Specalog for 824H Wheel Dozer, AEHQ5615-02

Transcript of Specalog for 824H Wheel Dozer, AEHQ5615-02

®®

EngineEngine Model Cat® C15 diesel with

ACERT™ TechnologyGross Power 299 kW 401 hpNet Power 264 kW 354 hp

WeightsOperating Weight 28 724 kg 63,325 lb

Blade SpecificationsBlade Capacities 4.67 m3-16 m3 (6.1 yd3-21 yd3)

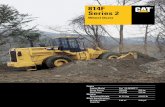

824HWheel Dozer

2

824H Wheel DozerRepresenting a long-standing commitment to quality and performance, this rugged,powerful machine is designed and built for tough applications.

The 824H Wheel Dozer was conceived anddesigned to surpass any competitor withexciting innovations that exceed customerexpectations for performance, reliabilityand operator comfort.

Complete Customer Support

Your Cat dealer is your single, safesource for all your equipment needs.He offers a wide range of services thatwill fit your operation and keep youworking longer with lower costs. pg. 14

Serviceability

Many convenient service featuressuch as hinged service doors, easilyaccessible scheduled maintenancepoints, conveniently located sightgauges and a separated cooling systemmake servicing easy. Service has beenimproved with new transmission remotepressure taps. pg. 12

✔

Structures

Advanced design, materials and roboticwelding contribute to increased durabilityand overall machine strength. pg. 7

Hydraulics

The 824H uses electro-hydraulics forease of operation and operator comfort.The new Automatic Blade Positioning(ABP) helps to improve the productivityof your machine. pg. 6

✔

Power Train

The 824H uses the Cat C15 dieselengine with ACERT™ Technologywhich is U.S. EPA Tier 3/EU Stage IIIcompliant. Smooth, consistent shiftingwith fingertip control and electroniccontrols contribute to increased levelsof productivity. pg. 4

✔

✔ New Feature

3

Operator Station and Controls

Experience a high level of productivitythrough Command Control steeringwith integrated transmission controls,fingertip blade controls, a large viewingarea and spacious operator station.pg. 10

Optional Features

Various optional features are availableto meet all your needs. pg. 9

✔

Blades

On the 824H, you can choose from thestraight blade, coal blade or the new6.9 m3 (9 yd3) standard and extremeservice U-blade to allow for maximumproductivity from your wheel dozer.pg. 8

✔

Cat® C15 Engine with ACERT™Technology. The Cat C15 engine is anincreased displacement version of theproven Cat 3406 engine. The C15 isU.S. EPA Tier 3/EU Stage III compliantand features a 3.5 percent horsepowerincrease over the previous 3406.The four stroke engine delivers fueleconomy, durability and reliability in themost demanding conditions. High torquerise delivers performance you can feelwith greater rimpull, lift force and fastercycle times. Resilient engine mountsdampen vibration for lower sound levels.

Engine Lubrication. Engine lubricatingoil is filtered, cooled and supplied bya gear-type pump.

Mechanical Electronic Unit Injector(MEUI™). MEUI is a high-pressure,direct injection fuel system that isvirtually adjustment-free. It electronicallymonitors operator and sensor inputs tooptimize engine performance.

Air-to-Air Aftercooler (ATAAC) System.The ATAAC system provides a separatecooling for the intake manifold air.It routes hot, compressed air from theturbo and cools it with a single pass,air-to-air aluminum heat exchanger.The cooled, compressed air greatlyreduces the emissions produced,meeting U.S. EPA Tier 3/EU Stage IIIrequirements.

• Airflow matched turbocharger withpower rating helps reduce emissions.

• 19 percent more bearing area allowsthe engine to operate at the maximumcylinder pressure.

• Higher cylinder pressure capabilityhelps reduce fuel consumption andimproves high altitude operation andprovides reduced emissions.

Cylinder heat exhaust port sleevesreduce heat rejection which results inless heat transfer into the water jacketsystem and provides high torque rise.

Next Generation Modular Radiator(NGMR). The parallel flow system withsix cores standard (seven on the highambient machine) improves coolingcapabilities. Serviceability is alsoenhanced as there is no top tank toremove. The NGMR uses copperbrazed brass tubes and copper fins.

ADEM™ IV (Advanced Diesel EngineManagement) System. ADEM IV uses a32-bit computer with sensors throughoutthe engine to regulate fuel delivery,valve timing and all other enginesystems that require input to manageload and performance.

