the floor and is easy for

the operator to reach.

4 Quick-shift feature allows quickercycle times by shifting from 1st

forward to 2nd reverse.

5 Throttle lock allows operator topreset the engine speed and

concentrate on productivity. The

throttle lock can be deactivated

pressing the brake pedal.

6 Computerized Monitoring Syste(CMS) uses a vacuum fluorescendisplay allowing gauges to be ea

read in direct sunlight or at nigh

The three category operator aler

system is retained as part of the

CMS. In addition, the system

provides four diagnostic modes,

resulting in easy system

troubleshooting and minimum

downtime.

7 Seat-mounted hydraulic bladecontrols are attached to the righ

side of the seat. They are adjustafore and aft, with a height-adjus

armrest so that operators of any

can find a comfortable operating

position. Single lever control all

operator to control blade functio

lift/lower, tip and tilt. Switch co

on top of control lever allows op

of single or dual-tilt operation.

8 Torque converter lockup clutch

activated when operator presses

switch on the console. The 844

automatically shifts from torqueconverter drive to direct drive w

a set speed in each gear is reach

providing faster travel speeds an

less fuel consumption.

Large, viewing area enhances viewin all directions. Bonded glass in th

front window eliminates distracting

metal frames with the best operator

visibility to the blade.

5

4

8

-

8/13/2019 Wheel Dozer 844

10/2010

Heavy-duty blade linkage is commonwith a Caterpillar D9 Track-Type

Tractor. These well-proven components

are designed for tough applications.

Lift cylinders raise and lower bladefor efficient dozing action.

Two position tilt cylinder mounting

for increased flexibility for various

applications.

Cutting edges are DH-2 steel. Endbits are DH-3 to provide maximum

service life in tough materials.

Trunnions, pusharms and tag link aresized for large dozing loads.

Single-lever blade control hydraulicallyoperates blade raise, lower, tilt and tip.

Lift circuit features:

Four positions: raise, hold, lower and

float

Detente hold on float

Tilt/tip circuit features:

Operator selected single or dual-tilt

Finger tip control for tip operation

Low-effort control:

Single-lever implement control

Seat mounted controls

Pilot operated tilt/tip for lower levereffort

Operator has the option of either singleor dual-tilt operation by using a switchlocated on top of control lever. A

generous range of tilt motion enables

excellent control for dozing.

Blade ControlWell-proven Cat components deliver dependable service and ease of operation.

-

8/13/2019 Wheel Dozer 844

11/20

Resilient and durable Caterpillar bl

are designed with excellent dozing

rolling characteristics.

Capacities and widths are set to

achieve increased productivity.

Special design allows for spreadi

of cover material as well as dozin

heavier loads.

High-strength, pressed rib

construction.

Large, Caterpillar track-type tract

bolt-on cutting edges and bottom

wear plates.

Fitted with Caterpillar standard

hardware and Ground Engaging

Tools (G.E.T.).

Rebuildable for long blade life.

1 Coal blade is designed for preciseproductive dozing while helping

retain load control with increased

capacity for lighter materials.

Wing angles help retain the lo

while dozing.

2 Semi-U blade combines thecharacteristics of the S and U bla

into one package.

Increased capacity with the

addition of short wings, whichinclude only the dozer end bit

without sacrificing spreading

characteristics of straight blad

The heavy-duty semi-U blade has thsame configuration as the semi-U b

but it is built with thicker plates for

more severe applications.

BladesCaterpillar blades are built to handle tough applications.

1

2

-

8/13/2019 Wheel Dozer 844

12/2012

Easy maintenance. In addition to theservicing features built into the engine,

the 844 includes:

Rear access stairs for easy,

comfortable access for operators and

service personnel.

Large engine access doors provide

excellent access to service points,

engine oil dipstick, diagnostic

connector, engine oil and fuel filters,

starting receptacle, air filter indicator,

air filters, fuel/water separator and the

ether starting aid cartridge.

Large service platform provides

passage to hydraulic filter, fuel fill

and transmission filters through easy-

to-open doors.

Large door provides entrance to

transmission and pumps when service

is required.

Large door in platform provides

access to fuses and electronic control

modules.

Batteries are accessible through

hinged doors in bumper.

Side access doors on the radiator

guard provide easy access for radiator

cleanout.

Grouped and labeled lube points,

accessible at ground level, make dailylube maintenance quick and easy.

Sight gauges in the hydraulic tanks

and radiator provide quick check for

fluid levels.

ServiceabilityLess time spent on maintenance means more time on the job.

-

8/13/2019 Wheel Dozer 844

13/20

Cat Dealers offer a wide range of

services that can be set up under a

customer support agreement when

purchasing equipment. The dealer will

help customers choose a plan that can

cover everything from machine and

attachment selection to replacement, tohelp get the best return on the machine

investment.

