Anchor Bolt Materials

-

Upload

neurolepsia3790 -

Category

Documents

-

view

269 -

download

0

Transcript of Anchor Bolt Materials

-

7/28/2019 Anchor Bolt Materials

1/44

1. Report No. 2. Government Accession No .

4. Title ond Subtitle"A Guide to the Selection of High-StrengthAnchor Bolt Materials"

7. Author1s)G. B. Hasse1wander, J . O. J i rsa , and J . E. Breen9. Performing Orgoni zation Name and AddressCenter for Highway ResearchThe University of Texas at AustinAustin, Texas 78712

~ ~ - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ~12. Sponsoring Agency Name and AddressTexas Highway DepartmentPlanning & Research DivisionP .O . Box 5051Austin. Texas 787631S. Supplementary N otes

TECHNICAL REPORT STANDARD TITLE PAGE3. Recipient's Catalog No.

5. Report DateOctober 1974

6. Performing Orgoni zotion Code

8. Performing Organization Report No.Research Report 29-1

10. Work Unit No.

11. Contract or Grant No.Research Study 3-5-74-29

13. Type of Report and Period CoveredInterimSeptember 1973 - August 1974

14. Sponsoring Agency Code

Work done in cooperation with the Federal Highway Administration, Departmentof Transportation.Research Study Tit le: "Strength and Behavior of Anchor Bolts"

16. Abstract

An evaluation of the sui tabi l i ty of various high-strength materials for anchorbolt applications was made. A selected group of materials meeting ASTM StandardSpecifications were tabulated. Based on the material properties, availabil i ty,and cost , several of the materials were determined to be most suitable for anchorbolt materials. To further assis t the designer in selecting materials not coveredby ASTM Standard Specifications, a brief review of AISI Grade Designations ispresented and cross-referenced with the ASTM Standard Specifications.

17. Key Wards 18. Distribution Statementanchor bolts , materials, selection,specifications

19. Security Classil. (01 this report) 20. Security Classi I. (01 this page)Unc lass ified Unclassified

Form DOT F 1700.7 ( 8 69 )

21. No. of Pages 22. Price43

-

7/28/2019 Anchor Bolt Materials

2/44

A GUIDE TO THE SELECTION OF HIGH-STRENGTHANCHOR BOLT MATERIALS

byG. B. Hasselwander, J . O. Jirsa , and J. E. Breen

Research Report No. 29-1

Research Project Number 3-5-74-29Strength and Behavior of Anchor Bolts

Conducted forThe Texas Highway Department

In Cooperation with theU. S. Department of TransportationFederal Highway Administration

byCENTER FOR HIGHWAY RESEARCH

THE UNIVERSITY OF TEXAS AT AUSTIN

October 1974

-

7/28/2019 Anchor Bolt Materials

3/44

The contents of this report reflect th e views of theauthors, who are responsible for the facts and theaccuracy of the data presented herein. The contentsdo not necessarily re f lec t the off ic ia l views orpolicies of th e Federal Highway Administration. Thisreport does not constitute a standard, specification,or regulation.

i i

-

7/28/2019 Anchor Bolt Materials

4/44

PRE F ACE

This report is the f i r s t in a ser ies aimed toward improvingprocedures for anchor bolt design. The report deals specif ical ly withhigh-strength anchor bol t materials. I t includes a summary of ASTMSpecifications applicable to anchor bol t usage. The most desirablematerials for anchor bol t applicat ions are selected on the basis ofava i lab i l i ty and cost . The ASTM Specifications are cross-referenced withAISI Grade Designations and a brief descript ion of the use of AISI GradeDesignations is presented. Subsequent reports wil l present the resultsof tests of high-strength anchor bol ts and the implications of the t es t son design procedure.

The work is being conducted under Research Project 3-5-74-29, whichis sponsored by the Texas Highway Department and the Federal HighwayAdministration, and administered through the Center for Highway Researcha t The University of Texas a t Austin. Close l ia ison with the TexasHighway Department has been maintained through Mr. Warran A. Grasso, thecontact representative, and the Federal Highway Administration throughMr. Jerry Bowman.

i i i

-

7/28/2019 Anchor Bolt Materials

5/44

A B S T RAe T

An evaluation of the suitabil i ty of various high-strength materialsfor anchor bolt applications was made. A selected group of materialsmeeting ASTM Standard Specifications were tabulated. Based on the materialproperties, availabil i ty , and cost, several of the materials were determined to be most suitable fo r anchor bolt materials . To further ass i s tthe designer in selecting materials not covered by ASTM Standard Specifications, a brief review of AISI Grade Designations is presented andcross-referenced with the ASTM Standard Specifications.

KEY WORDS: anchor bol ts , materials , selection, specifications.

iv

-

7/28/2019 Anchor Bolt Materials

6/44

SUM MAR YThis report presents a guide to selecting high-strength anchor

bolt materials. A review of applicable ASTM Standard Specif icat ions ismade with a selected group of Specif icat ions tabulated to indicatethose materials deemed most suitable on the basis of properties, availabi l i ty , and cost. AISI Grade Designations are also reviewed and crossreferenced with ASTM Standard Specifications.

v

-

7/28/2019 Anchor Bolt Materials

7/44

IM P L E M EN TAT IO N

With th e wide var iety of materials available for us e as anchorbolt stock, i t is often dif f icul t for th e designer to make a decisionregarding the specif ic material or specification to use. This report isintended to provide guidance to the designer in carrying out the taskof selecting and specifying high-strength anchor bol t mater ial . On th ebasis of ava i lab i l i ty and cos t , a selected group of materials meetingASTM Standard Specif icat ions is tabulated. Factors such as labor costsassociated with placement or quantity purchased are not considered.Lengths used in the tabulations are not based on rigorous design methodsbut provide only for re la t ive comparisons. Work underway, to be reportedl a ter , should provide guidance in determining embedment lengths. Coupledwith th e material in this report , the engineer should be able to ra t ional lydesign and specify th e anchor bolt ins ta l la t ion .

vi

-

7/28/2019 Anchor Bolt Materials

8/44

CON TEN T SPage

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Suitable ASTM Specifications . . . . . . . . . . . . . . . . . . 1

Relative Cost and Availabili ty . . . . . . . . . . . . . . . . 10Hydrogen Embrittlement . . . . . . . . . . . . . . . . . . . . 10APPENDIX A - Details of Selected ASTM Specifications . . . . . 11APPENDIX B - AISI Grade Designations . . . . . . . . . . . . 24

vii

-

7/28/2019 Anchor Bolt Materials

9/44

Table1

2

3

BlB2

Figure1

Bl

B2

B3

L IS T o F TA B L E S AND F I GURE S

ASTM Specif icat ions Applicable to Anchor Bolt UsagePropert ies of ASTM Specif icat ions Suitable fo rHigh-Strength Anchor Bolt Applications . .Representative Relative Costs for TypicalHigh-Strength Headed Anchor Bolts ....Basic Number System for AISI Grade DesignationsEstimated Minimum Mechanical Propert ies of CarbonSteel Bars by AISI Grade Designations . . . .

