IC Engines Construction and Working

-

Upload

shiv-kumar-singh -

Category

Documents

-

view

2.235 -

download

3

Transcript of IC Engines Construction and Working

MEE 216 – Thermal EngineeringMEE 216 – Thermal Engineering

Faculty Details:Faculty Details:

M.Natarajan.M.Natarajan. M.Tech. M.Tech.

(P.hD)(P.hD)

Room No: Room No: GDN - 127 – DGDN - 127 – D

Mobile No: Mobile No: 99400 8859099400 88590

Mail id: Mail id: [email protected]@gmail.com

Class Hours:Class Hours:

Mon:Mon: 10.05 – 10.5510.05 – 10.55

Wed:Wed: 08.00 – 08.5008.00 – 08.50

Thu:Thu: 11.00 – 11.5011.00 – 11.50

Thermal Engineering

Objectives of this course: L T P C – 2 1 2 4To enable the students understand the principles, working and performance of IC enginesTo introduce students to the working of compressors, steam nozzles and various refrigeration and air-conditioning.To teach students the principles of waste heat recovery and thermal storage systems

Outcome of this course:• Solve problems on internal combustion engines and prepare heat

balance sheet.• Get an insight of various components and principles of engines,

compressors etc.• Design refrigeration and air-conditioning system for a particular

application.• Demonstrate the knowledge of waste heat recovery and thermal

storage.

Thermal Engineering

Method of Evaluation:Method of Evaluation:

Internal Assessment Marks : 50 Marks50 Marks

Quiz – 1Quiz – 1 5 5CAT – ICAT – I 1515

Quiz – IIQuiz – II 5 5 CAT – IICAT – II 1515 Quiz – IIIQuiz – III 5 5 AssignmentAssignment 5 5

Total Marks 50

Thermal Engineering

Course Content:

Unit I Internal Combustion Engines Syllabus:

Review of construction and working of two stroke and four stroke engines - Wankel engines - SI engines, Fuel systems - Simple carburetor - Various compensation arrangements - Simple calculations involved in carburetors ignition systems combustion detonation factors and remedies - Rating of fuels -Type of combustion chambers - Introduction to multi point and microprocessor based fuel injection system. CI engines – Fuel injection system - Fuel pump – Combustion – Knocking - Factors and remedies - Rating of fuels - Types of combustion chambers - Cooling and lubrication of IC engines.

UNIT – I INTERNAL COMBUSTION ENGINES

Unit – 1: I.C Engines: Definition of Engine:

is a device which transforms one form of energy into another form.

It can converts thermal energy into mechanical energy.

Definition for ‘Heat Engines’:is a device which transforms the chemical energy of a fuel into thermal energy and utilizes this thermal energy to perform useful work.

Thermal Energy Mechanical Energy = Heat Engine

Internal Combustion EnginesInternal Combustion Engines

UNIT – I INTERNAL COMBUSTION ENGINES

UNIT – I INTERNAL COMBUSTION ENGINES

1. Internal Combustion 1. Internal Combustion EnginesEngines

(Combustion of fuel (Combustion of fuel takes place takes place withinwithin the Engine)the Engine)

Classification of Internal combustion Engines

2. External Combustion Engines

(Combustion of Fuel takes place Outside the Engine)

UNIT – I INTERNAL COMBUSTION ENGINES

Classification of Heat Engines:Heat Engines

Internal External

combustion Engine Combustion Engines

Rotary Reciprocating Reciprocating Rotary

Open Wankel Gasoline Diesel Steam Stirling Steam Closed

Cycle Engine Engines Engines Engines Engines Turbine CycleGas

GasTurbine

Turbine

UNIT – I INTERNAL COMBUSTION ENGINES

Basic Nomenclature: 1. Cylinder Bore: (D):

is the nominal inner diameter of the working cylinder. is usually measured in mm 2. Piston Area: (A)

Area of the circle diameter equal to the cylinder boreis expressed in square centimeters

3. Stroke: (L):is the nominal distance through which a working piston moves between two successive reversals of its direction of motion.is designated by “L” and is expressed in mm

4. Displacement or Swept Volume: (Vs):The nominal value swept by the working piston when traveling

from one dead centre to the other.

is expressed in terms of cubic centimeter Vs = (/4) d2 L = A X L

UNIT – I INTERNAL COMBUSTION ENGINESUNIT – I INTERNAL COMBUSTION ENGINES

Basic Nomenclature:5. Clearance Volume: (Vc)

The nominal volume of the combustion chamber above the piston when

it is at the top dead centre.

is designated as Vc and is expressed in Cubic centimeters. 6. Cubic Capacity or Engine Capacity:

The displacement volume of a cylinder multiplied by number of cylinders in an engine will give the cubic capacity or the engine capacity.

