Screw Compressors

-

Upload

chaituganta994200 -

Category

Documents

-

view

506 -

download

0

Transcript of Screw Compressors

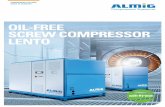

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 1 of 27

Rotary screw compressors are widely used today in industrial refrigeration forcompression of ammonia and other refrigerating gases. Simple in concept, the screwgeometry is sufficiently difficult to visualize that many people using screws today haveonly a vague idea how they actually work. An understanding of the basics of theiroperation will help in applying them correctly, avoiding nuisance problems in operation,and achieving the best overall system designs.

Construction

A typical oil flooded twin screw compressor consists of male and female rotorsmounted on bearings to fix their position in a rotor housing which holds the rotors inclosely toleranced intersecting cylindrical bores. (See Figure 1.) The rotors basicshape is a screw thread, with varying numbers of lobes on the male and female rotors.The driving device is generally connected to the male rotor with the male driving thefemale through an oil film. In refrigeration, four or five lobed male rotors generally drivesix or seven lobe female rotors to give a female rotor speed that is somewhat less thanthe male speed. Some designs connect the drive to the female rotor in order toproduce higher rotor speeds thus increasing displacement. However, this increasesloading on the rotors in the area of torque transfer and can reduce rotor life.

Figure 1

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 2 of 27

Oil Injection

All common refrigeration screws use oil injection into the compression area forlubrication, sealing of leakage paths, and cooling. Injected oil quantities areapproximately 10-20 gal/min per 100 HP. The use of such large oil quantities transfersmost of the heat of compression to the oil and allows discharge temperatures to be verylow even at high compression ratios. Running single stage at 20:1 compression ratioon ammonia would yield 650° F discharge temperatures in non-flooded types ofcompressors. With oil flooding, the screw discharge temperature does not exceed 200°F. Running screws at 20:1 or even higher, single stage, though not energy efficientcompared with two stage systems, will not harm the compressor. Many such systemsare running today.

Fundamentals of operation

A screw compressor is best described as a positive displacement volumereduction device. Its action is analogous to a reciprocating compressor more than anyof the other common compressor types. It is helpful to refer to the equivalent recip.process to visualize how compression progresses in a screw. Gas is compressed bypure rotary motion of the two intermeshing helical rotors. Gas travels around theoutside of the rotors, starting at the top and traveling to the bottom while it is transferredaxially from the suction end to the discharge end of the rotor area.

Suction process

Suction gas is drawn into the compressor to fill the void where the male rotorrotates out of the female flute on the suction end of the compressor. Suction charge fillsthe entire volume of each screw thread as the unmeshing thread proceeds down thelength of the rotor. This is analogous to the suction stroke in a reciprocating compressoras the piston is drawn down the cylinder. (See Figure 2.)

BeginningOf

Suction

Figure 2

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 3 of 27

The suction charge becomes trapped in two helically shaped cylinders formed bythe screw threads and the housing as the threads rotate out of the open suction port.The volume trapped in both screw threads over their entire length is defined as thevolume at suction, (Vs). In the recip. analogy the piston reaches the bottom of thestroke and the suction valve closes, trapping the suction volume, (Vs). (See Figure 3.)

Figure 3

The displacement per revolution of the recip. is defined in terms of suctionvolume, by the bore times the stroke times the number of cylinders. The totaldisplacement of the screw compressor is the volume at suction per thread times thenumber of lobes on the driving rotor.

VsMaximumSuction

Volume (Vs)TrappedVs

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 4 of 27

CompressionThe male rotor lobe will begin to enter the trapped female flute on the bottom of

the compressor at the suction end, forming the back edge of the trapped gas pocket.The two separate gas cylinders in each rotor are joined to form a "V" shaped wedge ofgas with the point of the "V" at the intersection of the threads on the suction end. (SeeFigure 4.) Further rotation begins to reduce the trapped volume in the "V" andcompress the trapped gas. The intersection point of the male lobe in the female flute islike the piston in the recip. that is starting up the cylinder and compressing the gasahead of it. (See Figure 5.)

Figure 4

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 5 of 27

Figure 5

Discharge Process

In the recip. compressor, the discharge process starts when the discharge valvefirst opens. As the pressure in the cylinder exceeds the pressure above the valve, thevalve lifts, allowing the compressed gas to be pushed into the discharge manifold. Thescrew compressor has no valves to determine when compression is over. The locationof the discharge ports determine when compression is over. (See Figure 6.) Thevolume of gas remaining in the "V" shaped trapped pocket at discharge port opening isdefined as the volume at discharge, (Vd).

