Method Statement for Anchor Bolt Strength Test

-

Upload

quitzs-quitzs -

Category

Documents

-

view

582 -

download

73

description

Transcript of Method Statement for Anchor Bolt Strength Test

Project: 1/F-2/F Silvercord Tower2, 30 Canton Road (Proposed Signboard).

Method Statement for Anchor Bolt Strength Test

1. Introduction

This method statement described the procedure for the strength test of anchor bolt pull out capacity in concrete beam.

2. Sampling

Strength tests on a representative number of the drilled-in anchors should be carried out as directed by the Registered Structural

Engineer on site. Sampling rate should be at least 1% or 5 numbers, whichever is more, of each type and size of the anchor

installed.

3. Testing Agent

The strength tests should be carried out by a recognized laboratory independent of the Contractor.

4. Test Load

Type of Anchor bolt: Hilti HST-R M12 (recommended tensile load = 4.0kN)

Hilti HST-R M16 (recommended tensile load = 8.3kN)

Each representative anchor should be tested for tensile load by pull out test to 1.5 times the recommended load (i.e. 1.5 x

4.0kN=6.0kN) and (i.e. 1.5 x 8.3kN=12.4kN) as specified by the anchor manufacturer.

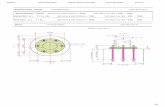

5. Test Equipment

Load cell, loading bolt, indicator and hydraulic ramp.

6. Testing Procedures

i. Check and record the location, type and size of the anchor bolt.

ii. Visually check the construction of the test anchor for any abnormally and check with the representative of the RSE the

readiness of the test specimen.

iii. Set the indicator to zero.

iv. Engage the loading unit with the anchor bolt and ensure solid contact to the concrete wall.

v. Apply an initial load of 10% test load to take up any slack in the apparatus and attachment.

vi. Test load will be applied in 5 increments up to a maximum 1.5 times the recommended tensile load as specified by the

manufacturer. Each applied load at the end of each increment/interval should be maintained for 2 minutes or longer

until the rate of settlement/recovery is less than 0.05mm in 2 minutes. The maximum test load will be maintained for 1

hour and then released to zero in an unloading sequence of three intervals.

vii. The test anchor should not show any signs of separation, plastic deformation or deleterious effect. Recovery of the

deformation after removal of all loading should be at least 80% of the total deformation at the maximum test load

condition.

7. Test Report

The report of test should be kept on site and made available for inspection by representatives of the Building Department.