Variation in cost with bolt diameter .Relationship between Brine11 Hardness and reductionof area . . Relationship between Brine11 Hardness and tensi lestrength . . . . . . . . . .Relationship between Brine11 Hardness and yieldstrength . . . . . . . . . .

v i i i

.

. .

Page3

4

526

27

8

31

33

. 34

-

7/28/2019 Anchor Bolt Materials

10/44

Introduction

A GUIDE TO THE SELECTION OF HIGH-STRENGTHANCHOR BOLT MATERIALS

The purpose of th is report is to provide a means of selectingand specifying mate rial for high-streng th (f > 50 ksi) anchor bolts .yThe information and suggestions contained herein are based on the resultsof a survey of materials meeting selected ASTM standards which were considered suitable for anchor bolt applications.

Generally, there are two ways to specify material for an anchorbol t . The more convenient approach is to cite th e ASTM Standard Specification which defines th e appropriate minimum mechanical properties,level of quality control, etc. A material may also be specif ied bycit ing the desired AISI Steel Grade Designation, chemical composition,necessary metallurgical treatment, f inishing and machining, and otherdesired properties. Except in special circumstances such an approach isunnecessary; the end product, a material meeting certa in minimum requirements, is far more easily obtained by cit ing the appropriate ASTM Specification. Consequently, th is report is concerned primarily with examiningASTM Specif icat ions suitable for high-strength anchor bolt applications.Appendix B contains supplemental information concerning the AISI GradeDesignation approach.Suitable ASTM Specif icat ions

The selection of high-strength anchor bolt material by ASTM Specifications may not be a straightforward process, because there are a largenumber of ASTM Specif icat ions for high-strength bars . The specificationsrange in organization from catalogs of chemical compositions of carbon andalloy steel bars to detailed mechanical and quality control requirementsfor special application bars. In addit ion, many specifications contain orimply certain rest r ict ions which l imi t their usefulness in high-strength"

I

-

7/28/2019 Anchor Bolt Materials

11/44

2anchor bolt applications. Table 1 l i s t s the ASTM Specifications whichwere examined to determine their sui tabi l i ty for specifying anchor boltmaterials. Several of the specifications have been or are being used bythe Texas Highway Department to specify anchor bol t material . Each ofthese specifications is discussed brief ly in Appendix A.

Of th e twenty ASTM Specifications l i s ted in Table 1, eightappear suitable for high-strength anchor bolt applications. Table 2l i s t s these specifications and the pertinent mechanical properties.

Relative Cost and AvailabilityI t would be desirable to compare th e specifications shown in

Table 2 on a basis of relat ive cost and availabil i ty . The present steelmarket makes i t dif f icul t to obtain information of this nature. However,contacts with steel industry sources have provided some data on relat ivecost. Availability, on the other hand, is dif f icul t to evaluate, exceptfor indications that some materials are not generally available.

Table 3 shows some relat ive cost information for several of theASTM Specif icat ions l is ted in Table 2. Such information for a l l thematerial shown in Table 2 was unavailable. The data in Table 3 werecompiled assuming a heavy hex head bolt with a length of 20 bar diameters.Length as a function of bar diameter was specif ied to ref lec t embedmentlength requirements. Work currently underway is aimed toward evaluationof the factors influencing the strength of anchor bol ts . With completionof the study, design recommendations for the embedment length of highstrength anchor bolts wil l be developed. Twenty bar diameters were chosenfor comparison purposes only, and are not intended as a design recommenda-t ion. The cost of an ASTM A307, 1 in . diameter by 20 in . long bol t , wasused as a base (100%) because i t is a low strength (36 ksi) materialreadily available and for which costs can be easily obtained. The relat ive cost data shown in Table 3 do not consider quantity ordered, whichwil l influence actual cost considerably.

-

7/28/2019 Anchor Bolt Materials

12/44

TABLE 1. ASTM SPECIFICATIONS APPLICABLE TO ANCHOR BOLT USAGE

1. ASTM A29 - General Requirements fo r Hot-Rolled and Cold-FinishedCarbon and Alloy Steel Bars

2. ASTM A108 - Cold-Finished Carbon Steel Bars and Shafting

3

3. ASTM A193 Alloy Steel and Stainless Steel Bolting Material for HighTemperature Services

4. ASTM A306 - Carbon Steel Bars Subject to Mechanical Property Requirements5. ASTM A307 - Carbon Steel Externally and Internal ly Threaded Standard

Fasteners6. ASTM A311 - Stress Relief Annealed Cold-Drawn Carbon Steel Bars7. ASTM A320 - Alloy Steel Bolting Materials fo r Low-Temperature Service8. ASTM A321 - Quenched and Tempered Carbon Steel Bars9. ASTM A322 - Hot Rolled Alloy Steel Bars

10 . ASTM A325 - High-Strength Bolts for Structural Steel Joints, IncludingSuitable Nuts and Plain Hardened Washers11. ASTM A331 - Cold-Finished Alloy Steel Bars12. ASTM A354 - Quenched and Tempered Alloy Steel Bolts and Studs withSuitable Nuts13. ASTM A400 - Recommended Prac t i ce fo r the Select ion of Stee l BarComposition According to Section14. ASTM A434 - Quenched and Tempered Alloy Steel Bars, Hot Rolled, orCold-Finished15 . ASTM A449 - Quenched and Tempered Steel Bolts and Studs16 . ASTM A458 - Hot-Worked, Hot-Co1d-Worked, and Cold-Worked Alloy SteelBars for High-Strength a t Elevated Temperatures17. ASTM A490 Quenched and Tempered Alloy Steel Bolts for StructuralSteel Joints18 . ASTM A540 - Alloy Steel Bolting Materials for Special Applications19. ASTM A575 - Merchant Quality Hot-Rolled Carbon Steel Bars20 . ASTM A576 - Special Quality Hot-Rolled Carbon Steel Bars

-

7/28/2019 Anchor Bolt Materials

13/44

Material

ASTM A193GRADE B7

ASTM A311

ASTM A320GRADE L7

ASTM A321

ASTM A325

ASTM A354GRADE BD

ASTM A449

ASTM A490

TABLE 2. PROPERTIES OF ASTM SPECIFICATIONSSUITABLE FOR HIGH-STRENGTH ANCHORBOLT APPLICATIONS

rn rn,.!:G ,.!:GBar Diameter P0..c ..c ~(!) .u .u ,j...J.--l 00 00 t1lP "0 P 00 =rn (!) .--l (!) PC'!P l-< (!) l-< 0(!) ,j...J ,j...J .--l PHU l >,Ul ~

