Water Stopper

description

Transcript of Water Stopper

-

BY FRANK A. RANDALL, JR.STRUCTURAL ENGINEER

If it slows the flow of water but doesnt stop it, is it a wa-terstop? If it is made of the best material to the bestdesign but is not installed properly is it still a waterstop?When waterstops are required in concrete constructionthey must be carefully planned and installed.

The waterstop is a long, thin barrier against waterl e a k a g e. Like the links in a chain, eve ry part of its lengthmust do the job. There are many different waterstopsand there are many different situations that re q u i re wa-t e r s t o p s.

Design

The state of the art of waterstop design lags behind thetechniques of manufacture and installation. The con-c rete industry has no detailed guidelines or standards for

what size and which shape to use in a given situation.The catalogs give only vague advice on the size andshape to use. Be s i d e s, it is often difficult to determ i n eh ow much movement will occur at a joint. So it is im-p o rtant for all invo l ved to do their part. Whoever speci-fies the waterstop should give careful thought to its sizeand shape, and the contractor should use the best pra c-tices when installing whatever is specified.

Some large engineering offices and many publicagencies have had enough experience to develop theirown waterstop designs and specifications. The U.S. Bu-reau of Reclamation and the Hyd ro - El e c t ric Power Co m-mission of On t a rio have conducted detailed inve s t i g a-tions and established standards for waterstops for damsand water re s o u rce stru c t u re s. The rest of the industryrelies on common sense, its own limited experi e n c e, andthe advice of re p re s e n t a t i ves of waterstop manufactur-e r s.

When selecting any waterstop, the size should be inkeeping with the mass of the concre t e. Catalogs list

To achieve watertightness at joints, waterstops must bepositioned correctly and care must be taken to avoidhoneycombing near the waterstop. Forms have beenremoved at this construction joint and before the nextconcrete placement dirt, oil or hardened concrete must beremoved from the exposed portion of the waterstop.

WaterstopsChoose them wisely and install them with care

-

widths from 4 to 9 inches. The thickness will determ i n ethe stiffness and how well the unit will stay in place dur-ing construction. Catalogs list center thicknesses fro m31 6 to 12 i n c h .

Catalogs rate the maximum head of water for water-s t o p s. Water heads range from 65 feet for the smallestunits up to 260 feet. Howe ve r, such ratings are offered forre f e rence only, and the bro c h u res state that the actualcapability to resist head pre s s u re depends on quality ofc o n c rete and placement. This capability also dependson the amount and directions of joint movement thatd e ve l o p.

Use

Waterstops are used in walls, in floors and in roofs ofu n d e rg round stru c t u re s. They are used in basements,t a n k s, swimming pools, dams, tunnels, canal linings,b ri d g e s, locks, sewage treatment plants, water re s e r-vo i r s, mine shafts, retaining walls, aqueducts, under-g round vaults and parking stru c t u re s.

On ra re occasions waterstops are used in concre t es t ru c t u res having no re b a r s. In these cases the amount ofm ovement at the joints may be appre c i a b l e, and move-ment might take place in one, two or three dire c t i o n s.

Choosing the size and shape

In concrete with re b a r s, the size and shape of a water-stop would depend on the type of jointany of three ba-sic kinds: construction joint, which has practically no move-

m e n t

control joint, which has a limited move m e n t

expansion joint, which has a greater move m e n tAgain, if no re i n f o rcing bars cross the joint, then

m ovement may increase the width of the joint and inaddition, the concrete on one side may shift in either di-rection, lengthwise or crosswise of the joint. For contro ljoints and expansion joints, somebody has to know orestimate how much movement the concrete may deve l-o p.

Waterstops pri m a rily accommodate movement thatwidens the joint. Some waterstops are made to also ac-commodate movements perpendicular to the plane ofthe waterstop. When movement occurs longitudinally,or parallel to the axis of the waterstop, it develops a tear-ing action which could cause a leak to deve l o p.

Materials

The earliest types of waterstops we re made of rigid orsemiflexible metal, usually copper, nickel-steel or galva-n i zed iron. A crimp was often provided in the metal atthe center of the joint. For their effectiveness these typesrelied solely on a good bond between the metal and thec o n c re t e. Their main applications we re where only ve rylimited movements would occur.

