November December2013

-

Upload

theshadowknight -

Category

Documents

-

view

220 -

download

0

Transcript of November December2013

-

8/13/2019 November December2013

1/22

November/December 2013

Story onpages 4-7

United States Department of Agriculture

Agricultural Research Service Solving Problems for the Growing World

A Bright Forecast for Catfish

-

8/13/2019 November December2013

2/22

Agricultural Researchl

November/December 20132

C onsumption of sh and seafood isincreasing, and half of the seafood pro -duced worldwide comes from aquaculture.Cat sh production is the largest sector ofaquaculture in the United States, and theAgricultural Research Service is workingon new advances as well as building on

past gains.The challenges addressed by aqua culture

research, like all research, are multifacetedand complex. The organisms, production

systems, environment, cost of inputs, andvalue of outputs are all changing dynami -cally. Oftentimes, out of necessity, researchwill focus on one piece of a large systemor one new technology, like the disease re -sistance and susceptibility of a new hybridcat sh. Simultaneously, other scientistswill be working on a different piece, such asimproving oxygen-management systems.

Generally, no single technology by itselfwill transform an industry. Instead, a seriesof improvements is needed, each of which

takes time in development and in exten -sion and transfer. Bene ts will accumulateas farmers adopt the new technologya

process estimated to take 15 to 30 years.The cat sh industry has been beset

by many of the same troubles seen inother animal-production industries. Thehigh price of feed and fuel has driven up

production costs. One factor the cat shindustry has to deal with, which is lesssevere for those in the poultry, beef, orswine industries, is the easy substitution

of cat sh with other white- eshed sh,such as tilapia. When the price of beefgoes up, people eat less beef; but whenthey do buy beef, it is generally beef thatwas produced in the United States. On theother hand, if the cost of cat sh goes up,consumers may look to similar products,often produced outside the United States,that can ll the same niche at a lower price.This has made the factors affecting the costof cat sh production especially critical.

In this issue, you will read about ad -vances in producing farm-raised cat sh.The research by ARS, Mississippi StateUniversity and other university partners,and industry scientists has been uniquelycollaborative, leading to innovations thatcould potentially double the historical

levels of production from 4,000 pounds peracre to more than 8,000 pounds. Productionof a new hybrid cat sh (blue cat sh male

by channel cat sh female) has increaseddramatically, from 30 million fry in 2007to more than 150 million in 2012, and itwill likely exceed 175 million in 2013.

New aeration strategies have resulted inimproved feeding and better conversionof feed into llet. These cumulative ad -vances result in shorter production cycles,improved rates of survival, and higher

pro tability. (See story on page 4.)As the interest in hybrid productiongrows, ARS scientists at our Stoneville,Mississippi, location are making inroadsinto genetic improvements, discovering

better methods of hybrid juvenile produc -tion, and enhancing pond systemsre -search that will help farmers deliver high-quality cat sh to meet consumer demand.

Cat sh strains are regularly evaluated tohelp farmers and processors improve traitsand increase pro ts. ARS scientists are

identifying the best blue males and chan-

nel females to produce hybrid offspringwith superior growth and llet yield. Theyalso investigate whether the performanceof purebred channel cat sh offspring is

predictive of the best female parents forhybrid production. This information will

bene t producers as they develop breed -ing plans to improve cat sh performance.

Channel cat sh have been well charac -terized for several decades, but there is less

data on blue cat sh production traits and blue-by-channel hybrid cat sh offspring.Research at Stoneville will determine theeffects of blue cat sh strains and indi -viduals within strains on hybrid offspringgrowth and llet yield.

Several scienti c advances are beingdeveloped and incorporated into cat shfarming. ARS scientists developed a setof molecular markers for DNA ngerprint -ing to ef ciently identify cat sh species

and parentage. They tested the markerson different populations and were able toidentify the parents of offspring collectedover 3 years and attribute all individualsto speci c crosses. This accuracy allowsfor greater and faster genetic gains in

performance.Strategies for progress also include

selective breeding to improve diseaseresistance, enhancing vaccine treatmentto protect against pathogens, and develop -ing better pond-management systems and

equipment. As soon as they are availableand tested, these improvements are passedon to farmers.

ARS remains committed to deliveringrelevant, high-quality research that bene tsthe aquaculture industry. This includesworking with the U.S. cat sh industry todevelop the tools and technology it needsto improve productivity, ef ciency, andquality so that it may rebound and thrive.The work of ARS scientists and collabo -rators has provided new knowledge and

technology that is contributing to a reneweddomestic cat sh industry.

2

Jeff Silverstein

ARS National Program Leader Aquaculture

Beltsville, Maryland

The Sum Is Greater Than the Parts

-

8/13/2019 November December2013

3/22

3 Agricultural Researchl

November/December 2013

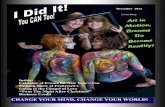

Cover: ARS geneticist Brian Bosworth (left) and animal caretaker Reese Mascagnioversee loading of market-size cat sh on a sh-hauling truck. Excess sh produced bythe ARS research program are often sold to processing plants. Story begins on page 4. Photo by Les Torrans. ( D3027-1 )

ECOVATIVE (D3063

4 Producing Better Cat sh the Hybrid Way

8 Dairy Farms Are Not a Source of Far-Flung Bioaerosols

10 Protecting Water Near Feedlots

11 Breadfruit: Not So Appetizing to Mosquitoes12 Better White Layer Cakes Ahead?

13 Breakfast Helps Kids Handle Basic Math,Study Suggests

14 Greenhouse Gas Emissions and Yields from Organicand Conventional Systems

15 Fungus Takes Down Another Weed

16 Biodegradable Packaging From Cotton Waste

19 Pairing Sesamol With Soybean Oil for Better Frying20 Ramping Up a Phytochemical Compound in Crops

20 New, Disease-Resistant Pea Lines Developed

21 Locations Featured in This Magazine Issue

November/December 2013Vol. 61, No. 10ISSN 0002-161X Solving Problems for the Growing WorldSolving Problems for the Growing World

Agricultural Research is published online 10 times

a year by the Agricultural Research Service, U.S.Department of Agriculture (USDA). The Secretaryof Agriculture has determined that this periodicalis necessary in the transaction of public businessrequired by law.

Tom Vilsack, SecretaryU.S. Department of Agriculture

Catherine E. Woteki, Under SecretaryResearch, Education, and Economics

Edward B. Knipling, Administrator Agricultural Research Service

Sandy Miller Hays, Director Information Staff

Editor: Robert Sowers (301) 504-1651Associate Editor: Sue Kendall (301) 504-1623Art Director: BA Allen (301) 504-1669Photo Editor: Tara Weaver-Missick (301) 504-1663Staff Photographers:

Peggy Greb (301) 504-1620 Stephen Ausmus (301) 504-1607

Most information in this magazine is public propertyand may be reprinted without permission (exceptwhere noted otherwise). Articles and high-resolutiondigital photos are available at ars.usda.gov/ar .

This magazine may report research involving pesticides. It does not contain recommendations for

their use, nor does it imply that uses discussed hereinhave been registered. All uses of pesticides must beregistered by appropriate state and/or federal agencies

before they can be recommended.

Reference to any commercial product or service ismade with the understanding that no discri mination isintended and no endorsement by USDA is implied.

The USDA prohibits discrimination in all its programs and activities on the basis of race, color,national origin, age, disability, and where applicable,sex, marital status, familial status, parental status,religion, sexual orientation, genetic information,

political beliefs, reprisal, or because all or part ofan individuals income is derived from any publicassistance program. (Not all prohibited bases applyto all programs.) Persons with disabilities who requirealternative means for communication of programinformation (Braille, large print, audiotape, etc.)should contact USDAs TARGET Center at (202)720-2600 (voice and TDD). To le a complaint ofdiscrimination, write to USDA, Director, Of ceof Civil Rights, 1400 Independence Avenue, S.W.,Washington, D.C. 20250-9410, or call (800) 795-3272(voice) or (202) 720-6382 (TDD). USDA is an equalopportunity provider and employer.

Biomass packaging material created using technology developed by ARS,collaborators, and Ecovative can be made to custom t a wide variety ofproducts. Story begins on page 16.

http://www.ars.usda.gov/is/graphics/photos/nov13/d3027-1.htmhttp://www.ars.usda.gov/arhttp://www.ars.usda.gov/arhttp://www.ars.usda.gov/is/graphics/photos/nov13/d3027-1.htmhttp://www.ars.usda.gov/is/graphics/photos/nov13/d3063-1.htmhttp://www.ars.usda.gov/ar -

8/13/2019 November December2013

4/22

Agricultural Researchl

November/December 20134

T he cat sh once ranked pretty far downamong sh species as a lowly bottomfeeder, but that was when it could only

be caught in the wild. With the birth offreshwater cat sh farming in the 1960s,the cat sh has made a big splash, nettingthe number-one spot in the U.S. aquacul -ture industry.

However, in recent years, U.S. cat sh producers have been struggling to keeptheir heads above water, avoiding thewaves of a slow economy, high feed costs,and sh imports from foreign countries.Sales of cat sh products were down toabout $341 million in 2012 from $423 mil -lion in 2011, and acreage has declined in themajor cat sh producing statesAlabama,Arkansas, Louisiana, and Mississippi.

