TECHNICAL PROPOSAL FOR 300,000T/Y USED BAR ROLLING MILL (TAIWAN) · PDF file ·...

Transcript of TECHNICAL PROPOSAL FOR 300,000T/Y USED BAR ROLLING MILL (TAIWAN) · PDF file ·...

-1-

CONTENTS I. GENERAL................................................................................... 1

II. DESIGN BASIS......................................................................... 4

III. ATTACHMENT...................................................................... 21

-2-

I. GENERAL

1.1 PREFACE

This offer sheet covers the supply of the equipment and materials for a Bar Mill

Project capable of producing 300,000 tones per year of Deformed Bar with

product size of D10, D12, D16, D20, D22, D25&D32. and Rung Bar with

product size of ∮9mm~∮32mm

1.2 Plant description

The main features of the rolling process and equipment composing the Plant

are described in the following article.

The layout and Mill capacity of the Plant is shown in the attached

”General layout and calculation plan”

1.3 General features of the rolling Mill Process

This rolling mill is provided with necessary equipments for rolling

of bars. Capacity of the rolling mill is 300,000tons/y. Production

ratio of the different bar sizes can be selected freely, according to

distinct market demands.

50tons/hr, top fired, Pusher type Reheating Furnace, energy saving

technology and easy operation procedure are applied.

Arrangement of mill stands is all tandem Horizontal type mill.

The Roughing Rolling Mill And Intermediate and Finishing Rolling Mill are

driven by AC motors, Total capacity of Main AC motors is 4,600kw.

Low tension rolling is applied by Loop Control System in the Finishing mill

depending on the size of the products.

-3-

CACULATION PLAN OF MILL CAPCITY ROLLING RATE (300,000T/Y)

Products Billet Annual Production

Size Area Unit-W Size Length WeightNo.

(mm) (mm2) (kg/m) (mm) (m) (kg)

Fin.RollingSpeed

(m/sec)

Pass Time

(sec)

Pause

(sec)

Rolling Cycle Time

(sec)

ProductYield (%) (%) (T/Year)

Expected Rolling Hours

(hrs)

1 D10 78.5 0.617 130 6 750 10.8 36 10 46 96 20 60,000 1,200

2 D12 113.0 0.888 130 6 750 7.78 30 15 45 96 20 60,000 1,200

3 D16 176.7 1.387 130 6 750 5.8 25.88 15 40.88 96 15 45,000 900

4 D20 314.2 2.466 130 6 750 5.23 16.18 15 31.18 96 15 45,000 900

5 D22 380.1 2.984 130 6 750 5 15.6 15 30.6 96 10 30,000 600

6 D25 490.90 3.853 130 6 750 3.29 14.1 15 29.1 96 10 30,000 480

7 D32 804.25 5.313 130 6 750 3.29 14.1 15 29.1 96 10 30,000 480

TOTAL 100 300,000 5,760

-4-

II. DESIGN BASIS 2.1 Product Mix and Rolling Rate

2.1.1 Product Mix

Product mix for annual production of 300,000 tons is described as the

table “Calculation Plan of Mill Capacity”.

2.1.2 Rolling Rate

With regard to rolling rate, please also refer to the table “Calculation Plan

of Mill Capacity”.

2.1.3 Others

Product length of bars: 12M or others

2.2 Billet

Billet: Continuously cast billets or hot rolled billets

Kind of steel: Low alloy steel for the manufacture of steel bars for reinforcement,

rolled steel for general structure.

Section 100~130 mm sq Length 6M ± 10 mm Weight 471~750kg

Camber (bow): Max.20mm in 6000mm length

Rhomboidity (right angularity): Less than 3%

Twist: Less than 1 degree per meter

Temperature of billet discharged: 1100℃ (Engineering basis)

Note: The billet above shall have the quality suitable for final products. In order

to attain high productivity, that is, improvement of rolling efficiency and

material yield, etc. which are resulted from high rolling Rate and most

suitable cutting of bar products , etc., it should be essential to well

control the billet tolerance and conditions.