Eg. If there are ‘n’ cylinders in an engine, then Cubic capacity = n X Vs

7. Compression Ratio: (r): it is the ratio of the total cylinder volume when the piston is at the bottom dead centre, VT, to the clearance volume, VC.

It is designated by the letter r.r = (VT/ VC) = (Vs+Vc)/Vc = 1+(Vs/Vc)

UNIT – I INTERNAL COMBUSTION ENGINES

INTERNAL COMBUSTION ENGINESINTERNAL COMBUSTION ENGINES

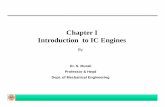

WORKING FOUR STROKE SPARK IGNITION ENGINESWORKING FOUR STROKE SPARK IGNITION ENGINES

INTERNAL COMBUSTION ENGINESINTERNAL COMBUSTION ENGINES

WORKING FOUR STROKE SPARK IGNITION ENGINESWORKING FOUR STROKE SPARK IGNITION ENGINES

INTERNAL COMBUSTION ENGINESINTERNAL COMBUSTION ENGINES

Ideal P-V diagram of four stroke SI Engines

INTERNAL COMBUSTION ENGINESINTERNAL COMBUSTION ENGINESWorking of 4 Stroke Petrol Engine: ChargeCharge = Air + Fuel Mixture= Air + Fuel Mixture

1. Suction Stroke or Intake Stroke:Piston displacement = From TDC to BDCCrank Revolution = First 1800CInlet Valve position = OpenExhaust Valve position = Fully closedPressure inside cylinder = Slightly below Atmospheric

PressureTemperature inside cylinder = Above Atmospheric Temp.charge Condition = Suction of charge into the

cylinder 2. Compression Stroke:

Piston displacement = From BDC to TDCCrank Revolution = Second 1800C and completes one

Revolution

Inlet Valve position = Fully ClosedExhaust Valve position = Fully closedPressure inside cylinder = Moderately high PressureTemperature inside cylinder = Moderately high Temp.Charge Condition = Compression of charge into the

cylinder

INTERNAL COMBUSTION ENGINESINTERNAL COMBUSTION ENGINES

The end of the compression stroke the mixture is ignited with the help of a spark plug located on the cylinder head.During the combustion process, the burning of the chemical energy of the fuel producing the temperature of 20000C.The pressure at the end of combustion process also increases due to heat release from the fuel.

3. Expansion Stroke: Piston Displacement = From TDC to BDC

Crank Revolution = third 1800CInlet Valve position = Fully ClosedExhaust Valve position = Fully ClosedPressure & Temperature = Decreases During this stroke only power is produced by the system.

4. Exhaust Stroke:Piston displacement = From BDC to TDCCrank Revolution = Completes Two strokesInlet Valve Position = Fully ClosedExhaust Valve = Fully OpenedPressure & Temperature = Falls to atmospheric level a part of burnt

gas escape.

When the piston stats move from BDC to TDC, it sweeps the burnt gases out from the cylinder almost at the atmospheric pressure.

