Blanking and Lamination - CB-CERATIZIT

Transcript of Blanking and Lamination - CB-CERATIZIT

Blanking and Lamination

YOUR SOLUTION MATTERS

EDM & PreformFor Precision Stamping

EN

03

C

atal

og

ue

CatalogueAbstract

Ab

stra

ct

Catalogue

CB-CERATIZITIntroduction.................................................................................................... 04

Corporate Value............................................................................................ 06

Production Sites......................................................................................... 08

Grade Property & RecommendationComposition & Property............................................................................ 10

Concept of NF Corrosion Free Grade..................................................... 13

Carbide Blocks For WEDMCorrosion Resistant Grade..................................................................... 14

Normal Grade................................................................................................. 15

Carbide Rods For High Speed StampingSintered Solid Rods................................................................................. 16

Ground Solid Rods.................................................................................. 17

Preform For StampingPreform............................................................................................................. 19

Technical InformationThickness Tolerance Table........................................................................ 20

Mechanical Property................................................................................... 21

04

CB

-CER

ATI

ZIT

Intr

od

uctio

n

CB-CERATIZITIntroduction

About CB-CERATIZIT

CB-CERATIZIT is the Asian market leader in carbide rod blanks, industrial wear parts and wood & stone applications and specific cutting tool segments through quality products, fast delivery and responsive customer service. CB-CERATIZIT offers global production and technological supports as well as localised services. CB-CERATIZIT combined has more than 130 years of tungsten carbide industry experience. We are confident CB-CERATIZIT is the best partner for our growth oriented customers by providing carbide solutions.

CB-CERATIZIT Industry Chain

AmmoniumParatungstate

(APT)

TungstenOre

TungstenPowder

IndustrialWearParts

Rods

05

1

1

1

21

5

1

1

17

Woodand

StoneCuttingTools

CB-CERATIZITIntroduction

Sales offices and Production sites worldwideCERATIZIT CB-CERATIZIT

C

B-C

ERA

TIZ

ITIn

tro

duc

tion

Ready toPress Powder

TungstenCarbide

06 CB-CERATIZITCorporate Value

CB-CERATIZIT

We value customer feedbackWe help to shape the industry trendWe improve continuouslyWe are CB-CERATIZIT

2

3

4

1 Customer ServiceGrade SelectionGuide our customer to apply best solution for success.

Training Continuous LearningNurturing talents for sustainable long term growth.

CB

-CER

ATI

ZIT

Cor

pora

te V

alue

BreakthroughAchieve OutperformanceEnable our customer to achieve outperformance is our key objective.

Competitiveness Enhance CompetitivenessStrengthen the competitiveness of our customer is our long term goal.

07CB-CERATIZITCorporate Value

Core Competency

Professional, Dedication, Tailor-made serviceOur Promises:

2

3

4

5

6

7

1 Customer FocusTo relentlessly work to provide better solutions for our customers.

Stable QualityTo keep stable quality contributes to our customer’s brand reputation.

On-time DeliveryTo provide lean production for our customers.

Stock AvailabilityTo find solution for each and every customer’sgrade requirements.

Comprehensive SpecificationTo work with customers for tailor-made products.

Sustainable CapacityTo grow together with our customers.

Continuous Research and DevelopmentTo provide leadership for industry specific solutions.

C

B-C

ERA

TIZ

ITC

orpo

rate

Val

ue

08 CB-CERATIZITProduction Sites

EDM & Preform Production Centre

Established in 1978 & 1999, CB-CERATIZIT Taiwan & Xiamen Industrial Wear Parts Production Centre, together with production lines dedicated to manufacture EDM and preforms for high speed stamping industry, we are capable to produce wide range of customized carbide wear parts upon customer requests, CB-CERATIZIT and CERATIZIT combined has more than 130 years of tungsten carbide industry experience. We are confident that CB-CERATIZIT is the best partner for our growth-oriented customers in providin solutions for machining problem.