-5-

2.3 Rolling Capacity

2.3.1 Rolling Hours Required

Rolling Hours Requires=5760 Hrs/Year

With regard to rolling hours required, please refer to the table to

“Calculation Plan of Mill Capacity”.

2.3.2 Annual Working Hours

8 hours/shift×3 shift/day×300 day/year=7200Hr

If operating rate is 80%

Operating Rate 0.8=Rolling hour required/Annual working hour

Rolling hour required=0.8×7200=5760Hr

This operating ratio is considered to be easily attained.

2.4 Steel Grades

The steel grades which are to be processed on the mill are as follows.

a. Deformed bar

D10~D32 Steel bars

Applicable standards:

JIS 20-2525&24-2536 “Rolled steel for general structure”

b. Rung bar

∮9.5mm~∮32mm Steel bars JIS G 3101&JIS G4051

2.5 Rolling Speed

Actual rolling speed: Max. 11 m/sec

2.6 Rolling Method

1. strand rolling

Deformed bars: D10(3/8〃), D12(1/2

〃), D16(5/8〃), D20(3/4

〃), D22(7/8〃), D25(1

〃) & D32(11/4〃)

Rung bars : ∮9.5, ∮12, ∮16, ∮ 20, ∮25 &∮32mm

-6-

2.7 Site (Environmental) Conditions

1) Ambient temperature:

Max. 35 deg. C (more than 15℃)

Electrical control room and pulpits will be kept in 20~30℃

2) Relative humidity: Max. 98%

3) Altitude: Less than 1,000 m above sea level

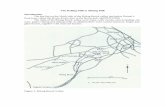

2.8 Layout

2.8.1 Please refer to attached GENERAL LAYOUT.〝A〞: Product D10~D16

1) Rolling Mill

The 6M length billet is charged on the Billet Charging Bed by the Billet Yard Crane,

and transferred to the Reheating Furnace by the Billet Charging Roller Table.

And the heated billets are discharged from Reheating Furnace and Billet shear

machine Cutting 3M processed through Roughing Mill Train, Intermediate Train,

Finishing Mill Train.

The Rolling Mill comprises a total of 13 stands, divide in roughing mill with 1

stands (5 pass), intermediate mill with 6 stands (6 pass), finishing mill with 6

stands (6 pass).

The Roughing Rolling Mill and Intermediate Mill and Finishing Mill is driven by

AC motors.All stands are arranged in horizontal arrangement.

2) Cooling bed

On the 66M Length×4.5M Wide Cooling Bed, products are cooled down to

desired temperature, while maintaining the straightness.

3) Cutting & Finishing System For Deformed bar

Those products are then discharged from the Cooling Bed and further processed

by Cutting and Finishing System.

All products are cut to length by cold shear transferred to receiving conveyor.

At the end of the conveyor, a conveyed table is located which transfer the

products to bundling area then to shipping area.

-7-

2.8.2 Please refer to attached GENERAL LAYOUT.〝B〞:Product D20~D32

1) Rolling Mill With hight pressure water quenching system 12M Length

The 6M length billet is charged on the Billet Charging Bed by the Billet Yard Crane,

and transferred to the Reheating Furnace by the Billet Charging Roller Table.

And the heated billets are discharged from Reheating Furnace and processed

through Roughing Mill Train, Intermediate Train, Finishing Mill Train. Those

products through hight pressure water quenching system and Pinch Roller to

Cooling bed.

The Rolling Mill comprises a total of 11 stands, divide in roughing mill with 1

stands (3 pass), intermediate mill with 6 stands (6 pass), finishing mill with 4

stands (4 pass).

The Roughing Rolling Mill and Intermediate Mill and Finishing Mill is driven by

AC motors.All stands are arranged in horizontal arrangement.

2) Cooling bed

On the 66M length ×7.5M Wide Cooling Bed, products are cooled down to

desired temperature, while maintaining the straightness.

