University of NewCastle- Pipeline Risk

-

Upload

hossein-zohdi-rad -

Category

Documents

-

view

216 -

download

0

Transcript of University of NewCastle- Pipeline Risk

-

8/13/2019 University of NewCastle- Pipeline Risk

1/19

Universityof

NewcastleuponTyne

Pipelines Safety - Risk Quantification

This lecture will cover the following aspects:-

MSc in Pipelines Engineering

How are pipeline failure risks quantified?

What pipeline databases exist for failure rates?

What are typical failure rates for pipelines

How is Consequence Analysis carried out?

Which Risk Criteria are applied for pipelines?

UniversityofNewcastleuponTyne

How are pipeline failure risks quantified?Risk Assessment Studies

Risk Tolerability

- i s i t OK?

- how bad?

Consequence Analysis

- how often?

Frequency Analysis

- what can happen?

Hazard Identification

Incident Data - Historical

Fault data - extrapolation

Predictive Modelling, FractureMechanics

Release - leak rate, rain out

Dispersion

Effects

External Impact, Corrosion

Mechanical defect, Natural

Other, Rupture, Puncture, Pinhole

Gas jet / plume

Pool Evaporation

Wind/ Weather

Individual Risk / Transects/ Societal Risk

Criteria / Land Use Planning Zones

Fire Radiation

Explosion Overpressure

Toxic Effects

-

8/13/2019 University of NewCastle- Pipeline Risk

2/19

Universityof

NewcastleuponTyne

How are pipeline failure risks quantified?

Usual measure is

frequency of specific incidentsuch as pinhole or puncture or rupture

Per 1000 kilometres per year ( per km.yrs)

which is equivalent to

Per metre per million years ( x 10-6 per year)

or

Per kilometre per thousand years ( x 10-3 per year)

UniversityofNewcastleuponTyne

s What pipeline databases exist for failure rates?

1 European Gas Pipeline Incident Data Group

(EGIG)

Objectives

To demonstrate the high safety level of European gas transmissionpipelines

To provide non-EGIG members with the best available failure dataon gas pipeline incidents

-

8/13/2019 University of NewCastle- Pipeline Risk

3/19

Universityof

NewcastleuponTyne

Objectives

To demonstrate the high safety level of Europe

an gas transmission pipelines

To provide non-EGIG members with the best

available failure data on gas pipeline incidents

Scope

Only pipeline incidents with an unintentional

gas release

Only onshore gas transmission pipelines

steel pipelines

design pressure > 15 bar

outside fences of installations

excluding associated equipment(e.g. valves, compressors) or parts other

than the pipeline itself

European Gas Pipeline Incident Data Group

UniversityofNewcastleuponTyne

Participants

Dansk Gasteknisk Center a/s represented by

DONG (Denmark)

ENAGAS, S.A. (Spain)

Gaz de France (France)

N.V. Nederlandse Gasunie (The Netherlands)Ruhrgas AG (Germany)

Distrigas n.v. (Belgium)

SNAM S.p.A. (Italy)

SWISSGAS (Switzerland)

Transco (part of BG), represented by

BG Technology (England)

European Gas Pipeline Incident Data Group

-

8/13/2019 University of NewCastle- Pipeline Risk

4/19

Universityof

NewcastleuponTyne

An extensive analysis on collected information has lead to thefollowing results:

Over the period 1970 - 1998 there has been no fatal accidentinvolving inhabitants.

The overall incident frequency with an unintentional gas release overthe period 1970 to 1998 is 0,480 incidents per year per 1000 km pipeline.However, the figure over the past 5 years is significantly lower:0,211 incidents per year per 1000 km pipeline.

External interference remains the main cause of gas pipeline incidentsinvolving gas leakage; an average of 0,239 incidents per year per1000 km pipeline for the period 1970 to 1998.

An improvement in the incident frequency has been observed inrecent years; over the past 5 years the figure is 0,087 incidents per yearper 1000 km pipeline.

For the incident causes 'corrosion' and 'construction defects/material failures no ageing could be demonstrated.

Summary 4th EGIG report 1999

UniversityofNewcastleuponTyne

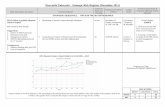

EGIG - Failure frequency trend 1970-98

-

8/13/2019 University of NewCastle- Pipeline Risk

5/19

Universityof

NewcastleuponTyne

2 CONCAWE - the oil companies study groupfor Conservation of Clean Air and Water - Europe

UniversityofNewcastleuponTyne

The latest in a series of annual issues, this report reviews the performance in

2000 of 30,870 km of on-shore oil pipelines in Western Europe with regards tohydrocarbon spillage. Incidents are analysed by cause and the effectivenessof the clean-up is recorded. Direct repair and clean-up costs are reported.