CB

-CER

ATI

ZIT

Pro

duct

ion

Site

s

Xiamen Production Centre Established in 2003, CB-CERATIZIT Xiamen Production Centre has grown to become the leading carbide production plant in Asia. Our Excellence production centre is technologically and capably equipped to support new carbide grade innovation and dynamic customer demands. We stand by our production and inspection procedures that upkeep strictly to ISO international standard.

09CB-CERATIZITProduction Sites

Innovative R&D Team In order to solve the corrosion problem of cementedcarbide, CB CERATIZIT experts collaborated with branded WEDM machine manufacturers to create the new corrosion resistant carbide grades –NF series, Corrosion resistance concept works in the beginning of grade preparation by mixing the powder with corrosion inhibitor elements. Once the NF grade carbide contacts with dielectric substance (e.g. water, lubricant etc.), a thin layer of oxide will form on the surface of the carbide for protection. It will isolate the carbide with the outside environment and thus preventing it from further corrosion, the protection is sustainable, and continuous throughout the whole machining processing.

The NF series corrosion free grade has the below advantages:1.) Able to sustain in more extreme dielectric medium condition in the WEDM process, thus help to eliminate corrosion factor due to poor filtration and also help to cut down filtration cost.2.) Reduce extra prevention measure to avoid carbide corrosion which may affect the quality of work pieces and therefore save cost.3.) Maintain a good surface quality after machining, improve tool life.

Har

dnes

s / W

ear R

esis

tanc

e

Toughness

The mechanical property of carbide can be altered by changing grain size and constitute to cope with wide range of tool performance demand. Consequently, features of CB-CERATIZIT grade can also be modified in accordance with different machining methodology. CB-CERATIZIT can offer best-fit solutions for special work piece metals such as harden material with high wear resistance, Nicochrome which can withstand high temperature, and Composite material with complicated mechanical properties.

Criteria relevant for application○ Wear resistance, Hardness○ Compressive strength○ Impact strength○ Transverse rupture strength○ Tribological properties○ Specific weight○ Magnetic properties○ Modulus of elasticity, Rigidity○ Thermal properties○ Corrosion resistance, Resistance to oxidation○ Toughness

Natural diamondPoly-crystal Diamond /Diamond CoatingCubic Boron Nitride Ceramic(O)Ceramic(N)

CermetHigh Speed SteelCarbide

C

B-C

ERA

TIZ

ITP

rodu

ctio

n S

ites

10 Grade Property & RecommendationComposition & Property

Grade ISOCode

Co Density Hardness T.R.S. FractureToughness KIC

(±0.5%) (g/cm3) HRA HV30 kgf/mm2 Mpa MPa*m1/2

SubmicronCorrosion Free Grade

Medium

Medium/Coarse

Ultrafine

Submicron

Fine

Medium

Medium/Coarse

NFM24=TNF25B, NFM25 =TNF25A* Taiwan Market Only.※Please contact our representative if additional grade requirement is needed.

* The classification of carbides grain size corresponds to the recommendations of the Powder Metallurgy Association.

