The Ellingham Diagram: How to Use It in Heat-Treat-Process Atmosphere Troubleshooting

description

Transcript of The Ellingham Diagram: How to Use It in Heat-Treat-Process Atmosphere Troubleshooting

-

arold Johann Thomas Elling-ham (1897-1975) was a Brit-ish physical chemist and is best known for the diagrams

named after him that plot the change in standard free energy with respect to tem-perature for reactions like the formation of oxides, sul des and chlorine of various elements, such as:

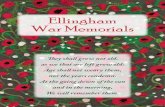

2x y M + O2 2 y MxOy The oxide plot tends to be the most common and will be highlighted here as its applicability to heat-treating processes is the most relevant. This phenomenon was known before Ellinghams time, but Ellingham demonstrated it more clearly and made it more accessible to industry as a tool. His diagram and its variants help to select the best reducing agent for various ores in the extractive-metal process. Ellingham discovered that by normal-izing the thermodynamic functions to a given reaction with one mole of oxygen he was able to compare the temperature sta-bility of many different oxides on the same diagram. In particular, and this reaction is critical to metal reduction systems that use carbon dioxide, he could show graphically that carbon becomes a stronger reducing agent as the temperature increases. The reduction of metal oxides with carbon (or carbon monoxide) to form the free, re-duced metals is of immense industrial im-portance (blast furnace reduction of iron ores), and Ellingham diagrams show the lowest temperature at which the reaction will occur for each metal.

Lets restate and go stepwise through the Ellingham diagram to set up and make clearer how metal heat treaters can use it. We can adapt the diagram from its origi-nal use as a higher-temperature extractive-metallurgy tool to one where we can pre-dict the effects of protective atmospheres and common atmosphere impurities and their impact on heat-treated product. See Fig. 1 for the classic Ellingham diagram that would typically be used for heat-treat-ing atmosphere processes.

BackgroundAn Ellingham diagram is a plot of 6G (change in Gibbs free energy) versus tem-perature, which, for our purposes, would be a temperature in a continuous furnace by zone or in a batch furnace by time in the cycle. The Ellingham diagram shown is for metals reacting to form oxides. Since any explanation of how to cal-culate and plot an Ellingham diagram is more about the mechanics of the deriva-tion process and less about how to use the tool, which is the intent of this article, the concept is covered very brie y here. Enthalpy (6H) and entropy (6S) are essentially constant with temperature. Unless a phase change occurs, the free en-ergy (6G) versus temperature plot can be drawn as a series of straight lines, where 6S is the slope and 6H is the y-intercept.

6G = 6H T 6S

The slopes of those plotted lines change when any of the materials involved melt (M) or vaporize/boil (B). In a heat-treat

system this is (for the most part) irrel-evant, except in the brazing and sinter-ing processes where those phase changes (melting) can indeed occur. The free energy of formation is nega-tive for most metal oxides, which means the reaction can proceed without further in uence. Therefore, the diagram is drawn with 6G=0 at the top of the diagram, and the values of 6G shown are all negative numbers. Temperatures where either the metal or oxide melt (M) or vaporize (B) are marked on the diagram. Note that the majority of the plots for metals slope upward because both the metal and the oxide exist as condensed solid or liquid phases. The oxygen partial pressure is taken as 1 atmosphere, and all of the reactions are normalized then plot-ted to represent consumption of one mole of O2. Interestingly, there are two plots that do not look like all of the others.

C + O2 => CO2

Carbon, a solid, reacts with one mole of oxygen and produces one mole of car-bon dioxide (CO2), which results in little change of entropy an almost horizontal plot. The other has a distinct negative slope:

2C + O2 => 2CO

In this reaction, a solid once more re-acts with one mole of gas but produces two moles of gas carbon monoxide (CO). This causes a substantial increase in entropy, and the plot has a distinct

ah

bHH

FEATURE | Industrial Gases/Combustion

IndustrialHeating.com - April 2011 55

The Ellingham Diagram: The Ellingham Diagram: How to Use it in Heat-Treat-Process How to Use it in Heat-Treat-Process Atmosphere TroubleshootingAtmosphere TroubleshootingMichael J. Stempo Air Liquide International U.S. LP; Houston, Texas

The Ellingham diagram is not always thought of as a heat-treaters tool. This article demonstrates its usefulness.

