Specalog for 854K Wheel Dozer, AEHQ5951 - · PDF filefor this wheel dozer size class. •...

Transcript of Specalog for 854K Wheel Dozer, AEHQ5951 - · PDF filefor this wheel dozer size class. •...

®®

EngineEngine Model Cat® C32 ACERT®

Gross Power (SAE J1995) 674 kW 904 hpNet Power (SAE J1349) 597 kW 801 hp

• Cat® engine with ACERT Technology – U.S. EPA Tier 2,EU Stage II compliant

Operating SpecificationsBlade Capacities 25 to 45 m3 33 to 58 yd3

WeightsOperating Weight 98 100 kg 216,273 lb

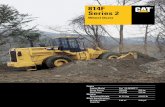

854KWheel Dozer

2

854K Wheel DozerPurpose Built Wheel Dozers designed for long life and low owning and operating costs.

Engineered for demanding work in largedozing applications, the 854K Wheel Dozeris the largest in the Cat Wheel Dozer lineand is an ideal match for large miningoperations, power generating utilities, thegeneral contracting industry and wherevermobility, versatility and compaction is needed.

Complete Customer Support

• Your Cat® dealer offers a wide rangeof services that help you operatelonger with lower cost. pg. 12

Blades and Blade Controls

• Choose from a number of differentblades with replaceable, bolt-oncutting edges and bottom wear platesthat protect the blade, resulting inlonger life.

• A single lever controls all hydraulicblade functions. pg. 7

Durability/Reliability

• Proven components with high hourrebuild and machine life standardsprovide unmatched reliability.

• Diagnostic programs are available tomonitor machine health and maintainuptime. pg. 6

Performance

• Improved system and componentdesign gives the 854K optimumproductivity.

• Operator productivity is enhancedwith easy to use controls. pg. 4

3

Serviceability

• Minimize service time and maximizeproduction through key ground levelaccess points and grouped service center.

• Monitoring the machine andforewarning of machine troubleallows you to schedule downtimeand ensure job site productivitycontinues without interruption. pg. 11

Safety

• The 854K design optimizes visibilityfor a safe working environment.

• Ease of access to daily and routinemaintenance components allow yourservice technician to safely servicethe machine.

• Enhance operator comfort and safetythrough a safe working environment.pg. 10

Operator Comfort

• Best-in-class working environmentfor this wheel dozer size class.

• 854K offers greater control and easeof operation for your operator.

• Ergonomically designed for the healthand safety of your operator. pg. 8

OPTIMUM PRODUCTIVITY. Building offthe legacy of the 854G, the 854K utilizesa number of key features from the 854Gwhile making enhancements to furtherimprove customer productivity.

Load-Sensing Steering. The 854Kfeatures the same load sensing steeringsystem as the 854G. Load sensingsteering maximizes machine performanceby directing power through thesteering system only when needed.This maximizes available powerfor productive work and improvingfuel efficiency.

Next Generation Modular Radiator(NGMR). The 854K introduces the highestlevel of cooling performance by using14 parallel (16 high ambient) modularcores. The NGMR system goes beyondthe proven AMOCS technology andincreases cooling performance by usingbrass tubes and copper fins for coreconstruction. Compared to the AMOCSsteel tube and steel fin construction,the copper in the NGMR design hasa higher heat transfer capability.This enables the 854K to improvecooling performance while minimizingthe cooling package area and maximizingrear machine visibility.

Cat Planetary Power ShiftTransmission. The 854K heavy-dutyplanetary power shift transmission is thesame field-proven transmission foundon the 854G. The 854K transmissionutilizes a planetary gear group similarto the one used in the 993K and 994F,which has proven strength and reliability.The electronically controlled powershift transmission features three forwardand three reverse speeds, and a maximumrimpull capacity of 75 432 kg(166,300 lb).

4

Delivery of performance is critical to your bottom line.

Performance

Impeller Clutch Torque Converter (ICTC).ICTC combined with the RimpullControl System (RCS) allows theoperator maximum flexibility inmodulating rimpull.

• Compensates for wear by providingthe ability to recalibrate for optimumleft pedal modulation regardless oftorque converter wear.

• The impeller clutch torque converteruses the left brake pedal to modulaterimpull from 100 to 24 percentof available rimpull for reducedtire slippage.