3) Cutting & Finishing System For Deformed bar

Those products are then discharged from the Cooling Bed and further processed

by Cutting and Finishing System.

All products are cut to length by cold shear transferred to receiving conveyor.

At the end of the conveyor, a conveyed table is located which transfer the

products to bundling area then to shipping area.

2.9 Utilities Conditions

The utilities having characteristics or conditions as described hereunder will be

utilized for the plant operation and supplied by the Customer in sufficient

quantities at termination points described hereunder.

1) Electric power

Normal Electric power

- Power receiving: One (1) line

-8-

FOR LAYOUT.〝A〞:ProductD10~D16

- Supplied power for 7set AC Motor: 3.3kv/3 phases /60HZ/50HZ /4,600KW

FOR LAYOUT.〝B〞:ProductD20~D32

-Supplied power for 6set AC Motor: AC3.3kv/3 phases /60/50HZ/4,200KW

- Voltage fluctuation: Within ±5%

- Frequency fluctuation: Terminals of 3.3kv receiving switch and distributing

panel in the electrical equipment room of the plant.

2) Cooling water

a. Direct cooling water (500 T/hr)

- pH valve: 6.5 to 8.5

- Suspended solid: Max. 20 mg/lit

- M-alkalinity as Ca Co3: Max. 300 mg/lit

- Total dissolved solids: Max. 1,500 mg/lit

- Total hardness as Ca Co3: Max. 300 mg/lit

- Fe: Max. 3 mg/lit

- Cl: Max. 200 mg/lit

- So4: Max. 200 mg/lit

- SiO2: Max. 50 mg/lit

- Temperature: Max. 32℃

- Pressure: Max. 4 kgf/cm2

Design pressure: 3 kgf/ cm2 at the battery Limit of the building

Hight pressure water quenching system: Min. 12 kgf/cm2

b. Indirect cooling water (150 T/hr)

- pH valve: 6.5 to 8.5

- Suspended solid: Max. 10 mg/lit

- M-alkalinity as Ca Co3: Max. 300 mg/lit

- Total dissolved solids: Max. 1,500 mg/lit

- Total hardness as Ca Co3: Max. 300 mg/lit

-9-

- Fe: Max. 2 mg/lit

- Cl: Max. 200 mg/lit

- So4: Max. 200 mg/lit

- O2: Max. 50 mg/lit

- Temperature: Max. 32℃

- Pressure: Max. 4 kgf/cm2

Design pressure: 3 kgf/cm2 at the battery Limit of the building

-10-

3. SCOPE OF SUPPLY SUPPLIER CUSTOMER REMARK

Country of originITEM NO. EQUIPMENT NAME Q’TY Supply

Country RemarksSupply

M1 REHEATING FURNACE (Max:50T/H) TAIWAN Billet 6M M101 -01 Charging BED 1set TAIWAN -02 Charging Roller Way For charging 1set TAIWAN 15M -03 Hyd. Unit 1set TAIWAN -04 Main Pusher 1set TAIWAN -05 Side Pusher 1set TAIWAN

-06 Furnace (Case7Mw/24Ml) 1set TAIWAN Without refractory bricks

-07 Hot Wind Fuel Duct 1set TAIWAN -08 Recuperator 1set TAIWAN -09 Chimney 1 p TAIWAN 36M -10 Blower 1 s TAIWAN -11 Burner 10p TAIWAN -12 Auto Contral Panel 1 s TAIWAN -13 Billet Hot Shear With Hyd. Unit 1 s TAIWAN -14 Chain Roller Way For Discharging 1 s TAIWAN 9M -15 Thermo-Sensor Control For Furnace 1 s TAIWAN -16 Day Tank for Heavy Oil 1 s TAIWAN -17 Refractory Bricks/Blocks 1Lot ---- M2 MILL MECHANCAL SECTION FOR LAYOUT 〝A〞 TAIWAN M201 ROUGHING MILL TRAIN (RM.) TAIWAN 1#~5#Pass

