Process time is g...⑤ Stopper bolt. You can disassemble this unit by removing the stopper bolt....

Transcript of Process time is g...⑤ Stopper bolt. You can disassemble this unit by removing the stopper bolt....

389

Process time is greatly reduced for piercing alignment work by means of a new piercing mechanism. Also, by using a compact punch unit, both piercing in areas where the cam unit cannot be used and the reducing number of processes become possible.

■Feature ●Unlike ordinary piercing, there are various merits as piercing is performed through dependence on button dies.

●In comparison to existing piercing, creating a large clearance (0.4 to 1.5mm) between the punch and the button die is

possible. This means that holes can always be opened even if the punch and button die are eccentric.

●Greatly reduces pierce alignment work.

●The panel and punch do not make contact. This means there is no burr on the panel.

●As it is machining by tearing off, there is no creation of cutting powder (shearing powder) when piercing aluminum

panels, which is different from shearing process.

■Application Examples for Breaking PunchUsed with a Cam Unit

Used when directly installed to a piercing die

Used as a punch unit built in a pad

Breaking PunchPunch Unit

390

It is said that the ordinary punch shears the panel in piercing. However, the best way to describe the piercing a hole with a

breaking punch is that it occurs with a tear of the panel.

Holes pierced with a regular punch cause clack to occur from both the front and rear end of the panel which originate from

both the end of the punch blade and the button die end. The panel is then blasted when connected to the clack. Thus, in order

to join the clack on both the front and rear of the panel in an appropriate manner, there was a need to make the clearance

between the punch and the button die extremely small (0.03mm to 0.05mm). However, by making the edge (shoulder) of the

breaking punch into an R-form, no clack occurs from the punch-side of the panel and occurs only on the button die side. From

the time when clack occurs to until it has made it to the panel surface, hole opening is performed by pulling (tearing).

The opening of holes with a breaking punch depends only on the button die edge. There is no need to adjust the

connection of clack of the panel front and back as seen in regular punching. This makes possible the securing of a large

amount of clearance (0.4mm to 1.5mm) in the area between the punch and the button die. This also allows eccentricity of the

punch (up to 0.2mm).

■Hole-opening mechanism by BreakingProfile of breaking punch

・Sharp point at the end of punch. ・At the end of the punch (shoulder) there is round chamfering on the punch edge.

R Shoulder

Eccentricity is up to 0.2mmEccentricity amount is 0.01 to 0.02

Clearance Clearance

Projection tip

Ordinary Punch

Ordinary Punch Breaking Punch

(Diagram) End point formation of breaking punch

Differences in Fundamentals for Hole Opening of the Regular Punch and Breaking Punch Methods

Breaking Punch

Clack

ClackPunch

SmallClearance Large

Eccentricity of the punch and button die

DifficultHole Adjustment Easy (unnecessary)

ButtonDie

Punch

ButtonDie

to

Brea

king

pun

ch

Breaking PunchPunch Unit

391

Breaking punch

Panel

Panel front Panel back

Button Die

Scrap

Breaking Punch Hole Opening Process

Projection tip thrusts and breaks through the panel.

The panel is stretched and clack (break) occurs from the button die edge side.

The clack (break) portion lines up with the button die edge and is expanded.

The projection tip catches onto the panel and the panel is torn.

The torn panel becomes scrap and is jammed into the button die.

The scraps falls and hole opening is complete.

Breaking PunchPunch Unit

392

■Application Range for Hole Opening by Breaking

Application Range for Hole Opening by Breaking

Application Range Table

Please perform design while referring to the application range shown below.

For any design that does not fall within the range of application, please contact one of our sales offices.

Application Range

Piercing Hole-diameter(mm)

Panel Plate Thickness

Application Range

Steel plate (270MPa or under)

t = 0.8mm or under

One-side under 0.2mm

Punch unit

Breaking punch

Panel Material

Panel Plate Thickness

Allowable Eccentricity Amount

Piercing Hole-diameter

Brea

king

pun

ch

Breaking PunchPunch Unit

393

■Product Dimensions for Breaking Punch The blade point length of the breaking punch and the shank diameter depend on the punch diameter. The form of the entire

unit can be specified by specifying the effective length and the punch diameter.

■Standard Configuration of the Breaking PunchHow to specify part codes

Effectivelength L

PunchDiameter

Punch Diameter (mm) Flange Diameter (mm) Blade Point Length (mm)Shank Diameter (mm)

tolerance

Breaking PunchPunch Unit

394

■Precautions when using the Breaking Punch ・ Even in the case in which hole-opening is performed using the Application Range Table on page 393, there is a chance that

a more appropriate hole does not open as a result of the plate thickness, materials and pierce conditions.

・ Please control the edge of the button die.

・ Please do not use punch with damaged projection tip. There is a chance that appropriate hole-opening cannot take place

as the scrap is not retained when there is a lack of protrusion height.

・ Please ensure that there is no space between the panel and button die. If there is a space, appropriate hole-opening may

not be possible.