• The RCS selector dial is usedto select the desired rimpullsetting from four factory presets(Maximum, High, Medium and Low).The reduced rimpull is only activein first gear forward.

• RCS will allow the operator tomatch rimpull to ground conditions.

• The torque converter is equippedwith a lock-up clutch for direct driveefficiency in second and third gear.

ICTC is standard with lock-up and freewheel stator.

Heavy-Duty Axles. The heavy-dutyaxles feature standard axle oil coolers,permanently lubed universal joints andstrong axle components in both thedifferentials and final drives for increasedperformance, serviceability and durability.

• Axle oil cooling system circulatesoil from the brakes and differentialsthrough an oil-to-air cooler thatprovides increased oil life whileextending component performanceand durability.

• The 854K features planetary reductionin each wheel. Torque is developedat the wheel, putting less stress onthe axle shafts. The planetary unitscan be removed independently fromthe wheels and brakes.

• Conventional differential is standard.

PROVEN ENGINE TECHNOLOGY.The 854K utilizes the Cat® C32 ACERT®

engine, certified to meet U.S. EPATier 2 and EU Stage II emission.The C32 is a Mechanically actuatedElectronically controlled Unit Injection(MEUI) diesel engine. This 597 kW(801 constant net hp), 12 cylinder,32 liter, turbocharged and aftercooledengine is common with the Cat 777F,993K, 992K and D11.

The 854K produces the same net poweras the 854G but has increased powerdensity with the C32 engine. The increasein power density yields improved engineresponse and fuel efficiency.

Single Lever Blade Controller. The 854Kis equipped with a new implementcontroller. The new implement controlleris a fully pilot driven control systemfrom the previous 854G with a cable-driven lift/lower. The new pilot drivenimplement system is easier to use andminimizes operator fatigue.

The right control pod contains a singlelevel blade control that permits theoperator to adjust lift, tilt and pitchwith minimal effort. Additionally,with all control centralized in one pod,the operator utilizes less effort whilecontrolling blade movements. Featureson the pod include:

1) A momentary switch at the front ofthe blade control lever changes left-right functionality from tilt to pitch

2) Horn

3) Set/Decelerate – Throttle Lock

4) Resume/Accelerate – Throttle Lock

5) Hydraulic Lockout

6) Dual Tilt

Load Sensing Steering. The 854K’sSTIC uses a single lever for steeringand transmission control. Left handoperation enables the operator to shiftor change directions without lettinggo of the steering control. The STICreduces operator fatigue by providingan ergonomic location that allows theoperator to work with a fluid andeffortless motion.

5

12

34

56

Caterpillar® Designed Components.Components used to build the Cat® WheelDozers are designed and manufacturedto Caterpillar quality standards.

Castings. The castings in the engine endframe are used in critical high-stressareas to help spread the load and reducethe number of parts. The casting for therear trunnion mount has been redesignedfor improved stress distribution.

Front Frame and Rear Frame.Highly engineered and field-proven,combination use of high-strengthplates and castings distributes loads andincreases structure robustness. A keydifferentiator from competitive machinesis the box section rear frame and frontframe. The box section absorbs torsionalforces experienced during dozing,maintaining alignment for hitch pinsand drive line.

Push Beam and Push Arm DozerArrangement. Solid one-piece pushbeam attached to heavy-duty box sectionframe provides structure for push arms.Push arms are constructed using thick,sturdy plate.

Spread Hitch Design. Double taperedroller bearings and hardened pins resistboth horizontal and vertical loads toincrease life. The spread-hitch alsomakes service access easier.

Engine and Transmission Mounts.The mounts are designed to use acombination of mushroom andcup-shaped ISO mounts, reducingcomponent vibration and sound levels.

Separate Hydraulic Systems.One system for brakes and steering andanother system for blade control and thehydraulically-driven engine cooling fan.The benefits of the separate hydraulicsystems are increased cooling andelimination of cross-contamination.Use of XT™-3 ES, XT-5 and XT-6hose, and reliable components helpreduce the risk of leaks and blown lines,helping protect the environment.

• Tandem gear pumps providehydraulic flow for the lift, tilt andtip functions.

• Well-proven pumps, valves andcylinders share commonality indesign with those used on largeCat Track-Type Tractors.

• For improved serviceability,all hydraulic pumps are mountedon a single pump drive.