-01 Horizontal 3HI-Mill Stand With Base Plates 1 s TAIWAN (∮475x1600L)

-11-

SUPPLIER CUSTOMER REMARK Country of originITEM NO. EQUIPMENT NAME Q’TY

SupplyCountry Remarks

Supply

-02 Roll(∮475×1600L) 3 p TAIWAN -03 Chock 6 p TAIWAN -04 Fiber Bearing (Bakelite) 6 p TAIWAN -05 1st Reducer Gear Box 1 s TAIWAN -06 Pinion Gear Box 3HI 1 s TAIWAN -07 Gear Coupling (Motor-Reducer-P. Stand ) 2 s TAIWAN -08 Joint Shaft (Pinion Stand-Mill Stand) 3 s TAIWAN -09 In & Out And Twist Guide 10 s TAIWAN -10 Oil Lubrication System 1 s TAIWAN

M202 1st Intermediate MILL TRAIN (1st IM.) TAIWAN 6#~9#Pass

-01 Horizontal 2HI-Mill Stand With Base Plates 4 s TAIWAN (∮360x800L) -02 Roll (∮360x800L) 8 p TAIWAN -03 Chock 16p TAIWAN -04 Fiber Bearing (Bakelite) 16 p TAIWAN -05 Reducer Gear Box With 2HI Pinion Stand 2 s TAIWAN 1 IN BY 2 OUT -06 Gear Coupling (Motor-Reducer-P. Stand ) 2 s TAIWAN -07 Cardon Shaft (Pinion Stand-Mill Stand) 8 s TAIWAN -08 In & Out And Twist Guide 16 s TAIWAN -09 Oil Lubrication System 1 s TAIWAN -10 Approach Roller Table (RM→IM) 12M 1 s TAIWAN

M202 2nd Intermediate MILL TRAIN (2nd IM.) TAIWAN 10#~13#Pass

-12-

SUPPLIER CUSTOMER REMARK Country of originITEM NO. EQUIPMENT NAME Q’TY

SupplyCountry Remarks

Supply

-01 2HI-Mill Stand With Base Plates 4 s TAIWAN (∮360x800L) -02 Roll (∮360x800L) 8 p TAIWAN -03 Chock 16 p TAIWAN -04 Fiber Bearing (Bakelite) 16 p TAIWAN -05 Reducer Gear Box With 2HI Pinion Stand 2 s TAIWAN 1 IN BY 2 OUT -06 Gear Coupling (Motor-Reducer-P. Stand ) 2 s TAIWAN -07 Cardon Shaft (Pinion Stand-Mill Stand) 8 s TAIWAN -08 In & Out And Twist Guide 16 s TAIWAN -09 Oil Lubrication System 1 s TAIWAN -10 Approach Roller Table (RM→IM) 12M 1 s TAIWAN M203 FINISHING MILL TRAIN (FM) M203-1 -01 2Hi Horizontal Mill Stand With Base Plates

(Roller Bearing Type) 4 s TAIWAN 14#~17#Pass

-02 Roll (∮310 x 800L x 4Stand) 8p TAIWAN -03 Roller Bearing Chock 16 p TAIWAN -04 Roller Bearing 16 p TAIWAN -05 2Hi Reducer Gear Box (with Pinion Stand) 2 s TAIWAN 1 IN BY 2 OUT -06 Cardon Shaft 8 p TAIWAN -07 Gear Coupling (Motor To Reducer-Support) 2 s TAIWAN -08 In & Out And Twist Guide 16 s TAIWAN -09 Oil Lubrication System 1 s TAIWAN