To help farmers, Agricultural ResearchService scientists in the WarmwaterAquaculture Research Unit (WARU)and their Mississippi State University(MSU) colleagues at the Thad Cochran

National Warmwater Aquaculture Centerin Stoneville, Mississippi, are looking at

breeding, nutrition, genetics, and manage -

ment practices to produce a better cat sh.For decades, its been known that hybridcat sha cross of the fast-growing chan -nel cat sh with its close relative, the slowergrowing and larger blue cat shgenerallyhave better growth, higher survival, and

better meat yield than either channel or blue cat sh. But hybrids have been dif -cult to produce in large quantities. Thatschanging.

Hybrid cat sh production has increasedsubstantiallycomprising about 20 per -

cent of cat sh harvested in 2011. In 2007,cat sh hatcheries produced 30 millionhybrid fry. That number is now estimatedto be 150 million hybrid fry.

ARS scientists have re ned the hybrid breeding process and are taking the tech -nology directly to cat sh farmers. Ourhybrid work is based on solid science,

but whats making a tremendous impactis our outreach effort to get the technol -

ogy out and rapidly implement it in theindustry, says WARU researcher leaderCraig Tucker.

How To Make a HybridOur best chance for a quick impact

on hybrid production was to help farmerslearn how to make what we call the fry,or baby sh, which was new to them, saysgeneticist Brian Bosworth.

Bosworth and geneticist NagarajChatakondi are conducting workshopsfor farmers, in collaboration with MSUscientists, to demonstrate how to produce

hybrid cat sh fry in hatcheries. They alsogive on-site consultations at hatcheries.To produce channel cat sh, farmers

typically place spawning cans in pondscontaining mature males and females,Bosworth says. The females lay eggs

Producing Better Catsh

LES TORRANS (D3029-1

ARS geneticist Nagaraj Chatakondi (second from right) from the Warmwater Aquaculture ResearchUnit in Stoneville, Mississippi, holds a fully mature female cat sh in a brood sh pond while trainingthe hatchery crew at a commercial hybrid cat sh production facility in Arkansas. Through hands-ontraining, ARS scientists are taking their hybrid cat sh production techniques to the farmer.

LES TORRANS (D3031-

inside the cans, and the males then fertilizethe eggs.

The hybrid cat sh, however, is a cross between two different species that do notmate with each other naturally. Hybrid

Two-year-old blue cat sh being released in apond for future use as brood stock in hybridproduction. ARS scientists have improved crossbreeding of blue and channel cat sh, whichproduces the hybrid.

http://www.ars.usda.gov/is/graphics/photos/nov13/d3029-1.htmhttp://www.ars.usda.gov/is/graphics/photos/nov13/d3031-1.htm -

8/13/2019 November December2013

5/22

5 Agricultural Researchl

November/December 2013

fry production involves hormone-assistedreproduction. The female channel cat sh is

given a hormone injection, which inducesher to ovulaterelease eggs. The sh isanesthetized, and eggs are stripped,meaning gently pushed out. Sperm takenfrom blue cat sh males is mixed onto theeggs. Hands-on training involves teach -ing farmers the process, ensuring thatthe hormone dosages and egg and sperm

preparations are right, and dealing withany other issues.

Once eggs have hatched, productionis pretty much the same as with regular

channel cat sh, Chatakondi says. Theonly difference is that hybrid cat sh gen -erally grow much faster and are easier toharvest and process. Farmers can increase

production 20 to 30 percent by using hy - brids instead of channel cat sh.

Still, many farmers prefer channel cat -sh because fry production costs are lowerthan those for hybrids, and more channelngerlings (juvenile sh) are available.

to hatch hybrid cat sh eggs, he says.Optimal levels improve the egg-hatchingsuccess and may contribute to a lower costof producing hybrid ngerlings.

Additionally, not all eggs are createdequal. Hormone-induced sh often ovulateeggs that vary in quality due to variation in

brood sh maturity, husbandry, nutrition,genetics, and mechanical damage duringmanual spawning. Poor-quality eggs aremore vulnerable to fungi, which couldspread to healthy eggs.

Chatakondi developed a method, whichcan be easily adopted in cat sh hatcheries,to identify poor-quality eggs before theyhatch. He found that the pH level of ovar -ian uid of stripped channel cat sh eggs

prior to fertilization can be used to predicthatching success in hybrid embryos.

It appears that a pH level of more than7.0 is indicative of better quality eggs, andusing egg lots of this pH or higher canimprove hatching rate, Chatakondi says.

Genetic Tools for BreedingScientists are constructing a genetic map

of the cat sh genome to identify chro -

mosomal regions that control signi canttraitssuch as meat yield and diseaseresistancethat are essential for selective

breeding programs.Molecular biologist Geoff Waldbieser

has developed DNA markers to analyzechannel cat sh parentage and kinshipto determine genetic diversity, produce

pedigree populations, and identify mark -ers associated with important traits. Thistechnology is being used to learn moreabout genetic background to further im -

prove hybrid performance. In a recentstudy, hybrids were grown in ponds andthen measured for growth and meat yield.The analysis indicated the presence ofsubstantial genetic effects of parents onoffspring performance.

This shows we can improve hybridcat sh growth and carcass yield by select -ing superior female channel cat sh andmale blue cat sh parents, Bosworth says.

Overcoming Inefciencies inHybrid Production

Factors such as inconsistencies in eggquality and suboptimal hatching conditionsincrease the cost of hybrid fry produc -tion. We need to nd ways to improveef ciency of hybrid embryo productionin cat sh hatcheries, Chatakondi says.

One approach is to look at the effects ofwater quality, such as its calcium content,or hardness, on the hatching successof eggs. Working with sh biologist LesTorrans, Chatakondi incubated fertilizedhybrid eggs in waters containing four levels

of calcium hardness to determine whichlevel yields the highest hatching success.The calcium hardness levels ranged from25 milligrams per liter to 100 milligrams

per literlevels maintained by commercialhybrid hatcheries. They found that lowercalcium levels may reduce hatchability andincrease vulnerability to diseases.

We recommend a calcium hardnesslevel of 75 milligrams per liter in waters

LES TORRANS (D3032-1)

the Hybrid Way

Hybrid fry are maintained in hatcheries until they reach swim-up stage and begin to eat commercialfry feed. These fry are turning black, a sign that they are nearly old enough to accept feed. ARSresearch is helping to raise the ef ciency and lower the cost of hybrid cat sh fry production.

http://www.ars.usda.gov/is/graphics/photos/nov13/d3032-1.htm -

8/13/2019 November December2013

6/22

Agricultural Researchl

November/December 20136

Waldbieser also designed a rapid DNA- based test that identi es and distinguisheschannel, blue, and hybrid cat sh within24 hours at all life stages, from 1 dayafter fertilization to a cooked llet. Thetest is a useful tool for hybrid productionmanagement and postharvest detection ofhybrid cat sh products, he says.

In other research, physiologist BrianPeterson investigated the relationship

between cat sh growth, immune function,and genes during early stages of develop -ment. Egg samples were taken before andafter fertilization, and embryos were col -lected at hatch and at swim-upthe stagewhen fry are not yet sexually developed.

Peterson examined changes in geneexpression of insulin-like growth fac -

LES TORRANS (D3033-1)

tors (IGFs) and toll-like receptors(TLRs), molecules involved in theinduction of the immune response,in hybrid and channel cat sh. Overtime, gene expression levels ofTLR5 and IGF-I mRNA increasedin channel cat sh. In hybrids, TLR3,IGF-I, and IGF-II mRNA increased.

It was known in mammalianspecies that IGF-II played a primaryrole in fetal development. The big -gest surprise in our cat sh studieswas that IGF-II plays a role in bothfetal development and juvenilegrowth, Peterson says. IGF-I incat sh also plays a role during fetaldevelopment and growth.

Making the Grade Against DiseaseProliferative gill disease (PGD) is

one of the most devastating parasiticinfections affecting cat sh. Thedeadly disease damages the gillsof sh and decreases their abilityto get oxygen from water.

To nd out if hybrids are moreor less susceptible to PGD, Bos -worth and his colleagues looked

at gill damage in different lines ofchannel, hybrid, and blue cat sh.Juvenile cat sh were placed in acommercial pond where cat shdeaths were attributed to PGD.They then identi ed and examined

channel cat sh and hybrid families withthe most gill damage and those with theleast gill damage.

The consistent differences we observedin gill damage between resistant andsusceptible families after PGD infection

suggest a genetic component for PGDresistance, Bosworth says. Therefore, itcould be possible to improve PGD resis -tance through genetic selection.

Selecting Superior FishScientists routinely evaluate and identify

cat sh strains with superior performanceto help farmers and processors improvetraits and increase their pro ts. In onestudy, three genetic groups of cat sh

NWAC103 line channel cat sh, Norrisline channel cat sh, and a hybrid betweenthe Norris channel cat sh and the DycusFarm line blue cat shwere compared for

production, meat yield, and meat qualitytraits. Juvenile sh were stocked in ponds,fed, and harvested after 200 days. Fishwere weighed, counted, processed, andmeasured for meat and body componentyield. Fresh, frozen-thawed, and bakedllets were measured for quality.