Selection. Make detailed comparisonsof the machines under consideration

before buying. How long do

components last? What is the cost of

preventive maintenance? What is the

true cost of lost production? Cat Dealers

can give precise answers to these

questions.

Operation. Improving operatingtechniques can boost ones profits.

Cat Dealers have training videotapes,

literature and other ideas to help

increase productivity.

Maintenance. More and moreequipment buyers are planning for

effective maintenance before buying

equipment. Choose from the dealers

wide range of maintenance services at

the time of purchase. Repair option

programs guarantee the cost of repairs

up front. Diagnostic programs such as

SOS oil analysis and Technical

Analysis help avoid unscheduled

repairs.

Product support. Nearly all parts aravailable at the Cat Dealer parts

counter. Cat Dealers utilize a world

computer network to find in-stock p

to minimize machine downtime. Sa

money with remanufactured parts a

receive the same warranty andreliability as new products at cost

savings of 40 to 70 percent.

Replacement. Repair, rebuild orreplace? Cat Dealers can help evalu

the cost involved so the right choice

made.

Complete Customer SupportCat Dealer services help keep machines operating longer with lower costs.

-

8/13/2019 Wheel Dozer 844

14/2014 844 Wheel Dozer specifications

EngineFour-stroke cycle, twelve cylinder, turbocharged, aftercooled 3412E diesel engine.

Ratings at 2000 rpm* kW hp

Gross power 503 675

Net power 466 625

The following ratings apply at 2000 rpm

when tested under the specific standard

conditions for the specified standard:

Net Power kW hp PS

Caterpillar 466 625

EEC 80/1269 466 625

ISO 9249 466 625

SAE J1349

(JAN90) 461 618

DIN 70020 648

Dimensions

Bore 130 mm 5.4 in

Stroke 152 mm 6.0 in

Displacement 27 liters 1649 in3

Features high pressure injectors full electronic control parallel manifold porting with two

intake and two exhaust valves per

cylinder. Stellite-faced valves, hard

alloy steel seats and valve rotators cam-ground and tapered, aluminum-

alloy pistons with three keystone

designed rings, each cooled by oil

spray steel-backed, copper-bonded,

aluminum bearings, through-hardened

crankshaft journals pressure lubricated with full-flow

filtered and cooled oil dry-type air cleaner with primary and

secondary elements direct-electric 24-volt starting system,

75-amp alternator and two, 12-volt

190-amp-hour batteries engine/torque divider module is

isolation mounted to the main frame

reducing machine vibration and

structure-radiated noise water cooled turbocharged bearing for

longer life

Transmission21" planetary power shift transmission

with three speeds forward and reverse.

Maximum speeds, forward and reverse,with 45/65 R39 XLD D1A - Type A (L4)tires:

km/h mph

Forward 1 7.2 4.5

2 12.9 8.0

3 22.5 14.0

Reverse 1 8.2 5.0

2 14.2 8.8

3 25.0 15.5

Features electronic shift control self diagnostics accessible through

Computerized Monitoring System quick-shift feature controls for electric shift transmission

are housed in STIC controller Impeller Clutch Torque Converter is

standard with lockup in all three gears

Power rating conditions based on standard air conditions of

25C (77F) and 99 kPa (29.32 in Hg)

dry barometer used 35 API gravity fuel having an

LHV of 42 780 kJ/kg (18,390 Btu/lb)

when used at 30C (86F) [ref. a fuel

density of 838.9 g/L (7.001 lb/gal)] net power advertised is the power

available at the flywheel when the

engine is equipped with fan, air

cleaner, muffler and alternator no derating required up to 2286 m

(7,500 ft) altitude

35

40

45

50

55

60

30

25

20

15

10

5

0

100

110

120

130

140

70

80

90

60

50

40

30

20

10

0

lbs x1000

kg x1000

0

GRADEABILITY-P

ERCENT

(Grade+

RollingResist)

3rd Gear

1st Gear

1st Gear

2nd Gear

3rd Gear

2nd Gear

844Rimpull

vs.Ground Speed

30

25

40

35

45

20

15

10

5

0 4 8 12 16 20 24 km/h

0 2 4 6 8 10 12 14 16 mph

Speed

Rimpull

Torque Converter Direct Drive

-

8/13/2019 Wheel Dozer 844

15/20844 Wheel Dozer specifications

CabIntegrated Rollover Protective Structure

(ROPS) is standard.

