Hyperloop- A 21st century transportation revolution

-

Upload

gyanendra-awasthi -

Category

Automotive

-

view

50 -

download

1

Transcript of Hyperloop- A 21st century transportation revolution

~ 1 ~

Hyperloop -

A 21st Century

Transportation Revolution

Submitted by-

Gyanendra Awasthi

Enrollment no. - (13135043)

Mechanical Engineering Dept.

IIT(BHU), Varanasi

~ 2 ~

Abstract

There are four existing conventional modes of transportation. They are rail, road, air, and water. These modes of transport tend to be either relatively slow (e.g., road and water), expensive (e.g., air), or a combination of relatively slow and expensive (i.e., rail). Hyperloop is a new mode of transport that seeks to change this paradigm by being both fast and inexpensive for people and goods.

Hyperloop consists of a low pressure tube with capsules that are transported at both low and high speeds throughout the length of the tube. The capsules are supported on a cushion of air, featuring pressurized air and aerodynamic lift. The capsules are accelerated via a magnetic linear accelerator affixed at various stations on the low pressure tube with rotors contained in each capsule. Passengers may enter and exit Hyperloop at stations located either at the ends of the tube, or branches along the tube length.

It eliminates direct emission, noise, delay, weather concerns, and pilot error. It is a Fifth mode of transportation. The energy required to run this system will be supplied by itself which will be produced by the solar panels affixed to upper part of tube. The energy consumed by the Hyperloop to drive its system is almost 80% of the total energy generated by the solar panels. Thus 20% energy will add extra money into Hyperloop pocket.

In this document the cost for the route from Los Angeles to San Francisco has been calculated. The calculation of the cost of capsule and cost of whole system has been originally done in ‘Hyperloop Alpha’ document.

~ 3 ~

Content

A. Abstract ………………………..2 B. Content ………………………..3 1. Hyperloop ………………………..4 2. Hyperloop transportation system ………………………..4

2.1. Capsule ………………………..6 2.1.1. Geometry ………………………..6 2.1.2. Interior ………………………..6 2.1.3. Compressor ………………………..7 2.1.4. Suspension ………………………..9 2.1.5. Propulsion ………………………..11

2.2. Tube ………………………..11 2.2.1. Pylon and tunnel ………………………..13 2.2.2. Station construction ………………………..14

2.3. Propulsion system ………………………..14 2.3.1. Capsule component ………………………..15 2.3.2. Tube component ………………………..16 2.3.3. Energy storage component…………………16 2.3.4. Cost ………………………..16

2.4. Route ………………………..17 3. Total cost of the overall system ………………………..18 4. Benefits ………………………..19 5. Possible problems ………………………..21 6. Current scenario ………………………..22 7. Conclusion ………………………..22 8. References ………………………..23

~ 4 ~

1. Hyperloop-

Hyperloop is a cross between a Concorde and rail gun and an air hockey. It uses the basic techniques of these three systems and a lot of new innovations are also combined with them. In other words, the Hyperloop is a combination of a supersonic plane with afterburning turbojets, a giant electric circuit capsule of firing at Mach 5, and a table that perpetually emits air out of a tiny porous surface. Hyperloop consists of low pressure tubes with capsules that are transported at low and high speeds throughout the capsule.

2. Hyperloop transportation system:-

The Hyperloop consists of several distinct components, including:

1. Capsule: a. Sealed capsules carrying 28 passengers each that travel along the interior of the tube depart on average every 2 minutes from Los Angeles or San Francisco (up to every 30 seconds during peak usage hours). b. A larger system has also been sized that allows transport of 3 full size automobiles with passengers to travel in the capsule. c. The capsules are separated within the tube by approximately (37 km) on average during operation.

~ 5 ~

d. The capsules are supported via air bearings that operate using a compressed air reservoir and aerodynamic lift.

2. Tube: a. The tube is made of steel. Two tubes will be welded together in a side-by-side configuration to allow the capsules to travel both directions. b. Pylons are placed every (30 m) to support the tube. c. Solar arrays will cover the top of the tubes in order to provide power to the system.