2-1/2" and under 125 105 16Over 2-1/2" -4" incl. 115 95 16Over 4" - 7" incl . 100 75 189/16" and under 105 85 10-12Over 9/16"-1-1/4" incl . 100 80 10-12Over -1-1/4" -2-1/ 2" incl . 95 75 10-122-1/2" and under 125 105 161" and under 110 75 18

Over 1" -2-1/ 2" incl . 105 70 18Over 2-1/2"-4" incl . 95 65 18Over 4" - 6" incl . 90 60 18Over 6" -9 -1/2" incl . 85 50 181 2" -1" incl . 120 92 141-1/8"-1-1/2" incl . 105 81 141/4"-1-1/2" incl . 150 125 141/4"-1" incl . 120 92 141-1/8"-1-1/2" incl . 105 81 141-3/4"-3" incl . 90 58 141/2" -1-1/ 2" incl . 50-170 130 14

4

~P0 rnt1l .--l rn.u (!) .--l (!)U l-< (!) P:: l

-

7/28/2019 Anchor Bolt Materials

14/44

Material

(4)ASTM A307

ASTM A193GRADE B7

ASTM A325ASTM A354GRADE BD

ASTM A449

ASTM A490

TABLE 3. REPRESENTATIVE RELATIVE COSTS FOR TYPICAL HIGH-STRENGTHHEADED ANCHOR BOLTS(l)

1" dia . x 20" 1-1/2" dia. x 30" 1-3/4" dia .Yield Relative Costi2) Yield Relative C o s t ~ 2 ) Yield RelativeStrength Cost Strength Strength Cost Strength Strength Cos tksi % Ratio ksi % Ratio ksi %

36 100 3.54 36 308 4.84 36 47 41

105 194 2.35 105 490 2.64 105 882

92 172 2.38 81 444 3.10 Not available indiameter125 194 1. 98 125 579 2.62 125 (3 ) 1077 (3 )

92 172 2.38 81 444 3.10 58 708

130 194 1.90 130 579 2.52 Not avai lable indiameter

x 35" (2 )Cost-StrengthRatio

5.48

3.49this

3.58(3)

5.08

this(1) Fo r heavy hex head bol ts , 20 bar diameters long. A length of 20 diameters is fo r comparison purposesonly and is no t intended as a design recommendation.(2) Cost-Strength Ratio Relative Cost, %= (Gross Bar Area, i n ~ ) ( Y i e l d Strength, ksi)(3) Although avai lable, material in this diameter is not covered by ASTM A354, Grade BD.(4 ) ASTM A307 is intended as a basis fo r comparison only and is not recommended fo r high-strengthanchor bol t applications.

-

7/28/2019 Anchor Bolt Materials

15/44

6The cost-strength rat io shown in Table 3 provides an index of

cost per kip of load-carrying capacity for a given bol t material and s ize .I t is calculated as:

Cost-Strength Ratio Relative Cost, %(Gross Bolt Area, in:)(Yie1d Strength, ksi)

The "units" of the cost-strength rat io are relat ive cost /kip. In devel-oping the concept of the cost-strength ra t io , i t was assumed that theallowable tension in a bolt was some appropriate fraction of the yieldst rength, and that this fraction was constant for a l l bolt diameters, lengths,and materials. I t was, therefore, possible to compare the various materialsin Table 3 on a basis of their yield strengths.

EXAMPLE 1. A force of 150 kips must be carried by an anchor boltins ta l l a t ion . An estimate of the relat ive economy of using ei therASTM A449, 1 in . diameter x 20 in . bol ts , or ASTM A193, Grade B7, 1-3/4 in .diameter x 35 in . bolts is desired.

From Table 3, cost-strength rat io for ASTM A449, 1 in . diameterx 20 in . bolts = 2.38

cost-strength rat io for ASTM A193, Grade B7,1-3/4 in . diameter x 35 in . bolts = 3.49I t can be seen from a comparison of the cost-strength rat ios that theASTM A449 bol ts are more economical than the ASTM A193 bolts . AlthoughASTM A193, Grade B7 bolts provide a 14 percent increase in yield strengthover A449 bol ts , th e cost increases by 47 percent.

EXAMPLE 2. To carry a force of 150 kips, 1 in . diameter bolts areto be used. An estimate of the relat ive economy of using ASTM A449 orASTM A193, Grade B7, is desired.

From Table 3, the cost-strength rat io for ASTM A449, 1 in . diameterx 20 in. bolts = 2.38

the cost strength rat io for ASTM A193, Grade B7,1 in . diameter x 20 in . bol ts = 2.35

-

7/28/2019 Anchor Bolt Materials

16/44

7I t can be seen that ASTM A193, Grade B7, bolts are s l igh t ly more economicalthan ASTM A449 bolts .

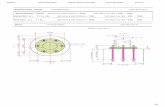

Figure 1 i l lus t ra tes the variation in re la t ive cost per crosssect ional bol t area with bolt diameter for bolts up to 4 in . Data arefor ASTM A193, Grade B7, mater ial . As before, bolt length was assumed tobe 20 diameters, with bol ts threaded at both ends and nuts and washersprovided. T e n - p i ~ c e lots were used for obtaining costs. As can be seen,th e re la t ive cost pe r unit area increases rapidly with diameter of bolt .Although not quite a l inear relationship exis ts , i t ca n almost be statedthat re la t ive cost per unit area increases in proportion to the diameter ofbolt used. I t should be noted that i f allowable stresses as a functionof the tensile strength of th e bolt are taken into account, th e coststrength ra t io for large bolts will be even higher because the strengthis reduced with increase in diameter.

Examination of Table 3 (and Examples 1 and 2) and Fig. 1 i l lus-t ra tes two trends regarding the re la t ive economy of bolt materials ands ize . Fi r s t , for a given diameter, an increase in yield strength resul tsin a decrease in the cost-strength ra t io . As shown by Example 2, however,the resul t ing increase in economy is not necessari ly proportional to theincrease in yield strength.