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 6 of 27

Figure 6

A radial discharge port is used on the outlet end of the slide valve and an axialport is used on the discharge end wall. These two ports provide relief of the internalcompressed gas and allow it to be pushed into the discharge housing. Positioning ofthe discharge ports is very important as this controls the amount of internalcompression.

In the recip., the discharge process is complete when the piston reaches the topof the compression stroke and the discharge valve closes. The end of the dischargeprocess in the screw occurs as the trapped pocket is filled by the male lobe at the outletend wall of the compressor. (See Figure 7.) The recip. always has a small amount ofgas, (clearance volume), that is left at the top of the stroke to expand on the nextsuction stroke, taking up space that could have been used to draw in more suctioncharge. At the end of the discharge process in the screw, no clearance volumeremains. All compressed gas is pushed out the discharge ports. This is a significantfactor that helps the screw compressor to be able to run at much higher compressionratios than a recip.

Volume atDischarge (Vd)

BeginningOf

Discharge

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 7 of 27

Figure 7

Volume Ratio

In a reciprocating compressor, the discharge valves open when the pressure inthe cylinder exceeds the pressure in the discharge manifold. Because a screwcompressor does not have valves, the location of the discharge ports determine themaximum discharge pressure level that will be achieved in the screw threads before thecompressed gas is pushed into the discharge pipe.

Volume ratio is a fundamental design characteristic of all screw compressors.The compressor is a volume reduction device. The comparison of the volume oftrapped gas at suction, (Vs) to the volume of trapped gas remaining in the compressionchamber when it opens to discharge, (Vd) defines the internal volume reduction ratio ofthe compressor. This volume index or "Vi" determines the internal pressure ratio of thecompressor and the relationship between them can be approximated as follows.

Vi = Vs/Vd

where;

Vi=Volume ratio or indexVs= Volume at suctionVd= Volume at discharge

Pi = Vik

ClearanceVolume

End ofDischarge

All compressedgas is expelled– no clearancevolume

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 8 of 27

where;

Pi = Internal pressure ratiok = specific heat ratio of the gas being compressed.

Only the suction pressure and the internal volume ratio determine the internalpressure level in the trapped pocket before opening to the discharge port. However, inall refrigeration systems the condensing temperature determines the discharge pressurein the system, and the evaporating temperature determines the suction pressure.

If the internal volume ratio of the compressor is too high for a given set ofoperating conditions the discharge gas will be kept trapped too long and be raisedabove the discharge pressure in the piping. This is called overcompression and isrepresented in the pressure-volume curve in Figure 8. In this case the gas iscompressed above discharge pressure and when the port opening occurs, the higherpressure gas in the screw thread expands out of the compressor into the discharge line.This takes more energy than if the compression had been stopped sooner, when theinternal pressure was equal to the system discharge pressure.

Figure 8

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 9 of 27

When the compressor volume ratio is too low for the system operating pressuresthis is called undercompression and is represented in Figure 9. In this case thedischarge port opening occurs before the internal pressure in the compressor trappedpocket has reached the system discharge pressure level. The higher pressure gasoutside the compressor flows back into the lower pressure pocket, raising the threadpressure immediately to the discharge pressure level. The compressor then has topump against this higher pressure level, rather than pump against a gradual build up todischarge pressure level if the volume ratio had been higher, keeping the trappedpocket closed longer.

Figure 9

In both cases the compressor will still function, and the same volume of gas willbe moved, but more power will be required than if the discharge ports are correctlylocated to match the compressor volume ratio to what the system needs. Variablevolume ratio compressor designs are used in order to optimize discharge port locationand minimize compressor power. (See reference 1)

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 10 of 27

The fact that screws have an internal volume ratio and internal compression setsthem apart from screw pumps or roots blowers even though their structure may looksimilar. A roots blower traps gas and moves it to the discharge, but only raisespressure by pushing against an external resistance. A roots blower always takes morepower to compress gas than a screw because it always runs undercompressed, with abuilt in volume ratio of 1:1.