Features

meets OSHA and MSHA limits for

operator sound exposure with doors

and windows closed (according to

ANSI/SAE J1166 MAY90) ROPS meets the following criteria:

- SAE J394- SAE 1040 APR88

- ISO 3471-1986 also meets the following criteria for

Falling Objects Protective Structure

(FOPS):

- SAE J231 JAN81

- ISO 3449-1984 ROPS structure is certified for

84 286 kg (185,650 lb) operating

weight standard machine meets CE 89/392

safety directive, and CE 86/662

spectator (ISO 6393) and operator(ISO 6394) sound requirements

NOTE: When properly installed andmaintained, the cab (tested with doors andwindows closed according to ANSI/SAEJ1166 MAY90) meets OSHA and MSHArequirements for operator sound exposurelimits in effect at time of manufacture. Theoperator sound pressure level is 75 dB(A)when measured per ISO 6394 or86/662/EEC.

Final DrivesPlanetary final drive consists of a ring

gear, 3 planet gears and planet gear

carrier, and a sun gear.

Features ring gears splined to axle housing proprietary gear cutting and heat treat

methods used in the manufacture of

components full-floating bronze sleeve bearings

used on planet gears oil-bath lubrication of final drive

AxlesFixed front, oscillating rear (11).

Features maximum single-wheel rise and fall

572 mm (22.5") bevel gear set and differentials Duo-Cone seal between axle hub and

housing axle shaft brakes use SAE 30 or 40W (depending on

temperature) (oil change interval

every 2000 hours or 1 year)

BrakesSystem meets SAE/ISO regulations

Service brake features fully hydraulic, completely enclos

and sealed, oil-disc brakes adjustment free separate circuits for front and rear

axles high capacity axle-shaft design easy access for service dual pedal braking

Parking brake features multiple-disc, oil-enclosed brake located on transfer gear case outp

shaft

Secondary brake features Computerized Monitoring System

alerts operator if pressure drops b

875 psi (6035 kPa) and automatic

applies parking brake manual override possible to allow

movement of machine

TiresTubeless, low-aspect ratio. All steel

radial construction for increased trac

and stability, lower rolling resistanc

Tire choices

45/65 R39 L-4 (XLDDIA), Miche 40.5/75 R39 1-Star, Goodyear

NOTE: Caterpillar recommends that yoconsult a tire supplier to evaluate allconditions before selecting a tire modOther special tires are available on req

Monitoring SystemComputerized Monitoring System uses

technology to make a dramatic

difference in operator efficiency,

machine productivity and availability.

Features

gauges display engine coolant

temperature, transmission oil

temperature, engine oil pressure,

hydraulic oil temperature and fueltank level

tachometer/speedometer displays

engine speed and gear indicator alert indicators include: charging

system, parking/secondary brake,

supplemental steering, brake oil

pressure, engine coolant flow and

transmission filter status

-

8/13/2019 Wheel Dozer 844

16/2016 844 Wheel Dozer specifications

Implement system with double-section vane pump

Output at 2126 rpm and 6894 kPa (1000 psi)

with SAE (No 10 oil at 66C 150F) 342 L/min 89 gpm

Cylinders, double-acting:

lift, bore and stroke 133.5 mm x 1535 mm 5.25" x 60.5"

Cylinder, double-acting:

tilt and tip, bore and stroke 209.5 mm x 188 mm 8.25" x 7.5"Relief valve setting

Bulldozer (large pump) 18 650 kPa 2700 psi

Tilt cylinders (small pump) 20 150 kPa 2920 psi

Implement Hydraulic SystemCompletely sealed system with innovative low-effort controls.

Features (standard) completely enclosed system two independent systems. One for

steering and hydraulically-driven

engine cooling fan, one for

implements and brakes Cat built main implement pumps Caterpillars XT-3, XT-5 hose used

on entire machine except pilot lines in

cab full-flow filtering reusable couplings with O-ring face

seals

Service Refill CapacitiesU.S.

L Gallons

Fuel tankstandard 930 245

Cooling system 183 47.5

Crankcase 50 13

Transmission 70 18

Hydraulic tank 541 141

Differentials and final drives

Front 218 56.5

Rear 218 56.5

Hydraulic system

Implement and brakes

Tank only 174 45

Steering and engine cooling fanTank only 129 33.5

Min. turning radius

(over tires) 9910 mm 32' 6"

Hydraulic output at 2128 rpm

and 1000 psi (6900 kPa)

410 L/min 108 gpm

Relief valve setting

31 005 kPa 4500 psi

Features STIC control steering system center-point frame articulation front and rear wheels track hydraulic power with efficient, load-

sensing system variable displacement piston pump steering angle of 35 in each direction,

one-hand operation full flow filtering

SteeringFull hydraulic load sensing steering system meets SAE J1511 FEB94 and ISO 5010:

1992 specified standards.

-

8/13/2019 Wheel Dozer 844

17/20844 Wheel Dozer specifications

844

ROPS5142 mm

(16' 9")

4600 mm(15' 1")

10 940 mm(35' 9")

2300 mm(7' 7")

3471 mm(11' 5")

552 mm(22")

3469 mm(11' 5")5185 mm

(17' 0")

DimensionsAll dimensions are approximate.