-

56 April 2011 - IndustrialHeating.com

FEATURE | Industrial Gases/Combustion

negative slope. The severe negative slope of this car-bon reaction results in an increasingly more powerful reducing agent as tempera-ture increases. For example, at 1500C (2732F), the carbon reaction crosses un-der that for silicon dioxide (SiO2), result-ing in the potential ability to reduce the highly stable compound of SiO2 to silicon under oxygen-starved conditions. Note on the diagram there is a scale on the right and along the bottom of the graph illustrating PO2 (atm). PO2 is plot-ted showing partial-pressure values from 1 to 10-100. It will be shown how to use this scale in the next section, along with the scales immediately to the right of this one showing the relationship of PH2/H2O and PCO/CO2 to the various metals and their oxides as a function of temperature. These partial-pressure values and their associat-ed ratios can be plotted on the Ellingham diagram and can be obtained by sampling the process atmosphere at various temper-atures, or at speci c times (temperatures) in a cycle, using familiar and readily avail-able atmosphere analytical tools (oxygen, hydrogen, dewpoint/moisture, CO and CO2).

Ellingham Diagram for Metals ProcessingWhen plotting whether a given metal sys-tem will oxidize, reduce or remain as an oxide or pure metal, the Ellingham dia-gram does not indicate the quantitative rate of the reaction, only the probability of it occurring based on a given set of con-ditions. One can make the assumption that the reaction will qualitatively occur more rapidly as temperature increases or as the conditions for reducing or oxidation deviate farther from neutral-atmosphere conditions. We can use the diagram to determine the relative ease by which a metal can be oxidized or an oxide can be reduced. Metals plotted high up on the diagram are easier to reduce (noble metals) than those plotted lower on the diagram, which naturally tend to exist in very stable oxide forms. For example, Ag, or silver, is very hard to oxidize, while Ca, or calcium, does

not naturally exist in its elemental form, indicating a very stable oxide form. The metal/metal oxide plots also interrelate to each other. A metal plotted below anoth-er metal can reduce the oxide of the one plotted higher up the diagram. Hence tita-nium, not the oxide, can reduce the oxide of chromium, which is plotted higher on the diagram. We can also use the diagram to de-termine the following at a given tem-perature: The ratio of hydrogen to water/dew-

point (PH2/H2O) that can reduce a metal oxide to metal or prevent a metal from oxidizing

The ratio of CO to CO2 (PCO/CO2) that can reduce a metal oxide to metal or prevent a metal from oxidizing

The partial pressure of oxygen that will be in equilibrium with a metal oxide

Determining the Equilibrium Partial Pressure of Oxygen For a PO2 higher than the equilibrium value at a given temperature, the metal will be oxidized. Conversely, for an oxy-gen partial pressure that is lower than the equilibrium value at a given temperature, that metal will be reduced. Use the scale or nomograph to deter-mine the equilibrium PO2 by the follow-ing method. Using a straightedge and knowing the temperature or series of tem-peratures you wish to use (and the metal/metal-oxide system), put the one side of the straightedge on the upper left-hand corner of the diagram that is labeled O (near the Ag to silver-oxide plot). Next, position the straightedge from that an-chor point to the temperature point where the metal in question intersects that temperature value. Now, continue across

10-14 10-12 10-10 10-910-8 10-7 10-6 10-5 10-4 10-3 10-8 10-7 10-6 10-5 10-4 10-3

