Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

Transcript of Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

1/61

1

INSPECCION EN SERVICIO DE RECIPIENTESY SISTEMAS DE TUBERIAS.

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

2/61

2

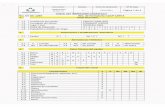

TEMARIO

pag1 CONCEPTOS Y OBJETIVOS DE LOS PROGRAMAS DE INSPECCION 3Tema 7 de api 572

2 DESCRIPCION DE LOS PRINCIPALES MECANISMOS DE DAO EXISTENTESEN LAS PLANTAS 4Tema 8 api 572

3 REQUISITOS DE DISEO Y DOCUMENTACION DE LA PLANTA ENRELACION A LA INSPECCION 11Tema 2.3 api 579

4 CONCEPTOS PRINCIPALES SOBRE LAS NORMAS APLICABLES EN LAINSPECCION (API 510,570.580,581,579.ASME SECC. XI) 14Introduccin

5 ALCANCE Y PLANES DE INSPECCION EN SERVICIO 17Alcance de cada uno

6 ENSAYOS NO DESTRUCTIVOS 23Asme sec V alcance y descripcin de cada mtodo

7 LINEAMIENTOS PARA EVALUAR LA INTEGRIDAD ESTRUCTURAL Y VIDAREMANENTE DE EQUIPOS E INSTALACIONES 36Tema 6 de DCSSI-SI-006

8 BASE DE DATOS PARA LAS INSPECCIONES EN SERVICIO 54Tema 4.3 api 579 o

9 CONCEPTOS Y DESCRIPCION DE LOS REGISTROS DE CALIDADRELACIONADOS CON LA INSPECCION EN SERVICIO 58Tema 6.7 y anex C y D de api 510

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

3/61

3

1CONCEPTOS Y OBJETIVOS DE LOS PROGRAMAS DE INSPECCIONTema 7 de api 572

Razones para la inspeccinLas razones bsicas para la inspeccin son determinar la condicin fsica del recipiente o

sistema de tuberas, y determinar el tipo, velocidad y causa de la degradacin. Estainformacin ser cuidadosamente documentada despus de cada inspeccin. Con talesdatos, la seguridad puede ser mantenida, el periodo de operacin sin un paro, puede serextendido, la velocidad de degradacin puede ser algunas veces reducida yrequerimientos de reparaciones futuras o reemplazos pueden ser estimadas.

Inspecciones peridicas programadas pueden revelar condiciones que resultaran en unaemergencia o programa de paro, una fuga o cualquier falla de recipiente si no escorregido.

La inspeccin peridica puede favorecer a un programa de mantenimiento bien planeado.

Las velocidades de corrosin y tolerancias de corrosin remanente determinada por lainspeccin son las bases normales para predecir las necesidades de reemplazo oreparacin. Estas predicciones provistas para un mantenimiento planeado y unacontinuidad de operacin y ayuda a asegurar una planta segura y viable.

Inspecciones externas ejecutadas mientras el equipo esta en operacin usandoinstrumentos acsticos, ultrasnicos o radiogrficos u otras tcnicas no destructivaspueden revelar importante informacin sin requerir entrar al equipo. Defectos tales comofugas, fracturas, mala instalacin de partes, lneas tapadas, vibracin inducida, ruidoinusual, y otra evidencia de malfuncionamiento puede ser encontrada. Si estos sntomasson apropiadamente analizados y correcciones son tomadas, la viabilidad de lasoperaciones mejorar.

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

4/61

4

2 DESCRIPCION DE LOS PRINCIPALES MECANISMOS DE DAO EXISTENTESEN LAS PLANTAS

La degradacin es posible sobre todas las superficies del recipiente en contacto con cualquiera de unamplio rango de compuestos orgnicos e inorgnicos, con agua contaminada o limpia, con vapores o con laatmsfera. La forma de degradacin puede ser electro-qumica, qumica, mecnica o una combinacin de

las tres. La degradacin puede ser acelerada por la temperatura, esfuerzos, vibracin, golpeteo, y altavelocidad o irregularidad del fluido.

La corrosin es la primer causa de degradacin en un recipiente a presin y puede ocurrir en cualquier partedel recipiente. La severidad de la degradacin es influenciada por la resistencia a lo corrosin de losmateriales usados en su construccin.

Muchos de los contaminantes in el crudo y qumicos manejados en las unidades de proceso, reaccionan conlos metales de tal forma que causa corrosin. Algunos flujos del proceso pueden causar erosin. En algunos

procesos ocurran ambas, erosin y corrosin. Cuando esto ocurre la prdida de espesor del metalsobrepasan grandemente las prdidas de metal estimadas en efectos considerados por separado, la erosin yla corrosin.

En general las prdidas de metal toman lugar en un periodo de tiempo. Registros adecuados de talesprdidas son muy importantes porque de ellos se desprenden los programas de inspeccin a intervalosregulares y la vida del equipo esperada. Sin embargo la prdida de metal, no siempre es constante, pero esten funcin de las variables como; sales, sulfuros, qumicos, custicos, cidos orgnicos, agua(especialmente con pH bajo), depsitos o ataques granulares de qumicos usados en refinacin ytemperaturas de operacin. Es esencial entonces que los inspectores estn generalmente enterados de laoperacin da con da del equipo y que l vigile las velocidades de corrosin a intervalos frecuentes.

2.1 DIFERENTES CLASIFICACIONES DEL FENMENO DE CORROSIN

La corrosin ocurre en muchas y muy variadas formas, pero su clasificacin se basaprincipalmente en alguno de los siguientes factores:

Naturaleza del Medio CorrosivoMecanismo de CorrosinApariencia del Metal Corrodo

A continuacin se detalla con mas precisin cada una de las clasificaciones.

2.2 Clasificacin de la corrosin, por la naturaleza del medio corrosivo.

Esta clasificacin, aunque no es muy usual, es muy til, ya que pueden generalizarse tcnicasde control para medios corrosivos similares.

En esta clasificacin, se dividen los medios corrosivos en dos grandes grupos, los que, a su vez,se subdividen en subgrupos:

Medios Hmedos o electrolticosMedios Secos (Altas Temperaturas)

Del primer grupo podemos tener los siguientes:

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

5/61

5

Agua de desecho industrialAgua de marAgua potableAgua para sistemas de enfriamientoHidrocarburos no refinadosHidrocarburos refinados

Medios Hmedos Medios amargos (cido Sulfhdrico)Medios dulces (cido Carbnico)cidos orgnicos e InorgnicosSoluciones alcalinasSoluciones oxidantesOxgeno atmosfricoContaminantes atmosfricos, etc.

Del segundo grupo dadas sus caractersticas, en trminos prcticos, el agente corrosivo mscomn es el oxgeno, aunque existen otros compuestos tales como el Bixido de Azufre, Cloro,etc., estables a temperaturas elevadas.