3. Propulsion: a. Linear accelerators are constructed along the length of the tube at various locations to accelerate the capsules. b. Rotors are located on the capsules to transfer momentum to the capsules via the linear accelerators.

4. Route: a. There will be a station at Los Angeles and San Francisco. Several stations along the way will be possible with splits in the tube. b. The majority of the route will follow I-5 and the tube will be constructed in the median.

The proposed capsule geometry houses several distinct systems to reside within the outer mold line.

Figure 1. Hyperloop passenger capsule subsystem notional locations (not to scale).

~ 6 ~

2.1- Capsule:- Two versions of hyperloop capusules have been proposed. These

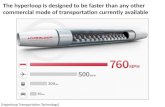

are 1). Hyperloop passenger capsule and 2). Hyperloop passenger and vehicle capsule. The operating pressure inside tube in which Hyperloop capsules opearate is 100Pa, which reduces the drag force of the air by 1,000 times relative to sea level conditions and would be equivalent to flying above 150,000 feet altitude. A hard vacuum is avoided as vacuums are expensive and difficult to maintain compared with low pressure solutions. The capsule travel at 760mph. Close to the cities where more turns must be navigated, capsules travel at a lower speed. This reduces the accelerations felt by the passengers, and also reduces power requirements for the capsule.

2.1.1- Geometry: -

In order to optimize the capsule speed and performance, the frontal area has been minimized for size while maintaining passenger comfort. The vehicle is streamlined to reduce drag and features a compressor at the leading face to ingest oncoming air for levitation and to a lesser extent propulsion. In both type of capsules the doors on each side will open in a gullwing (or possibly sliding) manner to allow easy access during loading and unloading. The luggage compartment will be at the front or rear of the capsule. Specifications of geometry of both type of capsule are given in the table1.

2.1.2- Interior: -

The interior of the capsule is specifically designed with passenger safety and comfort in mind. The seats conform well to the body to maintain comfort during the high speed accelerations experienced during travel. Beautiful landscape will be displayed in the cabin and each passenger will have access their own personal entertainment system. The interior portion of the Hyperloop passenger capsule includes the seats, restraint systems, interior and door panels, luggage compartments, and entertainment displays. Same as the interior portion of the Hyperloop passenger + vehicle capsule includes the seats, restraint systems, interior and door panels, luggage compartments, and entertainment displays. Weights and expected costs of the overall interior portion of both type of capsules are tabulated in table1.

~ 7 ~

Hyperloop passenger capsule

Hyperloop passenger + vehicle capsule

Overall structure weight 3100kg 3500kg

Overall cost of structure $245,000 $275,000

Overall interior weight 2500kg 2700kg

Overall cost of interior components

$255,000 $185,000

Maximum width 1.35m 1.35m

Maximum height 1.10m 1.10m

Frontal area 1.5 sq. m 4.0 sq. m

Aerodynamic power requirement at 700mph

Around 100kW Around 382kW

Table1. An overall comparison of Hyperloop passenger capsule and Hyperloop passenger + vehicle capsule 2.1.3- Compressor: -

There is an onboard compressor in the capsule, which serves two purposes. This system allows the capsule to traverse the relatively narrow tube without choking flow that travels between the capsule and the tube walls (resulting in a build-up of air mass in front of the capsule and increasing the drag) by compressing air that is bypassed through the capsule. It also supplies air to air bearings that support the weight of the capsule throughout the journey.

~ 8 ~

The air processing in Hyperloop passenger capsule occurs as follows-

1. Tube air is compressed with a compression ratio of 20:1 via an axial compressor.

2. Up to 60% of this air is bypassed: a. The air travels via a narrow tube near bottom of the capsule to the

tail. b. A nozzle at the tail expands the flow generating thrust to mitigate

some of the small amounts of aerodynamic and bearing drag.