Gra

de P

rope

rty

& R

ecom

men

datio

n

Com

posi

tion

& P

rope

rty

NFS16 K20~K30 8.2 14.56 92.0 1610 350 3430 9.5

NFS26 K40 13.0 14.08 90.5 1410 350 3430 12.0

NFM23 K30~K40 11.5 14.18 90.7 1430 340 3330 11.5

NFM24 K40 12.5 14.18 89.8 1330 350 3430 12.0

NFM25 K30~K40 12.5 14.18 88.8 1240 350 3430 17.0

TF25+ K10~K20 11.0 14.15 92.3 1660 380 3750 9.0

WF30 K10~K30 13.0 14.15 90.0 1355 350 3330 12.0

CF8* K20~K30 8.0 14.67 92.2 1645 330 3235 10.0

KG7 K40 15.0 13.95 89.3 1280 340 3330 13.0

CF10* K20~K30 10.0 14.46 91.0 1470 340 3330 12.0

CF12* K30~K40 12.0 14.27 90.3 1390 350 3430 12.5

KG4 K30~K40 12.0 14.30 89.3 1280 340 3330 13.0

KG5 K30~K40 12.0 14.31 88.3 1200 340 3330 17.0

Tungsten carbide grain size (μm) Classification

0.2-0.5 Ultrafine

0.5-0.8 Submicron

0.8-1.3 Fine

1.3-2.5 Medium

2.5-6.0 Coarse

11Grade Property & RecommendationComposition & Property

Gra

de P

rope

rty

& R

ecom

men

datio

nC

ompo

sitio

n &

Pro

perty

Corrosion Free Grade

Submicron

Medium

1μm

1μm

NFS16 : Innovative Grade. For stamping <0.6 stainless steel, Widely use in Electronics and Automotive connectors and lead frame industry. Hardness of HRA92, grade with combined high wear resistance and high toughness properties. Fine/ Ultrafine grain size & corrosion resistance that help to maintain a good surface quality and improve material stability & tool precision.

NFS26 : Optimized from WF30, for thin metal sheet and copper alloy stamping. Widely use in connector stamping, semi conductor stamping and electronics stamping industry. Submicron grain size & corrosion resistance help to maintain a good surface quality and improve material stability & tool precision.

NFM23: Optimized from KG4 (Hardness on upper limit of KG4). For stamping silicon steel, rotor, stator. Medium grain size & corrosion resistance properties help to improve tool stability & precision. Good wear and corrosion resistance. Highly optimized for general use.

NFM24: Optimized from KG4 (hardness on lower limit of KG4). Forstamping silicon steel, rotor, stator, Iron sheet and aluminum sheet. Medium grain size & corrosion resistance help to improve tool stability & precision. Good wear and corrosionresistance. Highly optimized for general use.

NFM25: Optimized from KG5, for stamping 0.5-1.5mm metal sheet, iron plate and for strippers purpose. Fine grain size & corrosion resistance help to improve tool stability & precision. Good balance of wear resistance and toughness.

1μm

Medium/Coarse

12

UltrafineTF25+ : For stamping thin copper alloy, lead frame and for making small

punches. Ultrafine grade with high wear resistance, homogenous grain size, tremendously improve tool life.

SubmicronWF30 : For thin metal sheet, copper alloy stamping. Widely used in

connector stamping, semi-conductor stamping and electronics stamping industry.

FineKG7 : For silicon steel, rotor, stator, iron sheet, aluminum stamping.

Fine grain size, highly optimized for general use, A balance between toughness and surface quality.

MediumKG4 : For silicon steel, rotor, stator, iron sheet, aluminum stamping.

Medium grain size, highly optimized for general application.

Medium / CoarseKG5 : For metal sheet stamping, medium/coarse grain size, high

toughness. Highly optimized for general use.

Grade Property & RecommendationComposition & Property

CF8 : For lead frame stamping and for perform making.

CF10 : For thin electronic plate and copper alloy stamping. For perform making.

CF12 : For thin metal sheet and copper alloy stamping.

Gra

de P

rope

rty

& R

ecom

men

datio

n

Com

posi

tion

& P

rope

rty

13Grade Property & RecommendationComposition & Property

Corrosion is still a topic which must be taken seriously. While in the past years corrosion was mainly associated with wire erosion, today’s increasing demands mean that fo l low-up processes like further machining operations and handling are now also becoming more and more important. Severe wear in active components is frequently due to corrosive damage.

Erosion

Transport

Storage

Coating Stamping,bending,forming

Grinding,regrinding

Cleaning

The causes for wear can often be determined only through detailed metallurgic examination. CB CERATIZIT offers this service to its PARTNERS in the tool and die industry.