Second, for a given mater ial , the cost-strength ra t io increasesas the bolt s ize increases. Examination of the data for ASTM A193,Grade B7, bolts shows that while the load-carrying capacity of the1-3/4 in . diameter bolt is about 300 percent that of the 1 in . diameterbol t , the re la t ive CORt of the 1-3/4 in . diameter bolt is 455 percentthat of the 1 in . diameter bol t . The cost-strength ra t io for the twobolts ref lec ts these values. For materials exhibit ing a decrease in yieldstrength with increasing diameter, such as ASTM A449, the increase incost-strength rat io for larger diameters is even more signif icant than fora material with a constant yield strength, such as ASTM A193. From com-parison of the cost-strength ra t ios for the five ASTM Specif icat ionssui table for high-strength anchor bol t applicat ions shown in Table 3, i tcan be seen that the 1 in . diameter bolt with the highest cost-strength

-

7/28/2019 Anchor Bolt Materials

17/44

C'I c:::-JC/lou

4

+JC\I.....QJ~

1

a

Fig. 1

Al93, Grade B7la-piece lots20 diameter bolt lengthThreads--3 to 4 in. one end

6 in. other endTwo nuts and washers

Grade 2H, Al94

1 2 3Bolt diameter, in 4

Variation in cost with bolt diameter.

8

-

7/28/2019 Anchor Bolt Materials

18/44

9ra t io , ASTM A449 (cost strength rat io = 2.38) is more economical thanany 1-1/2 in . or 1-3/4 in . bolt . I t should be emphasized that these com-parisons consider material cost only and do not include labor costsassociated with instal lat ion or unit costs based on quanti ty orders.

Based only on material cost information available, i t is apparentthat th e most economical combination is a small diameter bol t with a highyield strength. Of th e materials l is ted in Table 3, ASTM A490, 1 in .diameter x 20 in. bolts and ASTM A354, Grade BD, 1 in . diameter x 20 in .bol ts best satisfy th is cr i ter ion. However, both mater ials , and part icular ly ASTM A490, are presently dif f icul t to obtain. ASTM A193, Grade B7,A325, and A449 can be considered re la t ively more available.

I t was previously noted that Table 3 was developed assuming heavyhex head bolts . ASTM A193, Grade B7; A354, Grade BD; and A449 are morecommonly used in anchor bolt applicat ions in a threaded-both-ends con-figuration. Using the limited information available onthe re la t ive costs of headed bolts and bolts threaded both ends, i t canbe concluded that a headed bolt is generally more costly than a bolt withboth ends threaded.

For example, comparing 1 in . diameter by 20 in . headed bolts withbolts threaded both ends (nut on one end), cost information avai lableindicates that the headed A193, Grade B7, bolts are about 10 percent higherand headed A449 bolts are about 20 percent higher than similar bolts threadedboth ends. Both materials are l is ted under ASTM Standard Specif icat ionswhich include bolts and studs.

In addit ion to the increased cost of the headed bolt compared tothat of th e bolt with both ends threaded, headed bolts become di f f icu l tto fabricate as length increases. Fo r a l l pract ical purposes, headed boltsshould be considered unavailable in lengths exceeding 4 f t . I t is possiblethat a bolt with a strength comparable to that of ASTM A490 and a lengthexceeding 4 f t . may be necessary for a part icular appl icat ion. Appendix B,concerning AISI Grade Designations, provides information for such cases.Appendix B also provides information for cases requiring strengths greaterthan provided by ASTM A490.

-

7/28/2019 Anchor Bolt Materials

19/44

10Hydrogen Embrittlement

When working with the high s tress levels and the high-hardnesss teels associated with high-strength anchor bol ts , the possibil i ty ofhydrogen embritt lement should not be ignored. Although the exactmechanisms are not fully understood, i t is known that i f embritt lementoccurs a delayed fracture is very l ikely, possibly even a t s tress levelsconsiderably below normal working s tress levels .

Susceptibil i ty to hydrogen embritt lement decreases with decreasingstrength or hardness of the s teel and with decreasing applied s tress ; alloycomposition is re la t ively unimportant. Hydrogen may be absorbed by thes teel during cleaning (pickling) and plating operations, from electrochemical cel l act ion, and from corrosion processes. Defects in the coatingof high-strength s teel par ts coated with zinc, aluminum, e tc . , can causean electrochemical cel l when an electrolyte , such as water , is present .Consequently, i f th e anchor bolt is to be galvanized or otherwise coatedand/or is intended for a corrosive environment, use of a material with ayield strength greater than 105 ksi is not recommended; stronger, hardermater ial , which would also be under a greater level of s t ress , would beto o susceptible to hydrogen embritt lement under such circumstances. I tshould be noted that even th is l imit may be too high. Further researchinto the area of hydrogen embritt lement is defini te ly indicated.Summary

Based on material costs only, the re la t ive economy of varioushigh-strength anchor bolt materials and bolt sizes was determined. Theinformation gathered indicates that small diameter bolts threaded bothends are generally the most economical choice. The effect of bolt diameteron th e cost-strength rat io is so significant that use of any 1 in . diameterby 20 in . high strength bolt represents signif icant economy over th e use oflarger diameter bolts i f material costs only are considered. Labor costsassociated with ins ta l la t ion may a l te r these rat ios. Appendix B containsinformation for dealing with si tuat ions that require strengths and/ordimensions that are not avai lable under the ASTM Specif icat ions l is ted inTables 2 and 3.

-

7/28/2019 Anchor Bolt Materials

20/44

A P PEN D I X A

DETAILS OF SELECTED ASTM SPECIFICATIONS

Each of the ASTM Specifications l is ted in Table 1 is discussedbriefly. Where applicable, the suitabil i ty of particular specificationsfor high-strength anchor bol t applications is discussed.

-

7/28/2019 Anchor Bolt Materials

21/44

ASTM A29: General Requirements fo r Hot-Rolled and Cold-FinishedCarbon and Alloy Steel Bars

12

ASTM A29 establishes common requirements concerning chemicalanalysis and physical testing procedures, permissible chemical compositionvariations, and dimensional tolerances for a "family" of 11 ASTM Specifications, 9 of which are applicable to anchor bolt materials: A10S, A306,A311, A321, A322, A331, A434, A575, and A576 (each wil l be discussedseparately). The common requirements apply except when otherwise specified by the purchaser or by a given specification. The main purpose ofA29 is that i t provides a minimum level of qual i ty control for th e specifications under i ts jur isdict ion; in many cases individual specificationprovisions wil l prevail over the A29 provisions.

-

7/28/2019 Anchor Bolt Materials

22/44

ASTM A108: Finished Carbon Steel Bars and ShaftingProperties Available: Tensile Strength

Yield StrengthElongation in 2Reduction in AreaBrinell HardnessBar Diameters

49-108 ksi41.5-90 ksi= 10-20/030-45%95-217= 9 in. and under

13

ASTM A108, a member of the A29 "family", covers cold-finishedcarbon s teel bars of a type suitable for heat treatment, machining,as-finished shafting, constructional uses, or similar applications. I tl i s t s 29 AISI Grade Designations and chemical compositions; no physicalproperties are specifically defined. The ranges of properties l is tedabove were taken from th e SAE Handbook of Metals (see Appendix B forl i s t of properties by AISI Grade Designation). Other sources may givesl ight ly different values. To use ASTM A108 to specify high-strengthanchor bolt material , th e designer must use sources other than th e ASTMSpecifications to determine which AISI Grade will provide the propertiesdesired. The physical properties of the bar wil l vary to some degreewith bar diameter. No specific information is available for this variat ion. Consultation with the fabricator is necessary to determineavai labi l i ty and sui tabi l i ty of selected grades. The entire process isboth inconvenient and ineff icient . Consequently, the use of ASTM A108is not recommended for high-strength anchor bolt applications.