-13-

SUPPLIER CUSTOMER REMARK Country of originITEM NO. EQUIPMENT NAME Q’TY

SupplyCountry Remarks

Supply

M204 SHEAR MACHINE M204 -01 Flying Shear 2 s TAIWAN -02 Diveding Shear 2 s TAIWAN -03 Pinch Roller 4 s TAIWAN -04 Stop Shear 2 s TAIWAN M205 COOLING AND CUTTING SECTION M205 RUN IN GUIDING EQUIPMENT M205 -01 Run in Guiding Through (64M) 1 s TAIWAN -02 Separator (Line Selector) 4 way 1 s TAIWAN M206 64M×4.5M COOLING BED M206 -01 Cooling Bed 64M×4.5M 1 s TAIWAN -02 Cooling Bed Drive Unit 40HP x 6p 1 s TAIWAN -03 Bar Collecting Device 1 s TAIWAN -04 Bar Traversing Devise 1 s TAIWAN -05 Run Out Roller Table 64M 1 s TAIWAN M207 COLD SHEAR M207 -01 Cold Shear (Power-300ton) 1 s TAIWAN M208 BAR FINISHING SECTION M208 TRAVERSING FACILITIES FOR BAR 1 s TAIWAN

-14-

SUPPLIER CUSTOMER REMARK Country of originITEM NO. EQUIPMENT NAME Q’TY

SupplyCountry Remarks

Supply

M208 -01 Cold Shear Uun Out Table 1 s TAIWAN -02 Traverser 1 s TAIWAN -03 Product Transfer 1 s TAIWAN -04 Shipping Table 1 s TAIWAN -05 Auto Bundling Machine 1 s TAIWAN M3 MILL MECHANCAL SECTION FOR LAYOUT 〝B〞 M301 ROUGHING MILL TRAIN (RM.) 1#~3#Pass

-01 Horizontal 3HI-Mill Stand With Base Plates 1 s TAIWAN (∮475x1600L) -02 Roll(∮475×1600L) 3 p TAIWAN -03 Chock 6 p TAIWAN -04 Fiber Bearing (Bakelite) 6 p TAIWAN -05 1st Reducer Gear Box 1 s TAIWAN -06 Pinion Gear Box 3HI 1 s TAIWAN -07 Gear Coupling (Motor-Reducer-P. Stand ) 2 s TAIWAN -08 Joint Shaft (Pinion Stand-Mill Stand) 3 s TAIWAN -09 In & Out And Twist Guide 6 s TAIWAN -10 Oil Lubrication System 1 s TAIWAN

M302 1st Intermediate MILL TRAIN ( IM.) 4#~9#Pass

-01 Horizontal 2HI-Mill Stand With Base Plates 6 s TAIWAN (∮360x800L) -02 Roll (∮360x800L) 12 p TAIWAN -03 Chock 24p TAIWAN

-15-

SUPPLIER CUSTOMER REMARK Country of originITEM NO. EQUIPMENT NAME Q’TY

SupplyCountry Remarks

Supply

-04 Fiber Bearing (Bakelite) 24 p TAIWAN -05 Reducer Gear Box With 2HI Pinion Stand 3 s TAIWAN 1 IN BY 2 OUT -06 Gear Coupling (Motor-Reducer-P. Stand ) 3 s TAIWAN -07 Cardon Shaft (Pinion Stand-Mill Stand) 12 s TAIWAN -08 In & Out And Twist Guide 24 s TAIWAN -09 Oil Lubrication System 1 s TAIWAN -10 Approach Roller Table (RM→IM) 12M 1 s TAIWAN

M303 FINISHING MILL TRAIN (FM) M303-1 -01 2Hi Horizontal Mill Stand With Base Plates

(Roller Bearing Type) 4 s TAIWAN 10#~13#Pass

-02 Roll (∮310 x 800L x 4Stand) 8p TAIWAN -03 Roller Bearing Chock 16 p TAIWAN -04 Roller Bearing 16 p TAIWAN -05 2Hi Reducer Gear Box (with Pinion Stand) 2 s TAIWAN 1 IN BY 2 OUT -06 Cardon Shaft 8 p TAIWAN -07 Gear Coupling (Motor To Reducer-Support) 2 s TAIWAN -08 In & Out And Twist Guide 16 s TAIWAN -09 Oil Lubrication System 1 s TAIWAN M304 SHEAR MACHINE M304 -01 Flying Shear 2 s TAIWAN -02 Diveding Shear 2 s TAIWAN