3. Up to (0.2 kg/s) of air is cooled and compressed an additional 5.2:1 for the passenger version with additional cooling afterward.

a. This air is stored in onboard composite overwrap pressure vessels. b. The stored air is eventually consumed by the air bearings to

maintain distance between the capsule and tube walls.

4. An onboard water tank is used for cooling of the air. a. Water is pumped at (0.14 kg/s) through two intercoolers (290 kg

total mass of coolant). b. The steam is stored onboard until reaching the station. c. Water and steam tanks are changed automatically at each stop.

5. The compressor is powered by a (325 kW) onboard electric motor:

a. The motor has an estimated mass of (169 kg), which includes power electronics.

b. An estimated (1,500 kg) of batteries provides 45 minutes of onboard compressor power, which is more than sufficient for the travel time with added reserve backup power.

c. Onboard batteries are changed at each stop and charged at the stations.

~ 9 ~

Figure 2. - Compressor schematic of compressor diagram in Hyperloop passenger capsule 2.1.4- Suspension: -

The proposed design of capsule will ride on air bearings with a minimum of friction. Air bearings have natural stability, low friction, and long lifetime. Air bearings are also a natural fit for the Hyperloop, in which the capsules already contain a compressor system required to reduce air drag at high speeds. Externally pressurized and aerodynamic air bearings are well suited for the Hyperloop due to exceptionally high stiffness, which is required to maintain stability at high speeds. When the gap height between a ski and the tube wall is reduced, the flow field in the gap exhibits a highly non-linear reaction resulting in large restoring pressures. The increased pressure pushes the ski away from the wall, allowing it to return to its nominal ride height. Also each ski is integrated into an independent mechanical suspension, ensuring a smooth ride for passengers.

~ 10 ~

Figure 3. - Schematic of air bearing ski that support the capsule

The skis, each (1.5 meters) in length and (0.9 meters) in width, support the weight of the capsule by floating on a pressurized cushion of air (0.5 to 1.3 mm) off the ground. Lift is supplemented by injecting highly pressurized air into the gap. The specifications of suspension systems of Hyperloop passenger capsule and Hyperloop passenger + vehicle capsule is tabulated in Table2.

Hyperloop passenger capsule

Hyperloop passenger + vehicle capsule

Suspension system

Air bearing system weight 2800kg 3800kg

Overall cost of bearing system component

$475,000 $565,000

Total drag generated by 28 bearings at capsule speed of 760mph

140N 187N

Power loss due to drag 48kW 63kW

Length 1.5m 1.5m

Width 0.9m 1.2m

Flow rate required beneath the ski

0.2kg/sec at 9.4kPa 0.2kg/s at 11.2kPa

Table2. A comparison of suspension systems of Hyperloop passenger capsule and Hyperloop passenger + vehicle capsule

~ 11 ~

2.1.5- Propulsion: - The moving motor element (rotor) will be located on the vehicle

for weight savings and power requirements while the tube will incorporate the stationary motor element (stator) which powers the vehicle.

Hyperloop passenger capsule

Hyperloop passenger + vehicle capsule

Onboard power

Batteries weight 2500kg 5500kg

Weight of Batteries used by compressor

1500kg 4000kg

Cost of batteries, motor, and electronic component

$150,000 $200,000

Propulsion system

Weight 1300kg 1600kg

Overall cost of propulsion system

$125,000 $150,000

Table3. Onboard power and propulsion system specifications and cost in Hyperloop passenger capsule and Hyperloop passenger + vehicle capsule

2.2- Tube- The main Hyperloop route consists of a partially evacuated cylindrical tube

that connects the centers in a closed loop system. The tube is specifically sized for optimal air flow around the capsule improving performance and energy consumption at the expected travel speed. The expected pressure inside the tube will be maintained around 100 Pa. This low pressure minimizes the drag force on the capsule while maintaining the relative ease of pumping out the air from the tube. In order to minimize cost of the Hyperloop tube, it will be elevated on pillars which greatly reduce the footprint required on the ground and the size of the construction area required.