ADEM IV also offers automatic altitudecompensation, a cold mode start-upstrategy, oil pressure and coolantwarnings which result in precise enginespeed control, superior cold startcapability, low smoke and emissionsin all operating conditions.

Transmission. The extreme duty,planetary, powershift Cat transmissionfeatures heavy-duty components tohandle the toughest jobs. The four planetdrives operate in all gears forward andreverse. Electronic controls providefeatures to enhance productivity, durabilityand serviceability. The additions of theElectronic Clutch Pressure Control(ECPC) contributes to improved shiftquality, reduced torque spikes and overalltransmission durability. Control ThrottleShift (CTS) offers smoother shifts andimproves clutch and power train life.

4

Delivers top performance and durability in tough applications.

Power Train

Torque Converter. The torque converteruses a high-capacity impeller to handlethe engine’s increased torque rise(24 percent) and power.

Heavy-Duty Axles. The fixed front andoscillating (±13 degrees) rear heavy-dutyaxles feature strong gears and bearingsin both the differentials and heavy-dutyfinal drives for increased durability.Permanently lubricated, maintenance-free U-joints result in fewer parts andimproved serviceability. Free floatingaxles shafts can be removed independentlyfrom the wheels and planetary drives.

Spindles and Final Drives. Planetaryunits can be removed independentlyfrom the wheels and brakes. The finaldrives feature planetary reduction ateach wheel, and with torque developedat the wheel, less stress is placed onthe axle shafts.

Differentials. Conventional front andoptional No-SPIN rear differentialsdeliver maximum traction in low tractionor inconsistent ground conditions.

Service Brakes. Completely enclosedand located on the two front wheels, theservice brakes are self-adjusting withmodulated engagement and are designedfor easy servicing. With two brakepedals, the right pedal controls standardbraking while engine deceleration andbraking occurs with the left pedal.

Parking Brake. The spring-applied, oil-released, dry drum design parking brakeis mounted on the transmission outputshaft driveline for manual operation.The Caterpillar® Monitoring Systemalerts the operator if the transmissionis engaged while the parking brakeis applied.

Secondary Brake. The secondary brakecan be applied manually by the operator.In addition, the Caterpillar MonitoringSystem alerts the operator if pressuredrops and will automatically applythe parking brake.

Cold Start. This feature is improvedby not only ADEM IV but also anew larger starter and four higherCCA batteries (1000 CCA).

5

Hydraulic System. The hydraulicsystem provides low-effort blade control.Seat mounted levers send electricalsignals to a pilot valve mounted onthe front frame, moving the sound,heat and effort caused by the hydraulicvalve out of the operator’s station.

Command Control Steering. A mechanicalfeedback system combines with valveratio to provide quarter-turn, side-to-side steering. Unlike systems that relyon steering wheel velocity to activatesteering cylinders, Command Controlsteering directly links the steering wheelposition to articulation. The speed themachine turns is proportional to thesteering wheel position. The benefit isprecise control, quicker response anddramatically reduced operator motionand effort.

Hydraulic Power Steering. Center-pointframe articulation permits the frontand rear wheels to track with hydraulicpower steering. The hydraulic systemhas full-flow filtering. The steeringwheel operated pilot valve controls flowto the steering cylinders. The steeringangle is ±42 degrees.

Load Sensing Steering. With loadsensing steering, machine performanceis maximized because power is directedto the steering system only when theoperator steers the machine. This allowsmore power to be applied to the groundwhen the machine is not being steered.It also helps decrease fuel consumptionsince the steering system does notconstantly draw on the engine.

Positive Displacement Hydraulic Pumps.All hydraulic pumps are mounted ona single pump drive for improvedserviceability

XT™-3 and XT™-6 Hose. ReliableXT-3 ES and XT-6 ES hoses, alongwith o-ring face seals and a largecapacity life cylinder complete thehydraulic system. Reliable componentsreduce the risk of leaks and blown lines,helping protect the environment andreducing operating costs.

Automatic Blade Positioning.Operator automation is providedthrough the use of in-cylinder sensorsand implement software.

6

HydraulicsWell-balanced hydraulics deliver precise, low-effort control and trouble-free operation.