2.3 Clasificacin de la corrosin de acuerdo a su mecanismo.

Esta clasificacin tambin es muy til en el estudio de fenmenos de corrosin y su control, yaque conociendo el mecanismo de corrosin, se pueden desarrollar tcnicas apropiadas para laprevencin y control de la misma.

En esta clasificacin, dividimos a la Corrosin en dos grandes grupos:Corrosin Qumica

CorrosinCorrosin Electroqumica

2.4 Clasificacin de la Corrosin segn la apariencia del metal corrodo.

Esta Clasificacin es la ms empleada por la literatura tcnica, referente al tema, y se basa en lainspeccin visual de la superficie metlica del espcimen metlico corrodo, encontrando dos

grandes grupos de Corrosin: la Generalizada y la Localizada, donde para la primera no existensubgrupos pero para la segunda si, tal y como se muestra a continuacin:

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

6/61

6

Corrosin Uniforme:

La Corrosin Uniforme, como su nombre lo indica, es la que presenta un ataque igual o similaren toda la superficie metlica expuesta al medio corrosivo. Este tipo de corrosin es la mscomn y dada su naturaleza, es la que ofrece menos problemas para su medicin y control. Enel Esquema 2.4.1 se muestra la apariencia de sta:

Corrosin Uniforme

Esquema 2.4.1

Por otro lado, la corrosin localizada presenta en la mayora de los casos problemas ms serios,ya que no es tan fcil detectarla y medirla, presentndose en sitios donde la inspeccin omedicin es de difcil acceso, o bien, manifestndose en forma no apreciable a simple vista.

La corrosin localizada se divide en macroscpica y microscpica, de la primera tenemos lassiguientes:

Corrosin Localizada Macroscpica Corrosin Localizada MicroscpicaCorrosin Galvnica Corrosin por Ataque Selectivo

Corrosin Por Erosin Corrosin IntergranularCorrosin por Agrietamiento Corrosin Bajo Tensin

Corrosin por PicaduraCorrosin por Exfoliacin

A continuacin se describe cada uno de estos tipos de corrosin.

Corrosin Galvnica:

Este tipo de corrosin se presenta cuando dos metales de distinta naturaleza se encuentran encontacto elctrico y sometidos a un medio corrosivo electroltico, tal y como se muestra en elesquema 2.4.2.

Corrosin Galvnica

Esquema 2.4.2

El metal que se corroe, se le llama metal activo y el que no sufre daos por corrosin se le llamametal noble, teniendo como ejemplos de unin de metales activos con nobles:Acero - Cobre, Aluminio Acero, Zinc Acero, Aluminio Cobre, etc.

El mecanismo de este fenmeno, se origina por la diferencia de potenciales existentes entre losdos materiales, y en ocasiones esta propiedad se utiliza para generar corriente elctrica en pilas,bateras y acumuladores.

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

7/61

7

La forma mas adecuada de evitar este fenmeno, es diseando y construyendo equipos de unsolo tipo de material, pero si es indispensable el uso de mas de uno, habr que emplearaislantes elctricos entre los diferentes materiales.

Corrosin por Erosin:

La Corrosin por Erosin, se presenta cuando el flujo del medio corrosivo es intenso y se veincrementado por alguna reduccin de dimetro (Vntury) o cambio de direccin (Codos),ocasionando un desgaste mayor del material metlico, que si estuviera sometido a cualquiera delos dos fenmenos por separado ( Corrosin y Erosin).

En ocasiones es difcil distinguir entre Corrosin por Erosin y el desgaste mecnico, ya que elmedio corrosivo, frecuentemente porta slidos tales como arena, arcillas, etc. O bien productosde corrosin, como lo son xidos, sulfuros, etc.

En el esquema 2.4.3 se muestra un ejemplo de corrosin por erosin:

Corrosin por Erosin

Esquema 2.4.3

Este tipo de corrosin se puede atenuar desde el diseo, empleando materiales de construccinde mayor dureza y evitando al mximo los cambios de direccin y disminuciones de dimetro,as como tambin evitando la presencia de slidos abrasivos en el sistema.

Corrosin por Agrietamiento:

La formacin de grietas y hendiduras por el fenmeno de corrosin, suele formarse en regiones

donde existen uniones fsicas de dos o ms materiales de la misma naturaleza o bien, de unmetal con un no-metal, unin por la que penetra el medio corrosivo.

Como ejemplo de esta forma, tenemos los traslapes, empaques, juntas, tornillos, pelculas derecubrimiento daado, etc. En el esquema 2.4.4 se muestra un esquema de corrosin poragrietamiento:

Corrosin por Agrietamiento

Esquema 2.4.4

El origen de la corrosin por agrietamiento se atribuye a los siguientes factores existentes en elinterior de la grieta:

Cambio de pHEscasez de agentes corrosivosDesarrollo de iones diferentesAgotamiento del Inhibidor

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

8/61

8

Diferente velocidad de flujo.

Para controlar este tipo de corrosin es necesario sellar perfectamente las uniones antesmencionadas, con el fin de evitar la incursin del medio corrosivo en estas zonas.

Corrosin por Picadura:

Este tipo de corrosin localizada, se presenta formando orificios en superficies metlicasrelativamente no atacadas y se origina por los mismos factores atribuidos a la corrosin poragrietamiento, pudiendo considerar a una picadura como una grieta formada por s misma.

Corrosin por Picadura

Esquema 2.4.5En el esquema 2.4.5 se muestra la morfologa de la corrosin por picadura:

La corrosin por picadura se puede evitar desde el diseo, ya que hay materiales mssusceptibles que otros a sufrir de este fenmeno.

Adicionalmente, un buen control de corrosin aplicando correctamente inhibidores de corrosin ymanteniendo limpio el equipo o sistema son medidas convenientes para evitar este fenmeno.

Corrosin por Exfoliacin:

Esta es una corrosin subsuperficial que se esparce por debajo de la superficie metlica y difierede la corrosin por picadura, al presentarse en forma laminar.

Este tipo de ataque es, generalmente, identificado por el aspecto escamoso y en ocasiones

ampollado. En el esquema 2.4.6 se muestra el aspecto de este tipo de corrosin:

Corrosin por Exfoliacin

Esquema 2.4.6La mejor forma de evitar este dao, es seleccionando adecuadamente el material y sutratamiento trmico.

Corrosin por Ataque Selectivo:

Este tipo de corrosin localizada microscpica, se presenta en aleaciones en donde uno de loselementos (el ms activo), es removido o corrodo por el medio corrosive quedando el metalnoble remanente poroso y carente de propiedades mecnicas.