DIAGNOSTIC PROGRAMS. Monitoringproduct health is key to maintainingthe reliability of any equipment.Many programs are available on the854K, both standard and optionalfeatures, to help you track machinecondition.

Vital Information Management System(VIMS) . VIMS enables the monitoringof machine health and system statuswith over 100 machine parameters.VIMS interface includes:

• Machine diagnostics

• Calibrations and service modes

• Current machine information(such as engine rpm, active faults)

VIMS allows service access via theoperator interface in addition to twooff-board serial ports located in the caband bumper service center. A laptopcomputer loaded with VIMS PC softwaremay connect to the VIMS control unitvia the VIMS Serial Port.

Product Link. Product Link is a state-of-the-art satellite technology based productthat provides an information flowbetween machine on-board systemsand the Caterpillar operations center.Multiple types of information can becollected and tracked – from machinelocation and service meter hours tohealth and productivity information.

Equipment Manager. With a subscriptionto Equipment Manager through theCat Dealer StoreFront, the informationcollected through Product Link can betransmitted to a computer. With fast,easy-to-access machine information,you can optimize asset utilization, reducesecurity risks, improve maintenancemanagement and implement before-failure repair strategies.

S•O•SSM Services. Keep minor repairsfrom becoming major ones and avoidcomplete failures. By regularly takingsamples from the ports provided, yourCat dealer tracks wear of componentsand parts, oil performance and oilcondition and uses that data to predictwear-related problems before they happen.

6

Durability/ReliabilityMaximum uptime, long life of your machine – it’s what you expect for your bottom line.

Heavy-Duty Blade Linkage. This linkagehas similar design with the Cat D11Track-Type Tractor. These well-provencomponents are designed for largedozing loads in tough applications.

• Lift cylinders raise and lower theblade for efficient dozing action.

• Cutting edges utilize DH-2 steel andend bits utilize DH-3 steel to providemaximum service life.

• Pushbeam, pusharms and tag linkare sized for large dozing loads.

Single Lever Blade Control.Hydraulically operates blade raise,lower, tilt and pitch.

Lift circuit features:

• Four positions – raise, hold, lowerand float

• Detente hold on float

Tilt/Pitch circuit features:

• Operator selected single or dual-tilt

• Finger tip control for pitch operation

Low effort control:

• Single lever blade control

• Floor-mounted controls

• Full pilot oil operated implementcontrol

A switch on the control lever gives theoperator the ability to quickly switchfrom tilt to pitch blade operation.Further blade control is available witha switch on the pod for dual tilt functionof the blade. A generous range of motionenables excellent control for dozing.

Cat Blades. The blades are designedwith high strength, pressed ribconstruction and large Cat Track-TypeTractor bolt-on cutting edges and bottomwear plates that offer excellent dozingand rolling characteristics. Capacitiesand widths are set to achieve increasedproductivity while dozing heavy loadsor spreading cover material.

Coal Blade. The coal blade is designedfor precise and productive dozing whilehelping to retain load control withincreased capacity for lighter materials.

• Wing angles help retain the loadwhile dozing.

Semi-U Blade. Combine thecharacteristics of the S and U bladesinto one package.

• Increased capacity with the additionof short wings, which includeonly the dozer end bits, withoutsacrificing spreading characteristicsof straight blades.

Heavy-Duty Semi-U Blade. Utilizing thesame design as the standard Semi-U bladewith the addition of a Hardox 400 linerplate, Hardox material on the side platesand additional gusseting on the bottomof the blade provide increased strengthand durability in high wear applications.

7

Blades and Blade ControlsWell-proven Cat components deliver dependable service and ease of operation.

OPERATOR ENVIRONMENT. The 854Kmaintains the distinction of offeringthe largest, most ergonomic cab in itssize class.

Seat. With air suspension and aretractable 76.2 mm (3 in) seat belt,the seat is designed for additional comfortand support. The seat cushions reducepressure on the lower back and thighswhile allowing unrestricted arm andleg movement. The seat is six way

adjustable, and the retractable seat beltstays off the floor, making it easier forthe operator to reach.

The seat is critical to an operator’s healthand performance in those applicationsrequiring extended shift times. This seatcan be reclined when not in the operatingmode. Armrest height, tilt and fore/aftare adjustable for any size operator.