NWAC103 grew faster and had higher production than the other groups. But thehybrid had higher meat yield than eitherof the channel cat sh lines. No differencewas found in weight gain, survival, andfeed conversion among groups.

In a separate study, Bosworth lookedat winter feeding effects on growth, bodycomposition, and processing traits of blue,channel, and hybrid cat sh and found thathybrids gained the most weight among fedsh. Carcass yield was consistently higherfor blue cat sh and hybrids than for chan -nel cat sh, and llet yield was higher forhybrids than other sh.

A lthough the cat sh industry has takena blow, further research on hybrids mayyield what many farmers need to get backon the road to recovery. Work continuesto determine desirable heritable traits ofcat sh, improve germplasm for commer -cial production, and identify water-qualityvariables that limit production.

Im looking at how much better thehybrid sh is now and how much betterthese production systems have the potentialto be, and I really think it is having an im -

pact on the industry, Bosworth says.BySandra Avant, ARS.

This research is part of Aquaculture, an ARS national program (#106) describedat www.nps.ars.usda.gov .

To reach scientists mentioned in thisarticle, contact Sandra Avant, USDA-

ARS Information Staff, 5601 Sunnyside Ave. , Beltsville, MD 20705-5128; (30 1)504- 1627, [email protected]. *

Animal caretaker Mike Lofton weighs a basket of hybridcat sh going to a processor. The fast-growing, meatyhybrid is a cross between the blue and channel cat sh.

http://www.ars.usda.gov/is/contacts.htm#Sandrahttp://www.ars.usda.gov/is/contacts.htm#Sandrahttp://at%20www.nps.ars.usda.gov/http://www.ars.usda.gov/News/News.htmmailto:[email protected]:[email protected]:[email protected]://www.ars.usda.gov/News/News.htmhttp://at%20www.nps.ars.usda.gov/http://www.ars.usda.gov/is/contacts.htm#Sandrahttp://www.ars.usda.gov/is/graphics/photos/nov13/d3033-1.htm -

8/13/2019 November December2013

7/22

7 Agricultural Researchl

November/December 2013

growing out in 2 years, it takes 4 years and

sometimes 5 years.Torrans examined the impact of DO concentra -tion on channel, blue, and hybrid cat sh growth,yield, food consumption, and feed conversion.

A computer-controlled pond-oxygen monitoringsystem was used to maintain precise DO levelsin the morning3.0, 2.0, and 1.5 ppm. Scientistsfound that a DO level of 3.0 ppm is requiredfor optimum production. These minimum DOconcentrations improve growth, signi cantly

shorten the productioncycle, reduce sh losses,

and greatly improve foodconversion.

This revelation haschanged the industrysoxygen-managementpractices, says WARUresearch leader CraigTucker. We have gonefrom keeping sh aliveto keeping them grow -ing. You can double thegrowth rate of the sh in

your pond by managingoxygen. Its pretty incred -ible.

Were trying to reduceproduction costs asmuch as possible, Tor -rans says. We now haveexact numbers in termsof how much aeration isneeded to maximize shfood intake, growth, andproduction.By Sandra

Avant, ARS .This research is part of Aquaculture, an ARSnational program (#106) described at www.nps.ars.usda.gov .

Les Torrans is in the USDA-ARS Warmwater Aquaculture Research Unit , P.O. Box 38, Stone-ville, MS 38776; (662) 686-3595, [email protected] .*

LES TORRANS (D3030-2)

Ten-horsepower paddlewheel aerators (shown here)allow cat sh farmers to adjust dissolved oxygen (DO)concentrations in their ponds. ARS scientists havedetermined the minimum DO level needed to improvegrowth, shorten the production cycle, reduce shlosses, and improve feed conversion.

Airing Out Catfish Oxygen Needs

Cat sh farmers can breathe a sigh of relief.Years of research on dissolved oxygen (DO)management, the most critical water-qualityfactor in aquaculture, is paying off.

As you feed sh, phytoplankton also growpro -ducing oxygen in the daytime and consuming itat night, says sh biologist Eugene Les Torrans,who is in the Agricultural Research ServicesWarmwater Aquaculture Research Unit (WARU)at the Thad Cochran National Warmwater Aqua -culture Center in Stoneville, Mississippi. If youfeed too much, oxygengets too low, and shcan die.

Traditionally, oxygenmanagement was basedon farmers observa-tions. If sh were seenat the water surfacesucking oxygen in themorning, aeration equip -ment was turned on.If no sh were seen, itwas presumed there wasenough oxygen.

Torranss experienceand research has shownotherwise. Theres aDO concentration atwhich sh die and a littlehigher DO at which theysurvive, but are respond -ing to stress, he says.In the daytime, DO canget as high as 14 partsper million (ppm), and if

it gets down to 3 ppm atnight, sh are still ne.But when DO drops lower, the sh becomepartially asphyxiated.

Fish rst respond to oxygen stress by losing theirappetite. When DO drops too low in the morning,sh eat less feed. As a result, the productioncycle increases, Torrans says. Instead of sh

http://www.ars.usda.gov/is/contacts.htm#Sandrahttp://www.ars.usda.gov/is/contacts.htm#Sandrahttp://www.ars.usda.gov/is/contacts.htm#Sandrahttp://www.ars.usda.gov/is/contacts.htm#Sandrahttp://www.ars.usda.gov/is/contacts.htm#Sandrahttp://www.nps.ars.usda.gov/http://www.nps.ars.usda.gov/http://www.nps.ars.usda.gov/http://www.nps.ars.usda.gov/http://www.ars.usda.gov/main/site_main.htm?modecode=64-02-35-00http://www.ars.usda.gov/main/site_main.htm?modecode=64-02-35-00http://www.ars.usda.gov/main/site_main.htm?modecode=64-02-35-00http://www.ars.usda.gov/main/site_main.htm?modecode=64-02-35-00mailto:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]://www.ars.usda.gov/main/site_main.htm?modecode=64-02-35-00http://www.nps.ars.usda.gov/http://www.ars.usda.gov/is/contacts.htm#Sandrahttp://www.ars.usda.gov/is/graphics/photos/nov13/d3030-2.htm -

8/13/2019 November December2013

8/22

8 Agricultural Researchl

November/December 2013

Sampling equipment (left) is set up on thedownwind side of cattle pens to measure theamount of bioaerosols, such as endotoxins,bacteria, and fungi, in the air near the pens.

ROB DUNGAN (D3043

I n the late afternoon, when dgety dairycows start milling around, they stir up aheavy layer of dust that hangs over the yard.This airborne dust does more than signal

potential rowdiness among the livestock. Itcontains bacteria, viruses, fungi, and small

bacterial remnants called endotoxins,which can be dispersed through the air

beyond the facilities to the surroundinglandscape.

These airborne microorganisms andtheir byproducts and remnants are alsocalled bioaerosols. Agricultural Re -search Service microbiologist Rob Dunganis documenting how bioaerosol dispersaluctuates throughout the day and year, theirdownwind concentrations, and factors thataffect dispersal patterns.

In the western United States, dairycows are kept in large outdoor pens or in acombination of exercise pens and barns atopen-freestall facilities. Either way, peoplecan sometimes smell dairies before theycan see them, so they assume theres a

problem, says Dungan, who works at the Northwest Irrigation and Soils ResearchLaboratory in Kimberly, Idaho. Theres a

lot of interest from people in nearby com -munities in nding out more about their

potential exposure to airborne endotoxinsand other bioaerosols from these facilities.

Distance Makes All the Difference

For one study, Dungan, soil scientistApril Leytem, and research leader DavidBjorneberg set up three sampling sites ata 10,000-cow open-freestall dairy to mea -sure airborne endotoxins and culturablemicroorganisms like bacteria and fungiduring fall, spring, and summer. One sitewas slightly more than a tenth of a mileupwind of the facility. A second site was165 feet downwind from a barn, and thethird was 655 feet (about a tenth of a mile)downwind from the same barn.

The researchers found that overall aver -age inhalable airborne endotoxin concen -trations were 5 endotoxin units (EU) percubic meter at the upwind site, 426 EUdownwind near the barn, and 56 EU fartherdownwind. At the upwind and the distantdownwind sites, endotoxin concentrationsdid not vary signi cantly over 24 hours.But closer to the barn, nighttime endotoxin

concentrations were signi cantly higherthan morning concentrations and weresimilar to afternoon concentrationsin -creases the scientists attribute to increasedanimal activity and lower wind speedsduring these times.

Analysis of bacterial concentrationsshowed a similar pattern. Average bacterialcounts over the sampling period were 2,800colony forming units (CFU) per cubic me -ter of air at the upwind site; 84,000 CFU165 feet downwind of the barn; and 7,900CFU 655 feet from the barn. As with thedaily endotoxin concentrations, bacterialconcentrations near the barn increasedsigni cantly at night, but concentrationsfarther downwind did not.

When the scientists compared concen-

tration uctuations with weather conditions,they noted that endotoxin concentrationsrose with air temperature. Meanwhile,airborne bacteria concentrations increasedwhen air temperatures and wind speedsincreased, but dropped when solar radiationand relative humidity increased.