Capacity Control

Capacity control is used in screw compressors to vary the amount of gas drawninto the compressor. This is necessary in order to provide accurate suction temperaturecontrol as evaporator load varies. Common capacity control methods are:• Slide valve controlling discharge port• Slide valve controlling discharge port and volume ratio• Slide valve not controlling discharge port• Plug valves• Variable speed

Slide valves controlling the discharge port are a very common type of capacitycontrol device used in screw compressors. They are popular because they can giveinfinitely adjustable control of capacity, often from 10 to 100%. This type of slide valveworks by opening a recirculation passage in the high pressure cusp which allows aportion of the trapped gas in the "V" shaped compression chamber to be recirculatedback to the suction cavity before it begins compression. (See Figure 10.) This methodoffers good efficiency at part load for two reasons. First, the recirculated gas only hasto overcome a slight pressure drop in order to bypass back to suction since therecirculation slot opens to the trapped pocket before compression has started, avoidinga precompression loss. Second, as the slide valve moves, the radial discharge port isalso being moved. As the trapped volume at suction is decreased, the discharge portopening is also delayed, thus maintaining approximately the same volume ratio at partload as at full load for optimum part load efficiency.

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 11 of 27

Figure 10

A compressor designed to control capacity and volume ratio is shown in Figure11. In this design a movable slide stop is adjustable in the same bore as the slidevalve. In this design the discharge port position and the recirculation slot position canboth be adjusted. This allows an infinite number of adjustable positions for both valves,which provides volume ratio and capacity adjustment from full load to approximately40% load, with continuing capacity adjustment down to 10% load. This arrangementoffers improved energy efficiency at full and part load.

Figure 11

RecirculationPassage

Slide ValveRegulating Capacityand Discharge PortLocation

RecirculationPassage

Slide StopRegulatingVolume Ratio

Slide Valve RegulatingCapacity andDischarge PortLocation

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 12 of 27

Slide valves that do not control the discharge port come in several varieties, themost common is a round slide valve intersecting with slots in the rotor bore. (SeeFigure 12.) This type of unloader still gives good reduction of capacity but not as gooda reduction in part load power because it does not maintain the volume ratio duringunloading. There can also be some leakage across the slots in the rotor bore which canhurt performance at all loads. These devices are lower in cost than conventional slidevalves and used in some smaller compressors.

Figure 12

Plug valves are radial or axial devices which lift to open a recirculation passagefrom the trapped pocket back to suction. They will typically give unloading in steps of75, 50, and 25% of full load as each progressive plug is opened. These devices also donot give part load volume ratio correction like the first slide valves, thus part loadefficiency is comparable to slide valves that do not regulate the discharge port. Plugvalves also tend to be lower cost and simple in control method. (See Figure 13.)

Plug Moves inThis Bore

RecirculationPassages

Slide Valve RegulatingCapacity but not DischargePort Location

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 13 of 27

Figure 13

Variable Speed

Variable speed is occasionally used as a method of capacity control with screws.This can be provided with speed controlled engines, steam turbines, or variablefrequency electric drives. Compressor power does not decrease linearly with speedreduction but rather decreases as a function of rotor tip speed, and operatingcompression ratio. In general, the compressor part load efficiency will be slightly betterat low compression ratio and significantly better at high compression ratio with reducedspeed compared to slide valve control, but this is before taking into account the lossesin the driver at reduced speed.

Typical variable frequency drives will cause a loss in efficiency of around 3% atfull load. They will also cause an additional loss of motor efficiency of 2.5%. This givesa full load efficiency loss of about 5.5%. With some drives this loss may stay at thesame relative horsepower level as the drive speed is reduced, effectively becoming alarger percentage loss at lower speeds. If a compressor will operate at part load, and athigh compression ratio for many hours per year, the cost of the drive may be justified. Ifa compressor operates near full load for a high percentage of time, or operates primarilyat low compression ratios, it is unlikely that there is any advantage with a variable speeddrive, or that the cost of the drive can be justified against slide valve control. See typicalcurves below for differences in power consumption. (See Figures 14 & 15.) Thesecurves are calculated assuming drive and motor losses are a fixed percentage of powernot fixed kw at reduced speed.

SuctionGas

DischargeGas

Valve Open GasBypasses

Valve ClosedNo Gas Bypasses

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 14 of 27

Figure 14

50 100 150 200 250 300100

150

200

250

300

Tons Refrig.

KW

usa

ge

SV

VariSpd

Diff in KW Usage 20 F Evap.Slide Valve vs. Vari Speed

20 40 60 80 10050

100

150

200

250

Tons Refrig.

KW

usa

ge

SV

VariSpd

Diff in KW Usage -20 F EvapSlide Valve vs. Vari Speed

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 15 of 27

Figure 15

Whether variable speed is justified as a part load method must consider the loadprofile and operating conditions that are expected in a particular application.