A heated seat is available as an optionfor comfortable operation in coldweather conditions.

VISIBILITY. The 854K provides excellentvisibility to both the front and rear ofthe machine. Wipers with intermittentfeature on both front and rear keep thewindows clean in any condition.Additionally, this system containstwo-speed continuous corner wipers.

Rear Vision Camera. An optional rearvision camera is available to clearlymonitor movement behind the dozer.

Optional Features. Additional optionalfeatures that enhance visibility includehigh intensity discharge lights forexceptional lighting when working atnight, warning beacons placed on thecorners of the roof of the cab for visibilityfrom any parameter of the dozer andheated mirrors for quick defrost andgood visibility in winter conditions.

8

Comfort and control – a top quality operator station helps maximize productivity.

Operator Comfort

EASE OF OPERATION. The main controlpanel on the 854K is located to the rightof the operator’s seat, keeping everythingwithin reach of the operator. Convenientlyplaced switches and controls allow betterefficiency and improved productivitywhile minimizing operator fatigue.

Throttle Lock. The throttle lock enablesconstant elevated idle operation byallowing the operator to preset enginespeed for a variety of application.This feature reduces operator fatigue,allowing the operator to concentrateon productivity.

Quick Shift. Quick shift allows quickercycle times by automatically shiftingfrom first forward to second reverse.

Single Lever Blade Controller.The low-effort, fully pilot dozer controlis floor-mounted and adjusts fore andaft so operators of any size can finda comfortable operating position.The single lever control allows operatorsto control all dozer blade functions withone hand. Fore/aft movement of thehandle lowers and raises the blade.Left/right movement directionally tiltsthe blade.

The finger-tip button on top of thecontroller controls blade pitch fore andaft. Further blade control is availablewith a switch on the pod for dual tiltblade function.

OPERATOR TRAINING. A slight increasein cab size allows room for a trainerseat with a 76.2 mm (3 in) seat belt.

This provides a safe method to properlytrain the operator on the job.

9

IMPROVED VISIBILITY. Good visibilityis key to a safe work environment.The 854K offers the best visibility forthis size class wheel dozer. Additionalstandard visibility features that enhancesafety include long-life LED tail lightsand articulated wiper/washer systemwith intermittent feature on front andrear windows, as well as two-speedcontinuous corner wipers.

Optional Rear Vision Camera withIn-Cab Monitor. An optional rear visioncamera with 178 mm (7 in) in-cab colordisplay monitor is available to give aclose view of behind the wheel dozer.

Optional Windshield Cleaning Platform.A windshield cleaning platform packagehas an additional platform and handrailsto provide easy access for cleaning ofthe front window.

Working 24 Hours a Day. Any time ofthe day and in all types of weather, the854K has a number of features to ensuresafe visibility. Heated rearview mirrorsare available for quick defrost and goodvisibility in winter conditions.

The optional High Intensity Discharge(HID) lights provide exceptional lightingfor night work. HID lights are a newgeneration of 35-watt lights featuringa special flood lens and reflector whichprovides brighter output.

Optional warning light beacons are alsoavailable as a safety feature.

Optional roading fenders help preventmud and debris build-up on the stairs forsafety in getting on and off the machine.

SAFETY IN OPERATOR ENVIRONMENT.Cab comfort and operator safety gohand-in-hand. Many features that enhanceoperator comfort also aid in keepingyour operator safe. Examples rangefrom noise and vibration to designingfor decreased repetitive motion.

Key standard features that aid operatorsafety include low effort implementblade controls floor mounted for easeof adjustment to the operator and a seatbelted trainer’s seat for ease of trainingan operator on the job site.

Additional safety features include a cabfiltration system that removes dust anddebris from the cab air.

Optional for extremely dusty applicationsis a cab pre-cleaner that reduces theamount of dust that reaches the cab filter.

MAINTENANCE SAFETY. Daily androutine maintenance should not pose asafety hazard to your operator or servicetechnician. With the 854K, design effortwas taken to group service points withconvenient access. One key servicecenter that is focused on your operatorand service technicians safety is theBumper Service Center.

Bumper Service Center. A centralizedservice center located at ground levelon the left-hand, rear side of the 854Kincludes a stairway light (1), auxiliaryemergency shutdown switch (2), VIMSport (3), VIMS Service Key switch (4)and Cat Electronic Technician com-IIport (5). This center also contains lockoutswitches allowing your service technicianto perform routine maintenance whileensuring the machine stays static.