Performance in 2000 was markedly better than the long-term average,third party activities remaining the main cause of spillage incidents.

The report also gives the annual pigging inspection statistics.Some 3000 km of pipeline were internally inspected in 2000.

75% of the pipeline inventory has now been inspected with such tools.

Performance of cross-country oil pipelines in Western Europe

Statistical summary of reported spillages 2000

CONCAWE Database

-

8/13/2019 University of NewCastle- Pipeline Risk

6/19

Universityof

NewcastleuponTyne

Sixty-six companies and other bodies operating oil pipelines inWestern Europe currently provide statistics for the CONCAWE

annual report on the performance of cross-country oil pipelines.

These organisations operate some 250 different service pipelineswhich at the end of 2000 had a combined length of 30,780 km,an increase of 860 km since 1999.

Volume transported in 2000 was 672 Mm3 of crude oil and refinedproducts, which is 1.5 Mm3 less than in 1999.

Total traffic volume in 2000 amounted to 126 x 109 m3 x km,1% higher than in 1999.There were 6 reported oil spillages from pipelines during 2000

(12.6 per year on average since 1971).There were no associated fires or injuries.

The net oil loss into the environment amounted to 84 m3,equivalent to 0.1 parts per million (ppm) of the total volume transported.

The gross spillage was 360 m3, which is 0.5 ppm.A total of 276 m3, i.e., 77% of the spillage was recovered.

CONCAWE Database

UniversityofNewcastleuponTyne

The causes of the oil spillages are attributed to:

? Mechanical failure 1 incident

? Operational 0 incidents

? Corrosion 1 incident

? Natural hazard 0 incidents

? Third party activity 4 incidents

CONCAWE Database

-

8/13/2019 University of NewCastle- Pipeline Risk

7/19

Universityof

NewcastleuponTyne

CONCAWE Database

UniversityofNewcastleuponTyne

CONCAWE Database

Typical failure rate data for Crude Oil pipelines < 202 mm diameter:-

Pinhole Puncture Rupture Total

Third party 0.313 0.537 0.359 1.209

Mechanical 0.106 0.091 0.106 0.303

Natural 0.003 0.073 0.227 0.303

Total 0.412 0.701 0.692 1.815

-

8/13/2019 University of NewCastle- Pipeline Risk

8/19

Universityof

NewcastleuponTyne

UKOPA Database

for UK Gas Pipeline Data

Pipeline and product loss incident data from onshore Major Accident

Hazard Pipelines (MAHPs) operated by Transco, Shell UK, BP, Huntsman

and Powergen UK, covering operating experience up to the end of 2000.

United Kingdom Onshore Pipelines

Operators Association 14 major UK pipeline operators

includes gas and oil pipelines operators

covered by Pipelines Safety Regulations 1996

5 Companies have pooled Fault and Leak

Data covering 96% of Major Accident Hazard

Gas and Liquid Pipelines in the UK

UniversityofNewcastleuponTyne

The overall failure frequency overthe period 1961 to 2000 is 0.289incidents per 1000 km.year.

The failure frequency over the last 5 years is 0.093incidents per 1000 km.year.

A further report will cover predicted failurefrequencies based on models of the growth ofpart-wall defects where no product loss hasoccurred, in order to provide failure frequencies

for pipeline groups where historical failure dataare sparse.

UKOPA Database

for UK Gas Pipeline Data

-

8/13/2019 University of NewCastle- Pipeline Risk

9/19

Universityof

NewcastleuponTyne

Butane 19.5 Propylene 36.3CO 36.3 LPG 9.6

Condensate 24.0 Natural Gas (Dry) 19,947.7Crude Oil (Spiked) 212.6 Other 318.3

Ethane 38.1 Propane 19.5

Ethylene 1,198.5 TOTAL 21,860

Period Number of

Incidents

Total

Exposure[km.yr]

Frequency

[Incidents per 1000km.yr]961 - 1965 6 10,261 0.585966 - 1970 21 35,115 0.598971 - 1975 25 65,411 0.382

976 - 1980 27 80,322 0.336981 - 1985 40 90,497 0.442986 - 1990 33 96,728 0.341991 - 1995 9 103,672 0.087996 - 2000 10 107,508 0.093

