Lo-Cat Blanking Conveyors – t he original

Transcript of Lo-Cat Blanking Conveyors – t he original

Lo-Cat Blanking Conveyors – the original

LO-CAT blanking conveyors were developed in 1982, and are the worldwide number one for the recovery of blanks and scrap from stamping tools. They are also highly suitable for body shells as well as scrap recovery from hard-to-access locations, and for transporting multiple blanks at the same time. The constant ongoing further development of their design and features ensures the maximum possible reliability and efficiency.

We differentiate between two drive systems used in LO-CAT blanking con-veyors: pneumatic and electric. The pneumatic drive features a pneumatic motor controlled with pressurised air, while the electric drive uses a servo motor matched precisely to the control of the respective presses. The lifting movement is triggered by a pneumatic valve of the press in all LO-CAT blanking conveyors.

Continuous magnetic strips provide optimal adhesion and prevent the parts being transported from slipping. The very high output speed of the LO-CAT blanking conveyors ensures the best possible material flow, together with maximum process safety.

For all LO-CAT blanking conveyors, we offer a 15-year spare parts warranty.

Blanking Die Systems

Made in Germany

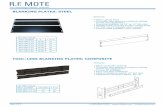

Lo-Cat Blanking Conveyors overview

Pneumatic magnetic roller

Pneumatic magnetic roller Pneumatic magnetic roller Pneumatic magnetic roller Pneumatic magnetic roller Type 61 02 020Type 61 02 021

Type 61 02 027 00Type 61 02 027 01

Type 61 02 039 Type 61 02 040

Type Super-compact roller vertical Standard horizontal Horizontal Standard vertical

Drive Pneumatic Pneumatic Pneumatic Pneumatic

Nominal lengths 145 mm 448 to 1120 mm 160 to 608 mm 640 to 1120 mm

Feed type Magnetic Magnetic Magnetic Magnetic

Pneumatic vacuum roller Electric magnetic roller

Pneumatic vacuum roller Electric servo motor-driven magnetic roller

Type 61 02 060 Type 61 04 041

Type Standard horizontal Standard vertical

Drive Pneumatic Electric

Nominal lengths 335 to 400 mm 320 to 1120 mm

Feed type Vacuum Magnetic

Pneumatic magnetic roller

Pneumatic magnetic roller Pneumatic magnetic roller Pneumatic magnetic roller Pneumatic magnetic rollerType 61 02 041 Type 61 02 042 Type 61 02 043 Type 61 02 044

Type Standard vertical Vertical or horizontal, without lift vertical (flange), without lift Compact roller vertical

Drive Pneumatic Pneumatic Pneumatic Pneumatic

Nominal lengths 192 to 608 mm 160 to 608 mm 160 to 608 mm 160 mm

Feed type Magnetic Magnetic Magnetic Magnetic

LO-CAT SySTemS GmbHBrand 12 / 79677 Schönau / Germany / Phone +49 7673 828-0 / Fax +49 7673 828-87 / [email protected] / www.lo-cat-systems.com

Lo-Cat Pneumatic Magnetic Rollertype 61 02 020 / 61 02 021

This LO-CAT magnetic roller can be used for removal of blanks, scrap recov- ery and component transport even external to the tools for small blanks. It is also suitable for lateral removal and for multiple cuts. Its nominal length of 145 mm makes it the optimal solution for cramped spaces and small blanks. And thanks to its slim design, it is the ideal blanking conveyor for die-cast tools and tools made of steel when installation space is restricted. The roller is designed for a maximum stroke rate of up to 60 per minute and a speed of 150 m/min.

This LO-CAT blanking conveyor is entirely maintenance-free.

Blanking Die Systems

Made in Germany

Lo-Cat Pneumatic Magnetic Rollertype 61 02 020 / 61 02 021

Notes• Oil-mist lubricators must be connected (this is included in the scope of supply).

The CAD data is also available for downloading at www.lo-cat-systems.com.