100,00000

10,00000

1,00000

0,10000

0,01000

0,00100

0,00010

0,00001-500 -250 0 250 500

Standard

NF Grade

Cor

rosi

on s

peed

Cur

rent

den

sity

[µA

/cm

2 ]

Reduced tendency towards corrosion

Potential[mv]

Corrosion-resistant carbideCB CERATIZIT’s corrosion-resistant NF grades have become the standard in the tool and die industry. Maximum metallurgical consistency in combination with a factor 80 reduction in susceptibility to and speed of corrosion provide for longer machining times and maximum security, as depicted in the graphic showing the NF processes.

Graph NF-process chain

Measured current density potential curves

Layer for protection

Re and Cr mixed binder

WC

Detailed information about our patented corrosion protection can be found in our technical article ‘Newsletter of EDM and High Speed Stamping’.

TEM picture of the protection layer of a carbide grade containing Cr and Re

If you are interested or have any question, you’re welcome to contact CB CERATIZIT or visit our website: www.cbceratizit.com

Gra

de P

rope

rty

& R

ecom

men

datio

nC

ompo

sitio

n &

Pro

perty

14 Carbide Blocks For WEDMCorrosion Resistant Grade

L

W

T

NF Grade sintered carbide blocks for EDM

L Tol. W Tol. T Grademm mm mm mm mm NFS16 NFS26 NFM23 NFM24 NFM25

100 +0/+1.0

100 +0/+1.0

1-60

● ● ● ● ●

150 +0/+1.5 ● ● ● ● ●

200 +0/+1.5 ● ● ● ● ●

105 +0/+1.0

105 +0/+1.0

1-60

● ● ● ● ●

150 +0/+1.5 ● ● ● ● ●

200 +0/+1.5 ● ● ● ● ●

150 +0/+1.5

105 +0/+1.0 1-60 ● ● ● ● ●

150 +0/+1.5 20-60 ● ● ● ● ●

200 +0/+1.5 20-60 ● ● ● ●

200 +0/+1.5 200 +0/+1.5 20-60 ● ● ●

1. Other dimensions and ground item are upon request2. Thickness tolerance refer to Pg20

●=Standard item

Car

bide

Blo

cks

For W

EDM

Cor

rosi

on R

esis

tant

Gra

de

15Carbide Blocks For WEDMNormal Grade

L

W

T

Sintered carbide blocks for EDM

L Tol. W Tol. T Grademm mm mm mm mm TF25+ WF30 KG4 KG7 KG5

100 +0/+1.0

100 +0/+1.01-20 ● ● ● ● ●

21-60 ● ● ● ●

150 +0/+1.51-10 ● ● ● ● ●

11-60 ● ● ● ●

200 +0/+1.51-10 ● ● ● ● ●

11-60 ● ● ● ●

105 +0/+1.0

105 +0/+1.01-20 ● ● ● ● ●

21-60 ● ● ● ●

150 +0/+1.51-10 ● ● ● ● ●

1-60 ● ● ● ●

200 +0/+1.51-10 ● ● ● ● ●

11-60 ● ● ● ●

150 +0/+1.5

105 +0/+1.01-20 ● ● ● ● ●

21-60 ● ● ● ●

150 +0/+1.5 20-60 ● ● ● ●

200 +0/+1.5 20-60 ● ● ● ●

200 +0/1.5 200 +0/+1.5 20-60 ● ● ●

1. Other dimensions and ground item are upon request2. Thickness tolerance refer to Pg20