10-2

10-1

1

10

102

103

104

105

106

107

108

109

1010

1011

1012

10-2

10-1

1

10

102

103

104

105

106

107

108

109

1010

1011

1012

1013

110-1

10-210-310-4

10-5

10-8

10-10

10-12

10-14

10-16

10-18

10-20

10-22

10-24

10-26

10-28

10-30

4Ag + O2 = 2Ag2O

C + O2 = CO2

4Cu + O2 = 2Cu2

O

2C + O2 = 2CO

3/2Fe + O2 = 1/3Fe3O4

4/3Cr + O2 =

2/3Cr2O3 2Mn +

O2 = 2MnO

Si + O 2 = SiO 2

Ti + O 2 = TiO 2

4/3Al + O 2 =

2/3Al 2O 3

2Mg + O 2

= 2MgO

2Ca + O 2 =

2CaO

2Ni + O 2 =

2NiO

2Co + O 2 =

2CoO6Fe

+ O 2 = 2F

e 3O 4

o

-100

-200

-300

-400

-500

-600

-700

-800

-900

-1000

-1100

-1200

O

H

C

O Kelvin 1014

1013

0 200 400 600 800 1000 1200 1400 1600

10-100 10-80 10-60 10-50 10-42 10-38 10-34PO2,(atm)

PCO/PCO2PH2/PH2O

PH2/PH2OPCO/PCO2

6G =

RTI

npO 2

,kj

M Melting point of metalB Boiling Point of metalM Melting point of oxide

M

M

MM

M

M

M

M

M M M

M BB

M M

Temp. C

1300 C

2Co + O 2 =

2CO 2 2H2 + O2 = 2H2O

-

IndustrialHeating.com - April 2011 57

the straightedge plot to the value on the PO2 scale. This is the equilibrium partial pressure of oxygen. For this diagram, it is expressed in atmospheres. Once again, any oxygen partial pressure that is lower than the one derived will cause metallic reduction. Any partial pressure above will cause oxidation. For a real-life example, nd the equilib-rium partial pressure of oxygen for chromi-um at a temperature of 1300C (2372F). Put the straightedge on the O dot in the upper left hand corner of the diagram. Find the chromium plot and where it in-tersects the temperature of 1300C. While anchoring the one end of the straightedge on the O dot, move the other end of the straightedge so that it runs through that intersection point and continue down the straightedge to the PO2 scale. Read off the value, which should be 10-16 expressed in atmospheres. This is an extremely small amount of oxygen than can be present in

this high-temperature system before the deleterious effects of oxygen will adversely oxidize the metallic chromium. The effect of chromium oxidation by even the smallest amounts of oxygen can be countered by using a strong atmosphere reducing agent such as hydrogen. Lets go next to determining the equilibrium ratio (PH2/H2O) or the hydrogen-to-water (dew-point) ratio.

Determining the Equilibrium PH2/H2O Ratio For a PH2/H2O, or hydrogen-to-water ratio, that is higher than the equilibrium value relatively more hydrogen to water at a given temperature, the metal will be re-duced. For a PH2/H2O that is lower than the equilibrium value (relatively less hy-drogen to water) at a given temperature, the metal will be oxidized. Using essentially the same straightedge method that we used above to plot the

equilibrium partial pressure of oxygen, we now plot from the H dot on the left side of the diagram through our desired metal and desired temperature and now read from the PH2/H2O plot on the right side of the diagram. A real-life example would be to nd the equilibrium hydrogen-to-water ratio for chromium at a temperature of 1300C. Lo-cate the straightedge left side on the H dot, pass through the chromium equation where it intersects at 1300C and read off the equilibrium hydrogen-to-water ratio value on the PH2/H2O scale. The value should be between 102 and 103. This rep-resents a value of between 100 and 1,000 to 1 ratio of hydrogen needed to water or dewpoint level. For this exercise, we can estimate the hydrogen-to-water ratio to be 400 to 1. This is a high level of hydrogen that is necessary to counter the oxidizing ef-fects of water or dewpoint on chromium,

Count on Furnace Parts, LLC, to meet all your needs for Industrial Thermocouplesand Temperature Sensors. We offer a full range of products and services, including:

Mineral Insulated Metal Sheathed Thermocouples (MgO) Noble Metal and High Temperature ThermocouplesTypes S, R, B and C Base Metal ThermocouplesTypes J, K, N, T and E Insulated Thermocouple and Extension Wire NIST Traceable Calibration Services

ISO 9001:2008 and ISO/IEC 17025:2005 accredited since 2000.