Starter Lockout Switch (6). Key to safety,another feature on the bumper servicecenter is a starter lockout that stops theability to start the machine, which isoften needed during service procedures.The machine will still have electricalpower, however, the engine can notbe cranked.

Transmission Lockout Switch (7).The transmission lockout switch doesnot allow the transmission to shift outof neutral, even if running. This featureis designed for service procedures thatrequire machines to be running butwant the transmission disabled foradded safety.

In-Cab Steering Lockouts. The steeringlockout feature in the cab locks thesteering handle in the neutral positionand disables the transmission controls,ensuring the machine will not be moveduntil the lock is disabled.

SAFETY.CAT.COM™.

10

People are the backbone of your business, and keeping them safe and productive is thenumber one priority.

Safety

1

2

3

4

7

6

5

11

SERVICE ACCESS. Ground level accessand grouped service points lead to easierservice, minimizing service time andmaximizing production. This allows aservice technician to perform a variety ofservice procedures, often from groundlevel or platform, ranging from accessto VIMS to grease fittings for the frame.

Optional Service Center. The 854Koffers an optional service center for onepoint of service. This includes a fill anddrain feature for the optional oil renewalsystem, radiator, implement tank,steering tank, transmission and engineoil. Optional AutoLube is only availablewith a fill tube. Additionally, the optionalAutoLube and Oil Renewal Systems areboth equipped with full lights. The fulllights allow the service technician toensure the system is full while fillingat ground level.

Bumper Service Center. The bumperservice center features safety servicecontrols including starter and transmissionlockouts, emergency engine shutdownand VIMS and Electronic Technicianconnections.

Swing-out Doors. The swing-out doorson both sides of the engine offer easeof access to a number of servicecomponents.

Engine Service Area. In the left-handside engine access door are groupedservice points for the engine includingoil and fuel filters, oil fill and oil check.The compartment also includes a lightfor service at night, along with one ofthe machine air filters and the air filterservice indicator. The right side engineaccess door houses the other air filter,the ether aid and another under hoodlight switch.

Batteries. The batteries sit in a built-inbattery box and are accessible througha hinged door on the platform.

Platform Service Areas. Hinged doorsin the platform provide access to thehydraulic tank fill, blade circuit andsteering filters. The transmission sightgauge and filler spout are serviced fromthe hitch area.

Remote and Grouped DiagnosticPressure Ports. Grouped, easilyaccessible pressure ports are designedinto the 854K to provide quick and easydiagnostic checks for the implement,steering, fan, axle oil cooler, brakes,impeller clutch and lock-up clutch.

Sight Gauges. To the hydraulic tanksand radiator fill tank provide quickchecks for fluid levels.

Hydraulic Filtration. Case drain filtrationis standard on all pumps and motors.For additional protection, high pressurescreens are available as an optionalattachment.

Power Train Filters. The power trainfilters are removed from the top sideto reduce the chance of fluid spillage.

Hydraulic Service Area. On top of theplatform behind the cab are access panelsfor the steering and implement pilotfilters, case drain filters, power trainfilters and hydraulic pumps.

Electronic Service Center. Acentralized electronic service centeris located on the right side of the cabplatform and provides one service pointfor transmission/implement ECM, VIMS,breakers and fuses. It is sealed againstweather elements.

Optional QuickLube System.The QuickLube system provides precise,automatic lubrication of all grease jointswhile the machine is in operation.Automatic lubrication reduces time spendon daily maintenance and downtime forunplanned repairs due to insufficientgreasing.

DIAGNOSTICS. The 854K offerscustomers the ability to troubleshootand monitor machine information,customize operator settings forcontinuity of operation and set machineconfiguration. A number of these tasksare accomplished through VIMS.

ServiceabilityLess time spent on maintenance means more time spent on the job.

Machine Selection. Make detailedcomparisons of the machines underconsideration before purchase. Cat dealerscan estimate component life, preventativemaintenance cost and the true cost oflost production.

Purchase. Look past initial price.Consider the financing options availableas well as the day-to-day operating costs.Look at dealer services that can beincluded in the cost of the machineto yield lower equipment owning andoperating costs over the long run.