-

7/28/2019 Anchor Bolt Materials

23/44

ASTM A193: Alloy Steel and Stainless Steel Bolting Material for HighTemperature Service

Properties Provided: Tensile Strength 75 - 125 ksiYield Strength = 30 - 105 ksiElongation in 2" 12 - 30%Reduction in Area = 45 - 50%Bar Diameters = 7" and under

14

ASTM A193 covers bolting materials (bars , bol ts , screws, studs, andstud bolts) for pressure vessels, flanges, and f i t t ings for high temperatureservices. I t is one of the specifications used by the Texas Highway Department for anchor bolts . Grade B7 provides the highest levels of strength ofthe grades defined under A193, and is the most commonly available (seeTable 2 for a detailed breakdown of Grade B7 propert ies) . Suitable nutsare defined under ASTM A194. Due to the high levels of strength and qualitycontrol provided, ASTM A193, Grade B7, is considered suitable for highstrength anchor bolt applications.

ASTM A306: Carbon Steel Bars Subject to Mechanical Property RequirementsProperties Provided: Tensile Strength = 45 - 90 ksiYield Point 22 - 40 ksiElongation in 2" = 17 - 33%Bar Diameters 9" and underASTM A306, a member of the A29 "family", covers carbon steel bars

furnished as-rolled, subject to mechanical property requirements and suitablefor general constructional use. Of th e 8 grades covered, 7 have yield pointsless than or equal to A36 s teel , and the yield point of the highest grade isonly 40 ksi. Obviously A306 would not be suitable fo r high-strength anchorbolt applications. Even in situations where strengths on th e levels shownabove are desired, the use of ASTM A36 would be more convenient.

-

7/28/2019 Anchor Bolt Materials

24/44

ASTM A307: Carbon Steel Externally and Internally Threaded StandardFastenersProperties Provided: Tensile Strength

Elongation in 2"Brinell HardnessBar Diameters

= 60-100 ksi== 18%::: 121-207= 1/4"-4" inclusive

ASTM A307 covers the mechanical and chemical requirements for

15

two grades of headed bolts with nuts. Grade A, intended for generalapplications, should be used for anchor bolts but Grade B, intended foruse in cast iron flanges of piping systems, has a higher tensile strength.ASTM A36 refers to A307 for "headed bolts used fo r anchorage purposes";however, A36 also notes that the yield strength of A307 steel is lowerthan that of A36 steel although no specific value is given in ei therspecification. Obviously not suitable for high-strength anchor bolts,ASTM A307 is not recommended even fo r lower strength anchor boltssince sl ightly bet ter strength is available from ASTM A36.

ASTM A3ll: Stress-Relief Annealed Cold-Drawn Carbon Steel BarsProperties Provided: Tensile Strength .. 90 - 105 ksiYield Strength == 70 - 85 ksiElongation in 2" = 10 - 15%Reduction in Area = 35 - 40%Bar Diameters = 9/16" - 2-1/2" inclusiveASTM A311, a member of the A29 "family", covers st ress- re l ie f

annealed, cold-drawn carbon steel bars of 4 AISI Grades covered by ASTM AlD8.These bars are suitable fo r applications where high strength, good machinabi l i ty , and decreased distortion are desired. Table 2 gives a breakdown ofproperties by AISI Grade. A3ll alleviates most of the objections to theus e of ASTM AlD8; minimum mechanical properties are defined, the processof specifying material under this Specification is straightforward, and thestrengths provided are sufficiently high. Consequently, ASTM A3ll can beconsidered suitable for high-strength anchor bol t applications.

-

7/28/2019 Anchor Bolt Materials

25/44

16

ASTM A320: Alloy Steel Bolting Materials for Low Temperature ServicePropert ies Provided: Tensile Strength = 75 - 125 ksi

Yield Strength 30 - 105 ksiElongation in 2" = 12 - 35%Reduction in Area = 35 - 50/Bar Diameters = 4" and underASTM A320 covers alloy s teel bolt ing material (bars, bol ts , screws,

studs, and stud bolts) fo r pressure vessels, valves, f langes, and f i t t ingsfor low temperature service. Grade L7 provides the highest levels ofstrength. See Table 2 fo r a detailed breakdown of Grade L7 properties.A320 is nearly ident ical to ASTM A193, except that certain impact energyabsorption cr i ter ia are included to meet low temperature service requirements. Consequently, unless impact is being considered, i t is not necessaryto use ASTM A320 for high-strength anchor bolt applications.

ASTM A32l: Quenched and Tempered Carbon Steel BarsPropert ies Provided: Tensile Strength

Yield PointElongation in 2"Reduction in AreaBar Diameters

= 85 - 110 ksi= 50 - 75 ksi= 18%35 - 45%9-1/2" and underASTM A32l, a member of the A29 "family", covers hot-rolled quenched

and tempered, carbon steel bars. Mechanical propert ies are defined by bardiameter (see Table 2). The strengths provided are low compared to thatavailable under other ASTM Specificat ions, but are nonetheless high enoughto consider ASTM A32l sui table for high-strength anchor bolt applications.

-

7/28/2019 Anchor Bolt Materials

26/44

ASTM A322: Hot-Rolled Alloy Steel BarsPropert ies Available: Tensile Strength

Yield StrengthBrinell Hardness= 95 - 205 ksi= 75 - 185 ksi= 388 - 496

17

ASTM A322, a member of the A29 "family", covers the chemicalrequirements for 73 AISI Grade Designations for alloy s teel suitable forbars 9" and under in diameter intended for regular constructional applicat ions. No specific propert ies are defined; the proper t ies l is ted abovewere obtained from ASTM A400, Selection of Steel Bar Compositions Accordingto Section (propert ies could be found for only 42 of the 73 grades, andonly for bar diameters 3-1/2" and under). Because of the large number ofAISI Grades covered, ASTM A322 is dif f icul t for the designer to use,par t icular ly since there is not a signif icant difference in th e mechanicalproperties of many of these s tee ls . The major cr i ter ia forchoosing one or another AISI Grade for a given strength range would be there la t ive ava i lab i l i ty of a part icular grade and such information is notconveniently available to the designer. Par t of the dif f icu l ty can beal leviated by noting that A322 includes AISI Grade 4140, which is one ofthe most common grades of alloy s teel available and has strengths in theupper ranges of those l is ted above. The same di f f icu l t ies are involvedin th e use of ASTM A322 as were involved in the use of Al08. Consequently,ASTM A322 is not recommended for anchor bolt applications. In specialcases, where very high strength is required (f > 130 ks i) , i t would beypossible to specify AISI 4140 with appropriate heat treatment. SeeAppendix B and the discussion of ASTM A540 for fur ther information onvery high strength bars; see also th e discussion of hydrogen embrittlement.