Structure Construction. Combines theuse of robotic welding on up to 90 percentof the 824H, while castings are used inseveral areas to increase strength byhelping to spread the loads and reducethe number of parts. This provideshighly consistent welds with deep platepenetration and excellent plate fusion.The benefits are increased durability andfatigue strength. The computer controlledmachining ensures the alignment ofpin bore, axle pad, cab mount andtransmission/engine components.

Box Section Engine End Frame.Designed to resist twisting and torsionalforces, the box section engine end frameprovides a solid foundation for theaxles, engine and transmission.

Dozer Front Frame. Built specificallyto handle greater amounts of rimpull,the 824H can readily push its weightplus the weight of the material for longdistances in heavy dozing applications.

Spread Hitch Design. The spread hitchdesign improves load distribution byreducing loads to the hitch bearings.The large center hitch design improveshydraulic line routing and makesservice access easier.

Upper and Lower Hitch Pins. The hitchpins pivot on double-tapered rollerbearings. Box-style sections in thehitch pins and crossmember assemblyimprove frame structure strength.Increased diameter lower hitch pinsadd to the robust design.

Engine and Transmission Mounts.A rubber isolation mount designreduces noise and vibration.

7

StructuresAdvanced design and materials provide superior strength to the purpose built structures.

Operator Controls. Lift, tilt, tip andABP are standard. The controls areconveniently located to the right ofthe operator.

Applications. The 824H excels at highproduction dozing and spreading fill,backfilling, stockpiling, charginghoppers, maintaining haul roads andcleaning up around job sites.

Blade Options. Contact your Cat® dealerfor blade options and availabilitythat include:

• Straight Blade. Straight blade is usedfor general work.

• Extended Wear BulldozerArrangement. The Extended Wearbulldozer arrangement is designed formoving large loads over long distancesin harsh conditions. It consists of a6.9 m3 (9 yd3) U-blade with AbrasionResistant Material (ARM) on the frontand sides, cutting edges, push armsand integrated cylinder guards, anda heavy-duty stabilizer.

• Coal Blade. The coal blade canincrease coal capacity up to 50 percentper cycle over standard U-blades.

• Woodchip Universal Blade.The woodchip U-blade has a uniquewing configuration that providesaggressive side setting into the chippile, quickly knocking down stackedchips and loading the blade.

Universal Bulldozer Arrangement.6.9 m3 (9 yd3) Universal blade for movinglarge loads over a long distance whileretaining control of the load.

Custom Options. Ask your Cat dealerabout Cat Work Tool or Custom options.

8

BladesMultiple box-section construction with heat treated moldboard and DH-2 steel edges andend bits contribute to long life.

Full Coverage Fenders. The frontfenders extend beyond the outermostsurface of the machine to prevent mudfrom splattering the front and sidewindows and to keep rocks fromflying into window glass.

The optional full coverage fenderpackage includes front fenders withmud flaps.

Full coverage rear fenders extend tothe bumper, along with a rear rubber(lateral) fender extension to ensurethe entire tire width is covered.

Optional Counterweight. This feature islocated on either side of the front frame.For each specific application, there isa correct machine weight for properbalancing of traction, flotation, mobilityand response. Lower machine weightis usually required for typical secondgear applications such as fill spreading,stockpiling, road maintenance, towingimplements and shovel cleanup.Higher machine weight is usuallyrequired for such typical first gearapplications as heavy dozing andpushloading.

Optional Sliding Cab Window.Located in the right and left doors areoptional sliding windows to provideaccess to outside air without openingthe door.

Floodlights. Located on the 824Hexterior, floodlights are super dampand will last up to seven times longerthan previous lights. An auxiliary lightpackage with the cab (two facing forwardand two facing rearward) is available.

Fast Fuel Fill. High speed fueling allowsyour 824H to stay in production longer.

Cat® Product Link (Attachment).Product Link allows tracking ofmachine location and service hoursthrough global positioning technology(GPS) and provides all logged diagnosticcodes. This feature is available to dealersin North America and certain licensedcountries. To verify if a license existsfor your location, please contactyour Cat dealer.

9

Optional FeaturesAvailable options can augment the 824H and meet your needs.

10

Ergonomically designed for operator comfort with low-effort controls increases efficiencyand productivity.

Operator Station and Controls

1

2

3

4

5

7

6

Right and Left Rear-Hinged Doors.A walk-through operator’s stationcomes from right and left doors thatcan be fully opened and latched foreasy entry and exit.