Scrap isretained

Scrap is notretained

Punch

Panel

ButtonDie

No space between it and the panel Space between it and the panel

Eccentricity less than 0.2mm Eccentricity 0.2mm or over is impossible

Less than 0.2mm 0.2mm or over

・ Make the eccentricity of the punch and the center of the button die less than 0.2mm.

*The less eccentricity there is, the greater the quality of the hole (burrs).

Brea

king

pun

ch

Breaking PunchPunch Unit

395

・ Ensure that the button die face that contacts the panel is flat. There is a chance of not being able to perform appropriate

hole-opening if a flat surface is not secured.

・ Make the punch intrusion is 3.0~4.0mm. There is a chance that appropriate hole-punching cannot be performed if intrusion

is 3.0~4.0mm.

・ Ensure that the Punch center axis angle against the button die face is 2.5 degrees or under.

Flat surface secured

Intrusion

Lack of flat surface

3.0~4.0mm

2.5 degrees or under 2.6 degrees or more

Breaking PunchPunch Unit

396

■Application Examples of Breaking Punch

■Used with a Cam Unit

Usage examples for the pierce die

Existing pierce punch

When using existing pierce punches, matching

precision of the upper and lower dies was sought after.

Also there were cases in which time was needed for

pierce alignment work after assembly took place.

By using it with our Cam unit with self-alignment mechanism

Further cutting of pierce alignment work can be realized.

The one-side clearance of the punch and button die can

be within 0.4 to 1.5.

The one-side clearance of the punch and button die

must be within 0.03 and 0.05.

Breaking Punch

By using the breaking punch, margin for errors for the

upper and lower dies can be absorbed by the

clearance of between the punch and button die. Thus,

there is no need for troublesome blade alignment work.

Eccentricity amount is 0.01 to 0.02

Clearance

Punch

ButtonDie

Eccentricity is up to 0.2mm

Clearance

Punch

ButtonDie

Cam unit with self-alignment mechanism

Retainer

Breaking Punch

(Cam unit with self-alignment mechanism)

・ OASA Series (See P. 114)

・ OASB Series (See P. 178)

・ OASL Series (See P. 204)

*All are 5 degrees pitch compatible

Breaking Punch Reduction of troublesome blade alignment work

Brea

king

pun

ch

Breaking PunchPunch Unit

397

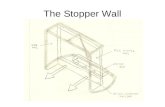

Flat type

Front side of the pad(Front surface of the structure)

Inclined type

■Example of the punch unit installation

Structure

●This unit consists of the following five components: ① Slide, ② Unit punch, ③ Case, ④ Spring and

⑤ Stopper bolt. You can disassemble this unit by removing the stopper bolt.

Back side of the pad

Spring

Unit punch (Breaking punch)

Stopper boltSlide

Case

■Feature ●It is a new type of hole-opening device that is implanted

into the pad and used.・Hole-opening by breaking punch. ・Layout is possible facing against the processing face.

Thus, stable piercing conditions can be secured.・Contributes to the shortening of processes as

hole-opening is possible even with respect to areas in which piercing with a cam unit is difficult.

●Small and light.・Size and weight that can be easily picked up with one hand (approx. 1kg)

●Reduces Punch and Button Die Alignment Work.・Eccentricity of up to 0.2mm can be allowed,

reducing the adjustment work.●Round hole-punch diameter of 4.5mm to 21mm

accommodated.

Breaking PunchPunch Unit OPF and OPA Series

398

Example of reducing the process

Conventional process

Drawing

Process when the punch unit is used

Firstprocess Cam piercingThird

processTrimming, piercing and flanging

DrawingFirstprocess

Trimming, piercing and flanging

Secondprocess

Secondprocess

Punc

h Un

it

Breaking PunchPunch Unit

399

●Select a flat type (OPF~) or an inclined type (OPA~) in accordance with a work angle.

Refer to Selecting method on the page 402.

●Installation dimensions of the unit (case-holding length)

For installation dimension of the unit, refer to the following figures for processing.

●Set the punch unit as the punch becomes perpendicular to the dice surface.

●Keep the dice face flat. In case the dice surface is not flat enough, it is hard to make a proper hole.

16 or larger M8 tap depth 20 or larger

Keep the dice surface flat

The dice surface is not flat enough

Perpendicular to thedice surface

At an angle to the dice surface

◎Precautions (Regarding die design)

Breaking PunchPunch Unit

400

●Set as some clearance exists between the unit and the panel. Do not use the unit as a panel retainer.

0.2mm Le

vel

●To prevent the pad being lowered during empty punching, use the pad balancer(spacer). During punching operation, the punch contacts the lower section of the die.

Pad balancer(spacer)

Pad balancer UnusedPad balancer use

●Attach sensors (panel loading switch, unloading switch etc.) to the unit to prevent punching two pieces of panels together or to prevent tucking a foreign object. During punching operation, the punch contacts to the upper section of the die.