●=Standard item

Car

bide

Blo

cks

For W

EDM

Com

posi

tion

& P

rope

rty

16 Carbide Rods For High Speed StampingSintered Solid Rods

DL

Sintered Rods For High Speed Stamping

OD L OD Tol. Grademm mm mm TF25+ WF30 KG4 KG7 KG5

2.0 330 +0.2/+0.4

3.0 330 +0.2/+0.4 ●

3.5 330 +0.2/+0.4

4.0 330 +0.2/+0.4 ●

4.5 330 +0.2/+0.4

5.0 330 +0.2/+0.4 ●

5.5 330 +0.2/+0.4

6.0 330 +0.2/+0.4 ● ● ● ● ●

6.5 330 +0.2/+0.4 ● ● ● ●

7.0 330 +0.2/+0.4 ● ● ● ●

7.5 330 +0.2/+0.5 ● ● ● ●

8.0 330 +0.2/+0.5 ● ● ● ● ●

8.5 330 +0.2/+0.5 ● ● ● ●

9.0 330 +0.2/+0.5 ● ● ● ●

9.5 330 +0.2/+0.5 ● ● ● ●

10.0 330 +0.2/+0.5 ● ● ● ● ●

10.5 330 +0.2/+0.5 ● ● ● ●

11.0 330 +0.2/+0.5 ● ● ● ●

11.5 330 +0.2/+0.5 ● ● ● ●

12.0 330 +0.3/+0.6 ● ● ● ● ●

13.0 330 +0.3/+0.6 ● ● ● ●

14.0 330 +0.3/+0.6 ● ● ● ● ●

15.0 330 +0.3/+0.6 ● ● ● ●

16.0 330 +0.3/+0.6 ● ● ● ● ●

17.0 330 +0.3/+0.7 ● ● ● ●

18.0 330 +0.3/+0.7 ● ● ● ● ●

19.0 330 +0.3/+0.7 ● ● ● ●

20.0 330 +0.3/+0.7 ● ● ● ● ●

24.0 330 +0.4/+0.8 ● ● ● ●

25.0 330 +0.4/+0.8 ● ● ● ●

32.0 330 +0.7/+1.3 ● ● ● ●

42.0 330 +0.7/+1.3 ● ● ● ●

1. Production range: Ø1-Ø80, other dimensions are upon request2. Length tolerance : +1mm/+1.5mm

●=Standard item

Car

bide

Rod

s Fo

r Hig

h Sp

eed

Sta

mpi

ngS

inte

red

Sol

id R

ods

17Carbide Rods For High Speed StampingSintered Solid Rods

DL

H6 Ground Solid Rods

OD L OD Tol. Grademm mm mm TF25+ WF30 KG4 KG7 KG5

2.0 330 +0.006/-0

3.0 330 +0.006/-0 ●

3.5 330 +0.008/-0 ●

4.0 330 +0.008/-0 ●

4.5 330 +0.008/-0 ●

5.0 330 +0.008/-0 ●

5.5 330 +0.008/-0 ●

6.0 330 +0.008/-0 ● ● ● ● ●

6.5 330 +0.009/-0 ● ● ● ● ●

7.0 330 +0.009/-0 ● ● ● ● ●

7.5 330 +0.009/-0 ● ● ● ● ●

8.0 330 +0.009/-0 ● ● ● ● ●

8.5 330 +0.009/-0 ● ● ● ● ●

9.0 330 +0.009/-0 ● ● ● ● ●

9.5 330 +0.009/-0 ● ● ● ● ●

10.0 330 +0.009/-0 ● ● ● ● ●

10.5 330 +0.011/-0 ● ● ● ● ●

11.0 330 +0.011/-0 ● ● ● ● ●

11.5 330 +0.011/-0 ● ● ● ● ●

12.0 330 +0.011/-0 ● ● ● ● ●

13.0 330 +0.011/-0 ● ● ● ● ●

14.0 330 +0.011/-0 ● ● ● ● ●

15.0 330 +0.011/-0 ● ● ● ● ●

16.0 330 +0.011/-0 ● ● ● ● ●

17.0 330 +0.011/-0 ● ● ● ● ●

18.0 330 +0.011/-0 ● ● ● ● ●

19.0 330 +0.013/-0 ● ● ● ● ●

20.0 330 +0.013/-0 ● ● ● ● ●

24.0 330 +0.013/-0 ● ● ● ● ●

25.0 330 +0.013/-0 ● ● ● ● ●

32.0 330 +0.016/-0 ● ● ● ● ●

1. Production range: Ø1-Ø80, other dimensions are upon request2. Length tolerance: +1mm/+1.5mm3. Ground tolerance can be upon request