Sound Levels. A thick, non-metallicfloor, along with outside the cabhydraulics and a separated coolingsystem contribute to a quiet workenvironment.

1 Viewing Area. The internal ROPSand bonded front glass eliminate thedistracting metal frames to help increasethe viewing area. The angled hood andlarger windows allow the operator tosee objects closer to the machine.

2 Cat® Comfort Series Seat. The six-wayadjustable seat provides comfort byreducing the pressure on the lower backand thighs while offering unrestrictedarm and leg movement. Air suspensionadds to the overall comfort level bysmoothing the ride over rough terrain.

3 Blade Control and Joystick. The podis situated at an 18 degree angle fornatural wrist positioning. The controlleroffers a sturdy handle for multiple handpositions. The actuation button for theblade tip function is located on thejoystick, providing total blade control.

Storage Space. The cab features roomfor a lunch cooler, insulated bottle, cupand other personal items. A coathookis also provided.

Radio Ready. A 12-volt, 15-ampconverter, speakers, antenna, all wiringand brackets for a communications orentertainment radio is provided.

4 Caterpillar Monitoring System.Gauges on the left side of the dashmonitor fuel level, engine coolant,hydraulic oil and torque converteroil temperatures.

The center panel contains thetachometer/speedometer.

On the right side panel, a three-levelwarning system provides full-timemonitoring of key functions. The systemalerts the operator of immediate orimpending problems with air inlettemperature, brake oil pressure, electricalsystem low voltage, engine oil pressure,engine overspeed, fuel filter status,parking brake status, steering oil pressureand transmission filter status.

12-Volt Power Supply. Radios, phonesand laptop computers can be poweredfrom the cab with the 12-volt, 15-amppower supply provided. A laptopcomputer can run Cat ElectronicTechnician (ET) software to accessthe enhanced engine, transmissionand blade control system diagnostics.

Service Brakes. Standard braking isoffered with the right pedal.

5 Decelerator Pedal. Engine decelerationfor the first 50 percent of travel is followedby the brakes engaging. This left pedalenables the operator to slow down whenthe throttle lock is engaged and return tothrottle lock without pressing a button.

6 Throttle Lock. Similar to cruise controlin an automobile, throttle lock allowsthe operator to preset the engine speedfor operator and machine efficiency.

Air Conditioning. Blended air providesimmediate temperature changes, clearswindows with ease and improvesoperator comfort. The system is locatedbehind the operator’s seat and usesR134a refrigerant.

Ventilation Ducts and Vents.More airflow is directed to the operatorand windows, while post-mounted ventsdirect air to the rear windows.

7 Automatic Blade Positioning (ABP).This patented system is intended to lowerfatigue, increase comfort and makeoperators more productive. It mimicsmanual functions by automaticallylowering the blade when the machine isshifted forward and raising it in reverse.The set points to where the blade raisesand lowers can be easily changed frominside the cab. Additionally, a kick-outfeature of the system will allow theoperator to raise/lower the bladewithout having to hold the joystick inplace. The operator always maintainsfull control of the blade during thiscycle with the ability to override ABP.

11

Caterpillar Monitoring System.Diagnostics are provided that allowtechnicians to review a machine’soperation and quickly troubleshootproblems. Operating parameters,diagnostic codes and out-of-rangegauge readings are displayed throughthe diagnostic connector. There arealso pressure taps for easy hydraulicsystem checks.

Service Access. Scheduled maintenancepoints are well within reach. A remotegrease fitting is provided to lubricatethe lift cylinder yoke. Removable treadplates in the platform give access toless commonly serviced components.With the 824H, the transmission (ECPC)pressure taps are now located behindthe cab, under the platform door foreasy access.

Daily Maintenance. Lockable groundlevel service doors give quick accessto engine oil fill and dipstick, coolantsight gauge, rear frame grease fittings,relay panel and electrical breakers.All four maintenance-free batteries aresecure in a built-in battery box locatedin the right rear frame. U-joints arelifetime lubricated, leaving the slipjoint as the only driveline componentneeding grease.

Filter Access. The left platform offersaccess to the primary filter, while theengine oil filter is accessed from theright platform.

Air Filter Restriction Sight Gauge.This can be viewed from the cabor platform.

Transmission Oil Fill Tube. The tube islocated beneath the platform area andthe transmission oil dipstick sight gaugeis located next to the fill tube for easymaintenance.