NOTE: Dimensions vary with blade. Refer to blade specifications chart on page 18.

-

8/13/2019 Wheel Dozer 844

18/2018 844 Wheel Dozer specifications

Blade Overall Digging Ground Maximum Total OperatingType Capacity Width Height Depth Clearance Tilt Weight Weight

Semi-U 15.9 m3 5418 mm 1813 mm 465 mm 1459 mm 829 mm 7273 kg 69 227 kg

20.7 yd3 213.3" 71.4" 18.3" 57.4" 32.6" 16,034 lbs 152,619 lbs

Heavy-duty

Semi-U 15.9 m3 5278 mm 1877 mm 609 mm 1372 mm 940 mm 7763 kg 69 717 kg

20.7 yd3

207.8" 73.9" 24" 54" 37" 17,100 lbs 153,685 lbsCoal 30.7 m3 5846 mm 2289 mm 609 mm 1372 mm 940 mm 6273 kg 68 227 kg

40.2 yd3 230" 90" 24" 54" 37" 13,830 lbs 150,415 lbs

Semi-U Blade: This unit combines the characteristics of the S and U blades into one package. It has increased capacity by the addition ofshort wings which include only the dozer end bits.

Blade Specifications

Blade ControlsMechanical operated raise/lower circuit.

Pilot operated tilt/tip circuit.

Lift circuit features four positions: raise, hold, lower and

float detente hold on float

Tilt/tip circuit features operator selected single or dual tilt finger tip control for tip operation

Control single-lever implement control seat mounted controls pilot operated tilt/tip for lower lever

effort

-

8/13/2019 Wheel Dozer 844

19/20844 Wheel Dozer specifications

Standard EquipmentStandard and optional equipment may vary. Consult your Caterpillar Dealer for specifics.

ElectricalAlternator, 105-ampere

Converter, for 12-volt accessories

Diagnostic connector for starting and

charging systems

Electric starter (heavy-duty)

Electrical system, 24-volt

External lighting system, front and rear

Maintenance-free batteries

Starting receptacle for emergency

starting

Operator environmentAir conditioner, R-134A refrigerant

Contour Series Seat with air suspension

Cigarette lighter and ashtray

Coat hook

Computerized Monitoring System

Action alert system, three-category

Gauges:

tachometerfuel level

hydraulic oil temperature

transmission oil temperature

engine oil pressure coolant

temperature

Dome light (cab)

Electric horn

External two-post ROPS structure

Heater and defroster

Load-sensing steering

Quick-shift feature

Radio-ready cab for entertainment or

two-way radio (three-point mounting)

Rearview mirrors (interior and exterior

mounted)

Retractable seat belt 76 mm (3") wide

ROPS cab with sound suppression

Seat-mounted hydraulic controls

Sight gauges, hydraulic oil and engine

coolant

Single-lever blade control

STIC Control System

Storage for thermos, lunch box, cup

Sunshade/visor, front and rear

Throttle lock

Tinted glass

Transmission gear indicator

Wet-arm wiper/washers, front and rear

Power train

Cat 3412E HEUI engine

Fuel priming aid

Full hydraulic, enclosed, wet multiple-

disc service brakes and

parking/secondary

Impeller Clutch Torque Converter w

lockup clutch

Precleaner/ejector

Remote-mounted hydraulic engine f

Separated cooling system

Sound suppressed muffler

Supplemental steering

Swing-out cooler cores

Transmission,

21" planetary power shift (electro

3-speed forward/3-speed reverse

Other standard equipmentBackup alarm

Drawbar hitch with pin

Fenders (front and rear)

Hydraulic oil cooler

Muffler

Lighting, general purpose (four)

Locking engine enclosures

Power train/guardRear access stairs

Vandalism protection and caplocks

Tires45/65 R39 L-4 (XLDDIA), Micheli

kg lb

Blades

Semi-U 7273 16,034

Heavy-duty Semi-U 7763 17,100

Coal 6273 13,830

Fuel system 1 3

High Ambient Cooling Arrangement 60 132

Oil change system 5 11

kg

Quarter panel wiper washer 17

Starting aids

Cold weather starting system 180

Diesel fuel heater 4

Heater, engine coolant 3

Tires 40.5/75 R39 1-Star, Goodyear -1030 -2,

Optional EquipmentWith approximate changes in operating weights.

-

8/13/2019 Wheel Dozer 844

20/20

844 Wheel Dozer

AEHQ5307 (3-98)

Materials and specifications are subject to change without notice

Featured machines in photos may include additional equipment

See your Caterpillar Dealer for available options

www.CAT.com 1998 Caterpilla

Printed in U.S.A