Usual operation Pad lifting by punching two pieces of panels

Pad lifting by tucking a foreign object

Set some clearance between the unit and the panelApproximately 0.2mm

Punc

h Un

it

Punch Units

401

●For the sliding section at the driver side, using a #2000 (sintered) wear plate is recommended.

●Please do not perform machining of the sliding surface on the slide of the punch unit.

●When a wear plate is not used for the sliding section at the driver side, set the roughness of the

sliding surface at Ra=1.6 or smaller.

●Scraps tend to remain when the work angle is from 0 to 30°. In that case, the following dice types

are recommended.

(φd indicates the dice inner diameter.)

Conventional dice

When the angle is small, scraps may rolls out.

Dice with a countermeasure for rolling-out scraps

A squeeze is installed at the back section of the dice edge, holding scraps.

Without a #2000 (sintered) wear plate

With a #2000 (sintered) wear plate

Do not machine sliding surface

Do not machine sliding surface

Punch Units

402

Do not pad-locked the unit.

Secure the contacting surface.

Fixing bolt

The punch stays inside of the dice; therefore, the unit gets damaged by lifting the upper die.

●Please do not use units in which the projection tip has been damaged.

●When a height of the projection is insufficient due to breakage, the scrap cannot be held and holing

becomes unavailable.

●Conduct the sliding operation of the pads. However, before sliding and adjusting the pad, be sure

to remove the punch unit.

●Before conducting the initial punching, be sure to confirm the deviation between cores of the punch

and the dice.

●Do not pad-lock the unit.

(When the upper die is lifted with the unit being pad-locked, the unit gets damaged with the punch

stayed inside of the dice.)

Precautions (Die manufacturing, productions)

●Apply an agent to prevent loosening of the fixing bolts.

●Adjust the contacting condition the sliding section.

Scrap is held Scrap

is not held

Punc

h Un

it

Punch Units

403

Type

OPF series (flat type) OPA series (inclined type)

Punch diameter

Flat type

Maximum stroke Unit

Punch diameter

inclined type

Maximum stroke Unit

Table of machining abilities

●Select a flat type (OPF~) or an inclined type (OPA~) in accordance with the process angle.

Selecting method

Flat type (OPF)

Inclined type (OPA)

Work angle 20°≦ θ < 90°

Work angle 0°≦ θ < 20°

Punch Units

404

Regarding application of part, consult with a sales office near you. A person in charge will explain the details.

Punc

h Un

it

Punch Units

405

This dimension is different by condition (plate thickness and material) of making a required hole diameter, consult with a sales office near you.

φP(φ4.5~φ5.5):

PUNCH UNIT

406

This dimension is different by condition (plate thickness and material) of making a required hole diameter, consult with a sales office near you.

φP(φ5.6~φ6.5):

Punc

h Un

it

PUNCH UNIT

407

This dimension is different by condition (plate thickness and material) of making a required hole diameter, consult with a sales office near you.

φP(φ6.6~φ8.5):

PUNCH UNIT

408

This dimension is different by condition (plate thickness and material) of making a required hole diameter, consult with a sales office near you.

φP(φ8.6~φ10.5):

Punc

h Un

it

PUNCH UNIT

409

This dimension is different by condition (plate thickness and material) of making a required hole diameter, consult with a sales office near you.

φP(φ10.6~φ13.5):

PUNCH UNIT

410

This dimension is different by condition (plate thickness and material) of making a required hole diameter, consult with a sales office near you.

φP(φ13.6~φ16.5):

Punc

h Un

it

PUNCH UNIT

411

This dimension is different by condition (plate thickness and material) of making a required hole diameter, consult with a sales office near you.

φP(φ16.6~φ21.0):

PUNCH UNIT

412

This dimension is different by condition (plate thickness and material) of making a required hole diameter, consult with a sales office near you.

φP(φ4.5~φ5.5):

Punc

h Un

it

PUNCH UNIT

413

This dimension is different by condition (plate thickness and material) of making a required hole diameter, consult with a sales office near you.

φP(φ5.6~φ6.5):

PUNCH UNIT

414

This dimension is different by condition (plate thickness and material) of making a required hole diameter, consult with a sales office near you.

φP(φ6.6~φ8.5):

Punc

h Un

it

PUNCH UNIT

415

This dimension is different by condition (plate thickness and material) of making a required hole diameter, consult with a sales office near you.

φP(φ8.6~φ10.5):

PUNCH UNIT

416

This dimension is different by the conditions (plate thickness and material) of making a required hole diameter, consult with a sales office near you.

φP(φ10.6~φ13.5):

Punc

h Un

it

PUNCH UNIT

417

This dimension is different by the conditions (plate thickness and material) of making a required hole diameter, consult with a sales office near you.

φP(φ13.6~φ16.5):

PUNCH UNIT

418

This dimension is different by the conditions (plate thickness and material) of making a required hole diameter, consult with a sales office near you.

φP(φ16.6~φ21.0):

Punc

h Un

it

PUNCH UNIT

419