La corrosin sufrida por los latones (aleaciones cobre Zinc) conocida como descincificacin, esel ejemplo ms comn de este tipo de corrosin, en la cual el zinc, que es ms activo que elcobre, se corroe con mayor facilidad. En el Esquema 2.4.7 se muestra la apariencia de este tipode ataque.

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

9/61

9

Corrosin por Ataque Selectivo

Esquema 2.4.7La nica forma de combatir este de dao, es no empleando estas aleaciones en medios dondesean susceptibles a corroerse.

Corrosin Intergranular:

Este tipo de corrosin se presenta debido a que los materiales metlicos sometidos a ciertosmedios corrosivos se ven atacados selectivamente en los lmites de grano.

En casos severos suelen desprenderse granos enteros debido al gran deterioro por sus lmites,pudindose observar a simple vista una superficie rugosa. En el esquema 2.4.8 se muestra este

fenmeno:Corrosin Intergranular

Esquema 2.4.8

Corrosin Bajo Tensin:

Cuando el material metlico es sometido, en forma conjunta a un esfuerzo mecnico y a unataque qumico, suelen generarse fracturas que no se formaran si dicho material solo estuvierasometido al esfuerzo fsico o al fenmeno de corrosin.

Este tipo de corrosin se presenta solo para algunos materiales, que estn en contacto conmedios corrosivos especficos, lo peligroso de sta, es que puede ser no appreciable durantemucho tiempo, o propagarse rpida e inesperadamente.

Las fracturas o daos causados por corrosin bajo tensiones presentan quebradizas, a diferenciade otras (esfuerzos mecnicos), que generalmente muestran ductibilidad. En le esquema 2.4.9se muestra un ejemplo de cmo se presenta este tipo de corrosin.

Corrosin Bajo Tensin

Esquema 2.4.9

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

10/61

10

La mejor forma de controlar esta corrosin es seleccionando adecuadamente los materiales ysus tratamientos.

Corrosin bajo aislamiento (CUI)

La inspeccin externa de recipientes aislados debe incluir una revisin de la integridad del sistema deaislamiento de condiciones que podran generar la corrosin bajo aislamiento. Las fuentes de muestreo

pueden incluir lluvia, fuga de agua, condensacin sistemas de drenaje, y torres de enfriamiento. Las formasms comunes de corrosin bajo aislamiento son corrosiones localizadas de acero al carbono y SCC deacero inoxidable austentico. El alcance de un programa de inspeccin de corrosin bajo aislamiento puedevariar dependiendo del clima local y del sistema de aislamiento/recubrimiento aplicado al metal.

En localizaciones marinas en reas calientes puede requerir un programa muy activo (mayor frecuencia deinspeccin), en reas ms fros y secos puede no necesitar un programa tan frecuente de inspeccin.

Ciertos recipientes aislados son potencialmente ms susceptibles a la corrosin bajo aislamiento e incluyen:

a) Aquellos expuestos a un sistema de rociado.b) Los expuestos a venteo de vapor.c) Los expuestos a sistemas de drenaje;d) Los expuestos a salpicaduras de proceso o ingreso de mezclas de vapores cidos.e) Recipientes de acero al carbono, incluyendo los aislados para proteccin personal, operando entre

25 F (4 C) y 250 F (121 C). La corrosin bajo aislamiento es particularmente agresiva donde latemperatura causa frecuente o continua condensacin y re-evaporacin de mezcla atmosfrica.

f) Recipientes de acero al carbono que normalmente operan en servicio arriba de 250 C (121 C)pero en servicio intermitente.

g) Recipientes de acero inoxidable que normalmente operan entre 150 F y 450 F (66 C a 204C)(susceptible a fallas por esfuerzo qumico CSCC).

h) Recipientes con aislamiento degradado, recubrimientos y/o envolventes. Burbujas o decoloradosdel aislamiento o sistemas de envolventes o bandas perdidas. Las burbujas indican ormalmentecorrosin.

i) Recipientes susceptibles a daos fsicos del aislamiento o recubrimiento, por su exposicin almedio ambiente.

j) Terminacin del aislamiento en bridas u otros componentes.k) Daos o prdida del aislamiento.l) Costuras del aislamiento localizadas en la parte superior del recipiente o impropiamente

traslapadas o selladas.m) Terminacin del aislamiento en recipientes verticales.n) Rellenos o calafateados perdidos o endurecidos.

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

11/61

11

3 REQUISITOS DE DISEO Y DOCUMENTACION DE LA PLANTA ENRELACION A LA INSPECCION

Tema 2.3 API 579

3.1 Data Requirements

3.1.1 Original Equipment Design Data

The following original equipment design data should be assembled to perform a FFS (containsFitness-For-Service) assessment. The extent of the data required depends on the damagemechanism and assessment level. A data sheet is included in Table 2.2 to record the requiredinformation that is common to all FFS assessments. In addition, a separate data sheet is includedwith each section of this document to record information specific to the flaw type, damagemechanism, and assessment procedure.

a. Data for pressure vessels may include some or all of the following:1. An ASME Manufacturer's Data Report or, if the vessel is not Code stamped, other equivalent

documentation or specifications.2. Vessel fabrication drawings showing sufficient details to permit calculation of the MAWP of

the component containing the flaw. If a re-rate to a different condition of pressure and/ortemperature is desired (i.e. increase or decrease in conditions), this information should beavailable for all affected components. Detailed sketches with data necessary to performMA FW calculations may be used if the original fabrication drawings are not available.

3. The original or updated design calculations for the load cases in Table A.l of Appendix A, asapplicable, and anchor bolt calculations.

4. The inspection records for the component at the time of fabrication.5. User Design Specification if the vessel is designed to the ASME Code, Section VIII, Division

2.6. Material test reports.7. Pressure-relieving device information including pressure relief valve and/or rupture disk

setting and capacity information.8. A record of the original hydro test including the test pressure and metal temperature at the

time of the test or, if unavailable, the water or ambient temperature.

b. Data for piping components may include some or all of the following:1. Piping Line Lists or other documentation showing process design conditions, and a

description of the piping class including material specification, pipe wall thickness andpressure-temperature rating.

2. Piping isometric drawings to the extent necessary to perform a FFS assessment. The pipingisometric drawings should include sufficient details to permit a piping flexibility calculation ifthis analysis is deemed necessary by the Engineer in order to determine the MAWP(maximum safe or maximum allowable operating pressure) of all piping components.Detailed sketches with data necessary to perform MAWPcalculations may be used if theoriginal piping isometric drawings are not available.