500 Hour Oil Change Interval.Uptime and production are increasedby doubling the time between oiland filter changes without requiringincreased oil sump capacity.

Separated Cooling System. The fanand radiator are isolated away from theengine for a quieter running machine.NGMR reduces radiator repair time.The new metal engine enclosure iscompletely redesigned for greaterdurability and to provide easy accessfor daily maintenance and inspection.

Hinged Hydraulic Oil Cooler. This canbe swung open 30 degrees withoutspecial tools.

12

Having easy daily maintenance is the way to get it done.

Serviceability

Hinged Air Conditioning Condenser.This swings open 30 degrees andcoupled with the swing-out oil cooler,allows the cooling system to be cleanedquickly and easily.

Operator Station. In about 45 minutes,the operator station can be removed orreplaced without having to disconnecthydraulic lines. Quick disconnectcouplings allow fast disconnect of theair conditioning unit without releasingrefrigerant.

Engine Shutdown Switch. This switchis located inside the left radiator screendoor for simple access and extendedswitch life.

Bolt-on Bumper. The angle ofdeparture is improved from 18 degreesto 20 degrees by shortening the overallmachine length.

Battery Box. Maintenance-freebatteries are located in the batterybox located in the right side bumperfor convenient access.

Tool Box. The tool box is locatedin the left side bumper to provideadditional protection against harshwork environments.

13

Machine Selection. Make detailedcomparisons of the machines underconsideration before purchasing.Cat dealers can estimate componentlife, preventive maintenance costand the true cost of lost production.

Purchase. Look past initial price.Consider the financing options availableas well as day-to-day operating costs.Look at dealer services that can beincluded in the cost of the machineto yield lower equipment owning andoperating costs over the long run.

Customer Support Agreements.Cat dealers offer a variety of productsupport agreements and work with theircustomers to develop a plan that bestmeets specific needs. These plans cancover the entire machine, includingattachments, to help protect thecustomer’s investment.

Product Support. You will find nearlyall parts at our dealer parts counter.Cat dealers use a worldwide computernetwork to find in-stock parts to minimizedowntime. Save money with genuineCat® Reman parts. You receive the samewarranty and reliability as new productsat cost savings of 40 to 70 percent.

Operation. Improving operatingtechniques can boost your profits.Your Cat dealer has training video tapes,literature, application and equipmenttraining courses and other ideas to helpyou increase productivity.

Maintenance Services. More equipmentbuyers are planning for effectivemaintenance before buying equipment.Choose from your Cat dealer’s widerange of maintenance services at thetime you purchase your machine.Repair option programs guarantee thecost of repairs up front. Diagnosticprograms such as S·O·SSM and CoolantSampling and Technical Analysis helpyou avoid unscheduled repairs.

Replacement. Repair, rebuild or replace?Your Cat dealer can help you evaluatethe cost involved so you can makethe right choice.

SAFETY.CAT.COM™.

14

Complete Customer SupportCaterpillar® dealers are there to help you keep your machines up and running formaximum productivity.

15824H Wheel Dozer specifications

Transmission

Converter Drive – Forward 1 6.1 kph 3.8 mphConverter Drive – Forward 2 10.5 kph 6.5 mphConverter Drive – Forward 3 18.3 kph 11.5 mphConverter Drive – Forward 4 32.1 kph 20 mphConverter Drive – Reverse 1 6.9 kph 4.3 mphConverter Drive – Reverse 2 12 kph 7.5 mphConverter Drive – Reverse 3 20.8 kph 13 mphConverter Drive – Reverse 4 36.6 kph 22.7 mph

• Travel speeds based on two percent rolling resistanceand 29.5-25 L-3 tires.

510

60555045403530252015

2

Machine Ground Speed (kph/mph)

Rim

pull

(kg/

lb)

Tota

l Res

ista

nce

(%)

(Gra

de +

Rol

ling)

mph

lb x1000

0 2 4 6 8 10 12 14 16 18 20 22 240

10

20

30

40

50

60

70

80

0

4

8

12

16

20

24

28

32

36

kph

kg x1000

1st Gear

2nd Gear

0 4 8 12 16 20 24 28 32 36

3rd Gear

4th Gear

Engine

Engine Model Cat® C15 diesel withACERT™ Technology

Gross Power 299 kW 401 hpNet Power 264 kW 354 hpDirect Drive Net Power – 264 kW 354 hpCaterpillarDirect Drive Net Power – 264 kW 354 hpEEC 80/1269Direct Drive Net Power – 264 kW 354 hpISO 9249Direct Drive Net Power – 261 kW 350 hpSAE J1349 (JAN90)Converter Drive Net Power – 264 kW 354 hpCaterpillarConverter Drive Net Power – 264 kW 354 hpEEC 80/1269Converter Drive Net Power – 264 kW 354 hpISO 9249Converter Drive Net Power – 261 kW 350 hpSAE J1349 (JAN90)Bore 137 mm 5.4 inStroke 171 mm 6.7 inDisplacement 15.2 L 928 in3