-

7/28/2019 Anchor Bolt Materials

27/44

ASTM A325: High Strength Bolts fo r Structural Steel Joints , IncludingSuitable Nuts and Plain Hardened WashersPropert ies Provided: Tensile Strength = 105 - 120 ksiYield Strength = 81 - 92 ksiElongation in 2" = 14%Reduction in Area = 35%Brinel l Hardness = 223 - 331Bar Diameters = 1/2" - 1-1/2"

18

inclusiveASTM A325 covers the chemical and mechanical requirements of several

types of quenched and tempered, high-strength, headed bolts for use ins tructura l jo ints . See Table 2 for a l i s t of proper t ies by bol t diameter.ASTM A325 specif ica l ly s ta tes that bolts for general applicat ions, includinganchor bolts , are covered by ASTM A449, Quenched and Tempered Steel Boltsand Studs. Nonetheless, A325 bolts may be used for high-strength anchorbolts i f the designer so chooses. I t should be noted, however, thathigh-strength headed bolts are extremely di f f icu l t to fabricate in lengthsgreater than 4 - 5 feet. I f greater lengths are required, a headed boltsuch as specif ied in ASTM A325 should not be used.

ASTM A33l: Cold-Finished Alloy Steel BarsPropert ies Available: Tensile StrengthYield StrengthBrinell Hardness

= 95 - 205 ksi= 75 - 185 ksi388 - 496ASTM A33l, a member of th e A29 "family", covers th e chemical

requirements for 73 AISI Grade Designations for cold-finished al loy s tee lbars suitable for heat- treatment, machining into components or in theas-f inished condition for constructional pruposes. Except for provisionsallowing heat treatment, A33l is nearly ident ical to ASTM A32l, and thesame objections to i t s use for anchor bolt applicat ions apply. The propert iesl is ted above were taken from A400. I t should be noted, however, thatalthough A400 does refer specif ica l ly to ASTM A32l, i t does not refer a ta l l to ASTM A33l.

-

7/28/2019 Anchor Bolt Materials

28/44

ASTM A354: Quenched and Tempered Alloy Steel Bolts and Studs withSuitable Nut s= 105 - 150 ksi= 83 - 125 ksi= 217 - 352

19

Propert ies Provided: Tensile StrengthYield StrengthBrinell HardnessBolt Diameters = 1/4" - 4" inclusive

ASTM A354 covers the chemical and mechanical requirements fo rquenched and tempered alloy steel studs and headed bolts for three levelsor grades of strength (see Table 2). Grade BD provides the higheststrengths and is the most commonly available. ASTM A354 defines suitablenuts as Grades 2 and 2H of ASTM 194, Carbon and Alloy Steel Nuts for Boltsfo r High Pressure and High Temperature Service. ASTM A193 ci tes thisSpecificat ion as suitable for alloy bolt ing materials for use at the lowerrange of high temperature service. Because of the high strengths provided,ASTM A354 is suitable for high strength anchor bol t applications.

ASTM A400: Recommended Practice for the Select ion of Steel BarCompositions According to Section

ASTM A400 provides a means of selecting AISI Grade Designationsaccording to desired tensi le and yield strength, bar diameter, and severityof service condition. I t provides three levels of service c o ~ d i t i o n s ,yield strength ranges from 30 ksi to 185 ksi , and diameters 3-1/2" andunder; over 150 carbon and alloy s tee l AISI Grade Designations are l i s ted .A400 is not a procurement specification. Once a part icular AISI Gradehas been chosen, the designer or th e purchaser must cite ASTM Al08, A306,A3ll , or A322 (Appendix B provides the information necessary to find whichspecification or specifications cover a part icular AISI Grade). Ingeneral , since AISI 4140 (see discussion under ASTM A322) is the mostcommon alloy steel available and can, with the pr.oper heat treatment,reach the highest levels of strength l i s ted in the A400 Selection Tables,i t is not necessary to use ASTM A400 to select high-strength anchor boltmaterials.

-

7/28/2019 Anchor Bolt Materials

29/44

ASTM A434: Quenched and Tempered Alloy Steel Bars, Hot-Rolled orCold -FinishedPropert ies Available: Tensile Strength

Yield StrengthElongation in 2"Reduction in AreaBar Diameters

90-155 ksi= 65-130 ksi14-30%35-50%9 -1/2" and und er

20

ASTM A434, a member of th e A29 "family", covers three classes ofhot-rolled and two classes of cold-finished, quenched and tempered alloys tee l bars. Grade BD provides th e highest levels of strength (see Table 2)and is available hot-rolled or cold-finished. The specif ica t ion providesgood quality control and high strengths. However, contacts with thes tee l industry indicate that this material is vir tua l ly unavailable.Therefore, ASTM A434 is not recommended for high-strength anchor boltapplications.

ASTM A449: Quenched and Tempered Steel Bolts and StudsPropert ies Provided: Tensile Strength = 90 - 120 ksiYield Strength = 58 - 92 ksi

Elongation in 2" = 14%Reduction in Area = 35%Brine11 Hardness 183 - 302Bolt Diameters = 1/4" - 3" inclusiveASTM A449 covers the mechanical and chemical requirements for

quenched and tempered s tee l bolts and studs for general applicat ions wherehigh strength is required (see Table 2 for a l i s t of mechanical propertiesby diameters) . I t can be considered a generalized version of ASTM A325,which ci tes A449 for use in specifying anchor bolt materials . ASTM A449can be considered sui table for high-strength anchor bolt applications; i tis part icularly useful where strengths equal to those provided by A325 boltsare desired, but the lengths required are to o great to permit easy fabrication of a headed bol t .