Operating pressure [bar] 6Stroke [max.] 25Speed [m/min] 150Torque [Nm] 15Stroke/min 60NL [mm] 145Maintenance-free yesContinuous speed control noSpecial design no

Part number 610202000 Part number 610202100

LO-CAT SySTemS GmbHBrand 12 / 79677 Schönau / Germany / Phone +49 7673 828-0 / Fax +49 7673 828-87 / [email protected] / www.lo-cat-systems.com

LO

-CAT

NL=

145 2xB Ø 11

106

130

70

H25

G 1/4"M

168

.567

VØ 6mm

LO

-CAT

NL=

145

2xB Ø 1180

150

B=1

31H

25

119

.5

G 1/4"M

116

Legend

V = Compressed air (controlled)M = MotorH = StrokeB = FixtureNL = Nominal length

Lo-Cat Pneumatic Magnetic Rollertype 61 02 027 00 / 61 02 027 01

The slim design of this LO-CAT magnetic roller makes it ideal for moulded tools when the space available for installation is extremely limited. Thanks to its brass slide rails, scratches to the sensitive metallic sheets are prevented during the feed process. With nominal lengths ranging from 448 mm to 1120 mm and a formidable torque of 25 Nm or 36 Nm, it is the perfect blanking conveyor for multiple cuts, for the transport and removal of small components and for scrap recovery.

This LO-CAT blanking conveyor is entirely maintenance-free.

Blanking Die Systems

Made in Germany

Lo-Cat Pneumatic Magnetic Rollertype 61 02 027 00 / 61 02 027 01

Features• Double-acting pneumatic cylinder.• 30 mm stroke.• The guides and bearings are maintenance-free.

Notes• Oil-mist lubricators must be connected (this is included in the scope of supply). • Nominal length from 448 to 608 mm or from 640 - 1120, in steps of 32 mm each.• Throttle is included in the scope of supply of type 61 02 027.

The CAD data is also available for downloading at www.lo-cat-systems.com.

Operating pressure [bar] 6Stroke [max.] 30Speed [m/min] 130Torque [Nm] 25 Type 61 02 027 01

36 Type 61 02 027 00Stroke/min 60NL [mm] 448 - 608 Type 61 02 027 01

640 - 1120 Type 61 02 027 00Maintenance-free yes

Continuous speed control yes Throttle 66104010 optional

Special design no

Example of an order 610202701-0544 *Model 00: NL 640 - 1120 mm640 / 672 / 704 / 736 / 768 / 800 832 / 864 / 896 / 928 / 960 / 992 1024 / 1056 / 1088 / 1120

*Model 01: NL 448 - 608 mm448 / 480 / 512 / 544 / 576 / 608

Legend

V = Compressed air (controlled)M = MotorH = StrokeB = FixtureNL = Nominal lengthR = Return air (controlled)Y = 100 + (NL-448)/2

Roller having nominal length of 544 mm6102 027 01 -0544

Item 6102Type 027Model* 01Nominal length (mm) -0544

VR

Ø 6mm

R 1/4"

77H

max

. 30

75 .5

97

Ø 140

120175

178

117

81

V

R

Ø 63

230

NL

NL

+80

2060

35 ±0.2

75 ±0.2

Y±0

.2Y

±0.2

4xB

Ø11

mm

M

LO-CAT SySTemS GmbHBrand 12 / 79677 Schönau / Germany / Phone +49 7673 828-0 / Fax +49 7673 828-87 / [email protected] / www.lo-cat-systems.com

Lo-Cat Pneumatic Magnetic Rollertype 61 02 039

This LO-CAT magnetic roller is perfect for tools with a low installation height (e.g. steel blanking die tools). It is suitable for removal of blanks, scrap recovery and component transport even external to the tools. It can also be used for lateral removal in tools. Thanks to its brass slide rails, scratches to the sensitive metallic sheets are prevented during the feed process. With a nominal length that starts at 160 mm, it is also suitable for cramped spaces and small blanks – and, because its nominal length goes up to 608 mm, for the removal of blanks and components with a length of up to 2,000 mm. It can do this up to a stroke rate of 60 per minute.

This LO-CAT blanking conveyor is entirely maintenance-free.