●=Standard item

Car

bide

Rod

s Fo

r Hig

h Sp

eed

Sta

mpi

ngS

inte

red

Sol

id R

ods

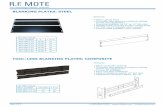

19Preform For StampingPreform

Customized PreformFor the tool and die industry we exclusively deliver sintered parts which are produced on our state-of-the-art machines by the CB CERATIZIT skilled workers. It is therefore necessary to speak the same ‘language’ with regard to the dimensions indicated in the drawings in order to manufacture products correctly (see illustrations below).

In this context, it is a big advantage for you that you can illustrate the hole specifications etc. in a simplified way. The part will then be supplied in accordance with the appropriate tables. The way of transmitting the drawing represents a significant factor with regard to the time taken to process an order and the quality that is achieved. This is why we are going to use drawing transmission via e-mail to a larger degree. The file format should be .dwg or .dxf and large data amounts should be zipped.

Preform

10 30 50 70 85 100

20

80

70

5020

6070

6575

20 55 60 80

110

(8X)

Counterbore for M6 head socket screw

Stepped bore for nuts fixed with adhesive

Brazeed steel plug for M6 Start hole(Ø1/1.5/2/2.5/3/4)

Preform drawing 1

Preform drawing 2 Preform drawing 3

Pref

orm

For

Sta

mpi

ngP

refo

rmDatum faces

20 Technical InformationThickness Tolerance Table

Blocks Thickness Tolerance Table

70

65

60

55

50

45

40

35

30

25

20

15

10

5

0

0 0.2 0.4 0.8 1.0 1.2 1.4 1.6 1.8 2.0 2.20.60.1 0.3 0.5 0.7 0.9 1.1 1.3 1.5 1.7 1.9 2.1

Thic

knes

s/m

m

Tolerance/mm

CB CERATIZIT provides customized semi-finished products as well

Tech

nica

l Inf

orm

atio

nTh

ickn

ess

Tole

ranc

e Ta

ble

21Technical InformationMechanical Property

1500

1300

1100

900

700

50005 10 15 20 25

1700

1900

2100

30

2300

2500

Har

dnes

s H

V30

Cobalt content [%]

Hardness Hardness is a material's mechanical resistance to another, harder, material which penetrates it. This value is usually measured by "Vickers Harndess Procedure" (ISO 3878) or "Rockwell Hardness Procedure" (ISO 3738). Like wear resistance, hardness also increases with a smaller grain size and lower cobalt content. Therefore, hardness is often used as a reference for wear resistance.

Ultrafine grades

Submicron grades

Fine / Medium grades

Coarse grades

Figure 1: Hardness in relation to the cobalt content and grain size

4000

3500

3000

2500

2000

150005 10 15 20 25

4500

30Tran

sver

se ru

ptur

e st

reng

th [M

Pa] Transverse Rupture Strength

Testing "Transverse Rupture Strength" is a common procedure to analyse the mechanical property of carbide. Based on ISO 3327 standard, a material with fixed length is placed on two contact points and certain stress is given in the milddle until the material breaks. The average value of several tests is then determined as T.R.S. (Transverse Rupture Strength)

Figure 2: Transverse rupture strength in relation to the grain size and thecobalt content

05 10 15 20 25 30

25

20

15

10

5

0

30

Toug

hnes

s K

IC [M

N/m

3/2 ]

Fracture Toughness When a material is exposed to external stress, this leads to mechanical tensions. Under this circumstances, both the strengh and ductility of the material indicate the basis for the concept of toughness. In other words, toughness is defined as the capacity to resist fracture or rupture growth. "Palmqvist Method" is frequently applied to determine the toughness value, KIC.