~ 12 ~

Solar panels would be lined on the surface of the tubes to produced required energy. If we expect that the solar panel production energy rate will be 120W/sq. m, the energy generated by all the solar panels fixed on the tube will be more than enough. It fulfills energy demand of Hyperloop system and also much percentage of the energy will be remained in its store.

Tube Hyperloop passenger Version

Hyperloop passenger + vehicle version

Inner diameter of the tube

2.23m 3.30m

Tube cross sectional area

3.91sq.m 8.85sq.m

Capsule/tube area ratio 0.36 0.47

Capsule/tube diameter ratio

0.60 0.68

Possible wideness of tube tracks

4.25m 6.60m

Expected max. solar energy produced

285MW 446MW

Table4. Specifications of tube and energy generated by solar panels in case of Hyperloop passenger capsule and Hyperloop passenger + vehicle capsule

~ 13 ~

Figure 4. Overview of the infrastructure of the Hyperloop

2.2.1- Pylons and tunnels: - The tube will be supported by pylons which greatly reduces the

footprints of track on the ground and size of area that required to construction. Since sheer quality of pillar or pylons are required, so reinforced concrete is selected as the construction material due to its very low cost per volume. The height of the pillar will be 6m whenever is possible. But it may vary in hilly areas or where obstacles in the way. Keeping all these points in to consideration the heights of the pillars are divided into three categories: Also pylons constrain the tube in the vertical direction but allow longitudinal slip for thermal expansion as well as dampened lateral slip to reduce the risk posed by earthquakes. In addition, the pillar to tube connection nominal position will be adjustable vertically and laterally to ensure proper alignment despite possible ground settling. The average spacing between the pillars will be 30m. Cost for pillar construction:

1. Hyperloop passenger version tube- $2.25billion USD 2. Hyperloop passenger+ vehicle version tube- $3.15 billion USD

In some areas tunneling will be required to avoid going over mountains and to maintain the straightness of route as much as possible.

~ 14 ~

Expected cost for tunneling- a. For larger diameter tube- $700million USD b. For smaller diameter tube- $600million USD

Dampers will be incorporated between the pylons and tubes to isolate movements in the ground from the tubes.

2.2.2- Station construction- Due to short travel time it is envisaged that there will be a continual

flow of passengers through each Hyperloop station. It creates the necessity of minimizing human error and delay time while operating various operations on the station. Hyperloop stations are intended to be minimalist but practical with a boarding process and layout much simpler than airports. All ticketing and baggage tracking for the Hyperloop will be handled electronically, negating the need for printing boarding passes and luggage labels. There would be a luggage limit of 2 bags per person, for no more than (50 kg) in total. Luggage would be stowed in a separate compartment at the rear of the capsule. This luggage compartment can be removed from the capsule, so that the process of stowing and retrieving luggage can be undertaken separately from embarking or disembarking the capsule’s passenger cabin.

In order to maximize efficiency, the loading and unloading of passenger luggage will be taken care by the Hyperloop staff.

The transit area at a Hyperloop terminal would be a large open area with two large airlocks signifying the entry and exit points for the capsules.

The process of loading and unloading would occur in parallel with up to three capsules at a given station at any time. The expected cost of each station would be around $125million USD for a total of $250million USD.

2.3. Propulsion system: - The Hyperloop uses a linear induction motor to accelerate and

decelerate the capsule. The benefits over a permanent magnet motor of this system are:

1. Lower material cost- rotor will be made of Al and of simple shape.

2. Lighter capsule 3. Smaller capsule dimensions

The lateral forces exerted by the stator on the rotor though low at (13

N/m) are inherently stabilizing. This simplifies the problem of keeping the rotor aligned in the air gap.

~ 15 ~

Figure 5. Rotor and Stator 3D diagram

Stator will be mounted on tube and rotor which is lighter part will be

mounted on the capsule as shown in figure. Each accelerator has two 70 MVA inverters, one to accelerate the outgoing capsule, and one to capture the energy from the incoming capsule. Relatively inexpensive semiconductor switches allow the central inverters to energize only the section of track occupied by a capsule, improving the power factor seen by the inverters.