-

7/28/2019 Anchor Bolt Materials

30/44

21ASTM A458: Hot-Worked, Hot-Co1d-Worked, Cold-Worked Alloy Steel Bars forHigh Strengths a t Elevated Temperatures

Properties Provided: Tensile Strength = 95 - 120 ksiYield Strength = 45 - 90 ksiElongation in 4Xdiam. = 18 - 20%Reduction in Area = 30 - 35%Brinell Hardness = 255 - 321Bar Diameters = 8" and underASTM A458 covers the chemical and mechanical requirements of Grade 651

hot/cold rolled high strength alloy steel bars for use at elevated temperatures. The material is available under two classes or conditions -Condition B represents a lower degree of cold work, and, consequently, alower strength level than Condition A, and is intended for very long-termappl icat ions. Considering that this specif icat ion covers one specificsteel grade for which l i t t l e information is presently available and thatsimilar strength levels are available under other specifications (such asASTM A193, Grade BD), ASTM A458 is not recommended for high-strength anchorbolt applications.

ASTM A490: Quenched and Tempered Alloy Steel Bolts for Structural SteelJoints

Properties Provided: Tensile Strength = 150 - 170 ksiYield Strength = 130 ksiElongation in 2" = 14%Reduction in Area 40%Bolt Diameters = 1/2" - 1-1/2" inclusiveASTM A490 covers the chemical and mechanical requirements for

quenched and tempered high-strength alloy steel headed bolts intended foruse in st ructural joints ; i t defines suitable nuts as ASTM A194 Grade 2Hnuts. The high strengths (see Table 2) available under ASTM A490 make i twell suited for high strength anchor bolts . Like ASTM A325, however, A490is subject to length l imita t ions , and should be considered unavailable inlengths greater than four feet.

-

7/28/2019 Anchor Bolt Materials

31/44

22

ASTM A540: Alloy Steel Bolting Materials for Special ApplicationsPropert ies Provided: Tensile Strength = 115 - 165 ksiYield Strength = 100 - 150 ksiElongation in 2" = 10 - 15%Reduction in Area = 35 - 50%Brine11 Hardness = 248 - 444

Bar Diameters = 9-1/2" and underASTM A540 covers the chemical and physical requirements for regular

and special quality alloy s tee l rolled or forged bars to be machined intobol ts , studs, washers, and nuts which may be used for nuclear and otherspecial applications. ASTM A540 provides a high degree of metallurgicalqual i ty control , and also includes provisions concerning impact properties.Seven optional supplementary requirements are provided i f special qualityis desired. Unfortunately, no information on the cost or the avai labi l i tyof material under A540 is available; fabricators contacted were to tal lyunfamiliar with this specif icat ion. ASTM A540 is not recommended forgeneral use in high-strength anchor bol t applications. I t is recommended,however, that A540 be considered for possible use in special si tuat ionswhere very high-strength and r igid quality control are required.

ASTM A575: Merchant Quality Hot-Rolled Carbon Steel BarsPropert ies Available: Tensile Strength = 44 - 80 ksiYield Strength 24.5 - 44 ksiElongation in 2" = 16 - 3010Reduction in Area = 40 - 55/0Brine11 Hardness = 86 - 163

Bar Diameters 3" and underASTM A575, a member of the A29 "family", covers 9'AISI Grade

Designations for hot-rolled merchant quality carbon s tee l bars intendedfor structural and miscellaneous bar applicat ions involving moderate coldbending, hot forming, and welding as used in the production of noncri t icalpar ts . No specif ic properties were defined by the Specificat ion i t se l f ; thepropert ies l is ted above were obtained from th e SAE Handbook of Metals.Due to the low strengths available, ASTM A575 is not recommended fo rhigh-strength anchor bol t applicat ions

-

7/28/2019 Anchor Bolt Materials

32/44

ASTM A576: Special Quality Hot-Rolled Carbon Steel BarsPropert ies Available: Tensile Strength = 44 - 122 ksiYield Strength = 24.5 - 67 ksi

Elongation in 2" = 10 - 30%Reduction in Area = 25 - 55%Brinell Hardness = 86 - 248ASTM A576, a member of the A29 "family", covers 67 AISI Grade

Designations for hot-rolled special quality carbon steel bars sui table

23

for forging, heat t reat ing, cold drawing, machining, and many structuralapplications. No specif ic propert ies or bar diameter ranges are provided(for hot-rolled bars , ASTM A29 specifies 7/16" and larger bar diameters);the properties l i s ted above were obtained from the SAE Handbook of Metals.Due to the low strengths available, ASTM A576 is not recommended forhigh-strength anchor bolt applications.

-

7/28/2019 Anchor Bolt Materials

33/44

A P PEN D I X B

AISI GRADE DESIGNATIONS

[24]

-

7/28/2019 Anchor Bolt Materials

34/44

25

An AISI Grade Designation is a numerical code used to definewithin certain l imits the chemical composition of a steel . Table B1summarizes the basic code. The f i r s t number shows the type of steel - "1"signif ies a carbon s tee l , "2" a nickel s tee l , etc . The second number usuallydefines an alloying element or alloy combination, and sometimes shows theapproximate percentage of the major alloying element. The las t two orthree numbers usually designate the approximate carbon content in hundredths of 1 percent. Thus, AISI 4140 indicates a chromium-molybdenums tee l with about 0.75 percent chromium, 0.20 percent molybdenum, and0.40 percent carbon. I t should be noted that AISI Grade Designations conform with SAE grade designations.

Although the AISI Grade Designation approach to specifying highstrength anchor bolt materials i s not considered part icularly advantageous,i t may, a t t imes, be necessary for the designer to be famil iar with theproperties of various AISI s tee l grades. Table B2 l i s t s the properties of70 carbon s tee l AISI Grade Designations, and the corresponding ASTMSpecificat ions in which these grade designations are ci ted . The informat ion in Table B2 was taken from the 1973 SAE Handbook of Metals.Appropriate heat- treat ing wil l develop higher strengths.

II t is not expected that the designer wil l have to concern himselfwith carbon steels in th e event that the AISI Grade Designation approachmust be used. Should a si tuat ion arise that requires strengths and/ordimensions unavailable under the more commonly used ASTM Specification, thepract ical solution would be to specify a heat-treated alloy s tee l . Themain advantage of heat-treated alloy steels over heat-treated carbon s tee l s ,as i l lust rated in Fig. B1, is that an alloy steel is considerably moreduct i le than a carbon s tee l heat-treated to the same level of strength,part icularly a t high tensi le strengths.