• These ratings apply at 1,800 rpm when tested under thespecific standard conditions for the specified standard.

• Engine is U.S. EPA Tier 3/EU Stage III compliant.

• Power conditions based on standard air conditions at 25° C(77° F) and 99 kPa (29.32 in Hg) dry barometer, using 35° APIgravity fuel having an LHV of 42 780 kJ/kg (18,390 Btu/lb)when used at 30° C (86° F). Reference a fuel density of838.9 g/L (7.001 lb/gal).

• Net power advertised is the power available (at theflywheel) when the engine is equipped with air cleaner,muffler, alternator and hydraulic fan drive.

• No derating required up to 3050 m (10,000 ft) altitude.

16 824H Wheel Dozer specifications

Cab

Cab ROPS/FOPS is standardSound Performance Levels Meet ANSI/SAE, SAE and

ISO standardsROPS/FOPS Meets SAE and

ISO standards

• Integrated Rollover Protective Structure (ROPS) andFalling Objects Protective Structure (FOPS) is standardin North America, Europe and Japan.

• Operator sound exposure Leq (equivalent sound pressurelevel) measured according to the work cycle proceduresspecified in ANSI/SAE J1166 OCT98 is 78 dB(A) for the caboffered by Caterpillar when properly installed, maintainedand tested with the doors and windows closed.

• Hearing protection may be needed when operating withan open operator station and cab (when not properlymaintained or doors/windows open) for extended periodsor in noisy environment.

• Exterior sound pressure level for the standard machinemeasured at a distance of 15 m (49.2 ft) according to the testprocedures specified in SAE J88 JUN86, mid-gear movingoperation is 81 dB(A).

• Sound power level is 114 dB(A) measured accordingto the dynamic test procedure and conditions specifiedin ISO 6395:1988/Amd. 1:1996 for a standard machineconfiguration.

• For CE marked configurations, labeled sound power level is109 dB(A) measured according to the test procedures andconditions specified in 2000/14/EC.

• ROPS meets SAE J1394, SAE J1040 APR88, ISO 3471-1:1986and ISO 3471:1994.

• FOPS meets SAE J231 JAN81 and ISO 3449-1992 Level II.

Blade Specifications

Blade Capacities 4.67 m3-16 m3

(6.1 yd3-21 yd3)Straight Blade – Capacity 4.67 m3 6.11 yd3

Straight Blade – Overall Width 4507 mm 14.78 ftStraight Blade – Height 1229 mm 4.03 ftStraight Blade – Digging Depth 430 mm 1.4 ftMaximum Lift Above Ground 1070 mm 3.5 ftStraight Blade – Maximum Tilt 1184 mm 3.88 ftStraight Blade – Weight 3196 kg 7,047 lbStraight Blade 28 724 kg 63,325 lb– Total Operating Weight

Hydraulic System

Lift cylinder, bore and stroke 120.65 mm × 915 mm(4.75 in × 36.0 in)

Steering cylinder, 114.3 mm × 576 mmbore and stroke (4.5 in × 22.7 in)Right tilt and tip, 152.4 mm × 255 mmbore and stroke (6 in × 10.0 in)Left tilt and tip, 133.75 mm × 255 mmbore and stroke (5.3 in × 10.0 in)Relief valve setting 24 125 kPa 3,500 psi

Brakes

Brakes Meet SAE/ISO 3450 1996

Axles

Front FixedRear Oscillating ±13°

Weights

Operating Weight 28 724 kg 63,325 lb

Service Refill Capacities

Fuel Tank – standard 700 L 185 galCooling system 83 L 21.9 galCrankcase 34 L 9 galTransmission 62 L 16.4 galHydraulic tank 88 L 23.2 galDifferentials and final drives 90 L 23.8 gal– FrontDifferentials and final drives 90 L 23.8 gal– Rear

17824H Wheel Dozer specifications

DimensionsAll dimensions are approximate.