Figure 3: Fracture toughness in relation to the grain size and the cobalt content

Tech

nica

l Inf

orm

atio

nM

echa

nica

l Pro

perty

Ultrafine grades

Submicron grades

Fine / Medium grades

Coarse gradesCobalt content [%]

Cobalt content [%]

Ultrafine grades

Submicron grades

Fine / Medium grades

Coarse grades

22 Technical InformationMechanical Property

7000

6000

5000

4000

3000

200010 15 20 25

8000

9000

10000

0 5

Com

pres

sive

stre

ngth

[N/m

m2 ]

Compressive Strength One of the most remarkable properties of carbide is the extremely high compressive strengh under uniaxial stress. This precious property is applied to almost all applications. When metal binder content decreases and the grain size decreases, the compressive strength increases. A small grain carbide with a low metal binder content typically has a compressive strength of almost 7,000 N/mm2. The compressive strength decreases when the temperature increases. The degree of plastic deformation increase notably with the temperature, so that the results are variable when temperatures are high.

Submicron grades

Fine / Medium grades

Figure 4: Compressive strength in relation to the grain size andthe cobalt content

Coarse grades

Extra-coarse grades

120

100

80

60

40

20

0 100 200 300 400 500 600 8007000

Temperature [°C]

Ther

mal

con

duct

ivity

[W/m

*n °

C]

Thermal Conductivity The thermal conductivity plays an important role in carbide applications, it determines the temperature in the wear areas and has a large influence on the carbide's thermal fatigure resistance and resistance to thermal fluctuations. The thermal conductivity of carbide is around twice as high as that of non-alloyed steel.

Submicron grades

Fine / Medium grades

High y-phase content

Figure 5: Thermal conductivity in relation to the temperature of variousmicro-structures and grain sizes

Coarse grades

Low y-phase content

Tech

nica

l Inf

orm

atio

nM

echa

nica

l Pro

perty

Cobalt content [%]

23Technical InformationMechanical Property

650

600

550

40

500

4500 5 10 15 20 25

700

B

BR

-HC

HS

H

Mod

ulus

of e

last

icity

[kN

/mm

2 ] Modulus of Elasticity The modulus of elasticity indicates the resistance of a material against elastic deformation. The modulus of elasticity for carbide is 2 to 3 times higher than in steel. It will increase linearly with decreaseing metal binder content.

Figure 6: Modulus of elasticity of WC-Co carbides

Magnetic Saturation Carbides with cobalt as a metal binder are ferromagnetic. If a ferromagnetic material is exposed to a magnetic field strength H, the magnetic flux density B in this material increases (blue line). The flux density decreases when the field strength rises, until maximum saturation is achieved.

Coercive Force Coercive Force is one of the property of magnetic material. The inverse field strength HC which is necessary to reduce the magnetic flux density to zero, or to 'de-magnetise' the material, is defined as coercive force. Coercive Force is usually measured in oersted (Oe) or ampere/meter (A/m) units and is denoted HC. It can be measured using a B-H analyzer or magnetometer.

Figure 7: Hysteresis curve of a ferromagnetic material

Tech

nica

l Inf

orm

atio

nM

echa

nica

l Pro

perty

Cobalt content [%]

For More Information, Please Contact Us:CB - CERATIZIT (Taiwan) Group Head OfficeADD: 3F., NO. 217, Sec. 2, New Taipei Blvd., Hsin Chuang Dist.,New Taipei City 24250, Taiwan (R.O.C.)TEL: + 886-2-8521-6688FAX: + 886-2-8521-1011E-mail: [email protected]

CB - CERATIZIT (Xiamen) China Head OfficeADD: 69 Xingxi Rd, Xinglin, Jimei, Xiamen, China 361022TEL: +86-592-666-1000FAX: +86-592-621-9599E-mail: [email protected]

YOUR SOLUTION MATTERS We

rese

rve

the

right

to m

ake

tech

nica

lch

ange

s fo

r im

prov

emen

t of t

he p

rodu

ct.