Variable speed control with screws should not be implemented without consultingthe compressor manufacturer. There are lower speed limits for compressors belowwhich bearings may fail due to inadequate bearing lubrication. Large compressors willhave lower minimum speeds than small compressors. Many small compressors may beable to accommodate drive speeds above the input line frequency, but separator limits,oil cooler size, and other package limitations must be investigated. It is also possible tofill a compressor up with oil and cause failure if the speed is reduced below anacceptable range with the compressor unloaded. Many of these limits are not publishedbut should be investigated early in a variable speed proposal or study.

Oil Systems: Separation and Cooling

As pointed out, oil injection performs many useful functions in the screwcompressor, however, since oil is not desirable in other parts of the refrigerating system,oil flooded screws bring with them the need for oil separators. One type of oil separatordesign is seen in attached Figure 16. The mixture of discharge gas and oil leaving thecompressor is directed against one head of the oil separator where it experiences achange in direction and a large reduction in velocity. The larger oil particles are drawnto the oil sump by gravity, with the smallest particles, or oil smoke being carried into thecoalescing filters. Here, these small particles impact on the internal fibers in the filtersand coalesce into larger oil droplets which can then be collected in the dry end sumpand returned to a low pressure area in the compressor. Besides removing oil from thegas stream, the separator also gives the oil in the main sump time for any liquidrefrigerant droplets to absorb heat and vaporize, or entrained bubbles to rise to thesurface of the oil, giving a more pure oil for reinjection in the compressor.

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 16 of 27

Figure 16

Since most of the heat of compression is transferred to the oil duringcompression, this heat must be removed by an oil cooling system. The three mostcommon systems are water cooled, thermosyphon cooled, or liquid injection. While air-cooled coolers are possible they are not as popular as the above three systems and willnot be addressed here.

Water Cooled Oil Cooling

Referring to Figure 17 the hot oil leaves the oil separator, through a strainer intothe oil pump. The oil is pumped through a shell and tube or plate type heat exchangerwhere the heat is rejected to circulating water, or glycol. The cool oil is then filtered andreturned to the compressor for reinjection. Primary disadvantages of this system involvethe initial cost and maintenance of the water or glycol system, and risks of tube rupture,or plugging if proper water condition is not maintained. It is generally preferred to leavewater flow to the cooler at a fixed rate and use a temperature regulated mixing valve onthe oil side of the cooler to blend hot and cold oil to the desired reinjection temperature.This will help to minimize water side fouling of the tubes by maintaining a higherminimum water velocity. The use of closed loop glycol eliminates fouling risks.

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 17 of 27

Figure 17

Thermosyphon Oil Cooling

Today, thermosyphon is the most common type of oil cooling in industrial plants.A typical thermosyphon system is shown in Figures 18 and 19. The thermosyphonsystem is similar to the water-cooled system except the water is replaced by refrigerantboiling on the tube side of the oil heat exchanger. The thermosyphon system isbasically a flooded evaporator, fed by the gravity head of a tank of liquid refrigerant in athermosyphon receiver, elevated above the level of the heat exchanger . As hot oilenters the shell side of the heat exchanger, refrigerant boils in the tube side with thebubbles rising in a return line back to the thermosyphon receiver. Vapor generated bythis process is vented back to the condenser inlet where it gives up heat and returnswith the system liquid. In effect the thermosyphon oil cooler is a gravity floodedevaporator, with its evaporating temperature set by the pressure at the condenser.

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 18 of 27

Thermosyphon systems are popular because they require virtually nomaintenance and they do not degrade compressor performance. Modest cost isrequired for installation, and piping can occasionally be challenging, particularly insystems with little headroom, or old engine rooms where the piping contractor has to getcreative. This subject will be left for another paper.

Figure 18

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 19 of 27

THERMOSYPHON OIL COOLING

Compressor Not Running

Compressor Running

Figure 19

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 20 of 27

Liquid Injection Oil Cooling

Liquid injection cools the oil by direct injection of refrigerant liquid into a lowpressure screw thread, part way down the compression process as seen in Figure 20.The oil and the discharge gas are controlled to the desired temperature by a thermalexpansion valve. This valve controls the injected liquid flow to maintain the temperatureof a thermal bulb installed in the compressor discharge line.