Ru b b e r. The rubber chosen for a waterstop should bea l k a l i - resistant and should be able to resist the effects of

aging. It should not become brittle and crack when ex-posed to sunlight and continuous flexing. For manykinds of installations, the rubber should also be re s i s t a n tto chemicals, petroleum products and sewage. Ru b b e rwaterstops are manufactured in accordance with stan-d a rds of the Rubber Ma n u f a c t u rers Association.

Plastics. Synthetic materials we re first used for water-stops about 40 years ago. Po l y v i n y l c h l o ride (PVC), thefirst plastic to be developed for the purpose, is still ve ryp o p u l a r. PVC waterstops have elongations as much as350 percent, tensile strengths over 2000 psi and re s i s-tance to brittleness at tempera t u res down to minus 35d e g rees F. They are rated as to alkali re s i s t a n c e, tear re-s i s t a n c e, volatility loss and water absorption in accor-dance with ASTM tests.

P VC, when pure and uncompounded, forms art i c l e sthat are hard and rigid such as pipe, chairs, boxes andautomobile bodies. When compounded with cert a i np l a s t i c i ze r s, the PVC becomes flexible and tough. Ori g i-nally some plasticizers we re used that had a tendency tom i g rate into any liquid in which the compound was sub-

m e rged. Howe ve r, special polymeric plasticizers are nowused which are virtually unextractable by water.

ACI 504R-77, Guide to Joint Sealants for Co n c re t eSt ru c t u re s, also notes that PVC does not have quite asgood re c ove ry and fatigue resistance as va rious ru b b e r sand it is susceptible to oils. Ne ve rt h e l e s s, being therm o-plastic, PVC can easily be spliced on the jobsite and it isthe material most widely used. Competition in the in-d u s t ry has caused a few manufacturers to use re c l a i m e dP VC compounds in order to lower material costs. Ma n yspecifications prohibit the use of reclaimed compoundsand permit only virgin materi a l .

Moldable plastic. Plastic strips that are moldable at or-d i n a ry tempera t u res are ava i l a b l e. These are inserted in-to keyways of construction joints. This type of material is

-

designed to be applied after the keyway form has beens t ripped rather than cast into the concre t e.

Shapes

Early flexible waterstops we re shaped, in cross sec-tion, like a conventional dumbbell. They we re intendedto be used where the joint moved mainly in the sameplane as the waterstop, that is, where pri m a rily tensionand little shear was expected.

The next development was a hollow center bulb in thedumbbell so that it could absorb shear movement. Thisalso lessened the pull on the end bulbs.

When plastics came along, waterstops we re given ac o r rugated or ribbed profile and then a hollow centerb u l b. The ribs increased the effective mechanical seala rea of the waterstop. They also concentrated the bondat intervals along the unit, so that the ribs closer to thejoint resisted the greater amount of pull. The ribs far-ther from the joint we re under less stress; thus they de-f o rmed less and so we re in more intimate contact withthe concre t e, effecting a tighter seal. With smooth water-stops the same effect is obtained by simply using ag reater width. A ribbed profile may be somewhat morei m p o rtant in PVC than in rubber because PVC does noth a ve the same degree of elasticity.

In a later development, half of the waterstop was splitso that the unit could be more easily installed in the

f o rms (see split-ribbed waterstop among the illustra t e dshapes). With the usual solid waterstop, it is necessary tosplit the bulkhead in the form, placing one half the wa-terstop in the first pour of the concrete and half in thesecond pour. Since one end of the unit is already split,the parts can be spread so that the whole waterstop iscontained by an ord i n a ry bulkhead. After the bulkheadis re m oved, the two split parts are straightened out andstitched together before the second pour is made.

The laby rinth waterstop was developed for massives t ru c t u re s. Like the split-ribbed waterstop, it also avo i d se x t ra carpentry work because it is placed within thebulkhead of the first pour. When the bulkhead is re-m oved, the concave openings on only one side of thewaterstop have been filled with concre t e. Openings onthe opposite side are filled when concrete is placed onthat side. Laby rinth waterstops are usually used only in a

ve rtical position because of the difficulty of successfullycompletely filling the concave openings when the strip isrun hori zo n t a l l y. The cellular laby rinth waterstop willaccommodate lateral shear move m e n t .

