Hydropower Plants - ing.unitn.itrighetti/lezioni HPP/HPP/2-HPP... · Plant installation generator...

Transcript of Hydropower Plants - ing.unitn.itrighetti/lezioni HPP/HPP/2-HPP... · Plant installation generator...

Hydropower Plants

Use of water power

Typical schemes and works

Barrages and Dams

Other works in reservoirs

Intakes

Part I:

Use of Water

Hydraulic Energy and Bernoulli theorem:

E = h + P/ + v2/2g

hydraulic machines: mechanical devices that use the hydraulicenergy of by a liquid (generally water) to produce mechanical workin the form of rotational motion (wheels and turbines) orreciprocating rectilinear motion (piston hydraulic motors).

Classification of hydraulic turbines

water wheels: use the potential energy or kinetic energy of a liquid mass, converting it into mechanical rotary work;

hydraulic piston turbines: exploit the work of the pressure forces in the fluid; their operation does not differ from that of the reciprocating pumps, taking into account, of course, the opposite purpose to be achieved;

hydraulic turbines: use the kinetic energy of a liquid jet thatcrosses (or strikes) the turbines at (relatively) high speed; theyare similar (but with opposite effects) to centrifugal pumps, evenif some of them are nevertheless very constructively sensibly

Definitions

Hg : geodetic head

Y = Q2 : distributed head losses

y = K (v2/2g) : concetrated head losses

H= Hg – Y -y : net head

Hp : turbine- discharge head

Lt = H : theoretical work

c= H/Hg : pipe-line efficiency

Turbine Efficiency

i = H1/ H : hydraulic efficiency

v = Q / Qt : volumetric efficiency

m = Le / Lu : mechanical efficiency

= iv m : global efficiency of the turbine

Global efficiency of the plant

e : power generator efficiency

t : transformers efficiency

C = c e t

Theorethical and True Power

Pt = Q H

Pe = Q H C

Plant installation

generator rotation regime has to be constant;

n = 60 f / p

with n the number of revolutions per minute, f frequency of the current produced, p the number of the pole pairs of the machine;

If the load at alternator does not vary, then the value of the driving torquedeveloped by the turbine must remain constant and hence its effective power;since the latter depends on the net head (H) and flow (Q), it follows that, notbeing able to vary in any case the value of H, you must maintain the flow ofinfluent liquid to the turbine;

the load on the electric net is subject to fluctuations, the flow rate must becontinuously adjusted so as to produce a driving torque at each instant equals theone resistant to achieve the constancy of the speed of rotation;

The installation of hydroelectric power is so constrained, both bywater resource and both by the altitude of the region; then theideal conditions for the realization of a hydroelectric plant arethe following:

availability of a remarkable natural level;

availability of an almost constant flow rate of the water course.

Plant installation

Regulated outflow power plantsProvided with a storage capacity at the intake, intended to modify the natural outflow to adapt it to the flow rate used by the power plant.

Such plants can be divided into:

Small basin plants, with modest storage capacity, adapted to regulate the flow rates at daily-weekly periods for the most;

Reservoir plants, having storage capacity such as to enable a seasonal/annual compensation.

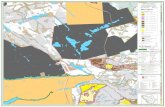

The most common solution for the realization of this kind of systems, is to build a damming of the water course where the topography of the surrounding territory allows to form an artificial basin. The barrage is achieved by a dam or a weir (the proportions of a common weir, sometimes up to gigantic size).

The damming of the river, preventing the free flow of water, creates a backwater effect and, due to the flooding of the valley, an accumulation of fluid whose volume often reaches several million m3.

This allows storing of the floods of the river with a slight increase in level and to give back the surplus during periods of low water.

HPP with free surface tailrace channel

the channel, the length of which can be also of several kilometers, opens into a second tank, said loading dock, of small size compared to the artificial reservoir. Such diversion channel is also characterized by e milder slope than that of the river bed. In this way you can increase, sometimes significantly, the available head.

HPP with pressure tailrace

allows a wide range of the flow rate regulation, it is sometimes made convenient bytopographic conformation of the territory and –indirectly- from irregular and windingpath of the river bed.

It is necessary, in this case, the installation of a surge shaft or rising tank to dissipatethe excess pressure due to water hammer.

Pump-storage HPPs

The pump-storage HPPs are completely independent to hydrological events, being ableto manage, in all circumstances, the upper reservoir level.

They have all the characteristics of the plant with pressure-pipe diversion, with the difference that, for the lack of sufficient natural availability of water in the upper reservoir, the same availability is obtained by electromechanical back-pumping of previously turbine powering water and collected in a reservoir placed downstream plant (basin of accumulation)

Run–of-the-river HPPs

The plants are mostly characterized by significant flow rate and low head, generally nomore than a few meters or a few tens of meters, and thus are characteristic of theintermediate and lower reaches of large rivers. The schemes of these plants include, ingeneral, a weir, to intercept the water course at the chosen section for the withdrawal,and a power plant directly built-in in the weir or joined to it.

There are also cases in which the power plant is located at a (short) distance from the weir and from the water course: in these cases the scheme has a water intake at the side of the dam, followed by structures to settle solid transport of the water, a free surface tailrace (in the tunnel or open-air channel), the power plant and a tailrace water discharge into the river.

Main components of a Hydro Power Plants

damming works opere di sbarramento

ancillary works-dam outlet works (spillways and outlets)

opere complementari degli invasi (scarichi superficiali e di fondo);

water intakes opere di presa

Inlet waterways opere d’adduzione a monte delle condotte forzate;

Surge tanks vasche d’oscillazione;

penstock condotte forzate;

Power plant equipment: macchinari delle centrali:

Shut off valves/gates organi d’intercettazione

Pressure/velocity regulation valves

organi di regolazione della velocità e della pressione;

turbines turbine idrauliche

pumps pompe

Pump-turbines (pump-storage plants)

macchine idrauliche reversibili

Downstream outlet opere di scarico

•Dam•Water reservoir•Gate•Spillway•Surge tank•Pressure tunnel•Penstock•Water turbine•Draft tube•Tail race level•Power house