Dairy FarmsAre Not a

Source ofFar-FlungBioaerosols

http://www.ars.usda.gov/is/graphics/photos/nov13/d3043-1.htm -

8/13/2019 November December2013

9/22

9 Agricultural Researchl

November/December 2013

No Lasting EffectsDungan and Leytem conducted another

investigation at a 10,000-cow open-lotdairy. For this study, they sampled airborneendotoxin concentrations at an upwind site

about one-tenth of a mile from the lot, at adownwind site at the edge of the lot, andat the dairy perimeters, which were morethan three-quarters of a mile downwindof the lot.

Average endotoxin concentrations at thedownwind edge of the open lots were about11 times higher than the concentrationsupwind, while the endotoxin concentra -tions at the most distant downwind sitewere found to be statistically similar tothose at the upwind site.

The scientists determined that the pri -mary factors affecting airborne endotoxinemissions were wind speed, lot manage -ment, and animal activity. As expected,the scientists observed that endotoxin

suspension and transport from the animalhousing areas increased as wind speedincreased and as animal activity increased.Other lot-management practices, including

breaking up the manure with harrowing,

also generated higher airborne endotoxinconcentrations.Unlike airborne microbes like bacteria

and fungi, endotoxins are highly resistantto solar radiation and temperature. Theresearchers did not observe any signi cantcorrelations between uctuations in endo -toxin levels and changes in air temperature,solar radiation, or relative humidity.

As with other types of livestock fa -cilities, dairies are a source of bioaerosols

because they house many animals that

generate lots of manure, says Dungan.But our data shows that bioaerosolconcentrations reach normal background

ARS microbiologist Rob Dungan sets up a type of sampling equipment known as a glass impinger,which is used to capture airborne microorganisms, or bioaerosols.

levels at a fairly short distance from theirsource at the dairies. So people who livenear these facilities can hopefully breathea sigh of relief about potential bioaerosolexposures.By Ann Perry, ARS .

This research is part of Agricultural and Industrial Byproducts (#214) and ClimateChange, Soils, and Emissions (#212), two

ARS national programs described at wwwnps.ars.usda.gov.

Robert Dungan, April Leytem, and David Bjorneberg are with the USDA-ARS Northwest Irrigation and Soils Research Laboratory , 3793 North 3600 East, Kim-berly, ID 83341; (208) 423-5582, [email protected] , april.leytem@ars. usda.gov, [email protected].

gov.*

ROB DUNGAN (D3047-1)

http://www.ars.usda.gov/is/contacts.htm#Annhttp://www.ars.usda.gov/is/contacts.htm#Annhttp://www.ars.usda.gov/is/contacts.htm#Annhttp://www.ars.usda.gov/Main/docs.htm?docid=3841http://www.ars.usda.gov/Main/docs.htm?docid=3841http://www.ars.usda.gov/Main/docs.htm?docid=3841mailto:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]://www.ars.usda.gov/Main/docs.htm?docid=3841http://www.ars.usda.gov/is/contacts.htm#Annhttp://www.ars.usda.gov/is/graphics/photos/nov13/d3047-1.htm -

8/13/2019 November December2013

10/22

10 Agricultural Researchl

November/December 2013

I ntensive management practices usedon cattle feedlot sites can produce largeconcentrations of manure with excessnutrients, antibiotics, and microorganisms.The contaminants may end up in surfaceand ground waters, and minimizing suchdamage is important to feedlot operators. This is particularly challenging in Ken -tucky, where the limestone and karstterrain offers contaminants subterranean

passage into underground caves, springs,and sinkholes. Cleaning up these sites iscostly, and the big question is how to applyresources to the right areas. Spatial sam -

pling and mapping is one of the best toolsavailable to identify the most intensivelycontaminated areas, nd out how contami -nants have spread, and decide which areasneed the most attention. The ultimate goalis to help producers develop managementstrategies that minimize contaminant loads.

Kim Cook and Karamat Sistani, at theAgricultural Research Services AnimalWaste Management Research Unit, inBowling Green, Kentucky, along with col -laborators at Western Kentucky Universityin Bowling Green and at ARS in Beltsville,Maryland, are using GIS (geographic in -

formation system) technologies to map thedistribution of contaminants across feedlotsites. Their approach is unique in its use ofthe technology to determine not just hownutrients ow through the soil, but also thefate of bacteria and pharmaceuticals givento cattle to protect their health.

The team measured the levels of con -taminants in soil samples collected froma 5-acre feedlot used to grow out weanedcalves for nishing. The site lies on a4-degree slope with a feeding and water -

ing area at the highest elevation, a grassygrazing area in the middle, and a shallowretention basin and sinkhole at the bottom.Most rainwater percolates into the soil, butheavy rain can cause ooding that lls the

ARS microbiologist Kim Cook (right) andWestern Kentucky University soil scientist

Annesly Netthisinghe collect soil samplesfrom a 5-acre experimental feedlot in westernKentucky for analysis of nutrients, antibiotics, andmicroorganisms.

JASON SIMMONS (K3045-

basin with water from the grazing area.The researchers analyzed the soil for

nutrients, including nitrogen and phos -

phorus; antibiotics used to treat diseasesand enhance growth; and for microorgan -isms commonly used to indicate fecalcontamination in waterways and soils

Escherichia coli , Bacteroides, and Entero-coccus . The study was one of the rst tosimultaneously measure all three types ofcontaminantsnutrients, antibiotics, andindicator microorganismsand to use GIStechnology to map patterns of contaminantdistribution.

The results, published in the Journal of Environmental Quality (2013), showed thatnutrients, microorganisms, and antibioticsall largely stayed in the feeding area at thetop of the slope.

Analysis of contaminants, particularlyantibiotics and microorganisms, on thisscale is not very common. Incorporatingthe GIS mapping allowed us to visualizethe distribution of all three contaminants innew ways. We were surprised to nd thatall were distributed in a similar manner and

there was no distinct ow pattern downhillfrom the barn, Cook says. The ndingssuggest that cleaning up the site may bemore manageable than previously thought,with efforts focused on soil remediation inthe feeding and nearby grazing areas wherecontaminants are concentrated.

To reduce nutrient loads, forage grassesthat take up nutrients are now being raisedon part of the site. The researchers are alsoevaluating soil treatments (alum, biochar,and gypsum) in the most contaminatedareas to see if they will bind with the nutrients, antibiotics, and microorganismsand give them time to decompose in thesoil.By Dennis OBrien, ARS .

This research is part of Climate Change,Soils, and Emissions (#212) and Agricul-tural and Industrial Byproducts (#214),two ARS national programs described atwww.nps.ars.usda.gov .

Kim Cook is in the USDA-ARS AnimalWaste Management Research Unit , 230

Bennett Ln., Bowling Green, KY 42104;(270) 781-2579 ext. 232, [email protected] .*

http://www.ars.usda.gov/is/contacts.htm#Dennishttp://www.ars.usda.gov/is/contacts.htm#Dennishttp://www.ars.usda.gov/is/contacts.htm#Dennishttp://www.ars.usda.gov/Main/docs.htm?docid=6500http://www.ars.usda.gov/Main/docs.htm?docid=6500http://www.ars.usda.gov/Main/docs.htm?docid=6500http://www.ars.usda.gov/Main/docs.htm?docid=6500mailto:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]://www.ars.usda.gov/Main/docs.htm?docid=6500http://www.ars.usda.gov/is/contacts.htm#Dennishttp://www.ars.usda.gov/is/graphics/photos/nov13/d3045-1.htm -

8/13/2019 November December2013

11/22

11 Agricultural Researchl

November/December 2013

A tropical food thats beinghailed by many as a possible solu -tion to world hunger also containscompounds that could help preventmosquitoes from spreading seri -ous and deadly diseases such asmalaria, yellow fever, and denguefever.

Breadfruit, Artocarpus alti-lis, is a tropical staple food croptraditionally cultivated for morethan 3,000 years throughout Ocea -niaMelanesia, Micronesia, andPolynesia. The fruit is plentiful,starchy, and packed with nutrients.In addition to being a valuable,nutritious food, breadfruit is usedin Hawaii and other regions tocontrol insects. People burn driedclusters of owerstechnicallyknown as male in orescences to repel ying insects, includingmosquitoes.

Scientists from the AgriculturalResearch Service and CanadasUniversity of British Columbiateamed together to identify thenatural chemicals in breadfruit thatdeter insects.

We found that three chemi -calscapric, undecanoic, andlauric acidswere responsible for therepellent activity, says Charles Cantrell,a chemist at the ARS Natural ProductsUtilization Research Unit (NPURU) inOxford, Mississippi. These chemicals arealso known as C10, C11, and C12 saturatedfatty acids.

Male in orescences from a diverse se -lection of breadfruit trees were sun dried atthe National Tropical Botanical GardensBreadfruit Institute in Kalaheo, Hawaii,and provided to scientists for testing. ARSscientists collected smoke samples as they

burned the in orescences in the traditionalmethod used in Paci c regions. More

This was the rst research toshow that breadfruit really worksas a repellent, validating a folkremedy, Cantrell says.

In a separate study, NPURUscientists looked at a wide rangeof saturated and unsaturated fattyacids and discovered similar re -sults. These same three chemicalsfound in breadfruit and other folkremedies were highly active andthe most repellent fatty acids thatweve seen, Cantrell says.