Customer Support Agreements.Cat® dealers offer a variety of productsupport agreements and work withcustomers to develop a plan that bestmeets specific needs. These plans cancover the entire machine, includingattachments, to help protect thecustomer’s investment.

Product Support. You will find nearlyall parts at our dealer parts counter.Cat dealers use a worldwide computernetwork to find in-stock parts to minimizemachine downtime. Save money withgenuine Cat Reman parts. You receivethe same warranty and reliability asnew products at cost savings of 40 to70 percent.

Operation. Improving operatingtechniques can boost your profits.Your Cat dealer has training videos,literature and other ideas to help youincrease productivity.

Maintenance Services. Choose fromyour dealer’s range of maintenanceservices when you purchase yourmachine. Repair option programsguarantee the cost of repairs up front.Diagnostic programs such as S•O•SSM andCoolant Sampling and Technical Analysishelp you avoid unscheduled repairs.

Replacement. Repair, rebuild or replace?Your Cat dealer can help you evaluatethe cost involved so you can make theright choice.

Complete Customer SupportCat® dealer services help keep machines operating longer with lower costs.

12

13854K Wheel Dozer specifications

Hydraulic System

Cylinders, Double-Acting: 177.8 mm � 7 in �Lift, Bore and Stroke 1759.5 mm 69.3 inCylinder, Double-Acting: 266.7 mm � 10.5 in �Tilt and Tip, Bore and Stroke 285.5 mm 11.25 inRelief Valve Setting – 22 675 kPa 3,289 psiBulldozer (Large Pump)Relief Valve Setting – 24 560 kPa 3,560 psiTilt Cylinders (Small Pump)

Steering

Steering Angle (max) 43ºSteering Meets ISO 5010:1992

• Steering angle in each direction, one-hand operation.

Service Refill Capacities

Fuel Tank – Standard 1562 L 413 galCooling System 200 L 53 galCrankcase 120 L 32 galTransmission 169 L 45 galDifferentials and 369 L 98 galFinal Drives – FrontDifferentials and 342 L 90 galFinal Drives – RearCooling System – NGMR System 86 L 22.7 gal

Engine

Engine Model Cat ® C32 ACERT ®

Net Power (SAE J1349) 597 kW 801 hpGross Power (SAE J1995) 674 kW 904 hpBore 145 mm 5.7 inStroke 162 mm 6.4 inDisplacement 32.1 L 1,959 in3

Max Net Torque 4242 N·m 3,129 ft-lbTorque Rise 30%

• Cat engine with ACERT Technology – U.S. EPA Tier 2,EU Stage II compliant

• Engine ratings apply at 1750 rpm when tested under specificstandard conditions for the specified standard.

• Power rating conditions based on standard air conditionsof 25° C (77° F) and 99 kPa (29.32 in Hg) dry barometer using35° API gravity fuel having an LHV of 42 780 kJ/kg (18,390 Btu/lb)when used at 30° C (86° F) [ref. a fuel density of 838.9 g/L(7.001 lb/gal)].

• Net power advertised is the power available when theengine is equipped with alternator, air cleaner, mufflerand hydraulic fan drive.

• No derating required up to 3050 m (10,000 ft) altitude.

Weights

Operating Weight 98 100 kg 216,273 lb

Transmission

Converter Drive – Forward 1 7.1 km/h 4.4 mphConverter Drive – Forward 2 12.4 km/h 7.7 mphConverter Drive – Forward 3 21.2 km/h 13.2 mphConverter Drive – Reverse 1 7.7 km/h 4.8 mphConverter Drive – Reverse 2 13.5 km/h 8.4 mphConverter Drive – Reverse 3 23.5 km/h 14.6 mphDirect Drive – Forward 1 Lock-up DisabledDirect Drive – Forward 2 13 km/h 8.1 mphDirect Drive – Forward 3 22.8 km/h 14.2 mphDirect Drive – Reverse 1 8 km/h 5 mphDirect Drive – Reverse 2 14.3 km/h 8.9 mphDirect Drive – Reverse 3 25.1 km/h 15.6 mph

• With 45/65-45 L-5 46 ply tires

Brakes

Brakes Meet ISO 3450:1996

Axles

Front FixedRear Oscillating at ±10°Maximum Single-Wheel 573 mm 22.6 inRise and Fall

Tires

Tire Choices Five options available

• Tubeless, low-aspect ration. All steel radial constructionfor increased traction and stability, lower rolling resistance.