3. The original or updated design calculations for the load cases in Table A. 1 of Appendix A,

as applicable.4. The inspection records for the component at the time of fabrication.5. Material test reports.6. A record of the original hydro test including the test pressure and metal temperature at the

time of the test, or if unavailable, the water or ambient temperature.

c. Data for tanks may include some or all of the following:1. The original API data sheet.2. Fabrication drawings showing sufficient details to permit calculation of the maximum fill

height (MFH) for atmospheric storage tanks and the MAWP for low pressure storage tanks.

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

12/61

12

Detailed data with sketches where necessary may be used if the original fabricationdrawings are not available.

3. The original or updated design calculations for the load cases in Table A.l of Appendix A, asapplicable, and anchor bolt calculations.

4. The inspection records for the component at the time of fabrication.5. Material test reports.6. A record of the last hydro test performed including the test pressure and metal temperature

at the time of the test or, if unavailable, the water or ambient temperature.

3.1.2 If some of these data are not available, physical measurements or field inspection of thecomponent should be made to provide the information necessary to perform the assessment.

3.2 Maintenance And Operational History

3.2.1 A progressive record including, but not limited to, the following should be available for theequipment being evaluated. The extent of the data required depends on the damage mechanismand assessment level.

a. The actual operating envelope consisting of pressure and temperature, including upsetconditions should be obtained. If the actual operating conditions envelope is not available, an

approximation of one should be developed based upon available operational data andconsultation with operating personnel. An operating histogram may be required consisting ofpressure and temperature data recorded simultaneously for some types of FFS assessments(e.g., Section 10.0 for components operating in the creep regime).

b. Documentation of any significant changes in service conditions including pressure,temperature, fluid content and corrosion rate. Both past and future service conditions shouldbe reviewed and documented.

c. The date of installation and a summary of all alterations and repairs including requiredcalculations, material changes, drawings and repair procedures. The calculations should includethe required wall thicknesses and MAWP (MFH for atmospheric storage tanks) includingdefinition and allowances for supplemental loads such as static liquid head, wind, and earthquake

loads.

d. Records of all hydro tests performed as part of the repair including the test pressure and metaltemperature at the time of the tests or, if unavailable, the water or ambient temperature at thetime of the test if known.

e. Results of prior in-service examinations including wall thickness measurements and other NDEresults that may assist in determining the structural integrity of the component and in establishinga corrosion rate.

f. Records of all internal repairs, weld build-up and overlay, and modifications of internals.

g. Records of "out-of-plumb" readings for vertical vessels.

h. Foundation settlement records if the corrosion being evaluated is located in the bottom shellcourse of the tank.

If some of these data are not available, physical measurements should be made to provide theinformation necessary to perform the assessment.

3.2.2 Required Data/Measurements For A FFS Assessment

Each section in this document which contains FFSassessment procedures includes specific

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

13/61

13

requirements for data measurements and flaw characterization based on the damage mechanismbeing evaluated. Examples of flaw characterization include thickness profiles for localcorrosion/erosion, pitting depth, and dimensions of crack-like flaws. The extent of information anddata required for a FFSassessment is dependent on the assessment level and damagemechanism being evaluated.

The Future Corrosion Allowance (FCA) should be established for the intended future operatingperiod. The FCA should be based on past inspection information or corrosion rate data relative tothe component material in a similar environment. Corrosion rate data may be obtained from APIPublication 581 or other sources (see paragraph A.2.7 of Appendix A). The FCA is calculated bymultiplying the anticipated corrosion rate by the future service period considering inspectioninterval requirements of the applicable inspection code. The FFS assessment procedures in thisdocument include provisions to ensure that the FCA is available for the future intended operatingperiod.

Recommendations For Inspection Technique And Sizing RequirementsRecommendations for Non Destructive Examination (NDE) procedures with regard to detectionand sizing of a particular damage mechanism and/or flaw type are provided in each section.

3.2.3 Assessment Techniques And Acceptance Criteria

Three Levels of assessment are provided in each Section of this document which cover FFSassessment procedures. A logic diagram is included in each Section to illustrate how theseassessment levels are interrelated. In general, each assessment level provides a balancebetween conservatism, the amount of information required for the evaluation, the skill of thepersonnel performing the assessment, and the complexity of analysis being performed. Level 1 isthe most conservative, but is easiest to use. Practitioners usually proceed sequentially from aLevel 1 to a Level 3 analysis (unless otherwise directed by the assessment techniques) if thecurrent assessment level does not provide an acceptable result, or a clear course of actioncannot be determined. A general overview of each assessment level and its intended use aredescribed below.

Level 1- The assessment procedures included in this level are intended to provide conservative

screening criteria that can be utilized with a minimum amount of inspection or componentinformation. Level 1 assessments may be performed by either plant inspection or engineeringpersonnel (see Section 1, paragraphs 1.4.2 and 1.4.3).

Level 2 - The assessment procedures included in this level are intended to provide a moredetailed evaluation that produces results that are more precise than those from a Level 1assessment. In a Level 2 Assessment, inspection information similar to that required for a Level 1assessment are needed; however, more detailed calculations are used in the evaluation. Level 2assessments would typically be conducted by plant engineers, or engineering specialistsexperienced and knowledgeable in performing FFSassessments.

Level 3 - The assessment procedures included in this level are intended to provide the mostdetailed evaluation which produces results that are more precise than those from a Level 2

assessment. In a Level 3 Assessment the most detailed inspection and component information istypically required, and the recommended analysis is based on numerical techniques such as thefinite element method. A Level 3 analysis is primarily intended for use by engineering specialistsexperienced and knowledgeable in performing FFS assessments.

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

14/61

14

4 CONCEPTOS PRINCIPALES SOBRE LAS NORMAS APLICABLES EN LAINSPECCION (API 510, 570, 580, 581, 579, ASME SECC. XI)

API 510This inspection code covers the maintenance inspection, repair, alteration, and re-ratingprocedures for pressure vessels used by the petroleum and chemical process industries.

The application of this inspection code is restricted to organizations that employ or have accessto an authorized inspection agency as defined in 3.4. Except as provided in 1.2, the use of thisinspection code is restricted to organizations that employ or have access to engineering andinspection personnel or organizations that are technically qualified to maintain, inspect, repair,alter, or re-rate pressure vessels.

Pressure vessel inspectors are to be certified as stated in this inspection code. Since other codescovering specific industries and general service applications already exist (for example, SectionsVI, VII, and XI of the ASME Boiler and Pressure Vessel Codeand the National Board InspectionCode), the industries that fit within the restrictions above have developed this inspection code tofulfill their own specific requirements.

This inspection code applies to vessels constructed in accordance with the API/ASME Code forUnfired Pressure Vessels for Petroleum Liquids and Gases, Section VIII of the ASME Code, andother recognized pressure vessel codes; to nonstandard vessels; and to other vesselsconstructed noncode or approved as jurisdictional special. Examples of nonstandard vesselsinclude:

a. A vessel fabricated to a recognized construction code but has lost its nameplate or stamping.b. A vessel not fabricated to a recognized construction code and meeting no known recognizedstandard.

