Construction and Properties of Structure- and Size-controlled ...were acquired in the ratio of...

Transcript of Construction and Properties of Structure- and Size-controlled ...were acquired in the ratio of...

Available online at www.sciencedirect.com

ScienceDirect

Defence Technology 9 (2013) 59e79www.elsevier.com/locate/dt

Construction and Properties of Structure- and Size-controlled Micro/nano-Energetic Materials

Bing HUANG a,b,c, Min-hua CAO a,b,*, Fu-de NIE c, Hui HUANG c, Chang-wen HU a,b,*

aKey Laboratory of Cluster Science, Beijing Institute of Technology, Beijing 100081, Chinab State Key Laboratory of Explosion Science and Technology, Beijing Institute of Technology, Beijing 100081, China

c Institute of Chemical Materials, China Academy of Engineering Physics, Mianyang 621900, China

Received 10 October 2012; revised 5 December 2012; accepted 26 February 2013

Available online 2 November 2013

Abstract

This article presents a comprehensive review of recent progress of research dedicated to structure- and size-controlled micro/nano-energeticmaterials. The development of the construction strategies for achieving zero-dimensional (0D), one-dimensional (1D), two-dimensional (2D),and three-dimensional (3D) micro/nanostructures from energetic molecules is introduced. Also, an overview of the unique properties induced bymicro/nanostructures and size effects is provided. Special emphasis is focused on the size-dependent properties that are different from those ofthe conventional micro-sized energetic materials, such as thermal decomposition, sensitivity, combustion and detonation, and compaction be-haviors. A conclusion and our view of the future development of micro/nano-energetic materials and devices are given.Copyright � 2013, China Ordnance Society. Production and hosting by Elsevier B.V. All rights reserved.

Keywords: Structure; Size; Micro/nano-energetic materials; Construction technologies; Properties

1. Introduction

It is well known that size, structure and shape have signifi-cant influence on properties of inorganic/organic materials, suchas optics, electrics, optoelectronics, gas-sensor, and magneticproperties [1e9]. Similarly, micro/nano-energetic materialswith distinct structures and extremely small feature sizes alsoexhibit structure- and size-dependent properties, includingthermal decomposition, sensitivity and operational performance[10e14]. Therefore, the controllable preparation of micro/nano-

* Corresponding authors. Key Laboratory of Cluster Science, Beijing Insti-

tute of Technology, Beijing 100081, China.

E-mail addresses: [email protected] (M.H. CAO), [email protected] (C.W.

HU).

Peer review under responsibility of China Ordnance Society

Production and hosting by Elsevier

2214-9147/$ - see front matter Copyright � 2013, China Ordnance Society. Produ

http://dx.doi.org/10.1016/j.dt.2013.10.003

energetic materials with different morphologies and sizes is ofgreat importance for achieving desirable properties.

However, it is more difficult for the synthesis of micro/nano-energetic materials than that of inorganic nano-structures because most of energetic compounds feature vander Waals or other weak intermolecular interactions amongmolecules, and they are dangerous explosives [15e17]. Up tonow, relatively few facile and simple approaches have beendeveloped to construct the micro/nanoparticles of energeticmaterials, mainly including reprecipitation [10,18], rapidexpansion of supercritical solutions [19,20], and physicalvapor deposition (PVD) techniques [21]. Moreover, to the bestof our knowledge, there have scarcely been any reports on thedetailed researches of micro/nano-energetic materials withvarious morphologies and dimensions so far. Accordingly, thedevelopment of mild and universal methods for the fabricationof micro/nano-energetic materials with novel morphologies isclearly of great urgency but a tremendous challenge.

In this review, the recent progress of the size- andstructure-controlled micro/nanomaterials based on energeticcompounds is introduced. In Section 2, the advanced

ction and hosting by Elsevier B.V. All rights reserved.

60 B. HUANG et al. / Defence Technology 9 (2013) 59e79

construction strategies developed for the fabrication of ener-getic micro/nanostructures are reviewed. The preparationmethods for energetic micro/nanostructures with diverse di-mensions and sizes are discussed in detail. In Section 3, somemore recently studied unique properties of micro/nano-energetic materials are introduced, with emphasis on thesize-dependent thermal decomposition and tunable sensitivitycharacteristics. In Section 4, a summary and our view of thefuture development trend in this area are given.