Blanking Die Systems

Made in Germany

Lo-Cat Pneumatic Magnetic Rollertype 61 02 039

Features• Single acting pneumatic cylinder.• The guides and bearings are maintenance-free.

Notes• For anticlockwise rotation (TYPE 61 02 039 10) the blanking conveyors must be installed with lateral inversion.• Oil-mist lubricators must be connected (this is included in the scope of supply). • Nominal length from 160 to 608 mm, in steps of 32 mm each.

The CAD data is also available for downloading at www.lo-cat-systems.com.

Operating pressure [bar] 6Stroke [max.] 28Speed [m/min] 130Torque [Nm] 25Stroke/min 60NL [mm] 160 - 608Maintenance-free yesContinuous speed control yesSpecial design no

Example of an order 610203910-0256 Model 00: Clockwise rotation Model 10: Anticlockwise rotation

NL to 160 - 608 mm160 / 192 / 224 / 256 / 288 320 / 352 / 384 / 416 / 448 480 / 512 / 544 / 576 / 608

Legend

V = Compressed air (controlled)M = MotorH = StrokeB = FixtureNL = Nominal lengthDrR = Clockwise rotationDrL = Anticlockwise rotation

Roller having nominal length of 256 mm, anticlockwise rotation6102 039 10 -0256

Item 6102Type 039Model* 10Nominal length (mm) -0256

LO-CAT SySTemS GmbHBrand 12 / 79677 Schönau / Germany / Phone +49 7673 828-0 / Fax +49 7673 828-87 / [email protected] / www.lo-cat-systems.com

246

(NL/

2)-8

NL/2

)-8

(NL/

2)-8

NL NL+7

4

50

70 752xB Ø 11mm

M

74

DrR61 02 039 00

Hm

ax

28

DrL61 02 039 10

V

Ø 6mm

Lo-Cat Pneumatic Magnetic Roller type 61 02 040

The slim design of this LO-CAT magnetic roller makes it ideal for moulded tools and steel blanking die tools when only limited space is available for installation. Thanks to its brass slide rails, scratches to the sensitive metallic sheets are prevented during the feed process. With nominal lengths ranging from 640 mm to 1,120 mm and a torque of 36 Nm, the blanking conveyor is also suitable for the transport and removal of very large and heavy blanks.

This LO-CAT blanking conveyor is entirely maintenance-free and can also be supplied in special designs.

Blanking Die Systems

Made in Germany

Lo-Cat Pneumatic Magnetic Rollertype 61 02 040

Features• Double-acting pneumatic cylinder.• The guides and bearings are maintenance-free. Notes• For anticlockwise rotation (TYPE 61 02 040 10) the blanking conveyor must be installed with lateral inversion.• Other stroke lengths on request.• Oil-mist lubricators must be connected (this is included in the scope of supply). • Nominal length from 640 to 1,120 mm, in steps of 32 mm each.

The CAD data is also available for downloading at www.lo-cat-systems.com.

Operating pressure [bar] 6Stroke [max.] 22Speed [m/min] 130Torque [Nm] 36Stroke/min 60NL [mm] 640 - 1120Maintenance-free yesContinuous speed control yes*Special design yes (on request)

* Throttle 66 10 40 10 optional

Example of an order 610204010-0960 * Model 00: Clockwise rotation Model 10: Anticlockwise rotation

NL 640 - 1120 mm640 / 672 / 704 / 736 / 768800 / 832 / 864 / 896 928 / 960 / 9921024 / 1056 / 1088 / 1120

Legend

V = Compressed air (controlled)R = Return air (controlled) M = MotorH = StrokeB = FixtureNL = Nominal lengthDrR = Clockwise rotationDrL = Anticlockwise rotation

Roller having nominal length of 960 mm, anticlockwise rotation6102 040 10 -0960

Item 6102Type 040Model* 10Nominal length (mm) -0960

LO-CAT SySTemS GmbHBrand 12 / 79677 Schönau / Germany / Phone +49 7673 828-0 / Fax +49 7673 828-87 / [email protected] / www.lo-cat-systems.com

(NL/

2)-1

92(N

L/2)

-192

NL

NL+1

00

50

2xB

Ø 11

mm

R 1/

4"