Possibly the single most signif icant steel property to be consideredin the selection of an alloy steel for heat-treatment is hardenabi1ity,which is a measure of the response of the material- to heat-treatment.Hardenabi1ity controls the depth and distr ibut ion of hardneps induced by

-

7/28/2019 Anchor Bolt Materials

35/44

26TABLE Bl. BASIC NUMBER SYSTEM FOR AISI GRADE DESIGNATIONS

Series Type Steel Series Type SteelNumber NumberlOxx 46xxl lxx 48xx Nickel-Molybdenum SteelsCarbon Steelsl2xx 50xxl5xx 5lxx13xx Manganese Steels 50lxx Chromium Steels23xx 511xx25xx Nickel Steels 52lxx3lxx 6lxx Chromium-Vanadium Steels32xx 71xx Tungsten-Chromium Steels33xx Nickel-Chromium Steels 72xx34xx 92xx Silicon-Manganese Steels40xx Molybdenum Steels 9xx Low-Alloy High-Tensile Steels44xx 302xx4lxx Chromium-Molybdenum Steels 303xx Stainless Steels43xx 5l4xx43BVxx 5l5xx47xx Boron Intensified SteelsxBxx8lxx (B denotes Boron Steel)Nickel-Chromium-86xx Molybdenum Steels Leaded SteelsxLxx87xx (L denotes Leaded Steel)88xx93xx94xx97xx98xx

-

7/28/2019 Anchor Bolt Materials

36/44

27

TABLE B2. ESTiMATED M I N I M L ~ MECHANICAL PROPERTIES OF CARBON STEEL BARSBY AISI GRADE DESIGNATIONS

AISI 1 Tensile Yield Elongation Reduction Brine11 Average2 ASTMGrade Process Strength, Strength, in 2" , % in Area, % Hardness Mach in - Specifi-ksi ka i ability cation1008 CD 49 41.5 20 45 95 55 A108

HR 44 30 55 S6 A575 A5761010 CD 53 144 20 40 105 55 A10S

HR 47 26 2S 50 95 A575 A5761012 HR 48 26.5 28 50 95 AS75 A5761015 CD 56 47

=t18 40 111 60 A108

HR 50 27.5 28 50 1 AS75. A5761016 CD 61 51 18 4'() 121 70 A10S

HR 55 30 25 SO 111 A5761017 HR 53 29 26 r 50 105 AS75 A576CD 64 54 15 40 126 70 AIDS1018

HR 58 32 25 50 116 A5761019 HR 59 32.5 25 50 116 A5761020 CD 61 51 15 40 121 65 AIDS

HR 55 30 25 50 111 AS75 A5761021 HR 61 33 24 48 116 A5761022 CD 69 58 15 40 137 70 AIDS

HR 62 34 23 47 121 IA5761023 HR S6 31 2S 50 111 A575 AS761024 HR 74 41 20 42 149 A5761025 CD 64 54 15 40 126 6S AIDS

HR 58 32 25 50 116 AS15 A5761026 HR 64 35 24 49 126 AS761027 HR 75 41 18 40 149 AS761028 HR A5761029 HR A5761030 CD 76 64 12 35 149 70 A108

HR 68 37.5 20 1 42 137 A5761035 CD 80 67 12 35 163 6S AlaSHR 72 39.5 18 40 143 A576

(continued)

-

7/28/2019 Anchor Bolt Materials

37/44

28

TABLE B2 (Continued)

AISI 1 Tensile Yield Elongation Reduction Brine11 Average2 ASTMGrade Process Strength, Strength, in 2" , % in Area, % Hardness Machin- Specifi-ksi ks ! ability cationHR 83 45.5 16 40 163 A576HR 74 40.5 18 40 143 A576HR 75 41 18 40 149 A576HR 79 43.5 16 40 156 A576

1040 CD 85 71 12 35 170 A108HR 76 42 18 40 149 A576

1041 HR 92 51 15 40 187 A5761042 HR 80 44 16 40 163 A5761043 HR 82 45 16 40 163 A5761044 HR 80 44 16 40 163 A575 A5761045 CD 91 77 12 35 179 55 A10a

HR 82 45 16 40 163 A5761046 HR 85 47 15 40 170 A5761048 HR 96 53 14 33 197 A5761049 15 35 179 A5761050 10 30 197 45 AI0815 35 179 A5761051 A5761052 12 30 2171053 A5761055 12 30 192 A5761066 30 201 A5761070 12 30 212 A5761078 12 30 207 A5761080 10 25 229 A5761084 10 25 24:1. A5761090 10 25 248 A5761095 10 40 197 45 AI08

10 25 248 A5761109 30 50 101 A576

(cont inued)

-

7/28/2019 Anchor Bolt Materials

38/44

29

TABLE B2 (Continued)

AISI 1 Tensile Yield Elongation Reduction Brine11 Average2 ASTMGrade Process Strength, Strength, in 2" , % in Area, % Hardness Machin- Specifi-ksi ksi ability cation1110 HR1115 CD 61 51 20 40 'H116 HR1117 CD 69 58 15 40 137 A108

HR 62 34 23 47 121 A5761118 CD 72 61 15 40 143 85 Al08

HR 65 36 23 47 131 A576f - - - - ~ 1 1 9 HR 62 34 23 47 121 A576

1132 HR 83 45.5 16 40 167 A576~ 98 82 10 30 197 70 A10S1137 95 75 15 40 A31188 48 15 35 179 A5761139 HR A5761140 79 43.5 16 40 156 A576

88 10 30 212 70 A1081141 80 12 40 A311

.5 15 35 187 A57690 10 30 217 80 Al08

1144 SRACD 1 80 12 40 A311HR 97 53 15 35 197 A576

1145 HR 85 47 15 40 170 A5761146 HR 85 47 15 40 170

CD 102 S6 10 30 207 65 AlOS1151 SRACD 100 SO 10 35 A311

HR 9.2 50.5 15 35 187 A5761211 CD&HR AI08 A5761212 CD&HR AI08 A5761213 CD&HR AIDS A576

(continued)

-

7/28/2019 Anchor Bolt Materials

39/44

AISIGrade

l2L141215

BlOlOB1111Bl112Bl113

30

TABLE B2 (Continued)

1 Tensile Yield Elongation Reduction Brine11 Average2 ASTMProcess Strength, Strength, in 2" , 7, in Area, 7, Hardness Machin- Specifi-ksi ksi abil i ty cationCD AlOaHR 57 34 22 45 121 A576HR A576CD AlOa

CD&HR AlOa A576CD&HR AlOa A576CD&HR AlOa A576

(1) Process: HR = Hot-Rolled; CD = Cold-Drawn; SACD = Spheroidize Annealed Cold-Drawn;SRACD = Stress Relief Annealed Cold-Drawn

(2) Average Machinability: Cold-Drawn 1112 Steel = 100%Mechanical properties shown above are fo r general information only; they ar e typical ofbars with diameters between 3/4" and 1/4". The properties of cold-drawn steels will vary withdifferent cold-drawing procedures, or with a combination of cold-drawing and heat treatment forgrades 1050 and lower. Grades with higher carbon content than 1050 are often annealed beforecold-drawing.

-

7/28/2019 Anchor Bolt Materials

40/44

280

260

240

22010~..c20001-10()c::QJ01-1en!18010c::QJE-