Hole SizeClass

Number ofIncidents

Frequency[Incidents per 1000

km.yr]

Full Bore* 7 0.012

50mm 16 0.02720mm 36 0.061

6mm 63 0.106

0 Full Bore 171 0.289

UKOPA Database

for UK GasPipeline Data

UniversityofNewcastleuponTyne

UKOPA Database

for UK Gas Pipeline Data

Development of Overall Incident Frequency

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1962

1964

1966

1968

1970

1972

1974

1976

1978

1980

1982

1984

1986

1988

1990

1992

1994

1996

1998

2000

Year

Frequencyper1000km.yr Overall Average up to Year

Moving 5-year Average

-

8/13/2019 University of NewCastle- Pipeline Risk

10/19

Universityof

NewcastleuponTyne

Development of Incident Frequency by Cause

0

0.05

0.1

0.15

0.2

0.25

0.3

0.35

0.4

0.45

19

60

19

62

19

64

19

66

19

68

19

70

19

72

19

74

19

76

19

78

19

80

19

82

19

84

19

86

19

88

19

90

19

92

19

94

19

96

19

98

20

00

Year

Frequencyper1000km.yr

External Corrosion External InterferenceGround Movement Internal CorrosionGirth Weld Defect Other Pipe Defect Seam Weld DefectUnknown

UKOPA Database

for UK Gas Pipeline Data

UniversityofNewcastleuponTyne

Historical and Recent Failure Frequencies

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

Extern

alCorrosion

ExternalIn

terference

Ground

Movem

ent

Intern

alCo

rrosio

n

GirthWe

ldDefe

ct Other

PipeD

efect

Seam

Weld

Defect

Unkn

own

Cause

Frequency

per1000km.yr

1960-2000

1996-2000

UKOPA Database

for UK Gas Pipeline Data

-

8/13/2019 University of NewCastle- Pipeline Risk

11/19

Universityof

NewcastleuponTyne

Product Loss Incidents Caused by External Interference

Frequency by Wall Thickness and Hole Equiv. Diameter

0

0.05

0.1

0.15

0.2

0.25

0.3

15Wall Thickness Class (mm)

Frequencyper1000km.yr

0 - 6

6 - 20

20 - 50

50+

Full Bore

UKOPA Database

for UK Gas Pipeline Data

UniversityofNewcastleuponTyne

Assimilate failure rate data into diameter ranges:-

Diameter

range mm

EGIG 1000-km-

year

BG 1000-km-year

0-100 0.719 0.239

125-250 0.429 0.168300-400 0.163 0.086

450-550 0.067 0.046

600-700 0.027 0.025750-850 0.011 0.014

900-1000 0.005 0.0071000+ 0.002 0.005

Adjust failure rate for mitigation factors:-

Depth of cover Normalised Failure Reduction

(Inflation) factor1.22 m 0.7

s What are typical failure rates for pipelines

-

8/13/2019 University of NewCastle- Pipeline Risk

12/19

Universityof

NewcastleuponTyne

Pipeline Location Normalised Failure Reduction

(Inflation) factorRural 1.0

Suburban 3.9Town 23.1

Mitigation measure Normalised FailureReduction (Inflation)

factorMarker posts 1.0

All other measuresSlabbing, concreteetc (under review)

0.9

Diameter Min wall

thickness

Normalised wall thickness failure frequency factor

4.8,

6.4,7.99.5

1504509001050 12.7 XXX XXX XXX XXX XXX

UniversityofNewcastleuponTyne

What do you do if no failures have

occurred for a pipeline diameter range?

- use Predictive Models

1 Linear regression Analysis - EGIG Data

-

8/13/2019 University of NewCastle- Pipeline Risk

13/19

Universityof

NewcastleuponTyne

Linear Regression Analysis

Log to base 10 of failure frequency

Diameter midpoints as X- values

Parameters calculated for known datasets giving

Y = MX + C equation = -0.00258X + 0.11456

UniversityofNewcastleuponTyne

Linear Regression Analysis

-

8/13/2019 University of NewCastle- Pipeline Risk

14/19

Universityof

NewcastleuponTyne

Alternatively, Use Fault Data to predict

Failure Rate

UKOPA Fault Database

Structural Reliability Analysis combines theoretical and

empirical structural mechanics with uncertainty analysisof structural parameters in order to determine failure

probabilities

Uses parameters for which statistically significant numbers of

measured values are often available (e.g. wall thickness and

yield strength) in predictive models (limit state functions) in

order to predict the uncertainty in parameters for which

statistically significant databases are unavailable

(e.g. leak & rupture incidents).