M

101 .5

3020

614

.5

92 .5

22 H

22 .5

45

DrL61 02 040 10

DrR61 02 040 00

VR

Ø 6mm

Lo-Cat Pneumatic Magnetic Roller type 61 02 041

The slim design of this LO-CAT magnetic roller makes it ideal for moulded and steel blanking die tools when only limited space is available for installation. Thanks to its brass slide rails, scratches to the sensitive metallic sheets are prevented during the feed process. With nominal lengths ranging from 192 mm to 608 mm and a formidable 25 Nm torque, it is the perfect blankingconveyor for multiple cuts, for the transport and removal of small com- ponents and also for scrap recovery.

This LO-CAT blanking conveyor is entirely maintenance-free and can also be supplied in special designs.

Blanking Die Systems

Made in Germany

Lo-Cat Pneumatic Magnetic Roller type 61 02 041

Example of an order 610204110-0256 * Model 00: Clockwise rotation Model 10: Anticlockwise rotation

NL 192 - 608 mm192 / 224 / 256 / 288320 / 352 / 384416 / 448 / 480512 / 544 / 576 / 608

Legend

V = Compressed air (controlled)R = Return air (controlled) M = MotorH = StrokeB = FixtureNL = Nominal lengthDrR = Clockwise rotationDrL = Anticlockwise rotation

Roller having nominal length of 256 mm, anticlockwise rotation6102 041 10 -0256

Item 6102Type 041Model* 10Nominal length (mm) -0256

LO-CAT SySTemS GmbHBrand 12 / 79677 Schönau / Germany / Phone +49 7673 828-0 / Fax +49 7673 828-87 / [email protected] / www.lo-cat-systems.com

(NL/

2)+3

0(N

L/2)

+30

NL

NL

+10

0

R1/

4"

M

2xB

Ø11

mm

101.5

14.5

3020

7

22.5

45

92.5

22 H

DrL61 02 041 10

D rR61 02 041 00

VR

Ø 6mm

Features• Double-acting pneumatic cylinder.• The guides and bearings are maintenance-free. Notes• For anticlockwise rotation (TYPE 61 02 041 10) the blanking conveyor must be installed with lateral inversion.• Other stroke lengths on request.• Oil-mist lubricators must be connected (this is included in the scope of supply). • Nominal length from 192 to 608 mm, in steps of 32 mm each.

The CAD data is also available for downloading at www.lo-cat-systems.com.

Operating pressure [bar] 6Stroke [max.] 22Speed [m/min] 130Torque [Nm] 25Stroke/min 60NL [mm] 192 - 608Maintenance-free yesContinuous speed control yes*Special design yes

* Throttle 66 10 40 10 optional

Lo-Cat Pneumatic Magnetic Roller type 61 02 042

The slim design of this fi xed LO-CAT magnetic roller makes it ideal for moulded and steel blanking die tools when only limited space is available for installation.With nominal lengths ranging from 160 mm to 608 mm and a formidable 25 Nm torque, it is perfect for the removal of small components and large scrap parts at cramped or hard-to-access locations. This variant is also suit-able for horizontal mounting.

This LO-CAT blanking conveyor is entirely maintenance-free.

Blanking Die Systems

Made in Germany

Lo-Cat Pneumatic Magnetic Roller type 61 02 042

Features• Choice of flat assembly or wall mounting.• The guides and bearings are maintenance-free. Notes• For anticlockwise rotation (TYPE 61 02 042 10) the blanking conveyor must be installed with lateral inversion.• Oil-mist lubricators must be connected (this is included in the scope of supply). • Nominal length from 160 to 608 mm, in steps of 32 mm each.

The CAD data is also available for downloading at www.lo-cat-systems.com.

Operating pressure [bar] 6Stroke [max.] 0Speed [m/min] 130Torque [Nm] 25Stroke/min 60NL [mm] 160 - 608Maintenance-free yesContinuous speed control yes*Special design no

* Throttle 66 10 40 10 optional

LO-CAT SySTemS GmbHBrand 12 / 79677 Schönau / Germany / Phone +49 7673 828-0 / Fax +49 7673 828-87 / [email protected] / www.lo-cat-systems.com

NL

NL+7

0

5020

NL/2

-27.