Chemist Uli Bernier, in the Mos -quito and Fly Research Unit at theCenter for Medical, Agricultural,and Veterinary Entomology inGainesville, Florida, used a stan -dard repellency test to evaluate thecompounds against mosquitoes.The test uses volunteers who wearcloth treated with various concen -trations of the chemicals. Bernierveri ed that the saturated fattyacids provide effective protection.

These studies were partiallyfunded by the Deployed War-Fighter Protection ResearchProgram, which develops andimproves methods to protect U.S.military personnel from disease-

transmitting insects.By Sandra Avant,ARS .

This research is part of Veterinary, Medical, and Urban Entomology, an ARSnational program (#104) described atwww.nps.ars.usda.gov .

To reach scientists mentioned in thisarticle, contact Sandra Avant, USDA-

ARS Information Staff , 5601 Sunnyside Ave., Belt sville, MD 20705-5128; (30 1)504-1627, [email protected] .*

Breadfruit Not So Appetizing to Mosquitoes

A mosquito feeding through an arti cial membrane and blood

substitute. In this test, ARS scientists found that when chemicalextracts from breadfruit were applied to the membrane,mosquitoes did not feed.

PEGGY GREB (K3056-1)

than 30 compounds in the smoke wereidenti ed, including a mixture of terpenes,aldehydes, fatty acids, and aromatics.

At the ARS Invasive Insect Biocontroland Behavior Laboratory in Beltsville,Maryland, chemist Kamal Chauhan testedthe compounds effectiveness againstadult Aedes aegypti female mosquitoesin a blood-feeding membrane system thatmosquitoes feed upon as if it were a human.

These natural chemicals were signi -cantly more effective at repelling mosqui -toes than DEET, the primary insecticideagainst biting insects, Chauhan says. Inregions where theyre available, driedclusters of breadfruit owers can be used

by people who may not be able to affordexpensive repellent products.

http://www.ars.usda.gov/is/contacts.htm#Sandrahttp://www.ars.usda.gov/is/contacts.htm#Sandrahttp://www.ars.usda.gov/is/contacts.htm#Sandrahttp://www.ars.usda.gov/is/contacts.htm#Sandrahttp://www.ars.usda.gov/News/News.htmmailto:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]://www.ars.usda.gov/News/News.htmhttp://www.ars.usda.gov/is/contacts.htm#Sandrahttp://www.ars.usda.gov/is/graphics/photos/nov13/d3056-1.htm -

8/13/2019 November December2013

12/22

Agricultural Researchl

November/December 201312

E xperiments led by Agricultural Re-

search Service food technologist MuktiSingh are showing how to boost the bercontent in white layer cakeor lower thecalorieswithout signi cantly under -mining many of the key qualities of thisall-time-favorite dessert.

Singhs edible- ber experiments fo -cused on corn bran, the corn kernelsber-rich outer layer. She determined that

puri ed, nely groundcorn bran can be usedas a substitute for up to20 percent of the ourcalled for in the AmericanAssociation of CerealChemists gold stan -dard test recipe for whitecake. That amount ofber didnt signi cantlyaffect qualities such ascolor, crumb grain size(an indicator of struc -ture), volume, moisture(moistbut not soggy is ideal), and springiness(the unfrosted top surfaceof a good cake willspring back when gentlytouched).

Whats more, the 25volunteer taste-testerswho sampled the 20-per -cent-corn-bran-enhancedcake rated it as acceptable. In taste-testerlingo, that counts as a vote of con dence.

Singh estimates that one slice of an8-inch, six-slice, two-layer white cakemade with that amount of bran would

provide about 5 grams of healthful ber.A slice from a standard white layer cakewould provide about 1 gram.

A peer-reviewed scienti c article thatSingh and colleagues Steven F. Vaughnand Sean X. Liu, all with the ARS Na -tional Center for Agricultural Utilization

Research in Peoria, Illinois, publishedin 2012 in Biocatalysis and Agricultural Biotechnology has details that may inter -est bakers and companies that make cakemixes for commercial or home baking.

The study is apparently among the fewthat provide publicly accessible data aboutthe effects that relatively high concentra -tions of puri ed, nely ground corn brancan have on the quality of white cake.

In tests aimed at cutting calorieswith -out sacri cing qualitySingh workedwith a patented, ARS-developed processthat uses steam-jet cooking to encapsu -late microdroplets of cooking oil (in thiscase, canola) with our and water. Thecream-textured mixture that results canthen be dried to form a smooth- owing,shelf-stable powder thats ready for themixing bowl.

Explains Singh, Encapsulation helpsdistribute the oil evenly throughout thecake, so you can use less of it and still have

Better White Layer Cakes Ahead?

some of the smooth mouthfeel of a higheroil, higher calorie cake. And the approachoffers busy bakers the convenience ofhaving oil already included in the mix, sotheres no need for pouring, measuring, orcleanup of this ingredient.

In these tests, Singh used only 25 percentof the cooking oil called for in the standardtest recipe. She showed that cakes madewith the our-oil-water composites were

softer and springier, andstayed moist longer, thancakes made with the sameamount of nonencapsu -lated our and oil.

Noted brie y in Agricultural Research inMarch 2010, the workwas reported in detailin the Journal of Food

Processing and Technol-ogy in 2012. The study

presents what is likelythe rst data, publishedin a scienti c research

journal, about use ofthe composites in cake.The ndings provide afoundation for furtherresearch and develop -ment, including taste-testing.By MarciaWood, ARS.

This research is part of Quality andUtilization of Agricultural Products, an

ARS national program (#306) described

at www.nps.ars.usda.gov . Mukti Singh is with the USDA-ARS

National Center for Agricultural Utiliza-tion Research, Functional Foods ResearchUnit, 1815 N. University St., Peoria, IL60605; (309) 681-6357, [email protected]. *

Bakery cakes like this one may one day have more ber. ARS scientists are usingnely ground corn bran as a substitute for some of the our used to make white layercake, raising its ber content without sacri cing quality. Additional research is aimed atreducing the confections calorie content.

STEPHEN AUSMUS (D3066-1)

http://www.ars.usda.gov/is/contacts.htm#Marciahttp://www.ars.usda.gov/is/contacts.htm#Marciahttp://www.ars.usda.gov/is/contacts.htm#Marciahttp://www.ars.usda.gov/is/contacts.htm#Marciahttp://www.nps.ars.usda.gov/http://www.ars.usda.gov/main/site_main.htm?modecode=36-20-00-00http://www.ars.usda.gov/main/site_main.htm?modecode=36-20-00-00http://www.ars.usda.gov/main/site_main.htm?modecode=36-20-51-00http://www.ars.usda.gov/main/site_main.htm?modecode=36-20-51-00mailto:[email protected]:[email protected]:[email protected]://www.ars.usda.gov/main/site_main.htm?modecode=36-20-51-00http://www.ars.usda.gov/main/site_main.htm?modecode=36-20-00-00http://www.ars.usda.gov/is/contacts.htm#Marciahttp://www.nps.ars.usda.gov/mailto:[email protected]://www.ars.usda.gov/is/graphics/photos/nov13/d3066-1.htm -

8/13/2019 November December2013

13/22

13 Agricultural Researchl

November/December 2013

PEGGY GREB (D1678-2)

E ven people who know a lot about thehuman brain may be impressed by the ex -tent to which eating a single breakfastorskipping itcan in uence a childs abilityto solve math problems.

Just ask scientist Terry Pivik, whoseresearch with 81 children has shown thatthose who ate breakfast were better ableto tackle dozens of math problems inrapid- re succession than peers whodidnt have a morning meal.

As a psychophysiologist, Pivikstudies how our brains in uenceour behavior. Based in Little Rock,Arkansas, he directs the Brain Func -tion Laboratory at the AgriculturalResearch Service-funded ArkansasChildrens Nutrition Center and is aresearch professor in pediatrics at theUniversity of Arkansas for MedicalSciences.

In his study of healthy 8- to11-year-old volunteers, Pivik usedEEG (electroencephalographic)sensors to harmlessly record electri -cal activity generated in regions ofchildrens brains involved in solvingmath problems. The sensors weretted into a soft cap that the young -sters wore as they viewed simplemath problems presented to themon a computer monitor, calculatedthe answer in their heads, and thenquickly selected one answer fromamong three onscreen choices.

In all, the kids had a little more than1 second to process each problem.

Each child took two math testsin the morning. Half of the children ate

breakfast during a break in the testing; theothers did not.

Factors that could skew results werecarefully controlled. For example, to

prevent sleepiness, a watchful nurse anda wristband-mounted monitor that thevolunteers wore ensured that each childhad a full 8 hours of rest the night beforethe tests.

EEG data showed that children whoskipped breakfast had to exert more effortto perform the mental math that the tests

required and to stay focused on the task athand, says Pivik. In contrast, those whoate the breakfast that we provided used lessmental effort to solve the problems, stayedmore focused on the tests, and improvedtheir scores in the post-breakfast test.

Previous studies by researchers else -where have shown an association betweennutrition and academic performance. How -ever, the design of the Arkansas study hadsome important differences. We carefullycontrolled when the kids either had break -fast or skipped it, and what they ate, Pivikexplains. To the best of our knowledge,this is the rst published study, with kids

of this age group, that both controlledthe morning meal and used EEGtechnology to monitor brain activitywhile the children were processingmathematical information.