This inspection code is only applicable to vessels that have been placed in service (includingitems further described in 1.2) and have been inspected by an authorized inspection agency orrepaired by a repair organization as defined in 3.15.

Adoption and use of this inspection code does not permit its use in conflict with any prevailingregulatory requirements.

API 570

API 570 covers inspections, repair, alteration, and re-rating procedures for metallic piping systemthat have been in-service.

API 570 was developed for the petroleum refining and chemical process industries but may beused, where practical, for any piping system. It is intented for use by organizations that maintainor have access to an authorized inspection agency, a repair organization and technically qualifiedpiping engineers, inspectors, and examiners, all as defined in Seccion 3.

API 570 Shall not be used as a substitute for the original construction requirements governing apiping system before it is placed in-service; not shall it be used in conflict with any prevailingregulatory requirements.

API 572

This Recommended Practice (RP) cover the inspection of pressure vessels and the standards fortheir constructions and maintenance. The reasons for inspection, causes of deterioration,

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

15/61

15

frequency and methods of inspection, methods of repair, and preparation of records and reportsare covered. Safe operation is emphasized.

API 579

The ASME and API design codes and standards for pressurized equipment provide rules for thedesign, fabrication, inspection and testing of new pressure vessels, piping systems, and storagetanks. These codes do not address the fact that equipment degrades while in-service and thatdeficiencies due to degradation or from original fabrication may be found during subsequentinspections. Fitness-For-Service (FFS ) assessments are quantitative engineering evaluationswhich are performed to demonstrate the structural integrity of an in-service component containinga flaw or damage. This Recommended Practice provides guidance for conducting FFSassessments using methodologies specifically prepared for equipment in the refining andpetrochemical industry. The guidelines provided in this recommended practice can be used tomake run-repair-replace decisions to help ensure that pressurized equipment containing flawswhich have been identified by inspection can continue to operate safely.

API 580

The purpose of this document is to provide users with the basic elements for developing and

implementing a risk-based inspection (RBI) program. The methodology is presented in a step-by-step manner to the maximum extent practicable.

Items covered are:a. An introduction to the concepts and principles of risk based inspection for risk management;and.b. Individual sections that describe the steps in applying these principles within the framework ofthe RBI process:

1. Planning the RBI Assessment.2. Data and Information Collection.3. Identifying Deterioration Mechanisms and Failure Modes.4. Assessing Probability of Failure.5. Assessing Consequence of Failure.

6. Risk Determination, Assessment and Management.7. Risk Management with Inspection Activities.8. Other Risk Mitigation Activities.9. Reassessment and Updating.10. Roles, Responsibilities, Training and Qualifications.11. Documentation and record-keeping.

The expected outcome from the application of the RBI process should be the linkage of risks withappropriate inspection or other risk mitigation activities to manage the risks.

The RBI process is capable of generating:

a. A ranking by risk of all equipment evaluated.

b. A detailed description of the inspection plan to be employed for each equipment item,including:

1. Inspection method(s) that should be used (e.g., visual, UT, Radiography, WFMT).2. Extent of application of the inspection method(s) (e.g., percent of total area examined orspecific locations).3. Timing of inspections/examinations.4. Risk management achieved through implementation of the inspection plan.

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

16/61

16

c. A description of any other risk mitigation activities (such as repairs, replacements or safetyequipment upgrades).

d. The expected risk levels of all equipment after the inspection plan and other risk mitigationactivities have been implemented.

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

17/61

17

5 ALCANCE Y PLANES DE INSPECCION EN SERVICIO

API 510

All pressure vessels used for Exploration and Production (E&P) service [for example, drilling, producing,gathering, transporting, lease processing, and treating liquid petroleum, natural gas, and associated salt

water (brine)] may be inspected under the alternative rules set forth in Section 8.

Except for Section 6, all of the sections in this inspection code are applicable to pressure vessels in E&Pservice. The alternative rules in Section 8 are intended for services that may be regulated under safety, spill,emission, or transportation controls by the U.S. Coast Guard; the Office of Hazardous MaterialsTransportation of the U.S. Department of Transportation (DOT) and other units of DOT; the MineralsManagement Service of the U.S. Department of the Interior; state and local oil and gas agencies; or anyother regulatory commission.

The following are excluded from the specific requirements of this inspection code:a. Pressure vessels on movable structures covered by other jurisdictional regulations (see Appendix A).

b. All classes of containers listed for exemption from construction in the scope of Section VIII, Division 1,of the ASME Code (see Appendix A).

c. Pressure vessels that do not exceed the following volumes and pressures:1. Five cubic feet (0.141 cubic meters) in volume and 250 pounds per square inch (1723.1 kilopascals)design pressure.2. One and a half cubic feet (0.042 cubic meters) in volume and 600 pounds per square inch (4136.9kilopascals) design pressure (see Appendix A).

This inspection code recognizes fitness-for-service concepts for evaluating in-service degradation ofpressure-containing components. API RP 579 provides detailed assessment procedures for specific types ofdegradation that are referenced in this code.

API 570

Except as a provided in 1.2.2, API 570 applies to piping systems for process fluids, hydrocarbons, and

similar flammable or toxic fluid services, such as the following:

a. Raw, intermediate, and finished petroleum products.b. Raw, intermediate, and finished chemical products.c. Catalyst line.d. Hydrogen, natural gas, fuel gas, and flare system.e. Sour water and hazardous waste streams above threshold limits, as defined by jurisdictional regulations.f. Hazardous chemical above threshold limits, as defined by jurisdictional regulations.

LimitationsAPI 570 shall not be used as a substitute for the original construction requirements governing a pipingsystem before it is placed in-service; nor shall it be used in conflict with any prevailing regulatoryrequirements.

API 572

Before starting the inspection of a pressure vessel, especially one in severe service, the inspector shoulddetermine the pressure, temperature, and service conditions under which the vessel has been operated sincethe last inspection. The inspector should also be aware of equipment construction details includingmaterials of construction, the presence of internal attachments, and weld details. He should also confer withoperations to determine whether there have been any abnormal operating conditions or disturbances such as

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

18/61

18

excessive pressures or temperatures. This data may offer valuable clues to the type and location ofcorrosion and to other forms of deterioration that may have occurred such as scaling, bulging, and warping.The inspector should develop and exercise sound judgment on the extent and kinds of inspection requiredfor each vessel.

Careful visual inspection of every vessel is of paramount importance to determine other forms of inspectionthat may need to be made. Appropriate surface preparation is essential to all inspection methods. The extentto which special surface preparation may be required depends on the particular circumstances involved.Wire brushing, sandblasting, high-pressure water blasting, chipping, or a combination of these operationsmay be required in addition to routine cleaning.