5

2xB

Ø11

mm

M

NL/2

-27.

5

48.5

142

.5

60 12

78

DrL61 02 042 10

DrR61 02 042 00

V Ø 6mm

Example of an order 610204210-0256 * Model 00: Clockwise rotation Model 10: Anticlockwise rotation

NL to 160 - 608 mm160 / 192 / 224 / 256 / 288 320 / 352 / 384 / 416 / 448 / 480 512 / 544 / 576 / 608

Legend

V = Compressed air (controlled)M = MotorB = FixtureNL = Nominal lengthDrR = Clockwise rotationDrL = Anticlockwise rotation

Roller having nominal length of 256 mm, anticlockwise rotation6102 042 10 -0256

Item 6102Type 042Model* 10Nominal length (mm) -0256

Lo-Cat Pneumatic Magnetic Roller type 61 02 043

The slim design of this fi xed LO-CAT magnetic roller makes it ideal for mouldedand steel blanking die tools when only limited space is available for installation. With nominal lengths ranging from 160 mm to 608 mm and a formidable 25 Nm torque, it is perfect for the removal of small components and large scrap parts at cramped or hard-to-access locations.

This LO-CAT blanking conveyor is entirely maintenance-free.

Blanking Die Systems

Made in Germany

Lo-Cat Pneumatic Magnetic Roller type 61 02 043

Features• The guides and bearings are maintenance-free. Notes• For anticlockwise rotation (TYPE 61 02 043 10) the blanking conveyor must be installed with lateral inversion.• Oil-mist lubricators must be connected (this is included in the scope of supply). • Nominal length from 160 to 608 mm, in steps of 32 mm each.

The CAD data is also available for downloading at www.lo-cat-systems.com.

Operating pressure [bar] 6Stroke [max.] 0Speed [m/min] 130Torque [Nm] 25Stroke/min 60NL [mm] 160 - 608Maintenance-free yesContinuous speed control yes*Special design no

* Throttle 66 10 40 10 optional

LO-CAT SySTemS GmbHBrand 12 / 79677 Schönau / Germany / Phone +49 7673 828-0 / Fax +49 7673 828-87 / [email protected] / www.lo-cat-systems.com

NL/

2-2

7.5

NL

NL

+70

5020

M

NL/

2-2

7.5

60 12 40

2024

.5

142

.5

2xB Ø 11mm

DrL61 02 043 10

22 .5

78

DrR61 02 043 00

V Ø 6 mm

Example of an order 610204310-0256 * Model 00: Clockwise rotation Model 10: Anticlockwise rotation

NL to 160 - 608 mm160 / 192 / 224 / 256 / 288 320 / 352 / 384 / 416 / 448 / 480 512 / 544 / 576 / 608

Legend

V = Compressed air (controlled)M = MotorB = FixtureNL = Nominal lengthDrR = Clockwise rotationDrL = Anticlockwise rotation

Roller having nominal length of 256 mm, anticlockwise rotation6102 043 10 -0256

Item 6102Type 043Model* 10Nominal length (mm) -0256

Lo-Cat Pneumatic Magnetic Roller type 61 02 044

The slim design of this LO-CAT magnetic roller makes it ideal for moulded and steel blanking die tools when only limited space is available for installation. Thanks to its brass slide rails, scratches to the sensitive metallic sheets are prevented during the feed process. It is the smallest of the LO-CAT blanking conveyors, with a nominal length of 160 mm and slide rails on the inside. With a formidable 25 Nm torque, it is the blanking conveyor for multiple cuts, andalso for transporting and removing small components and for scrap recovery.

This LO-CAT blanking conveyor is entirely maintenance-free and can also be supplied in special designs.

Blanking Die Systems

Made in Germany

Lo-Cat Pneumatic Magnetic Roller type 61 02 044

Features• Slide rails located inside.• Super-compact construction.• Double-acting pneumatic cylinder.• The guides and bearings are maintenance-free. Notes• For anticlockwise rotation (TYPE 61 02 044 10) the blanking conveyor must be installed with lateral inversion.• Other stroke lengths on request.• Oil-mist lubricators must be connected (this is included in the scope of supply).