1 Height to Top of Cab 3700 mm 12.14 ft2 Height to Top of Exhaust Pipe 3590 mm 11.78 ft3 Height to Top of Hood 2635 mm 8.64 ft4 Ground Clearance to Bumper 885 mm 2.9 ft5 Height to Bottom of Ladder 446 mm 1.46 ft6 Center Line of Rear Axle 2787 mm 8.82 ft

to Edge of Bumper

7 Center Line of Rear 1850 mm 6.07 ftAxle to Hitch

8 Wheelbase 3700 mm 12.14 ft9 Length with Blade on Ground 8224 mm 26.98 ft10 Ground Clearance 358 mm 1.17 ft

12

3

45

6 7

8

9

10

Overall Digging Ground MaximumBlade Type Capacity Width Height Depth Clearance TiltNo-Blade Option N/A

Straight Blade – Skid Plate 4.67 m3 4507 mm 1229 mm 430 mm 1070 mm 1184 mm6.11 yd3 14.78 ft 4.03 ft 1.4 ft 3.5 ft 3.88 ft

Straight Blade – Wear Plate 4.67 m3 4507 mm 1229 mm 430 mm 1070 mm 1184 mm6.11 yd3 14.78 ft 4.03 ft 1.4 ft 3.5 ft 3.88 ft

SU-Blade 6.88 m3 4439 mm 1584 mm 542 mm 996 mm 1166 mm9.0 yd3 14.56 ft 5.2 ft 1.78 ft 3.27 ft 3.82 ft

U-Blade 6.88 m3 4336 mm 1365 mm 518 mm 956 mm 1139 mm9.0 yd3 14.23 ft 4.48 ft 1.69 ft 3.13 ft 3.73 ft

Extreme Service U-Blade includes 6.88 m3 4336 mm 1365 mm 518 mm 956 mm 1139 mmBulldozer Arrangement with ARM 9.0 yd3 14.23 ft 4.48 ft 1.69 ft 3.13 ft 3.73 ft

Woodchip Blade 23.7 m3 4775 mm 2261 mm 536 mm 1060 mm 1254 mm31.0 yd3 15.67 ft 7.42 ft 1.75 ft 3.47 ft 4.11 ft

Coal Blade 16.0 m3 4800 mm 1803 mm 536 mm 1060 mm 1254 mm21.0 yd3 15.75 ft 5.92 ft 1.75 ft 3.47 ft 4.11 ft

Blade Specifications

18 824H Wheel Dozer specifications

Standard EquipmentStandard equipment may vary. Consult your Caterpillar dealer for details.

Seat, Comfort Series (cloth), air suspensionSeat belt, retractable, 76 mm (3 in) wideTilt and lift control system lockTransmission gear indicatorWet-arm wipers/washers (front and rear)

Intermittent front wiperPOWER TRAIN

Brakes, full hydraulic, enclosed, wet-discCat axles, outboard final drivesDemand fan, hydraulicElectronic fuel priming pumpEngine, Cat C15 MEUI with ACERT™ Technology,

ATAAC, ADEM™ IV controllerMuffler, sound-suppressedPrecleaner, engine air intakeRadiator, Next Generation Modular Radiator (NGMR)Separated cooling systemStarting aid (ether)Throttle lockSwitch, transmission neutralizer lockoutTorque converterTransmission, planetary, autoshift (4F/4R)

OTHER STANDARD EQUIPMENTAuto Blade Positioner (ABP)Caterpillar o-ring face seals couplings and XT™ hosesCoolers

Engine oil, hydraulic oil and transmission oilDoors, service access (locking)Engine, crankcase, 500 hour interval with CH-4 oilGrouped Electronic Clutch Pressure Control, remote

mounted pressure tapsHitch, drawbar with pinHood, metallic with lockable service doorsMuffler (under hood)Oil sampling valvesVandalism protection caplocksVenturi stack

BULLDOZERSBulldozer is not included in standard equipment

TIRES, RIMS AND WHEELSA tire must be selected from the mandatory attachments

section – base machine price includes a tire allowanceANTIFREEZE

Premixed 50 percent concentration of Extended LifeCoolant with freeze protection to –34° C (–29° F)