Some of the injected liquid expands through the expansion valve into the screwthreads, requiring additional power to compress it. All of the remaining liquid mixes withthe oil and is carried down the discharge line with the discharge gas. The injected liquidremains in the compressor less than 0.01 second. As heat transfer takes time, much ofthe cooling takes place in the discharge line and the oil separator, where the liquid hastime to absorb heat and be evaporated. Some of the liquid mixed with the oil will leakthrough internal compressor clearances to the suction. Oil leaked to suction has littleeffect, however, the liquid will expand into the suction as vapor, with a large increase inspecific volume, reducing the amount of suction charge that can be drawn in. Thiscauses a reduction in capacity with liquid injection, with larger effect at highcompression ratios.

Low initial cost, and low maintenance made liquid injection popular several yearsago, however, the power and capacity penalties make it unattractive for mostapplications with high heat of compression. Liquid injection is also not recommendedfor systems with even temporary conditions of high suction, and low head, whereinadequate differential across the expansion valve causes erratic liquid feed.

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 21 of 27

Figure 20

Economizers and Sideloads

Since the pressure in a screw compressor is gradually increasing along thelength of the rotor, it is possible to locate holes down the rotor bore at any pressurebetween suction and discharge. An economizer port is a hole located at a fixed volumeratio from suction that can be used as a secondary suction port on the compressor.Additional gas can be drawn into the screw thread while it is open to the economizerport, raising the pressure in the thread, with the combined massflow being compressedtogether to discharge.

In the case of a sideload, the additional gas generally comes from a secondevaporator. The refrigerant pressure at the evaporator must be higher than theeconomizer port pressure by a sufficient amount to overcome pressure drop and beable to force gas into the screw thread. As an example, if the economizer port islocated at 1.6 Vi the following table, (Figure 21), gives a comparison of how muchsideload capacity would be available at various suction pressures.

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 22 of 27

-40 -20 0 200%

100%

200%

300%

400%

Sat. Suct Temp. F

% o

f Suc

t. T

ons

Ref

r.

40F

20F

0F

-10F

Sideload Capacityas a % of suction capacity

Sideload Temp.

Figure 21

An economizer is a special case of a sideload where a portion of the liquid fromthe condenser is evaporated, with the flash gas going to the economizer port, in order tosubcool the remaining condenser liquid to the saturated temperature at the portpressure, (See Figure 22). This allows an increase in capacity because the liquid goingto the main evaporator is colder, and an increase in overall efficiency because of thethermodynamic advantage of subcooling and the fact that the compression of vapor atthe economizer port is generally very efficient.

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 23 of 27

Figure 22

When the compressor is spinning, there are certain sources of inefficiency thatmust always be overcome; friction in the bearings and at the walls, shearing of the oilfilms, leakage of a certain amount of oil from thread to thread, and friction at the shaftseal. The addition of the economizer gas does not significantly increase any of theselosses, and thus the economizer compression is almost like it is performed in africtionless, "loss-less" compressor.

Economizer Piping

Sideload - Secondary EvaporatorPiping

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 24 of 27

Installation Requirements

Following a few simple guidelines will add greatly to trouble free compressoroperation. First, it is always important to follow manufacturer's recommendations, butthe following summarizes a few of the basic issues that are frequently overlooked intypical installations.

Install compressors on proper foundations. Level package to eliminate stressand grout under feet to assure full contact with the floor. Good quality anchors shouldbe used to attach the package to the foundation.

Use pipe hangers on the suction line within 2 ft of the vertical riser to avoidadding pipe stress to the compressor housing. The discharge line should also besupported in the case of long pipe runs.

As much as possible, keep dirt out of the system during fabrication. A dirtyinstallation will cause problems for years with plugged valves, damaged parts, andpotential compressor damage. Screws are very rugged and forgiving but ingestion ofdirt will eventually effect performance or longevity.

Use only refrigerant grade ammonia in systems, never agricultural grade. Useproper service techniques to avoid contaminating the system with water. A properlymaintained system should not have over 80 ppm of water. Most good systems are 25-35 ppm.

Use the right oil for the application. Not all oils are equivalent. Very low suctiontemperatures, (<-50°F), should use special low pour point oils. Don't mix different oils inthe same compressor, and make sure to keep engine and hydraulic oils away from thescrew compressors. Additives in non-refrigeration oils are not compatible withrefrigeration systems.

Proper sizing of suction accumulators is vital to trouble free compressorinstallations. While screw compressors can accept some amount of liquid withouthydraulic damage, it is possible to cause rotor galling failures in low temperatureammonia systems with continuous wet ammonia return. Proper sizing of suctionaccumulators to avoid liquid carryover can avoid expensive problems.