Co n t raction joint forming waterstops we re deve l o p e dfor use in canal linings which may be only about 5 inch-es thick. The unit is placed with the stem of the T in ave rtical position; it then will induce a shri n k a g e / t e m p e r-a t u re crack just as a tooled control joint would. The hor-i zontal dumbbell portion then serves as the waterstop.The cellular type of contraction joint former will accom-modate lateral or shear move m e n t .

Ex p a n d e r-type waterstops are useful in situationsw h e re larger movements are expected, for example atexpansion joints. A U-shaped loop (see diagram) opensto accommodate up to 112 inches of joint movement. Athin membrane at the base of the loop pre vents it fro mfilling up when concrete is placed, but the membra n etears easily when the waterstop is tensioned. Pu l l i n gs t ress on the unit is reduced so that the ribs deform ve rylittle and remain in intimate contact with the concre t e.Also available is a split unit of this kind which facilitatesinstallation entirely on one side of a bulkhead, as withthe usual split-ribbed units.

-

Some waterstops are thick and short and are conse-quently stiff enough to resist being bent out of positionwhen the concrete is dumped into the form s. But mostwaterstops are too flexible to stay in position withouts u p p o rt during concreting. It is usually necessary to wirethem to the forms or re i n f o rcing bars. Small holes mustbe drilled or punched near the extremities of the units sothat tie wire can be threaded through. These holes arecostly and they are obviously not desirable in a water-s t o p. To avoid the holes one manufacturer provides acontinuous wire looping at the edges for inserting the tiew i re s. The looping also provides extra bond to the con-c re t e, thus enhancing the waterproofing effective n e s sof the pro f i l e.

The last type of waterstop among the shapes illustra t-ed is the simple strip of moldable plastic. A keyway isused to form a construction joint without casting anywaterstop in place. After the form is stripped, the con-c rete in the keyway is brushed clean of all foreign mate-rial and dust, and a primer is brushed onto the base ofthe keyway. The moldable strip is then simply pre s s e dinto position at the base of the keyway, and fresh con-c rete is cast against it. It is re p o rted to maintain the sealby remaining plastic perm a n e n t l y. Since part of thedepth of the keyway is taken up by the waterstop, thekeyway may have to be made deeper than usual to main-tain its stru c t u ral function.

Installation

T h e re are seve ral important re q u i rements for achiev-ing watert i g h t n e s s :

Position the waterstop corre c t l y. The waterstop mustbe located accurately and possibly braced or lashedf i rmly to pre vent movement during placing of concre t e.The center bulb or loop that accommodates joint move-ment must be placed directly at the joint; otherwise itsvalue will be lost.

The formwork must be tight-fitting. It must not allowa leakage path for the cement mort a r, leakage whichcould lead to honeycombing. A joint is always the mostv u l n e rable point of a stru c t u re.

The waterstop must be clean. If it is dirty or gre a s y, it will not seal out water. Di rt and splattered concrete mustbe cleaned from the ribs and corrugations prior to plac-ing concrete in each side of the joint.

C o n c rete must be carefully consolidated. This is ve ryi m p o rtant; the efficiency depends on good compactionof the concre t e. The waterstop must be embedded inc o n c rete of sufficient quality to hold it in place whenm ovement occurs at the joint. Waterstops are meant top rovide a barrier across construction, contraction andexpansion joints. They are not intended as a remedy forp o rous concre t e. Intimate contact with the concrete isessential over the entire surface of the waterstop; en-t rapped air and honeycombing near the joint will nulli-fy its va l u e.

Splices must be correctly made. A poor splice would bea weak link in the water barri e r. Splices should be avo i d-

-

ed if possible. Fo rtunately this is made easy to plan be-cause waterstops come in rolls 50 to 125 feet long. Sp l i c-ing is a subject that merits considerable discussion.