The inverters are physically located at the highest speed end of the track to minimize conductor cost.

2.3.1. Capsule component (Rotor):- The rotor of the linear induction motor in capsule consists of an

Aluminium blade which is 15m long, 0.50m tall and 0.50mm thick. Current flows mainly in outer (10mm) of this blade, allowing it to hollow to decrease weight and cost. The gap between rotor and stator is 20mm on both side. A combination of the capsule control system and electromagnetic centering forces allows the capsule to safely enter, center within, and exit such a precise gap.

~ 16 ~

Figure 6. Magnetic field strength inside linear induction motor

2.3.2. Tube component (Stator): - The stator is mounted to the bottom of the tube over the entire 2.5 miles (4.0 km) it takes to accelerate and decelerate between 300 and 760 mph (480 and 1,220 km). It is approximately 0.5 m wide (including the air gap) and 10 cm tall, and weighs 800 kg/m. Its electrical configuration is 3-phase, 1 slot per pole per phase, with a variable linear pitch (0.4 m maximum). The number of turns per slot also varies along the length of the stator, allowing the inverter to operate at nearly constant phase voltage. The two halves of the stator require bracing to resist the magnetic forces of 300N/m that try to bring them together.

2.3.3. Energy storage components: - The energy storage cell will be built of same Lithium ion cells which are

used in Tesla Model-S. They allow to this linear accelerator only draw its average power of 6MW (rather than peak power of 55MW) from its solar array.

2.3.4. Cost-

The cost of energy components for the both versions of Hyperloop are tabulated in Table5.

~ 17 ~

Propulsion Hyperloop passenger version

Hyperloop passenger + vehicle version

All tube side propulsion cost including linear accelerator

$140 million USD $200 million USD

Required average power supplied by solar array

21MW 49MW

Expected cost for setting solar panels

$210 million USD $490 million USD

Table 5. Cost of energy components for both versions of Hyperloop

2.4. Route: - The Hyperloop route will be based on several considerations, including:

1. Maintaining the tube as closely as possible to existing rights of way 2. Limiting the maximum capsule speed to 760 mph (1,220 kph) for

aerodynamic considerations. 3. Limiting accelerations on the passengers to 0.5g. Optimizing locations

of the linear motor tube sections driving the capsules. 4. Local geographical constraints, including location of urban areas,

mountain ranges, reservoirs, national parks, roads, railroads, airports, etc. The route must respect existing structures.

For aerodynamic efficiency, the speed of a capsule in the Hyperloop is typically:

a) 300 mph (480 kph) where local geography necessitates a tube bend radii < 1.0 mile (1.6 km)

b) 760 mph (1,220 kph) where local geography allows a tube bend > 3.0 miles (4.8 km) or where local geography permits a straight tube.

These bend radii have been calculated so that the passenger does not

experience inertial accelerations that exceed 0.5g. This is deemed the

~ 18 ~

maximum inertial acceleration that can be comfortably sustained by humans for short periods.

3. Total Cost of the overall system: -

The total cost of the Hyperloop passenger transportation system as outlined is less than $6 billion USD (Table6). The passenger plus vehicle version of Hyperloop is including both passenger and cargo capsules and the total cost is outlined as $7.5 billion USD (Table7). The total cost is calculated for the 560km long route stretched from Los Angeles to San Francisco. Cost for the single capsule either be of Hyperloop passenger version or be of Hyperloop passenger + vehicle version will remain same for other routes, if they were proposed. Cost and weight of the single capsule for Hyperloop passenger version is $1,350,000 and 15,000kg respectively. The cost and weight of the single capsule for Hyperloop passenger + vehicle version is $1,525,000 and 26,000kg respectively.