If external or internal coverings such as insulation, refractory linings, or corrosion-resistant linings are ingood condition and without evidence of an unsafe condition behind them, it may not be necessary toremove them for inspection of the vessel. However, it may sometimes be advisable to remove small

portions to investigate their condition and the condition of the metal behind them, particularly if previousinspections have indicated corrosion. When any covering is found to be defective, a sufficient amount ofthe covering in the vicinity of the defect should be removed to find out whether the base metal isdeteriorating and to determine the extent of the deterioration.

Where operating deposits such as coke are normally permitted to remain on a vessel surface, it is important

to determine the condition of the vessel surface behind the deposits.

This may require through removal of deposit in selected critical areas for spot check examination.

Where vessel are equipped with removable internals, the internals need not be completely removed,provided reasonable assurance exists that deterioration in not occurring beyond that found in more readilyaccessible parts of the vessel.

API 579

The methods and procedures in this recommended practice are intended to supplement andaugment the requirements in API 510, API 570 and API 653.

The assessment procedures in this recommended practice can be used for fitness-for-serviceassessments and/or re-rating of components designed and constructed to the following codes:

ASME B&PV Code, Section VIII, Division 1ASME B&PV Code, Section VIII, Division 2ASME B&PV Code, Section 1ASME 831.3 Piping CodeASME B31.1 Piping CodeAPI 650API 620

The assessment procedures in this recommended practice may also be applied to pressurecontaining equipment constructed to other recognized codes and standards, including

international and internal corporate standards. This recommended practice has broad applicationsince the assessment procedures are based on allowable stress methods and plastic collapseloads for non- crack-like flaws, and FAD-based strategies for crack-like flaws (see Section 2,paragraph 2.4.2).

The user is advised to first review the validation discussion of Appendix H when the proceduresof this recommended practice are applied to pressure containing equipment not constructed tothe codes listed in paragraph 1.2.2. The information in Appendix H, along with a knowledge of theof differences in design codes, should enable the user to factor, scale, or adjust the acceptancelimits of this recommended practice such that equivalent FFSin-service margins can be attained

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

19/61

19

for equipment not constructed to these codes. When evaluating other codes and standards thefollowing attributes of the ASME and API design codes should be considered:

Material specificationsUpper and/or lower temperature limits for specific materialsMaterial strength properties and the design allowable stress basisMaterial fracture toughness requirementsDesign rules for shell sectionsDesign rules for shell discontinuities such as nozzles and conical transitionsDesign requirements for cyclic loadsDesign requirements for operation in the creep rangeWeld joint efficiency or quality factorsFabrication details and quality of workmanshipInspection requirements, particularly for welded joints

As an alternative, users may elect to correlate the pressure-containing component's materialspecification to an equivalent ASME or API listed material specification to determine anassociated allowable stress. This approach provides an entry point into the ASME or API codes(refer also to Appendix A) wherein the pressure-containing component is reconciled or generallymade equivalent to the design bases assumed for this recommended practice. Hence generalequivalence is established and the user may then apply the acceptance limits of these fitness for

service procedures unaltered. Equivalent ASME and ASTM material specifications provide asatisfactory means for initiating a reconciliation between the ASME and API design codes andother codes and standards.

However, the user is cautioned to also consider the effects of fabrication and inspectionrequirements on the design basis (e.g., joint efficiency with respect to minimum thickness sizing).

The Fitness-For-Service assessment procedures in this recommended practice cover both thepresent integrity of the component given a current state of damage and the projected remaininglife.

Assessment techniques are included to evaluate flaws including: general and localized corrosion,widespread and localized pitting, blisters and laminations, weld misalignment and shell

distortions, and crack-like flaws including environmental cracking. In addition, evaluationtechniques are provided for condition assessment of equipment including resistance to brittlefracture, long-term creep damage, and fire damage.

Analytical procedures, material properties including environmental effects, NDE guidelines anddocumentation requirements are included in the fitness-for-service assessment procedures in thisdocument. In addition, both qualitative and quantitative guidance for establishing remaining lifeand in-service margins for continued operation of equipment are provided in regards to futureoperating conditions and environmental compatibility.

The Fitness-For-Service assessment procedures in this recommended practice cover situationsinvolving flaws commonly encountered in the refining and petrochemical industry in pressurevessels, piping and tankage. The procedures are not intended to provide a definitive guideline for

every possible situation that may be encountered. However, flexibility is provided to the user inthe form of an advanced assessment level to handle uncommon situations that may require amore detailed analysis.

The methods and procedures in this recommended practice can also be used in conjunction withthe National Board Inspection Code (NBIC) to the extent currently permitted by that documentand local regulations.

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

20/61

20

API 580

Key elements that should exist in any RBI program are:a. Management systems for maintaining documentation, personnel qualifications, data

requirements and analysis updates.b. Documented method for probability of failure determination.

c. Documented method for consequence of failure determination.d. Documented methodology for managing risk through inspection and other mitigationactivities.

However, all the elements outlined in 1.1 should be adequately addressed in RBI applications, inaccordance with the recommended practices in this document.

RBI Benefits and Limitations

The primary work products of the RBI assessment and management approach are plans thataddress ways to manage risks on an equipment level. These equipment plans highlight risks froma safety/health/environment perspective and/or from an economic standpoint. In these plans,cost-effective actions for risk mitigation are recommended along with the resulting level of riskmitigation expected.

Implementation of these plans provides one of the following:a. An overall reduction in risk for the facilities and equipment assessed.b. An acceptance/understanding of the current risk.

The RBI plans also identify equipment that does not require inspection or some other form ofmitigation because of the acceptable level of risk associated with the equipments currentoperation. In this way, inspection and maintenance activities can be focused and more costeffective. This often results in a significant reduction in the amount of inspection data that iscollected. This focus on a smaller set of data should result in more accurate information. In somecases, in addition to risk reductions and process safety improvements, RBI plans may result incost reductions.

RBI is based on sound, proven risk assessment and management principles. Nonetheless, RBIwill not compensate for:

a. Inaccurate or missing information.b. Inadequate designs or faulty equipment installation.c. Operating outside the acceptable design envelope.d. Not effectively executing the plans.e. Lack of qualified personnel or teamwork.f. Lack of sound engineering or operational judgment.

Industry scope

Although the risk management principles and concepts that RBI is built on are universally applicable, RP580 is specifically targeted at the application of RBI in the hydrocarbon and chemical process industry.

Flexibility in Application

Because of the broad diversity in organizations size, culture, federal and/or local regulatory requirements,RP 580 offers users the flexibility to apply the RBI methodology within the context of existing corporaterisk management practices and to accommodate unique local circumstances.