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 25 of 27

Maintenance

Follow manufacturer's recommended maintenance schedules as requirementsvary between products. However, some general comments can be made that should fitmost applications.

Oil analysis is an important part of any compressor maintenance program. It ismost important to watch for water content (Karl Fischer test), and viscosity change overtime which would indicate oil breakdown or dilution. Excessive water will killcompressors if allowed to remain in the system. Metals analysis may detect someproblems, but usually indicates problems rather late in the failure cycle.

Vibration analysis is the best method of monitoring bearing condition. It is veryeffective with anti-friction bearings, giving an indication of bearing deterioration in thevery early stages of failure. A good vibration monitoring program or onboard vibrationmonitoring employed with anti-friction bearing compressor designs can eliminate theneed for routine disassembly inspection if properly implemented, and greatly minimizethe risk of catastrophic compressor failure.

Troubleshooting

Despite our best efforts compressors may sometimes have problems. It is thepurpose of thoughtful troubleshooting to pinpoint the cause of problems withoutexpensive component replacement or teardowns of the wrong components.

One of the most useful troubleshooting aids is a careful consideration ofdischarge temperature. A discharge temperature higher or lower than predicted atoperating conditions should be investigated, as it may be indicating a potential problem.A logical troubleshooting process should be followed to determine why the dischargetemperature might be out of line.

Low Discharge Temperature

1. Discharge temperature could be too low because liquid refrigerant is being carriedinto the suction or economizer lines. Excessive foaming in the separator or frostappearing far down the compressor suction housing can also indicate this.

2. Low discharge temperature may indicate condensing in the discharge line during offcycle, running back into the oil separator, and feeding excess liquid to thecompressor until the package warms up.

3. Low discharge temperature could indicate oil flow above design level. Is maininjection adjusted properly or could balance piston wear be increasing the flow of oil.

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 26 of 27

High Discharge Temperature

1. High discharge temperature can be caused by suction or economizer superheatrunning above design level.

2. Restricted oilflow to the compressor will cause high discharge temperature. Checkfor main injection valve, oil orifice, or filter blockage.

3. Is the volume ratio and slide valve correctly calibrated and working properly. If thecompressor is running at the incorrect volume ratio for the application, excessivehorsepower will be consumed in the compression. Excess power consumptionalways shows up as too high a discharge temperature.

4. Is the compressor in the early stages of failure or loosing axial rotor position due tothrust bearing wear? Any condition that causes a loss of rotor position will lead toexcessive thread to thread leakage and higher discharge temperatures. If this issuspected, vibration analysis is the best way to assess compressor condition. Ifvibration analysis is not possible, teardown inspection may be called for if all otherpossibilities have been investigated.

5. Is the oil cooling working correctly? This is easy to sort out as a possibility withrating software for the compressors if the actual operating oil temperature is input tothe rating program. If the measured discharge temperature at an elevated oiltemperature is still in agreement with predictions, it is fairly certain the compressor ishealthy but perhaps the oil cooler should be investigated.

The Future of Screw Compressors in Refrigeration

Conditions in our industry are changing and screw compressors are alsochanging to meet customer's demands. Some of the areas that we see as opportunitieswith today’s screw compressors are listed below.

Modern machine tools and automated inspection equipment are making itpossible to hold tighter tolerances in day to day manufacturing environments. Thisimproves compressor performance and consistency from one compressor to the next.

Greater use of electronics to save energy, simplify maintenance, and anticipateproblems before they occur will reduce energy consumption, operating costs, andmaintenance costs. Just as personal computers have changed all our lives they arealso changing the engine room. I believe these changes are still in their infancy. Ourindustry is significantly behind automotive in use of electronics but I believe it isinevitable and coming very fast.

Basics of Operation, Application &Troubleshooting of Screw Compressors

J.W. Pillis, January 1998 Page 27 of 27

We see the regulatory requirements and concern over leakage drivingcompressor designs to new levels. New shaft seal designs, elimination of pipe threads,smaller charge requirements, and more welded construction are all areas that are herenow or coming fast.

Lower noise requirements in engine rooms are becoming increasingly important.Quieter compressor and motor designs are being specified in an increasing number ofapplications.

It is certain that change will occur in our industry. The screw compressor hasproven to be a strong central component in many of our systems because of its inherentefficiency, safety, and flexibility. It is certain that continuing innovation in screwcompressor design will be key in improving our system designs for the future.

Bibliography

1. Pillis, Joseph W., “Development of a Variable Volume Ratio ScrewCompressor”, March 3, 1983.