• Options

– 45/65-R45, L-4 I STAR Michelin

– 45/65-R45, L-5 I STAR Michelin

– 45/65-R45, L-5 58 PR Goodyear

– 45/65-R45, L-5 58 PR Bridgestone

– 1150/65-R45, RL-5K 2 STAR Goodyear

• NOTE: Caterpillar recommends that you consult a tiresupplier to evaluate all conditions before selecting atire model. Other special tires are available on request.

Operating Specifications

Blade Capacities 25 to 45 m3 33 to 58 yd3

Cab

ROPS/FOPS Meets SAE andISO standards

• Rollover/Falling Object Protective Structure (ROPS/FOPS)is standard.

• ROPS meets the following criteria:

– SAEJ1040 MAY94

– ISO 3471:1994

• FOPS meets the following criteria:

– SAEJ/ISO 3449 APR98 LEVEL II

– ISO 3449:1992 LEVEL II

• The operator sound exposure Leq (equivalent soundpressure level) measured according to the work cycleprocedures in ANSI/SAE J1166 OCT98 is 73 dB(A) for thecab offered by Caterpillar when properly installed andmaintained and tested with the doors and windows closed.

• The exterior sound pressure level for the standard machinemeasured at a distance of 15 m (49.2 ft) according to the testprocedures specified in SAE J88 APR95, mid-gear-movingoperation, is 83 dB(A).

• The dynamic operator sound pressure level is 72 dB(A)when ISO 6396:1992 is used to measure the value foran enclosed cab. The cab was properly installed andmaintained. The test was conducted with the cab doorsand the cab windows closed.

• Hearing protection may be needed when operating withan open station and cab (when not properly maintainedor doors/windows open) for extended periods or in noisyenvironment.

14 854K Wheel Dozer specifications

15854K Wheel Dozer specifications

Dimensions All dimensions are approximate.

NOTE: Dimensions vary with blade. Refer to blade specifications chart.

Blade Overall Digging Ground Maximum Total OperatingType Capacity Width Height Depth Clearance Tilt Weight WeightSemi-U 25.4 m3 6321 mm 2179 mm 398 mm 1540 mm 1165 mm 10 161 kg 98 488 kg

33.1 yd3 20.75 ft 7.2 ft 1.3 ft 5.04 ft 3.8 ft 22,400 lb 217,128 lb

Heavy-duty Semi-U 25.4 m3 6321 mm 2179 mm 398 mm 1540 mm 1165 mm 10 750 kg 99 077 kg

33.1 yd3 20.75 ft 7.2 ft 1.3 ft 5.04 ft 3.8 ft 23,700 lb 218,427 lb

Coal 44.7 m3 7200 mm 2500 mm 398 mm 1540 mm 1706 mm 10 333 kg 98 660 kg58.2 yd3 23.6 ft 8.2 ft 1.3 ft 5.04 ft 5.6 ft 22,780 lb 217,507 lb

Semi-U Blade: This unit combines the characteristics of an S and U blade into one package. It has increased capacity by the addition ofshort wings which include only the dozer end bits.

Blade Specifications

Standard EquipmentStandard equipment may vary. Consult your Caterpillar dealer for details.

POWER TRAINAxle oil coolers (front and rear)Brakes, full hydraulic, enclosed, wet multiple disc service

brakes and dry parking/secondary brakeDemand fanElectric fuel priming pumpEngine, Cat® C32 ACERT ®

Ground level engine shutdownGround level starter lockoutImplement, steering and coolingPrecleaner, engine air intakePrecleaner, engine air intakeRadiator, Next Generation Modular (NGMR)Separated cooling systemStarting aid (ether) automaticThrottle lock

OTHER STANDARD EQUIPMENTCouplings, Cat O-ring face sealsDoors, service access (locking)Fenders, steel (front and rear)Guards, power train and crankcaseHitch, drawbar with pinHoses, Cat XT™Hydraulic oil coolerOil sampling valvesPiston pump case drain filtersStairway, left rear accessSteering, load sensingSteering, secondaryVandalism protection caplocksVenturi stack

BULLDOZERSBulldozer Arrangements are included in the standard

equipment. Bulldozer blades are optional.TIRES, RIMS AND WHEELS

A tire must be selected from the mandatory attachments section. Base machine price includes a tire allowance.