We are dedicated to providing our customers with the highest level of service, creativesolutions and short product lead times. Call (800) 321-0796 or visit www.furnacepartsllc.com for information.

QUICK TURNAROUND, QUALITY SERVICEREDUCE YOUR INVENTORY AND ADD TO YOUR BOTTOM LINE

Proud member of:

-

58 April 2011 - IndustrialHeating.com

FEATURE | Industrial Gases/Combustion

hence the reason why most stainless steel (chromium present as an alloy) high-temperature processing is usually done in very high levels of hydrogen often 100%. At the processing temperature of 1300F, in the presence of hydrogen, oxygen species will convert to water and become a part of whatever background moisture or dewpoint that might be in the process-atmosphere system. Enough hydrogen must be present in the atmo-sphere system to counter oxidation of chromium. With too low of a hydrogen ratio to a given moisture level, chromium oxidation will occur. With no hydrogen in such an atmosphere system (vacuum-furnace processes excluded), it is liter-ally impossible to exclude enough oxygen from the system to prevent chromium oxidation.

Determining the Equilibrium PCO/CO2 RatioThe PCO/CO2, or CO/CO2 ratio, is used with more frequency in extractive-metal-lurgy systems for all metals to determine whether this reaction will reduce or oxi-dize a given metal system at a given tem-perature. In heat-treated metals, the ratio is usually used for carbon-bearing iron al-loys to determine whether the metal will decarburize or carburize. It is the back-bone of carburizing and hardening and all of its derivative processes. The topic of carburization and its de-rivative processes is reserved for articles far beyond the space allotted and the scope of this article on the Ellingham diagram. There is far more to consider than merely plotting the equilibrium value for the CO/CO2 ratio. In these sys-tems, we are often interested in depth of the carbon in the iron, activities, diffu-sion rates, time at temperature, degree of surface oxidation and its removal, carbon concentration pro les, avoiding inter-granular oxidation (IGO), etc. to name but a few variables. However, we can get a rough idea of what the equilibrium ratio should be so that conditions can be set to promote deliberate decarburization in the case of electrical steels. In the case of

carburization of steel, we can at least see what equilibrium ratio we must roughly exceed to cause the carburization process to occur.

SummaryHarold Ellinghams work made clearer and more accessible, in an easy-to-understand graphical format, the well-known concepts of standard free energy with respect to temperature for reactions like the formation of oxides, sul des and chlorides. In the case of his metal and metal-oxide diagram, by normalizing the thermodynamic functions to reaction with one mole of oxygen, Ellingham was able to compare the temperature stabil-ity of many different oxides on the same diagram. The result was his relatively easy-to-use Ellingham Diagram to deter-mine reduction and oxidation conditions without resorting to painstaking efforts to interrelate all metal systems free-ener-gy-based calculations from scratch. The addition of the original nomograph tool that plots, in a continuous scale, the val-ues of PO2 for ease of calculation by the user is the work of F. D. Richardson and Jeffes. Since CO/CO2 and H2/H2O ratios are often used in conjunction with de-termining equilibrium partial pressure of oxygen, L.S. Darken and R.W. Gurry added their calculations as nomograph scales for these additional ratios. These diagrams have subsequently been referred to as Ellingham, Ellingham-Richardson, Darken and Gurry, or modi ed Elling-ham diagrams. IH

For more information: Contact Michael J. Stempo, P.E., business development/applica-tions engineering, Air Liquid Industrial U.S. LP, 2700 Post Oak Blvd., Suite 1800, Houston, TX 77056; tel: 610-997-0936; fax: 713-803-7344; e-mail: [email protected]; web: www.us.airliquide.com

Use this Mobile Tag to go to a printable copy of the Ellingham Diagram. You can also use www.industrialheating.com/diagram

![Ti and Ni - Oxidation Paper - REVISED · 2013-05-21 · [22] added a nomographic scale to the Ellingham diagram. The Ellingham-Richardson diagram for a series of oxides is shown in](https://static.fdocuments.in/doc/165x107/5f0fe5457e708231d4466bdd/ti-and-ni-oxidation-paper-revised-2013-05-21-22-added-a-nomographic-scale.jpg)