-16-

SUPPLIER CUSTOMER REMARK Country of originITEM NO. EQUIPMENT NAME Q’TY

SupplyCountry Remarks

Supply

-03 Pinch Roller 4 s TAIWAN -04 Stop Shear 2 s TAIWAN -05 Quenching Box System 2 Way 1 s TAIWAN -06 Quenching Pump Unit System 1 s TAIWAN M305 COOLING AND CUTTING SECTION M305 RUN IN GUIDING EQUIPMENT M305 -01 Run in Guiding Through (66M) 1 s TAIWAN -02 Separator (Line Selector) 4 way 1 s TAIWAN M306 66M×7.5M COOLING BED M306 -01 Cooling Bed 66M×7.5M 1 s TAIWAN -02 Cooling Bed Drive Unit 40HP x 6p 1 s TAIWAN -03 Bar Collecting Device 1 s TAIWAN -04 Bar Traversing Devise 1 s TAIWAN -05 Run Out Roller Table 66M 1 s TAIWAN M307 COLD SHEAR M307 -01 Cold Shear (Power-300ton) 1 s TAIWAN M308 BAR FINISHING SECTION M308 TRAVERSING FACILITIES FOR BAR 1 s TAIWAN M308 -01 Cold Shear Uun Out Table 1 s TAIWAN

-17-

SUPPLIER CUSTOMER REMARK Country of originITEM NO. EQUIPMENT NAME Q’TY

SupplyCountry Remarks

Supply

-02 Traverser 1 s TAIWAN -03 Product Transfer 1 s TAIWAN -04 Shipping Table 1 s TAIWAN -05 Auto Bundling Machine 1 s TAIWAN M4 SIMPLE PARTS M401 FOUNDATIOM BOLTS AND GAUGE PLATE M401 -01 Foundation Bolts (Steel Bar) 15 t -02 Installation Liner (Steel Plate) 5 t M402 SAFETY COVER M402 -01 Safety Cover (5 tons Steel Plate&5 tons Angle And Channel ) 10 t M403 WORKING DECK M403 -01 Working Deck (Steel Plate) 5 t M404 PIT AND DUCT COVER M404 -01 Pit And Duct Cover (5 tons Steel Plate&5 tons Angle And

Channel ) 10 t

M406 CROP CHUTE AND BAG M406 -01 Crop Chute 1 s -02 Crop Dag 1 s

-18-

SUPPLIER CUSTOMER REMARK Country of originITEM NO. EQUIPMENT NAME Q’TY

SupplyCountry Remarks

Supply

M407 MISCLLANIOUS ITEMS M407 -01 Supporting For Detectors 1 s -02 Scrap Box 1 s -03 Dust Box 1 s -04 Tool For Election 1 s -05 Tool For Operation And Maintenance 1 s -06 Coiler For Mis-Rolled Material 1 s M5 PIPING M501 OUTDOOR PIPING M501 -01 Outdoor Piping For Utilities

(Air 200M,Oil 100M,Water 300M) 15 t

-02 Indoor Piping For All Utilities (Air 800M,Oil 300M,Water 500M)

25 t

-03 Valve And Piping Accessories 1 s E1 POWER RECEIVING & DISTRIBUTION SYSTEM〝A〞 E101 -01 3.3 KV Power Receiving Switch And Distributing Panel 7 s TAIWAN -02 Power Factor Compensation Equipment 1 s -03 Main AC Motors 1200HP/60HZ/3300V/12P 1 s TAIWAN -04 Main AC Motors 800HP/60HZ/3300V/12P 6 s TAIWAN -05 Main AC 1200HP On/Off Panel&Control Panel 1 s TAIWAN -06 Main AC 800HP On/Off Panel&Control Panel 6 s TAIWAN