INTERNAL COMBUSTION ENGINESINTERNAL COMBUSTION ENGINES

Working of 4 stroke Diesel EngineWorking of 4 stroke Diesel Engine

INTERNAL COMBUSTION ENGINESINTERNAL COMBUSTION ENGINES

INTERNAL COMBUSTION ENGINESINTERNAL COMBUSTION ENGINESWorking of 4 Stroke Diesel Engine:

Charge = Air aloneCharge = Air alone

1. Suction Stroke or Intake Stroke:Piston displacement = From TDC to BDCCrank Revolution = First 1800CInlet Valve position = OpenExhaust Valve position = Fully closedPressure inside cylinder = Slightly below Atmospheric PressureTemperature inside cylinder = Above Atmospheric Temp.Charge Condition = Suction of charge into the cylinder

2. Compression Stroke:Piston displacement = From BDC to TDCCrank Revolution = Second 1800C and completes one

RevolutionInlet Valve position = Fully ClosedExhaust Valve position = Fully closedPressure inside cylinder = Moderately high PressureTemperature inside cylinder = Moderately high Temp.Charge Condition = Compression of charge into the

cylinder

INTERNAL COMBUSTION ENGINESINTERNAL COMBUSTION ENGINES

During the combustion process, the burning of the chemical energy of the fuel producing the temperature of 18000C.

3. Expansion Stroke: Piston Displacement = From TDC to BDC

Crank Revolution = third 1800CInlet Valve position = Fully ClosedExhaust Valve position = Fully ClosedPressure & Temperature = Decreases During this stroke only power is produced by the system.

4. Exhaust Stroke:Piston displacement = From BDC to TDCCrank Revolution = Completes Two strokesInlet Valve Position = Fully ClosedExhaust Valve = Fully OpenedPressure & Temperature = Falls to atmospheric level a

part of burnt gas escape.

INTERNAL COMBUSTION ENGINESINTERNAL COMBUSTION ENGINES

Two stroke petrol Engine

INTERNAL COMBUSTION ENGINESINTERNAL COMBUSTION ENGINES

Introduction: Two stroke Engine:Discuss the special feature of two stroke engines?

If the two unproductive strokes, the suction and exhaust could be served by an alternative arrangement, especially without the movement of the piston then there will be a power stroke for each revolution of the crank shaft. Theoretically the power output of the engine can be doubled for the same speed compared to a four stroke engine.The Dugald Clark (1878) invented the two-stroke engines.Summarize the suction and exhaust strokes are compensated in two stroke Engines?The filling of charge in chamber process is accomplished by the charge compressed in crankcase or by a blower.The induction of the compressed charge moves out the product of combustion through exhaust ports.

Therefore, no piston strokes are required for these two operations. Hence, two strokes are sufficient for complete the cycle.

INTERNAL COMBUSTION ENGINESINTERNAL COMBUSTION ENGINES

Working two Stroke Petrol Engine:

Charge: Air + Fuel Mixture

1. Upward Stroke (OR) Compression Stroke:

Assume piston is at BDC position,

Piston moves from BDC to TDCFirst Piston Closes transfer port and then

Piston closes exhaust port.The charge is already in the cylinder is

compressed.Due to the upward movement of the

piston, a partial vacuum is created in the crankcase and the fresh charge is drawn into the crankcase through the uncovered inlet port.

At the end of this stroke, the piston reaches the TDC position.

Upward Stroke (OR) Compression Stroke

INTERNAL COMBUSTION ENGINESINTERNAL COMBUSTION ENGINES

Working two Stroke Petrol Engine:

2. Downward Stroke or Expansion Stroke:

Compressed charge is ignited by spark produced by spark plug.

The piston is forced by gases and is pushed down producing useful power.

The inlet port is covered by piston, the charge is compressed in the crankcase.

Further piston, uncovers the exhaust port and then transfer port.

The expanded gases escaping through the exhaust port, fresh charge is already compressed in the crankcase is forced into the cylinder through the transfer port simultaneously.

The charge strikes the deflection of piston crown, rises to the top of the cylinder and pushes out the most of exhaust gases.

The piston is now at the BDC position. The cylinder is now completely filled with the

fresh pre-compressed charge. The cycle is events is repeated.

Downward Stroke (OR)

Expansion Stroke

INTERNAL COMBUSTION ENGINESINTERNAL COMBUSTION ENGINESWorking two Stroke Diesel

Engine

Charge: Air alone

Downward Stroke (OR) Expansion Stroke:

As the piston moves down on

the power stroke, it first uncovers the exhaust port, and the cylinder pressure drops to atmospheric pressure as the products of combustion come out of the cylinder.

Further downward movement of the piston uncovers the transfer port, and slightly compressed air enters the engine cylinder from the crankcase.