Pivik and nutrition center col -leagues Yuyuan Gu and Kevin B.Tennal, along with Stephen D.Chapmanformerly at the cen -terpublished their ndings in a

peer-reviewed article in Physiology& Behavior in 2012.

The research is part of ongoinginvestigations in Piviks lab to dis -cover more about how to nourishthe brain and enhance childrensability to learn. Theres much moreto uncover about the role that nutri -tion plays in in uencing the neuralnetworks that kids engage whentheyre doing mental arithmetic,Pivik says. Were addressing thisknowledge gap because math skillsare so critical in todays world.ByMarcia Wood, ARS .

This research is part of Human Nutrition, an ARS national program(#107) described at www.nps.ars.usda.gov.

R. Terry Pivik is with the USDA-ARS Arkansas Childrens Nutrition Center, 15Childrens Way, Little Rock, AR 7220 2;(501) 364-3346, [email protected] .*

An ARS-funded study with children ages 8-11 showed thatstarting the day with breakfast can enhance the ability tosolve math problems.

Breakfast Helps Kids HandleBasic Math, Study Suggests

http://www.nps.ars.usda.gov/http://www.nps.ars.usda.gov/http://www.nps.ars.usda.gov/http://www.ars.usda.gov/main/site_main.htm?modecode=62-51-10-00mailto:[email protected]:[email protected]:[email protected]://www.ars.usda.gov/main/site_main.htm?modecode=62-51-10-00http://www.nps.ars.usda.gov/http://www.ars.usda.gov/is/graphics/photos/nov13/d1678-2.htm -

8/13/2019 November December2013

14/22

Agricultural Researchl

November/December 201314

STEPHEN AUSMUS (D1621

Greenhouse Gas Emissions and Yields fromOrganic and Conventional Systems

Using closed vented chambers, biological scienceaide Rochelle Jansen (right) and soil scientistJane Johnson collect gas emissions from soil ata research farm. Samples will be analyzed forcarbon dioxide, nitrous oxide, and methane.

O ur human activities affect the envi -ronment, so agriculture is likely to leave

a footprint, says Agricultural ResearchService soil scientist Jane Johnson. Whatwe need to know is what we can do toreduce that footprint.

As part of that goal, Johnson led a studyto see whether reduced-tillage organic andconventional production systems differedin yields or in the emission of greenhousesgases that have greater global warming ef -fects than carbon dioxide, like methane andnitrous oxide. That is, would greenhousegas emissions from an acre of conventional

corn exceed greenhouse gas emissionsfrom an acre of organic corn, or vice versa?

Johnson works at the ARS North CentralSoil Conservation Research Laboratoryin Morris, Minnesota. Her project teamincluded Morris soil scientist SharonWeyers and biologist Nancy Barbour, aswell as agricultural scientist David Archer,who works at the ARS Northern GreatPlains Research Laboratory in Mandan,

North Dakota.The scientists studied yields from or -

ganic and conventional production of a4-year corn-soybean-wheat-alfalfa rota -tion in Minnesota. While both systemsrelied primarily on alfalfa for nitrogen,the conventional plots were also amendedwith urea-based fertilizer, while the or -ganically managed plots were amendedwith solid dairy manure. This meant thatduring the study period, the conventionalsystems received 590 pounds of syntheticnitrogen, almost twice as much as the or -ganic systems received via dairy manure

amendments.The team used closed-vented chambers

to monitor greenhouse gas emissions for3 years during the growing season from

May to November, as well as during earlyspring thaws. They found that both systems

produced similar corn grain yields during2007. But organic corn yields were 60 per -cent lower than conventional corn yieldsin 2006 and 40 percent lower during 2008.

During 2007 and 2008, organic andconventional soybean yields were similar,

but 2006 organic soybean yields were 90 percent lower than conventional yields. In2006, organic wheat yields were 50 percentlower than conventional wheat yields.

Field measurements of greenhouse gasemissions indicated that both systemsemitted 3.75 pounds of nitrous oxide

per acre every yearmeasurements thatcumulatively represent 4.74 percent ofthe nitrogen added to the conventionalsystem and 9.26 percent of the nitrogenadded to the organic system. This meantthat the nitrous oxide emissions per unit ofnitrogen applied were nearly twice as largefrom the organically managed system asfrom the conventionally managed system.

The scientists believe that the greater biomass production in the conventional

system and the lower productivity ofthe organic system indicate that the

conventional crops were able to use appliednitrogen more effectively to support plantgrowth. Because the yield was lowerfrom the organic system, the nitrousoxide footprint per unit of crop yield wasgreater in the organic system than in theconventional system.

This study suggests that the ability oforganic production to mitigate greenhousegas may be less attractive to producers ifit also results in lower yields. This empha -sizes the importance of management to

maintain crop productivity in any system,Johnson says. By Ann Perry, ARS.

This research is part of Climate Change,Soils, and Emissions, an ARS national

program (#212) described at www.nps.ars.usda.gov.

Jane Johnson is with the USDA-ARS North Central Soil Conservation Research Laboratory, 803 Iowa Ave., Morris, MN 56267; (320) 589-3411 ext. 131, jane.

http://www.ars.usda.gov/is/contacts.htm#Annhttp://www.ars.usda.gov/is/contacts.htm#Annhttp://www.ars.usda.gov/is/contacts.htm#Annhttp://www.ars.usda.gov/Research/Research.htmhttp://www.ars.usda.gov/Research/Research.htmhttp://www.ars.usda.gov/Main/docs.htm?docid=3118http://www.ars.usda.gov/Main/docs.htm?docid=3118http://www.ars.usda.gov/Main/docs.htm?docid=3118http://www.ars.usda.gov/Main/docs.htm?docid=3118http://www.ars.usda.gov/Main/docs.htm?docid=3118mailto:[email protected]:[email protected]:[email protected]:[email protected]://www.ars.usda.gov/Main/docs.htm?docid=3118http://www.ars.usda.gov/Research/Research.htmhttp://www.ars.usda.gov/is/contacts.htm#Annhttp://www.ars.usda.gov/is/graphics/photos/nov13/d1621-5.htm -

8/13/2019 November December2013

15/22

15 Agricultural Researchl

November/December 2013

P almer amaranth is an aggressivesouthern weed that can grow at the rate of 2inches a day and outcompete corn, cotton,soybean, and other crops for resources atthe cost of their full yield potential.

To make matters worse, the prodigiousowering weed has built up resistanceto glyphosate, the main herbicide usedto control it, prompting a search foralternatives. One possibility beingexplored by Agricultural Research Servicescientists in Stoneville, Mississippi, is thefungus Myrothecium verrucaria. Priorstudies conducted there by Doug Boyette,Robert Hoagland, and others demonstrated

Myrotheciums potential as a biologically based herbicide against sicklepod, kudzu,hemp sesbania, and other weeds. (SeeFormidable Fungus Goes Toe to Toe With Kudzu , Agricultural Research, July 2009.)

Now, based on recent greenhouse trials,it appears the fungus will also infect and

kill or weaken Palmer amaranth, includingweed biotypes that can resist glyphosateand other herbicides, such as triazines.According to Hoagland, a chemist in ARSsCrop Production Systems Research Unit,

Myrothecium attacks its weedy hosts leafand stem tissues, causing wilt, necroticlesions, loss of chlorophyll, and otherdisease symptoms that can kill young

plants and weaken older ones, renderingthem less competitive with crops.

To test the infectivity of Myrothecium ,the researchers used a filamentousgrowth stage of the fungus known asmycelium and sprayed a mycelial-surfactant formulation onto two batchesof 4-week-old Palmer amaranth seedlings:those with glyphosate resistance and thosewithout. They repeated the same pro cedurefor 6-week-old plants. All groups werevisually checked for symptoms over theexperiments 7-day (168-hour) period andweighed for reductions in shoot growth.

Seedlings were most susceptible,with all plants exposed to a full-strengthapplication of the fungus showing diseasesymptoms. By 48 to 72 hours, nearly 100

percent had died. In 6-week-old plants,symptoms progressed more slowly, butthere was no signi cant difference ininjury between glyphosate-resistant andglyphosate-susceptible plants. Both groupsshowed disease symptoms, most notablychlorosis, some necrosis, and stuntedgrowth.

The ndings, which were published in theMarch 2013 Allelopathy Journal, mark therst report of Myrotheciums bioherbicidalactivity against a weed species withglyphosate resistance. The research is acontinuation of prior studies at Stonevilleand elsewhere evaluating Myrotheciumshost speci city, environmental safety, easeof production, and optimal delivery.

On a related front, the researchers arescrutinizing the genetic and biochemicalmechanisms underpinning herbicideresistance in Palmer amaranth and otherweeds. They have also begun studies ona strain of Xanthomonas bacteria foundto infect the leaves of common cocklebur,marestail (or horseweed), and otherherbicide-resistant threats to southerncrops and potential targets for bioherbicideuse.By Jan Suszkiw, ARS .

This research is part of Crop Protectionand Quarantine (#304) and Crop

Production (#305), two ARS national programs described at www.nps.ars.usda.gov .