The CAD data is also available for downloading at www.lo-cat-systems.com.

Operating pressure [bar] 6Stroke [max.] 22Speed [m/min] 130Torque [Nm] 25Stroke/min 60NL [mm] 160Maintenance-free yesContinuous speed control yesSpecial design yes (on request)

* Throttle 66 10 40 10 optional

Example of an order 610204410-0160 * Model 00: Clockwise rotation Model 10: Anticlockwise rotation

NL 160 mm

Legend

V = Compressed air (controlled)R = Return air (controlled) M = MotorH = StrokeB = FixtureNL = Nominal lengthDrR = Clockwise rotationDrL = Anticlockwise rotation

Roller having nominal length of 160 mm, anticlockwise rotation6102 044 10 -0160

Item 6102Type 044Model* 10Nominal length (mm) -0160

LO-CAT SySTemS GmbHBrand 12 / 79677 Schönau / Germany / Phone +49 7673 828-0 / Fax +49 7673 828-87 / [email protected] / www.lo-cat-systems.com

NL

= 16

0

230

M

R1/

4"B=N

L/2

B=N

L/2

101 .5

14.5

3021

1

22 .5

45

92 .5

22 H

2xB Ø 11mmDrL61 02 044 10

DrL61 02 044 00

VR

Ø 6mm

Lo-Cat Pneumatic Vacuum Rollertype 61 02 060

This LO-CAT vacuum roller is suitable for non-magnetic sheets or com-ponents – made of stainless steel, for example, or aluminium or copper. It is fi tted with special suction belts, to protect sensitive surfaces. The vacuum is generated using a vacuum pump with a permanent pneumatic connection, and the drive too is likewise controlled by a pneumatic connection. The roller’s space-saving construction makes it easy to integrate into new and existing projects. The design of the LO-CAT vacuum roller can be fi ne-tuned to meet the customer’s requirements and even coupled via a Cardan shaft, thus making it possible to remove large components and ensuring an absolutely synchronous feed. Up to 4 vacuum rollers can be connected to one another.

This LO-CAT blanking conveyors is entirely maintenance-free.

Blanking Die Systems

Made in Germany

Lo-Cat Pneumatic Vacuum Roller type 61 02 060

Notes• Different directions of rotation.• The stroke can be adjusted as desired between 16 and 22 mm. • The pressure gauge can be positioned externally if desired.• Available as a coupled version with 2, 3 or 4 rollers.• Oil-mist lubricators must be connected (this is included in the scope of supply).

The CAD data is also available for downloading at www.lo-cat-systems.com.

Operating pressure [bar] 6Stroke [max.] 16 - 22Speed [m/min] Torque [Nm] 36Stroke/minNL [mm] 335 und 400Maintenance-free yesContinuous speed control noSpecial design yes (on request)

Features• Double-acting pneumatic cylinder.• The guides and bearings are maintenance-free.

Example of an order 610206000-0400 * Model 00: Clockwise rotation Model 10: Anticlockwise rotation

NL 335 and 400 mm

Legend

V = Compressed air (controlled)D = Compressed air (permanent)R = Return air (controlled)H = StrokeB = FixtureNL = Nominal lengthDrR = Clockwise rotationDrL = Anticlockwise rotationVD = Vacuum canF = Conveyor belt

Roller having nominal length of 400 mm, anticlockwise rotation6102 060 00 -0400

Item 6102Type 060Model* 00Nominal length (mm) -0400

LO-CAT SySTemS GmbHBrand 12 / 79677 Schönau / Germany / Phone +49 7673 828-0 / Fax +49 7673 828-87 / [email protected] / www.lo-cat-systems.com

155

55NL

NL+

80

6565

NL+

15

196

30

207 .5

VR

D

Ø 6mm

62

193

50

234

H16

-22

2xBØ 11mm

FVDDrL61 02 06 0 10

ø 60

DrR61 02 06 0 00

Lo-Cat Electric Magnetic Rollertype 61 04 041

The LO-CAT electric magnetic roller delivers total accuracy in the removal of the blanks cut from the tool, thanks to its stop & go operation. The removal speed can be adjusted precisely to match the speed of the conveyor belts at the press and, if necessary, modified for higher or lower speeds. The stacking accuracy of the cut blanks is +/- 1 mm. Under certain conditions, the LO-CAT electric magnetic roller requires the one-time installation of a switching cabinet with controller at the press. Depending on the tool, different stacking intervals can be set using a speed controller.