ANTIFREEZEPremixed 50 percent concentration of extended life coolant

with freeze protection to –34° C (–29° F).

ELECTRICALAlarm, back-upAlternator, 150 ampBatteries, low-maintenanceDeutsch and Amp Seal terminal connectorsLighting system, halogen (front and rear)Lighting, access stairwayStarter, electric (heavy-duty)Starting and charging system (24-volt)ECM diagnostic connectorStarting receptacle for emergency start

OPERATOR ENVIRONMENTAir conditionerCab, sound suppressed, pressurized, rollover protective

structure (ROPS/FOPS)Radio ready for (entertainment) includes antenna,

speakers and 2x 12V converters (24-volt, 15-amp)for use with laptop/cell phone

Cigar lighter and ashtrayCoat hookHeater and defrosterHorn, electricLight, (dome) cablock-up clutch disable switchLunch box and beverage holdersMonitoring system (VIMS) with gauges

Action alert system, three categoryInstrumentation, gauges:

Engine coolant temperatureFuel levelHydraulic oil temperatureTachometerTransmission oil temperature

Mirrors, rearview (externally mounted)Pilot hydraulic blade controlsSeat, Cat Comfort (cloth) air suspensionSeat belt, retractable, 76 mm (3 in) wideSTIC control systemTinted glassTrainer seat with lap belt, retractable, 76 mm (3 in) wideTransmission gear indicatorWipers/washers, wet-arm (front, rear and corner)

Intermittent front and rear wipersTwo speed corner continuous wipers

16 854K Wheel Dozer specifications

17854K Wheel Dozer specifications

Optional EquipmentOptional equipment may vary. Consult your Caterpillar dealer for details.

No-SPIN rear differentialOil Renewal System (for use with service center)Oil Renewal System (cannot be used with service center)Operator Environment

Radio, AM/FM, CD BasicRadio, Satellite XMRadio, Satellite, SiriusRadio Ready, SatelliteSeat, HeatedPrecleaner, Cab

Service Center120V engine coolant heater240V engine coolant heater

BladesSemi-U 25.4 m3 (33.1 yd3)HD Semi-U 25.4 m3 (33.1 yd3)Coal 44.7 m3 (58.2 yd3)

CAES, Attachment Ready OptionElectrical

Camera, Rear VisionLighting, Warning BeaconLights, HIDConverter, 10A

Extended Life Coolant with freeze protection to –50° C (–58° F)Kits

Deluxe, FiltrationAir Intake Preclean EngineOil RenewalQuickLube

Mandatory EquipmentMust choose from each category. Consult your Caterpillar dealer for more information.

Lube ArrangementsLines, GreaseQuickLube (with service center option)QuickLube (without service center option)

Mirror ArrangementMirror, StandardMirror, Heated

Steps and WalkwaysStepsWalkway, Cab Front

TiresSee your Cat dealer for current tire options.

Access StairsStandard – Left-hand StairsLeft and Right-hand StairsLeft and Right-hand Stairs with Roading Fenders

Cooling PackagesStandard – for ambient temperatures up to 43° C (110° F)High Ambient – for ambient temperatures up to 55° C (131° F)

ElectronicsSoftware, VIMS (Language is English/Spanish)Product Link, NA (ANSI)

Engine ArrangementEngine, StandardEngine, Standard, Sound Suppression

Filtration SystemStandard – Case DrainDeluxe – Case Drain and High Pressure Screens

Fuel SystemsStandardFast FillHeaterFast Fill and Heater

18 854K Wheel Dozer specifications

R

For more complete information on Cat products, dealer services,and industry solutions, visit us on the web at www.cat.com

© 2008 CaterpillarAll Rights Reserved

Printed in U.S.A.

Materials and specifications are subject to change without notice.Featured machines in photos may include additional equipment.

See your Caterpillar dealer for available options.

CAT, CATERPILLAR, ACERT, SAFETY.CAT.COM, their respective logos, “Caterpillar Yellow”and the POWER EDGE trade dress, as well as corporate and product identity used

herein, are trademarks of Caterpillar and may not be used without permission.

AEHQ5951 (4-08)

Replaces AEHQ5488

854K Wheel Dozer