The document is designed to provide a framework that clarifies the expected attributes of a quality riskassessment without imposing undue constraints on users. RP 580 is intended to promote consistency and

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

21/61

21

quality in the identification, assessment and management of risks pertaining to material deterioration,which could lead to loss of containment.

Many types of RBI methods exist and are currently being applied throughout industry. This document isnot intended to single out one specific approach as the recommended method for conducting a RBI effort.The document instead is intended to clarify the elements of a RBI analysis.

Mechanical Integrity Focused

The RBI process is focused on maintaining the mechanical integrity of pressure equipment items andminimizing the risk of loss of containment due to deterioration. RBI is not a substitute for a process hazardsanalysis (PHA) or HAZOP. Typically, PHA risk assessments focus on the process unit design andoperating practices and their adequacy given the units current or anticipated operating conditions. RBIcomplements the PHA by focusing on the mechanical integrity related deterioration mechanisms and riskmanagement through inspection.

RBI also is complementary to reliability centered maintenance (RCM) programs in that both programs arefocused on understanding failure modes, addressing the modes and therefore improving the reliability ofequipment and process facilities.

Equipment Covered

The following types of pressurized equipment and associated components/internals are covered by thisdocument:

a. Pressure vesselsall pressure containing components.b. Process pipingpipe and piping components.c. Storage tanksatmospheric and pressurized.d. Rotating equipmentpressure containing components.e. Boilers and heaterspressurized components.f. Heat exchangers (shells, heads, channels and bundles).g. Pressure relief devices.

Equipment Not Covered

The following non-pressurized equipment is not covered by this document:a. Instrument and control systems.

b. Electrical systems.c. Structural systems.d. Machinery components (except pump and compressor casings).

TARGET AUDIENCE

The primary audience for RP 580 is inspection and engineering personnel who are responsible for themechanical integrity and operability of equipment covered by this recommended practice. However, whilean organizations Inspection/Materials Engineering group may champion the RBI initiative, RBI is notexclusively an inspection activity.

RBI requires the involvement of various segments of the organization such as engineering, maintenanceand operations.

Implementation of the resulting RBI product (e.g., inspection plans, replacement/upgradingrecommendations, etc.) may rest with more than one segment of the organization.

RBI requires the commitment and cooperation of the total organization. In this context, while the primaryaudience may be inspection and materials engineering personnel, others within the organization who are

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

22/61

22

likely to be involved should be familiar with the concepts and principles embodied in the RBImethodology.

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

23/61

23

6 ENSAYOS NO DESTRUCTIVOSAsme sec V alcance y descripcin de cada mtodo

Los ensayos no destructivos se realizarn de acuerdo con el cdigo ASME Sec. V.

En el cdigo ASME Sec. V se cubren los mtodos siguientes:

Artculo 1.- Requerimientos GeneralesArtculo 2.- Examinacin radiogrficaArtculo 4.- Examinacin ultrasnica mtodos para inspeccin en servicioArtculo 5.- Examinacin ultrasnica mtodos para materiales y fabricacinArtculo 6.- Examinacin por lquidos penetrantesArtculo 7.- Examinacin por partculas magnticasArtculo 8.- Examinacin por corriente de Eddy para productos tubularesArtculo 9.- Examinacin visualArtculo 10.- Examinacin por prueba de fuga

Artculo 11.- Examinacin por emisin acstica de recipientes de FRPArtculo 12.- Examinacin por emisin acstica de recipientes metlicosArtculo 13.- Examinacin por emisin acstica de monitoreo continuo

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

24/61

24

Artculo 1.- Requerimientos Generales

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

25/61

25

Artculo 2.- Examinacin radiogrfica

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

26/61

26

Artculo 4.- Examinacin ultrasnica mtodos para inspeccin en servicio

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

27/61

27

Artculo 5.- Examinacin ultrasnica mtodos para materiales y fabricacin

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

28/61

28

Artculo 6.- Examinacin por lquidos penetrantes

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

29/61

29

Artculo 7.- Examinacin por partculas magnticas

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

30/61

30

Artculo 8.- Examinacin por corriente de Eddy para productos tubulares

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

31/61

31

Artculo 9.- Examinacin visual

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

32/61

32

Artculo 10.- Examinacin por prueba de fuga

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

33/61

33

Artculo 11.- Examinacin por emisin acstica de recipientes de FRP

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

34/61

34

Artculo 12.- Examinacin por emisin acstica de recipientes metlicos

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

35/61

35

Artculo 13.- Examinacin por emisin acstica de monitoreo continuo

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

36/61

36

7.- LINEAMIENTOS PARA EVALUAR LA INTEGRIDAD ESTRUCTURAL YVIDA REMANENTE DE EQUIPOS E INSTALACIONES

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

37/61

37

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

38/61

38

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

39/61

39

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

40/61

40

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

41/61

41

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

42/61

42

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

43/61

43

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

44/61

44

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

45/61

45

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

46/61

46

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

47/61

47

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

48/61

48

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

49/61

49

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

50/61

50

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

51/61

51

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

52/61

52

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

53/61

53

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

54/61

54

8 BASE DE DATOS PARA LAS INSPECCIONES EN SERVICIO

8.1.-Data Requirements

8.1.1.- Original Equipment Design Data

The following original equipment design data should be assembled to perform a FFSassessment.

The extent of the data required depends on the damage mechanism and assessment level. Adata sheet is included in Table 2.2 to record the required information that is common to all FFSassessments. In addition, a separate data sheet is included with each section of this document torecord information specific to the flaw type, damage mechanism, and assessment procedure.

a. Data for pressure vessels may include some or all of the following:1. An ASME Manufacturer's Data Report or, if the vessel is not Code stamped, other equivalent

documentation or specifications.2. Vessel fabrication drawings showing sufficient details to permit calculation of the MA FW of

the component containing the flaw. If a rerate to a different condition of pressure and/ortemperature is desired (i.e. increase or decrease in conditions), this information should beavailable for all affected components. Detailed sketches with data necessary to perform MAFW calculations may be used if the original fabrication drawings are not available.

3. The original or updated design calculations for the load cases in Table A.l of Appendix A, asapplicable, and anchor bolt calculations.

4. The inspection records for the component at the time of fabrication.5. User Design Specification if the vessel is designed to the ASME Code, Section VIII, Division

2.6. Material test reports.7. Pressure-relieving device information including pressure relief valve andlor rupture disk

setting and capacity information.8. A record of the original hydrotest including the test pressure and metal temperature at the

time of the test or, if unavailable, the water or ambient temperature.

b. Data for piping components may include some or all of the following:1. Piping Line Lists or other documentation showing process design conditions, and a

description of the piping class including material specification, pipe wall thickness andpressure-temperature rating.