Table 6. Total cost of the Hyperloop passenger system

~ 19 ~

Table 7. Total cost of the Hyperloop + vehicle transportation system

4. Benefits:- Hyperloop is the technology of future. The benefits of these transportation

systems are such:

4.1. Little Fiction loss:- In the tube there is extremely low pressure due to use of air

bearing ski which ensures that the pods (booths in which passengers sit) can travel with very little friction and thus they can travel fast.

~ 20 ~

4.2. High speed of Hyperloop- With very little air friction and using the technique of magnetic levitation, which is currently used in MAGLEV trains, Hyperloop train can achieve high speeds. Speeds of 700 mph (1,220 km / h), which is just below the sound barrier, are well possible. 4.3. Using clean energy-

The system would be self-sufficient in clean energy. It basically uses solar energy which will be generated through solar panels fixed on the upper part of tube.

4.4. Immune to weather conditions-

Since the tube will be sealed. So it will be immune to changing atmospheric conditions. There will not be any effect of storms, fast air on the traffic of Hyperloop due to sealed tubes. And also the speed of train will not be affected by fog and other weather conditions.

4.5. Resistant to earthquake-

The pylons on which the track of Hyperloop will be designed will be resistant to earthquake. Pylons are the basically high steels structures on which wire is fixed to carry electricity. One can say pylons are high pillars to support some kind of structure on them.

4.6. More reliable : - The Hyperloop system comprising all infrastructure, mechanical, electrical, and software components will be designed so that it is reliable, durable, and fault tolerant over its service life (100 years), while maintaining safety levels that match or exceed the safety standard of commercial air transportation. 4.7. Lower cost :-

It will cost less than other modes of transportation for the same distance of route travelled in a minimum time period. In the proposed route for Hyperloop from Los Angeles to San Francisco, the distance between these two population centers being 560km apart, it will cost only $20 USD.

~ 21 ~

It can also be seen from the figure that energy cost of this system

is less than any existing mode of transportation.

Figure 7. Energy cost per passenger for a journey between Los Angeles and San Francisco for various modes of transport.

5. Possible problems:- Since any technique cannot be completely perfect. There is always

some faults present in that system or in that technique. In the same way Hyperloop also have its flaws, lacks. Since it is in its developing state. So the expected problems and flaws related with it can be such.

1. Small space is available in capsules. 2. There is no any space for washroom in current design of Hyperloop

capsule.

~ 22 ~

3. There will be needed a lot of money to build its infrastructure around $6 billion and cost may be high than anticipated. Nothing is cash proof in this world. So it may be very risky to invest a huge amount of money into a specific technique and who knows what will be the future of Hyperloop.

4. The critics of Hyperloop say experience could be frightening because passengers would be in narrow shield, windowless capsule inside a tunnel.

5. Fast acceleration and noisy vibrations can cause motion signals. 6. There is also a logistic question regarding malfunction, accidents and

emergency evacuations.

6. Current Scenario: - The prototype of this modal is in its developing state in USA and is

expected to be completed at the end of the year 2016. The first testing of the prototype was performed on 11 May, 2016 at Apex National Park, City of North Las Vegas, Nevada in USA by the startup Hyperloop One. The length of the track was 0.50 mile. It was an open air test. It meant that no any tube was used on the track. The maximum speed of sledge was only 116mph but it was able to achieve its maximum speed in 2 sec. The working model of the Hyperloop transportation system in expected to be prepared till 2020 and possibly it will start working on the tracks on 2021. Three companies Hyperloop one, Hyperloop Transportation Technology (HTT), and SpaceX have started working on it.

7. Conclusion: - This report talks about the Hyperloop transportation system. There are

two version of Hyperloop have been envisaged in this document. Calculation of all the data either be weight or be cost, all are calculated for the route between Los Angeles and San Francisco. The distance between these two population centers is 560km which will be travelled by the Hyperloop in 30 min.

~ 23 ~

8. References: -

1. Title ‘Hyperloop Alpha’ document outsourced by Elon Musk, CEO of TESLA Motors, SpaceX.

2. spacex.com 3. hyperloopone.com 4. newatlas.com 5. digitaltrend.com 6. teslamotors.com