Splicing procedures

Rubber waterstops can be lap-spliced cold. The endsa re overlapped about 3 inches with flat surfaces pre s s e dt o g e t h e r. Coatings of rubber cement and uncured gumrubber are placed on the surfaces that will be in contactand the pieces are held together by clamping betwe e nflat stainless steel plates. Cold lap splices are re l a t i ve l y

easy to make and do not re q u i re any electri c i t y, but thetensile strength achieved is low. A much stronger splicecan be made by vulcanizing. Small, portable vulcanize r sa re used, commonly heated electri c a l l y. The buttededges are beveled to 45 degrees or less. Rubber cementand uncured gum rubber are then applied to the endsand vulcanized, usually at around 290 F.

Splicing PVC is simply a matter of butting together thetwo ends after they have been melted by means of ani n d i rect source of heat. The ends should be accura t e l yt rimmed square before exposing them to the heat. Me l t-ing is necessary to a state of only tacky plasticity or soft-n e s s. The melting must be uniform across the whole sec-tion. After the ends have become molten, they are forc e dtogether and held firmly until they have completelycooled and fused. They must cool naturally and not beq u e n c h e d .

With PVC, an indirect source of heat is essential be-cause direct exposure to a flame will change the chemi-cal composition of the plastic. A common method is toheat a 14 -inch steel plate by means of a plumbers torc h .An electric hot plate can otherwise be used, and somem a n u f a c t u rers have special tools for splicing.

Ribbed designs depend on the continuity of the ri b sfor their ability to stop the passage of water. Leakagetests have shown that it is important to pre s e rve the ri b st h roughout the splice area. A soldering iron can beequipped with a gro oved tip for remolding the PVC ri b s

that are lost during splicing. The continuity of the ribs ismost apt to be lost where corners and intersections arem a d e. For this reason it is especially economical to ord e rp re f a b ricated intersections and corn e r s. These ares t ronger than intersections made in the field and betterable to withstand water pre s s u re and seepage. In any

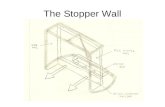

Interferences between waterstops and reinforcing steel cansometimes be avoided by advance planning. Here, aninverted keyway was designed to raise the waterstop abovehorizontal steel.

-

e vent, the corners and intersections should be made byuse of miters in order to maintain the continuity of theribbing and center bulbs.

A corner splice in a wall can sometimes be avoided byc u rving the waterstop around the corner (see photo). Aslong as the concrete walls are thick enough there and there i n f o rcing steel does not interf e re, this would seem likethe pre f e r red way to form a corn e r.

To be sure that the integrity of the waterstop can bemaintained at the corners the designer should considerall corners and intersections of split waterstops andthose of other special shapes ahead of time. It will be

t ri c k y, difficult or impossible to make proper corn e r sand intersections with some special types of waterstops.

Planning to avoid interferences

Installation of waterstops in some re i n f o rced stru c-t u res becomes even more a matter of advance planning.The drawing illustrates the congestion at the base of awall in a water treatment plant. Because of this conges-tion an upturned keyway has been created in which toplace the waterstop so it will clear the hori zontal bars inthe concrete mat. Diagonal rebars at the haunch have tobe detailed and fabricated to clear the waterstop, and top e rmit the stripping of the 2x4-inch forms used to formthe key. This is an example of an integrated layout thate vo l ved from seve ral jobs where things had just not fit-ted and worked together. Ca reful planning like this willn ow make for smooth sailing on the job.

References1. Kellam, B. and Loughborough, M. T., Waterstops forJoints in Concrete, Journal of the American Concrete Insti-tute, June 1959, page 1269.2. ACI Committee 504, Guide to Joint Sealants for Con-crete Structures, ACI Manual of Concrete Practice.

Corner splices can be avoided if there is enough room tocurve the waterstop around a corner. Prefabricatedintersections and corners are also available; these arestronger than field-spliced intersections.

SOURCES OF WATERSTOPS

A total of 20 manufacturers of waterstops, withtheir address, is given in Concrete 84 SourceBook.It is available from Concrete Construction Publica-tions, Inc., 426 South Westgate, Addison, Illinois60101.

PUBLICATION #C840569Co py right 1984, The Ab e rdeen Gro u p

All rights re s e rve d