-19-

SUPPLIER CUSTOMER REMARK Country of originITEM NO. EQUIPMENT NAME Q’TY

SupplyCountry Remarks

Supply

E1 MILL LINE DRIVE CONTROL SYSTEM〝A〞 E102 -01 Operating Desk 2 s TAIWAN -02 PLC Control For Mill Line 1 s TAIWAN -03 Sensor Control-Photocell 8 s TAIWAN E2 POWER RECEIVING & DISTRIBUTION SYSTEM〝B〞 E201 -01 3.3 KV Power Receiving Switch And Distributing Panel 6 s TAIWAN -02 Power Factor Compensation Equipment 1 s -03 Main AC Motors 1500HP/60HZ/3300V/12P 1 s TAIWAN -04 Main AC Motors 800HP/60HZ/3300V/12P 5 s TAIWAN -05 Main AC 1500HP On/Off Panel&Control Panel 1 s TAIWAN -06 Main AC 800HP On/Off Panel&Control Panel 5 s TAIWAN -07 Transformers For AC(3000KVA/3300v/60HZ) 2 s For〝A〞&〝B〞 E2 MILL LINE DRIVE CONTROL SYSTEM〝B〞 E202 -01 Operating Desk 2 s TAIWAN -02 PLC Control For Mill Line 1 s TAIWAN -03 Sensor Control-Photocell 6 s TAIWAN E3 CABLING, WIRING, BUS, DUCT & PIPING E301 -01 Power Cable And Accessories 1 s -02 Control Cable And Accessories 1 s -03 Instrument Pipe And Fitting 1 s

-20-

SUPPLIER CUSTOMER REMARK Country of originITEM NO. EQUIPMENT NAME Q’TY

SupplyCountry Remarks

Supply

-04 Cable Duct, Tray, Conduit Tube And Fitting 1 s -05 HV & LV Cable 1 s -06 Cabling Material & Accessories 1 s -07 Piping Material & Accessories 1 s E4 LIGHTING AND SOCKET OUT SYS. E402 -01 Lighting Transformer & Distribution Board 1 s -02 Socket Outlet Switch 1 s E5 COMMUNICATION SYSTEM E501 -01 Paging system 1 s -02 Closed Circuit T.V. System 1 s -03 Mil Status Indication Lamp 1 s -04 Clocks 1 s -05 Telephone System 1 s -06 Loud Speaker System 1 s E6 MAINTENANCE TOOL AND INSTRUMENT E601 -01 Tools And Instrument For Election 1 s -02 Tools And Instrument For Maintenance 1 s E7 FIRE DETECTION AND FIGHTING SYSTEM E701 -01 Fire Detection System 1 s

-21-

SUPPLIER CUSTOMER REMARK Country of originITEM NO. EQUIPMENT NAME Q’TY

SupplyCountry Remarks

Supply

-02 Fire Fighting System 1 s E8 AUXILIARY SYSTEM FOR BUILDING E801 -01 Air Conditioning System 1 s -02 Ventilation System 1 s -03 Lighting Protection System 1 s S OTHER SUPPORTING FACILTIES S1 ROLL SHOP S101 ROLL SHOP EQUIPMENT S101 -01 Roll Turning Lathe 4 s -02 Guide Roller Lathe 1 s -03 Universal Tool Gridding Machine 1 s -04 Drilling Machine 1 s -05 Double Ended Gridding Machine 1 s -06 Rid cutting Machine 1 s -07 Tools 1 s S2 MACHINE SHOP & LABORATORY S201 -01 MACHINE SHOP EQUIPMENT 1 s S202 -01 MECHANICAL LABORATORY Tension & Compression Load Tester 1 s