Blanking Die Systems

Made in Germany

Lo-Cat Electric Magnetic Rollertype 61 04 041

Notes• The blanking conveyor can also be mounted with lateral inversion.• Other stroke lengths on request.• The motor can also be positioned externally via a Cardan shaft.• Electrical sensing via the position of the stroke.• Oil-mist lubricators must be connected (this is included in the scope of supply). • One control unit must be installed for each roller on the compression side (optional).• Nominal length from 320 to 1,120 mm, in steps of 32 mm each.

The CAD data is also available for downloading at www.lo-cat-systems.com.

Operating pressure [bar] 6Stroke [max.] 22

Speed [m/min] continuous control up to 240 metres/minute

Torque [Nm] 40Stroke/min 60NL [mm] 320 - 1120Maintenance-free yesSpecial design yes (on request)

Features• For Stop & Go operation with a stacking tolerance of <= +- 1 mm.• Double-acting pneumatic cylinder.• The guides and bearings are maintenance-free.

Example of an order 610404100-0960 NL 320 - 1120 mm320 / 352 / 384 / 416 / 448 / 480512 / 544 / 576 / 608 / 640 / 672704 / 736 / 768 / 800 / 832 / 864 896 / 928 / 960 / 9921024 / 1056 / 1088 / 1120

Legend

V = Compressed air (controlled)R = Return air (controlled)H = StrokeB = FixtureNL = Nominal lengthM = Servo motor

Roller having nominal length of 960 mm6104 041 00 -0960

Item 6104Type 060Model* 00Nominal length (mm) -0960

LO-CAT SySTemS GmbHBrand 12 / 79677 Schönau / Germany / Phone +49 7673 828-0 / Fax +49 7673 828-87 / [email protected] / www.lo-cat-systems.com

H22

2x B Ø 11

375

345

146.5

367

.5

45

22.5

B=NL

+60

NL

NL+1

40

368

82

M

max.

100

VR

Ø 6mm

Lo-Cat Blanking Conveyorsoriginal Spare Parts

Description Part number Suitable for typeCompressed air motor, 15 Nm, 370 W 6610012 61 02 020

61 02 021

Compressed air motor, 25 Nm, 370 W 6610010 61 02 027 01

61 02 039

61 02 041

61 02 042

61 02 043

61 02 044

Compressed air motor, 36 Nm, 620 W 6610011 61 02 027 00

61 02 040

61 02 060

Micro oil mist lubricator G1/4“ with mounting accessories

66104015 All types

Magnetic roller 66106330 All types except 61 02 060

Sprocket wheel with 9 teeth 66120009 All types

Sprocket wheel with 13 teeth 67120013 All types

Spare chain 500 mm length 68120017 All types

Chain joint for spare chain 69120018 All types

Flow control valve G1/4“ 66104010 61 02 027 00

61 02 027 01

61 02 039

61 02 041

61 02 042

61 02 043

61 02 044

61 02 040

Endless vacuum belt NL = 335 mm 1204080 61 02 060 00-335

Endless vacuum belt NL = 400 mm 1204081 61 02 060 00-400

Single-acting compact cylinder 50-10 66105010 61 02 039

Double-acting compact cylinder 50-25 66105025 61 02 041

61 02 044

61 02 060

Double-acting compact cylinder 63-25 66106325 61 02 027 00

61 02 027 01

Double-acting compact cylinder 63-30 66106330 61 02 040

LO-CAT SySTemS GmbHBrand 12 / 79677 Schönau / Germany / Phone +49 7673 828-0 / Fax +49 7673 828-87 / [email protected] / www.lo-cat-systems.com