Robert Hoagland is in the USDA-ARSCrop Production Systems Research Unit

141 Experiment Station Rd., Stoneville, MS, 38776-0350; (662) 686-5210, [email protected] .

Douglas Boyette is in the USDA-ARS Biological Control of Pests Research Unit National Biological Control Laboratory 59 Lee Rd. , Stoneville, MS 38776; (66 2)686-5217, [email protected] .*

Plant pathologist Doug Boyette prepares afermenter for growing fungus. Boyette andcollaborators have found a fungus that maycontrol Palmer amaranth, an aggressive weedthat is developing resistance to some herbicides.

LYNN LIBBOUS-BAILEY (D1484-1)

Fungus Takes DownAnother Weed

http://www.ars.usda.gov/is/AR/archive/jul09/fungus0709.htmhttp://www.ars.usda.gov/is/AR/archive/jul09/fungus0709.htmhttp://www.ars.usda.gov/is/AR/archive/jul09/fungus0709.htmhttp://www.ars.usda.gov/is/AR/archive/jul09/fungus0709.htmhttp://www.ars.usda.gov/is/AR/archive/jul09/fungus0709.htmhttp://www.ars.usda.gov/is/contacts.htm#Janhttp://www.ars.usda.gov/is/contacts.htm#Janhttp://www.nps.ars.usda.gov/http://www.nps.ars.usda.gov/http://www.nps.ars.usda.gov/http://www.nps.ars.usda.gov/http://www.ars.usda.gov/main/site_main.htm?modecode=64-02-55-00mailto:[email protected]:[email protected]:[email protected]:[email protected]://www.ars.usda.gov/main/site_main.htm?modecode=64-02-45-00http://www.ars.usda.gov/main/site_main.htm?modecode=64-02-45-00http://www.ars.usda.gov/Main/docs.htm?docid=7542http://www.ars.usda.gov/Main/docs.htm?docid=7542mailto:[email protected]:[email protected]:[email protected]://www.ars.usda.gov/is/graphics/photos/nov13/d1484-1.htmhttp://www.ars.usda.gov/is/graphics/photos/nov13/d1484-1.htmmailto:[email protected]://www.ars.usda.gov/Main/docs.htm?docid=7542http://www.ars.usda.gov/main/site_main.htm?modecode=64-02-45-00mailto:[email protected]://www.ars.usda.gov/main/site_main.htm?modecode=64-02-55-00http://www.nps.ars.usda.gov/http://www.ars.usda.gov/is/contacts.htm#Janhttp://www.ars.usda.gov/is/AR/archive/jul09/fungus0709.htmhttp://www.ars.usda.gov/is/graphics/photos/nov13/d1484-1.htm -

8/13/2019 November December2013

16/22

Agricultural Researchl

November/December 201316

S ummer ip- ops, garden planters, paver stones, and outdoor decking actuallyhave something in common. If based onwork conducted by Agricultural ResearchService engineer Greg Holt and colleagues,all of these products can be made fromagricultural waste and would biodegradenicely.

Holt is working on a wide variety ofcomposite materials using waste such ascotton burs, cotton seed hulls, cornstarch,gypsum, kenaf, ax, switchgrass, andwheat straw. He is with the ARS CottonProduction and Processing Research Unitin Lubbock, Texas.

One of Holts recent projects is provid -ing a type of biomass that is just right foruse with a new process that literally growscustom packaging material. The processinvolves combining cotton gin waste andfungi inside a cast, called a tool wherethe two ingredients become one, result -ing in a spongy-looking material similarin appearance to polystyrene foam. Thecustom-shaped end product is providinga cost-effective green alternative to ex -

truded polystyrene foam packaginganestimated $2 billon market. Products in -clude custom packaging that protects, forexample, computers and other breakablesduring shipping.

Holts industry partnerNew York- based Ecovative Designdevelopedthe patented method that uses fungi as aworkhorse. The technology uses the fungalgrowth stage, called mycelium. First,woody cotton waste is blended, pasteur -ized, and embedded into a customizedcast tool. Then, the tool is injected withthe fungus. The mycelium grows onto, in,and around the cotton waste, eventuallyforming a new, consistently textured, solidmass. Once the tool is opened, a custom-shaped bio-package emerges that is then

put into a kiln-like oven, where the livefungi are killed.

The nal formed protective packageinsulation is biodegradable, compostable,and ame retardant, yet it has the cushion -ing strength of synthetic packing material,says Holt. Ecovative Design is manufactur -ing these cost-competitive packaging parts

for their corporate clients, including Dell,Steelcase, Crate & Barrel, and others.Which Waste Works Best?

In a test of types of gin waste, the labevaluated the physical and mechanical

properties of six different cotton-byproduct blends as a substrate for fungal colonization to manufacture the molded packagingmaterials. We wanted to learn which onesmet or exceeded the same characteristics

of extruded polystyrene foam, says Holt.The six proprietary recipes consisted ofcottonseed hulls, gypsum, or cornstarch

blended with two sizes of cotton burr particles ne or coarse. Each blend wasthen inoculated with a single fungus usingtwo different inoculation methods, grain

GREG HOLT (D3061-1)

ARS and collaborators developed this biomasspressboard, made from a blend of cotton burrand pine bers, for use as building material.

http://www.ars.usda.gov/is/graphics/photos/nov13/d3065-1.htmhttp://www.ars.usda.gov/is/graphics/photos/nov13/d3061-1.htm -

8/13/2019 November December2013

17/22

17 Agricultural Researchl

November/December 2013

and liquid, for a total of 12 treatments.The 12 treatments were evaluated for

numerous physical and mechanical prop -erties. Overall, the treatments tested well,and the results indicated that the blend andinoculation method needed are based onthe end use of the product. The materialsare water resistant, but they degrade intoorganic matter on sustained contact withwater or soil, says Holt.

The study was published in September2012 in the Journal of Biobased Materialsand Bioenergy .

A Substitute for Other Products

In another project, Holt worked witha team to evaluate agricultural waste

materials that can be used for recyclable,termite-resistant particleboards and press -

boards and for thermoplastics (meltable athigh heat), such as outdoor decking planks.

Because wood fiber is a premium product, manufacturers would like to userecyclable agricultural waste materialsin place of some of the wood ber incomposite building materials. Composite

boards and planks are used in nonstructuralapplications. Previous laboratory-scaleresearch had shown that waste from cot -ton production holds great potential as aber ller, but the team wanted to test the

products on a commercial scale.The process of ginning seed cotton gen -

erates a signi cant amount of wasteasmuch as several million tons each year which contains woody cotton burrs, stems,and other materials. For the study, Holt andcolleagues Sreekala Bajwa and Dilpreet

Bajwa, both with North Dakota State Uni -versity, evaluated using cotton burrs andstems as ller. The study was supported

by Cotton, Inc., and the test materials weremanufactured at a Greenland Composites,Inc., facility in Greenland, Arkansas.

For the study, the team manufacturedthermoplastic composite boards on a com -mercial scale with four different levels ofadded cotton burrs and stems. The fourlevels were 0 (controls, containing onlywood ber), 12.5, 25, and 37.5 percent

by weight. The samples were tested for physical and mechanical properties that arerelevant to nonstructural building applica -tions, including water absorption, thicknessswelling, thermal expansion, strength,hardness, and nail-holding capacity.

Testing showed that the commercial-scale samples they made by adding cot -ton burs and stems were comparable tothe control boards containing only woodber. The study demonstrated overall thatup to 12.5 percent of the wood ber usedin commercially available wood-plasticcomposite materials can be replaced or

DILPREET BAJWA (D3062

This Greenland Garden Box was created frombiomass using technology developed by ARS,collaborators, and Ecovative.

Biomass packaging material made usingtechnology developed by ARS, collaborators,and Ecovative.

ECOVATIVE (D3065-1)

http://www.ars.usda.gov/is/graphics/photos/nov13/d3065-1.htm -

8/13/2019 November December2013

18/22

Agricultural Researchl

November/December 201318

supplemented by cotton burrs and stemswith no signi cant deterioration in me -chanical and physical properties that areimportant for all composites.

Testing of composites produced fromcotton burrs and stems showed that up to25 percent of the wood- ber ller could bereplaced without signi cantly increasingthe composites water-absorption andexpansion performance, Holt says.

Bales That Come Wrapped

The researchers also added a different, but relatively new, agricultural waste tocomposites during the study. Some cotton

producers are now using harvesters thatmake large, cylindrical bales of eld-harvested cotton called modules. Themodules are wrapped in a protective lmmade out of low-density polyethylene.These cotton module wraps (CMWs)are removed at cotton gin facilities.If not recycled, they could become anenvironmental burden.

The researchers demonstrated the potential of using shredded CMWs as aningredient in thermoplastic composites.They added up to 30 percent by weightof CMW to composite boards, as areplacement for wood- ber ller. Theyshowed that CMWs could replace up to30 percent of total composite weight whilemaintaining the physical and mechanical

properties of commercially availablecomposites used for decking, window

Protecting Buoys That Protect Us

The National Oceanic and Atmo -spheric Administration (NOAA) hasintroduced its next generation oftsunami-warning buoys placed atstrategic locations throughout theoceans. These buoys work togetherto monitor and measure tsunamis inthe deep ocean, forming an array.NOAA needed a moldable, biode -gradable material to keep the buoysand instrumentation from gettingdamaged during and after launchinto the ocean.