ELECTRICALAlarm, back-upAlternator (95-amp)Batteries, maintenance-free (four 1,000 CCA)Diagnostic connectorElectrical system (24-volt)Lighting system, halogen (front and rear)Lockable master disconnect switchStarter, electric (heavy-duty)Starting receptacle for emergency starts

OPERATOR ENVIRONMENTAir conditionerCab, pressurized and sound suppressed

Internal four-post rollover protective structure(ROPS/FOPS), radio ready (communication/entertainment) includes antenna, speakers and converter(12-volt, 15 amp), 12 volt power port, tinted glass

Cigar lighter (12-volt, 15-amp) and ashtrayCoat hookCommand Control steeringElectro-Hydraulic tilt, tip and Automatic Blade Positioning

(ABP) controlsFingertip shift controls (steering wheel mounted)Gear selection displayHeater and defrosterHorn, electricAction alert system, three category

Instrumentation, gauges:Engine coolant temperatureFuel levelHydraulic oil temperatureSpeedometer/TachometerTorque converter oil temperature

Instrumentation, warning indicatorsAir inlet temperatureBrake oil pressureElectrical system, low voltageEngine oil pressureEngine overspeedFuel filter statusParking brake statusSteering oil pressureTransmission filter status

Light, cab (dome)Lunchbox and beverage holdersMirrors, rearview (externally mounted)

19824H Wheel Dozer specifications

kg lb

Tires, Rims and WheelsNote: All tires are tubeless, include

rims and come in sets of fourFirestone

29.5-25 22 PR FS L3 –437 –96429.5-25 22 PR FS L4 85 18829.5-25 22 PR FS L5 622 1,372

General 29.5-25 22 PR GEN L4 40 8829.5-25 22 PR GEN L5 314 692

Goodyear 29.5R25 GP 2B * GY L3 –82 –18029.5-25 22 PR GY L3 –323 –71229.5-25 22 PR GY L4 337 74429.5-25 22 PR GY L5 951 2,096

Michelin (no charge option) 29.5RR25 XHA * MX L3 0 0

Omission, Tires and Rims –3852 –8,492Omission of Tires –3158 –6,962

kg lb

Bulldozer ArrangementStraight Blade – Skid Plate4.67 m3 (6.11 yd3) 5320 11,730Straight Blade – Wear Plate4.67 m3 (6.11 yd3) 5320 11,730Extended Wear –6.9 m3 (9.0 yd3) 7705 16,990Coal Blade –16 m3 (21 yd3) 6543 14,425No Blade 3350 7,385

Mandatory Attachments (select one from each group)

Mandatory equipment may vary. Consult your Caterpillar dealer for specifics.

kg lb

Counterweight 2227 4,910

Electrical

Lights, cab auxiliary 3 7

Lights, directional signal 2 4

Fast Fuel Adapter 4 9

Fenders, Front and Rear Roading 604 1,333

Guards, Drive Shaft

Use with counterweight 20 44

Use without counterweight 58 127

Operator Environment

Mirror, internal (panoramic) 5 10

Mirror, internal (rearview) 3 7

Radio, AM/FM, weatherband, cassette 2 4

Sliding cab window 13 28

Visor, front 5 10

Wiper, intermittent (rear) 1 2

kg lb

Power Train

Differential, No-SPIN rear 2 4

Starting Aids

Heater, engine coolant 2 4

Heater, 220-volt 1 3

Miscellaneous Attachments

Oil change, high speed 1 3

Precleaner, turbine/trash 14 30

Product Link 3 7

Secondary steering 37 72

Sound suppression 103 227

Special application end bits 15 32

Computer Aided EarthmovingSystem (CAES) ready 8 18

Antifreeze 0 0

Optional Equipment (with approximate change in operating weight)

Optional equipment may vary. Consult your Caterpillar dealer for specifics.

R

For more complete information on Cat products, dealer services,and industry solutions, visit us on the web at www.cat.com

© 2007 CaterpillarAll Rights Reserved

Printed in U.S.A.

Materials and specifications are subject to change without notice.Featured machines in photos may include additional equipment.

See your Caterpillar dealer for available options.

CAT, CATERPILLAR, ACERT, SAFETY.CAT.COM, their respective logos, “Caterpillar Yellow”and the POWER EDGE trade dress, as well as corporate and product identity used

herein, are trademarks of Caterpillar and may not be used without permission.

AEHQ5615-02 (10-07)

Replaces AEHQ5615-01

824H Wheel Dozer