2. Piping isometric drawings to the extent necessary to perform a FFS assessment. The pipingisometric drawings should include sufficient details to permit a piping flexibility calculation ifthis analysis is deemed necessary by the Engineer in order to determine the MA WP(maximum safe or maximum allowable operating pressure) of all piping components.Detailed sketches with data necessary to perform MA WAF' calculations may be used if theoriginal piping isometric drawings are not available.

3. The original or updated design calculations for the load cases in Table A. 1 of Appendix A,as applicable.

4. The inspection records for the component at the time of fabrication.

5. Material test reports.6. A record of the original hydrotest including the test pressure and metal temperature at thetime of the test, or if unavailable, the water or ambient temperature.

c. Data for tanks may include some or all of the following:1. The original API data sheet.2. Fabrication drawings showing sufficient details to permit calculation of the maximum fill

height (MFH) for atmospheric storage tanks and the MA FW for low pressure storage tanks.Detailed data with sketches where necessary may be used if the original fabricationdrawings are not available.

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

55/61

55

3. The original or updated design calculations for the load cases in Table A.l of Appendix A, asapplicable, and anchor bolt calculations.

4. The inspection records for the component at the time of fabrication.5. Material test reports.6. A record of the last hydrotest performed including the test pressure and metal temperature at

the time of the test or, if unavailable, the water or ambient temperature.

8.1.2 If some of these data are not available, physical measurements or field inspection of thecomponent should be made to provide the information necessary to perform the assessment.

8.1.3 Maintenance And Operational History

8.1.3.1 A progressive record including, but not limited to, the following should be available for theequipment being evaluated. The extent of the data required depends on the damage mechanismand assessment level.

a. The actual operating envelope consisting of pressure and temperature, including upsetconditions should be obtained. If the actual operating conditions envelope is not available, anapproximation of one should be developed based upon available operational data andconsultation with operating personnel. An operating histogram may be required consisting of

pressure and temperature data recorded simultaneously for some types of FF,S assessments(e.g., Section 10.0 for components operating in the creep regime).

b. Documentation of any significant changes in service conditions including pressure,temperature, fluid content and corrosion rate. Both past and future service conditions shouldbe reviewed and documented.

c. The date of installation and a summary of all alterations and repairs including requiredcalculations, material changes, drawings and repair procedures. The calculations shouldinclude the required wall thicknesses and UAFW (MFHfor atmospheric storage tanks)including definition and allowances for supplemental loads such as static liquid head, wind, andearthquake loads.

d. Records of all hydrotests performed as part of the repair including the test pressure and metaltemperature at the time of the tests or, if unavailable, the water or ambient temperature at thetime of the test if known.

e. Results of prior in-service examinations including wall thickness measurements and other NDEresults that may assist in determining the structural integrity of the component and inestablishing a corrosion rate.

f. Records of all internal repairs, weld build-up and overlay, and modifications of intemals.

g. Records of "out-of-plumb" readings for vertical vessels.

h. Foundation settlement records if the corrosion being evaluated is located in the bottom shell

course of the tank.If some of these data are not available, physical measurements should be made to provide theinformation necessary to perform the assessment.

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

56/61

56

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

57/61

57

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

58/61

58

9 CONCEPTOS Y DESCRIPCION DE LOS REGISTROS DE CALIDADRELACIONADOS CON LA INSPECCION EN SERVICIO

6.7 RECORDSPressure vessel owners and users shall maintain permanent and progressive records of their pressurevessels. Permanent records will be maintained throughout the service life of each vessel; progressive

records will be regularly updated to include new information pertinent to the operation, inspection, andmaintenance history of the vessel.

Pressure vessel records shall contain four types of vessel information pertinent to mechanical integrity asfollows:

a. Construction and design information. For example, equipment serial number or other identifier,manufacturers data reports (MDRs), design specification data, design calculations (where MDRs areunavailable), and construction drawings. For pressure vessels that have no nameplate and minimal or nodesign and construction documentation, the following steps may be used to verify operating integrity:

i. Perform inspection to determine condition of the vessel. Make any necessary repairs.

ii. Define design parameters and prepare drawings and calculations.

iii. Base calculations on applicable codes and standards and condition of the vessel following any repairs.Do not use allowable stress values based on design factor of 3.5.See ASME Code Section VIII, Division 1, paragraph UG-10(c) for guidance on evaluation ofunidentified materials. If UG-10 (c) is not followed, then for carbon steels, use allowable stresses for SA-283 Grade C; and for alloy and nonferrous materials, use x-ray fluorescence analysis to determinematerial type on which to base allowable stress values.When extent of radiography originally performed is not known, use joint factor of 0.7 for butt welds, orconsider performing radiography if a higher joint factor is required.(Recognize that performing radiography on welds in a vessel with minimal or no design and constructiondocumentation may result in the need for a fitness-for-service assessment and significant repairs.)

iv. Attach a nameplate or stamping showing the maximum allowable working pressure and temperature,minimum allowable temperature, and date.v. Perform pressure test as soon as practical, as required by code of construction used for designcalculations.

b. Operating and inspection history. For example, operating conditions, including process upsets that mayaffect mechanical integrity, inspection reports, and data for each type of inspection conducted (for example,internal, external, thickness measurements), and inspection recommendations for repair. See Appendix Cfor sample pressure vessel inspection records. Inspection reports shall document the date of each inspectionand/or test, the date of the next scheduled inspection, the name of the person who performed the inspectionand/or test, the serial number or other identifier of the equipment inspected, a description of the inspectionand/or test performed, and the results of the inspection and/or test.

c. Repair, alteration, and rerating information. For example,

(1) repair and alteration forms like that shown in Appendix D,(2) reports indicating that equipment still in-service with identified deficiencies or recommendations forrepair are suitable for continued service until repairs can be completed, and (3) re-rating documentation(including rerating calculations, new design conditions, and evidence of stamping).

d. Fitness-for-service assessment documentation requirements are described in API RP 579, Section 2.8.Specific documentation requirements for the type of flaw being assessed are provided in the appropriatesection of API RP 579.

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

59/61

59

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

60/61

60

-

7/29/2019 Inspeccion en Servicio de Recipientes y Sistemas de Tuberias

61/61

Refrencias.

API 510 Pressure Vessel Inspection Code: Maintenance Inspection, Rating,Repair, and Alteration

API 570 Piping Inspection code: Inspection, repair, alteration and rerating of In-Service Piping System.

API 572 Inspection of Pressure Vessels (Towers, Drums, Reactors, HeatsExchangers, and Condensers).

API 579 Fitness-for-Service

API 580 Risk-based Inspection

DCSSI-L-SI-006 LINEAMIENTO CORPORATIVO PARA LA INSPECCION DERECIPIENTES A PRESION