UniversityofNewcastleuponTyne

Assess Zones affected by each failure:

- pinhole - small area - ignored

- puncture

- rupture - most significant affect

Consequence Analysis carried out for

- fireball - circular area affected by thermal radiation

from fireball formed by up to 30 seconds

release from the ruptured pipeline

- flammable fluid - ignition / no ignition probability

How is Consequence Analysis carried out?

-

8/13/2019 University of NewCastle- Pipeline Risk

15/19

Universityof

NewcastleuponTyne

- flash fire - directional ellipse area affected

Complex geometric calculation to

assess probability of being affected

at a specific distance from the pipeline

- jet fire - directional dependent of whether jet is

free and unobstructed or there is

interference with crater

- often modelled as worst-case circular effect

- explosion - directional dependent on source of

overpressure and location of source of

ignition

- not usually modelled for Natural gas

Probabilities of each OUTCOME calculated from an

EVENT TREE:-

UniversityofNewcastleuponTyne

MISHAP Event Tree for Gas Release

Immediate Release Delayed Delayed

Ignition Obstructed Local Remote Ignition Ignition

0.25 Yes Fireball+jetfire

0.2 0.2

0.8 Daytime

0.75 No 0.5 Yes 0.25 Yes Jetfire

Gas Release 0.6 0.3 0.075 0.075

0.75 No No ignition

0.225 0.225

0.5 No 0.25 Yes Jetfire

0.3 0.075 0.075

0 .75 No 0.1 Yes Flahfire+jetfire

0.225 0.0225 0.0225

0.9 No No ign ition

0.2025 0.2025

0.25 Yes Fireball+jetfire

0.05 0.05

0.2 Nightime

0.75 No 0.5 Yes 0.25 Yes Jetfire

0.15 0.075 0.01875 0.01875

TOTALS0.75 No No ignition

Fireball + jetfire 0.25 0.05625 0.05625

Jetfire 0.1875

Flashfire + jetfir 0.0281 0.5 No 0.25 Yes Jetfire

No Ignition 0.5344 0.075 0.01875 0.01875

total 10. 75 No 0.1 Yes Flahfire+jetfire

0.05625 0.0056 0.005625

0.9 No No ign ition

0.0506 0.050625

-

8/13/2019 University of NewCastle- Pipeline Risk

16/19

Universityof

NewcastleuponTyne

Important to calculate the length of pipeline

which can affect someone at various distances

from a pipeline:-

Interaction distance = 2 x radius of circle= length of pipeline which could affect you

Pipeline

Fireball

If you are standing here

Interaction

distance

If you are standing here

Interaction

distance

Fireball RR

D

Int Dist

Interaction distance = 2 x (R2-D2)

UniversityofNewcastleuponTyne

Risk = frequency of rupture incidents / metre per 10-6 years

x number of metres of pipeline which can affect individual

(interaction distance)

= effect per 10-6 years

-

8/13/2019 University of NewCastle- Pipeline Risk

17/19

Universityof

NewcastleuponTyne

Frequency and Consequences of each event

are assessed to give the RISK TRANSECT:-

Risk

Pipeline

50 100 150 200200 150 100 50

FireballFlashfire

Jetfire

Total

Risk

UniversityofNewcastleuponTyne

Typical Risk Transect from IG/TD/1

-

8/13/2019 University of NewCastle- Pipeline Risk

18/19

Universityof

NewcastleuponTyne pipeline

innerzon

e

inner zone

- no housing at all allowed

- calculated from fireball radius full bore rupture

(NOT risk based)

- typically 85 metres for 10.75 " (270mm) 100 bar

ethylene pipeline

Risk Criteria - Land Use Planning

UniversityofNewcastleuponTyne

middlezo

ne pipeline

middle zone

- only a small increase in population allowed

- calculated from risk to 1 in a million (10-6 per year)

- typically 240 metres for 10.75 " (270mm) 100 bar

ethylene pipeline

Risk Criteria - Land Use Planning

-

8/13/2019 University of NewCastle- Pipeline Risk

19/19

Universityof

NewcastleuponTyne

outerz

one

pipeline

outer zone

- no vulnerable population allowed

- calculated from risk to 0.3 in a million (3 X 10-7 per year

- typically 320 metres for 10.75 " (270mm) 100 bar

Risk Criteria - Land Use Planning

UniversityofNewcastleuponTyne

Typical Societal

Risk Curve from

IG/TD/1