AR S sc ie nt is t Gr eg Hol t an dEcovative, based in Green Island,New York, created a biodegradablematerial made from a proprietaryblend of biomass substrates andcotton byproducts to cushion thebuoys. NOAAs Pacific MarineEnvironmental Laboratory based inSeattle, Washington, has success-fully tested the new material in avariety of oceanic conditions andhopes to launch buoys wrappedin the protective cushioning in thenear future.

The technology was developed byEcovative with support from Holt,research leader of the ARS CottonProduction and Processing ResearchUnit, a division of the Cropping Sys -tems Research Laboratory in Lub-bock, Texas.By Rosalie MarionBliss and Peggy Greb, ARS.

and door components, and landscaping products.

We want to give ginners a way to selltheir wastes for value-added applications,says Holt.

The study was published in January2013 in Journal of Thermoplastic Com-

posite Material .By Rosalie Marion Bliss, ARS.

This research is part of Quality and Uti-lization of Agricultural Products, an ARS

national program (#306) described at www.nps.ars.usda.gov.

Gregory A. Holt is in the USDA-ARS Cotton Production and Processing Re-

search Unit, 1604 E. FM 1294, Lubbock, TX 79403; (806) 746-5353, [email protected]. *

Right: A tsunami buoy is launched into theocean from a NOAA ship. Below: ARS andEcovative made this protective cushion, whichis molded especially to t tsunami buoys andprevent damage prior to launch by NOAA.

Biomass packaging material created using technology developed by ARS, collaborators, andEcovative can be made to custom t a wide variety of products.

ECOVATIVE (D3063-1)

NOAA (D3059-1)

ECOVATIVE (D3060-1)

http://www.ars.usda.gov/is/contacts.htm#Rosaliehttp://www.ars.usda.gov/is/contacts.htm#Rosaliehttp://www.ars.usda.gov/is/contacts.htm#Rosaliehttp://www.ars.usda.gov/is/contacts.htm#Rosaliehttp://www.ars.usda.gov/is/contacts.htm#Rosaliehttp://www.nps.ars.usda.gov/http://www.nps.ars.usda.gov/http://www.ars.usda.gov/main/site_main.htm?modecode=62-08-05-10http://www.ars.usda.gov/main/site_main.htm?modecode=62-08-05-10http://www.ars.usda.gov/main/site_main.htm?modecode=62-08-05-10mailto:[email protected]:[email protected]:[email protected]:[email protected]://www.ars.usda.gov/main/site_main.htm?modecode=62-08-05-10http://www.nps.ars.usda.gov/http://www.ars.usda.gov/is/contacts.htm#Rosaliehttp://www.ars.usda.gov/is/graphics/photos/nov13/d3059-1.htmhttp://www.ars.usda.gov/is/graphics/photos/nov13/d3060-1.htmhttp://www.ars.usda.gov/is/graphics/photos/nov13/d3063-1.htm -

8/13/2019 November December2013

19/22

19 Agricultural Researchl

November/December 2013

W hether its spicy stir-fried vegetablesfrom your favorite Chinese restaurant or acrisp, deep-fried chicken from your neigh -

borhood diner, chances are good that bothof these foods were prepared using soybeanoil. In fact, soy oil makes up an estimated70 to 80 percent of all cooking oil usedcommercially in restaurants, bakeries, andmore, all across America.

Though its generally regarded as ahealthier choice than edible oils that arehigher in saturated fat, soy oils good-for-you polyunsaturated fatty acids are prone tooxidation at the high temperatures typicallyused for frying.

Oxidation can make the oil heavy andgummy, lead to off- avors and odors, andcause the oil to form a messy foam duringdeep-frying.

These effects may combine to shorten

the usable life of the oil, which, in somecommercial settings, is reused until healthregulations or quality problems dictatediscarding it .

Though hydrogenation of the oil at the processing plant will retard oxidation, the procedure creates synthetic trans -fats thathave been associated with increased riskof cardiovascular disease.

Agricultural Research Service chemistHong-Sik Hwang, in collaborations withfellow chemists Erica L. Bakota, Mark A.

Berhow, Jill K. Winkler-Moser, and re-

search leader Sean X. Liu, is investigatinginteresting natural antioxidant compoundsthat might effectively and affordably

protect soybean oil from oxidation dur -ing frying.

In preliminary experiments at the ARS National Center for Agricultural Utiliza -tion Research in Peoria, Illinois, Hwangand colleagues found that sesamol, ex -

tracted from sesame oil, provided betterantioxidant protection for soy oil than nineother natural antioxidants that they tested.

Followup experiments pitted sesamolagainst a synthetic antioxidant, TBHQ(tert -butylhydroquinone). TBHQ is com -monly added to soy cooking oil thats soldin bulk for commercial use, according toHwang.

In tests with french fries, sesamol added at the rate of 6,600 parts sesamol

per 1 million parts soy oilprovided better protection than TBHQ added atthe allowable maximum of 200 parts permillion, the team found.

Two well-accepted indicators of oxida -tionpolymerization of certain soy oilmolecules and loss of speci c soy-oil

protonswere used to evaluate samplesof the oil throughout the 8-hour frying test.

More research is needed to ensurethat using sesamol at levels that provideantioxidant protection would, at the sametime, meet federal GRAS (GenerallyRecognized As Safe) standards. Even anatural ingredient such as sesamol has to

be evaluated for safety, Hwang notes.The idea of pairing a sesame seed com -

pound with soybean oil to thwart oxidationisnt new. But the Peoria group is appar -

ARS scientists are investigating natural antioxidant compounds that might effectively protect soybeanoil from oxidation during frying. In tests with french fries, sesamol, extracted from sesame oil, provedbetter at this task than a commonly used synthetic antioxidant.

STEPHEN AUSMUS (D3041-

ently the rst to investigate the conceptusing deep-frying tests that simulate commercial conditions.

Hwang and co-workers are nowdeveloping an approach that may enablechefs and fry cooks to automatically addsesamol to soy oil in the right amount atthe right times. The tactic helps offset lossof sesamol caused by the compounds ownvulnerability to oxidation at high temps.Explains Hwang, You actually get betterresults if you make multiple additions ofsesamol instead of just adding it all atonce.

Peer-reviewed articles published in 2012and 2013 in the Journal of the AmericanOil Chemists Society document the research.By Marcia Wood, ARS .

This research is part of Quality andUtilization of Agricultural Products, an

ARS national program (#306) describedat www.nps.ars.usda.gov . Hong-Sik Hwang is at the USDA-ARS

National Center for Agricultural Utiliza-tion Research , 1815 N. University St., Peo-ria, IL 61604; (309) 681-6584, [email protected] .*

Pairing SesamolWith Soybean Oilfor Better Frying

http://www.ars.usda.gov/is/contacts.htm#Marciahttp://www.ars.usda.gov/is/contacts.htm#Marciahttp://www.ars.usda.gov/main/site_main.htm?modecode=36-20-00-00http://www.ars.usda.gov/main/site_main.htm?modecode=36-20-00-00http://www.ars.usda.gov/main/site_main.htm?modecode=36-20-00-00mailto:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]:[email protected]://www.ars.usda.gov/main/site_main.htm?modecode=36-20-00-00http://www.ars.usda.gov/is/contacts.htm#Marciahttp://www.ars.usda.gov/is/graphics/photos/nov13/d3041-11.htm -

8/13/2019 November December2013

20/22

Agricultural Researchl

November/December 201320

N ew garden- and dry-pea breeding linesdeveloped by Agricultural Research Ser-vice and cooperating scientists may offergrowers added insurance against outbreaksof Aphanomyces root rot, a disease that cancause yield losses of 20 to 100 percent inthe legume crop.

The moldlike culprit, Aphanomyceseuteiches, infects roots and undergroundstems of susceptible pea plants and otherlegumes, rotting them and causing stuntedgrowth, lesions, wilted leaves, and othersymptoms.

Currently no fungicides are registered

for use with peas to control Aphanomyces root rot. Growers must either avoid plantingin elds with a history of the disease or tryrotating in nonhost crops until pathogennumbers drop to acceptable levels.

But avoidance and crop rotation may notalways be economically feasible. Breed-ing peas for Aphanomyces resistance has

proven dif cult because multiple genesare involved. Resistance genes are alsoassociated with undesirable traits, which

A team of Agricultural Research Ser-vice scientists has reported a biotechno-logical approach that enables crop speciesto produce, or to increase production of, the

phytochemical compound pterostilbene.Stilbenes are a subgroup of phytochemi-cals called polyphenols. The approachcould pave the way for ramping up levelsof potentially healthful pterostilbene incrops that normally produce it, such asgrapes and berries.

Molecular biologists Scott R. Baersonand Zhiqiang Pan, and chemist AgnesRimando, headed the study. They and plant

physiologist Franck Dayan, a coauthor,are with the Natural Products UtilizationResearch Unit in Oxford, Mississippi.

Also a coauthor, ARS plant pathologistJames Polashock is with the GeneticImprovement of Fruits and VegetablesLab in Beltsville, Maryland, but based in

Chatsworth, New Jersey.There are two stilbenesresveratrol and