-22-

SUPPLIER CUSTOMER REMARK Country of originITEM NO. EQUIPMENT NAME Q’TY

SupplyCountry Remarks

Supply

S3 TRANSPORTATION EQUIP MENT S301 TRANSFER CAR S301 -01 Transfer Car For Roll Shop 1 s -02 Transfer Car For Shipping Yard 1 s S4 CRANE AND HOIST S401 -01 OHT Crane For Billet Yard 10t Load 1 s Span:20M -02 OHT Crane For Mill Yard 10t Load 2 s Span:20M -03 OHT Crane For Bar Product Yard 10t Load 3 s Span:20M -04 Crane Trolley Wire 1 s S5 PULPIT S501 -01 Furnace Control Room 1 s -02 Main Control Room 1 s -03 Cold Shear Control Room 1 s -04 Bar Finishing Control Room 1 s S6 COMPRESSED AIR SUPPLY FACILTIES S601 -01 Compressed Air Station 12M3/min 3 s TAIWAN AC100HP -02 Receiver Tank 2 s TAIWAN A SPARE PARTS & CONSUMABLES

-23-

SUPPLIER CUSTOMER REMARK Country of originITEM NO. EQUIPMENT NAME Q’TY

SupplyCountry Remarks

Supply

A1 SUPPLY OF UTILITIES -01 Cooling Water DCW, ICW -02 Lubrication Oil

-03 Grease -04 Hydraulic Oil -05 Fuel Oil

-06 Electric Power -07 Gases

A2 MATERIALS

-01 Erection Material

A3 ITEMS EXCLUDED FROM SUPPLIER’S SCOPE

-01 Civil work & Building -02 Equipment Foundation

-03 Erection Work

-04 Wiring Work -05 Piping Work -06 Air Compressor & Receiving Tank

-07 Water Treatment Facility -08 Drainage Pump

-24-

SUPPLIER CUSTOMER REMARK Country of originITEM NO. EQUIPMENT NAME Q’TY

SupplyCountry Remarks

Supply

-09 Fire Fighting Facilities -10 Lighting -11 Communication System

-12 Simple Structure -13 Crane / Transportation Equipment -14 Air Conditioning & Ventilation

-15 ITV -16 Roll Shop Equipment -17 Maintenance Equipment

-18 Laboratory

-19 Sewage Facility -20 Template

-21 Consumables

-22 Tools -23 Grounding Material 1 s

A4 SUPPLY SPARE PARTS

A401 -01 Rough Mill Roller(∮475×1600L) 9ps TAIWAN

-02 Rough Mill Fiber Bearing (Bakelite) 24ps TAIWAN

-03 Joint Shaft (R.M. Pinion Stand-Mill Stand) 3 s TAIWAN

-25-

SUPPLIER CUSTOMER REMARK Country of originITEM NO. EQUIPMENT NAME Q’TY

SupplyCountry Remarks

Supply

A402 -1 Intermediate Mill Roll (∮360 x 800L ) 36ps TAIWAN

-2 Intermediate Mill Fiber Bearing (Bakelite) 24ps TAIWAN

-3 Cardon Shaft (I.M. Reducer-Mill Stand) 2 s TAIWAN

-4 Intermediate Mill In & Out And Twist Guide 4 s TAIWAN

-5 Intermediate Mill Inlet Guide Plate 16ps TAIWAN

-6 Intermediate Mill Outlet Twist Guide Roller 20ps TAIWAN

M203 -1 2Hi Horizontal Mill Stand (2HI FM) 2 s TAIWAN

-2 Finisher Mill Roll (∮310 x 800L) 48ps TAIWAN

-3 Finisher Mill ChockWith Roller Bearing 8ps TAIWAN

-4 Cardon Shaft (F.M. Reducer-Mill Stand) 2ps TAIWAN

-5 Finisher Mill In & Out And Twist Guide 16s TAIWAN

-6 Finisher Mill Inlet Guide Plate 24ps TAIWAN

-7 Finisher Mill Outlet Twist Guide Roller 16ps TAIWAN