Due to reflector on the top of the piston, the air will move up to the top of the cylinder and expels out the remaining exhaust gases through the exhaust port.

INTERNAL COMBUSTION ENGINESINTERNAL COMBUSTION ENGINESWorking two Stroke Diesel Engine2. Upward Stroke or

Compression Stroke:During this stroke, piston closes the transfer

port and then the exhaust port.It means the compression of the air starts.As the piston moves up, the fresh air is

drawn into the crankcase through the open inlet port

Just before the end of compression stroke, the fuel is forced under pressure in the form of fine spray into the engine cylinder through the nozzle into this hot air.

At this moment, the temperature of the compressed air is high enough to ignite the fuel which in turn suddenly increases the pressure and temperature of the products of combustion.

Due to increased pressure the piston is pushed down with the great force.

When the piston is near the BDC it uncovers exhaust port which permits the gases to flow out of the cylinder.

During expansion some of the heat energy produced is transformed into mechanical work.

This completes the cycle and the engine cylinder is ready to suck the air once again.

INTERNAL COMBUSTION ENGINESINTERNAL COMBUSTION ENGINES

WANKEL ENGINESWANKEL ENGINES

INTERNAL COMBUSTION ENGINES

Comparison of SI and CI Engines

S. NoS. No DescriptionDescription S I EnginesS I Engines C I EnginesC I Engines

1. Basic CycleBasic Cycle OttoOtto DieselDiesel

2. FuelFuel GasolineGasoline Diesel oilDiesel oil

3. Introduction of fuelIntroduction of fuel Gaseous mixture through Gaseous mixture through carburettorcarburettor

Fuel is directly injects Fuel is directly injects through injectorthrough injector

4. Load ControlLoad Control Throttle valve control the Throttle valve control the quantity of chargequantity of charge

The quality of charge The quality of charge controls by fuel controls by fuel regulationregulation

5. IgnitionIgnition Requires a spark plug Requires a spark plug Self ignition systemSelf ignition system

6. Compression ratioCompression ratio 6 to 106 to 10 16 to 2016 to 20

7. SpeedSpeed Due to light weight, they Due to light weight, they are high speed enginesare high speed engines

Due to heavy weight, Due to heavy weight, they are low speed they are low speed enginesengines

8. Method of combustionMethod of combustion HomogeneousHomogeneous HetrogeneousHetrogeneous

9. Thermal EfficiencyThermal Efficiency Due to Low CR, Efficiency Due to Low CR, Efficiency also lowalso low

Due to high CR. Thermal Due to high CR. Thermal Efficiency also high.Efficiency also high.

10. WeightWeight Lighter due to lower peak Lighter due to lower peak pressurespressures

Higher due to higher Higher due to higher peak pressurespeak pressures

INTERNAL COMBUSTION ENGINES

Comparison of Two and Four Stroke EnginesComparison of Two and Four Stroke EnginesS.No Two Stroke Engines Four Stroke Engines

1.The cycle completes in one revolution of Crankshaft. One power is obtained in every revolution of Crankshaft.

Thermodynamics cycle completes in two revolution of Crankshaft. One power is obtained in two revolution of Crankshaft.

2. Turning moment is uniform and hence lighter flywheel can be used.

Turning moment is not uniform and hence heavier flywheel can be used.

3. The size of the engine is lighter and more compact.

The size of the engine is heavier and bulkier.

4. Higher rate of wear and tear. Greater cooling and lubrications are required.

Lower rate of wear and tear. Lesser cooling and lubrications are required.

5.No Valve mechanisms are used. But there are only ports are available regulates by piston itself.

Valve mechanisms are used for opening and closing of inlet and exhaust valves.

6. The initial cost of the engine are less. The initial cost of the engine are high.

7. Volumetric efficiency is low due to lesser time for induction.

Volumetric efficiency is high due to more time for induction.

8. Thermal Efficiency is lower: Part load efficiency is poor.

Thermal Efficiency is higher. Part load efficiency is better.

9.Used where low cost, compactness, light weight ie in mopeds, Scooters, Motor cycles etc.,

Used where high efficiency is required. ie in Buses, Trucks, Tractors, Generators, Power generation etc.,