2. Construction technologies

The development of effective and universal constructiontechnologies is prerequisite to the further investigation ofmicro/nano-energetic materials. However, most current ap-proaches which have been developed to prepare the inorganicnanomaterials, are not applicable for energetic materials dueto the lower melting/sublimation points and huge potentialdanger. In the field of organic small-molecule nanomaterials,the considerable efforts have been dedicated to the control-lable synthesis of various organic nanomaterials with distinctshapes, such as nanoparticles [22e24], nanotubes [25,26],nanowires [27e29], nanorods [30,31], and nanobelts [32,33].These fruitful attempts should give a useful enlightenment forthe design and fabrication of micro/nano-energetic materialswith peculiar structures. Therefore, in this section, we justintroduce in more detail the recent successful examples ofsynthesizing micro/nano-energetic materials with the preva-lent methods which have been used extensively in other fields.

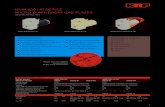

Fig. 1. (a) SEM image of spherical NTO and (b) comparison of cooling rates

on particle size at 200 and 700 rpm [38].

2.1. Re-precipitation method

2.1.1. Cooling crystallizationCooling crystallization has achieved a great success in the

synthesis of energetic materials with special structures andnarrow size distribution [34]. For this technique, the type ofco-solvent, cooling rate and solvent composition are theimportant process parameters to control the morphology andsize of the crystals. However, it is difficult to reduce the size ofthe products when the energetic compounds are used as targetsources.

Han and coworkers recently studied the solubility andrecrystallization of highly hydrogen-bonded 1,3,5-triamino-2,4,6-trinitrobenzene (TATB) in various ionic liquid solventsystems [35]. They synthesized TATB microparticles grown bythe cooling crystallization process in ionic liquidedimethylsulphoxide (DMSO) co-solvent systems. It is known that thespherical crystals of energetic materials exhibit improvedperformance over non-spherical crystals, such as insensitivityto sudden shock, processability and packing density [36,37].Vijayalakshmi et al. fabricated spherical 3-nitro-1,2,4-triazol-5-one (NTO) particles in NTO : water : N-methyl-2-pyrolidone (NMP) ternary system by using cooling crystalli-zation technique [38]. By adjusting the process parameters,such as cooling rate, agitator configuration and speed, a se-lective particle size distribution ranging from 10 to 200 mmcould be achieved (Fig. 1). Kim and his coworkers used a

similar assembly method to prepare spherical NTO particles inthe co-solvent of water and NMP [39e43]. The sphericalparticles with average diameter ranging from 30 to 300 mmwere acquired in the ratio of NTO/NMP ranging from 0.2 to0.6 and in the ratio of water/NMP ranging from 1.0 to 4.8 atthe cooling rate of 10 K/min. Besides, Kim’s group usedoctahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine (HMX) asseed to direct the zero-dimensional (0D) coreeshell structuregrowth of HMX/NTO by two-step cooling crystallization[44,45]. The typical scanning electron microscopy (SEM)images of these energetic composites in Fig. 2 reveal that thesurface of the coreeshell HMX/NTO structures is compactand uniform. They pointed out that the agglomeration kineticfor the coating of NTO on HMX core particles was correlatedwith the 3rd power of the solution supersaturation and the 2ndpower of the number of the suspended particles.

2.1.2. Solvent/nonsolvent processSince the first use of solvent/nonsolvent method in the

preparation of organic nanocrystals by Nakanishi in 1993 [46],this technology has been extensively adopted in the field ofenergetic materials due to its facility and versatility[18,47e50]. The method mainly includes a rapid mixing ofconcentrated solution of the objective compound in a goodsolvent with excess of a poor solvent, leading to the nucleationand growth of the molecules to small-sized particles withdesired structures. The significant difference between thesolubilities of the target molecules in the good and poor

Fig. 2. (a) Diagram of experimental apparatus and (b)e(g) effect of supersaturation on coating morphology. [44].

61B. HUANG et al. / Defence Technology 9 (2013) 59e79

solvents and the good compatibility of the two solvents areessential.

A series of energetic micro/nanoparticles were successfullyfabricated by using this method. For example, Liu et al. re-ported that reticular nano-sized HMX was simply constructedat room temperature [10]. SEM and transmission electronmicroscopy (TEM) show that the spherical HMX particleswith diameter of about 50 nm aggregate into reticularlystructured conglomerates, as shown in Fig. 3. Subsequently, Liet al. prepared HMX microcrystals and studied their micro-scopic morphologies [51,52]. Moore and coworkers also ob-tained submicron-sized HMX by pouring a solution of HMXin acetone into a cold nonsolvent with strong stirring [53,54].van der Heijden’s group and Arya’s group prepared hexahy-dro-1,3,5-trinitro-1,3,5-triazine (RDX) and 2,20,4,40,6,60-hex-anitrostilbene (HNS) ultrafine particles, respectively. Ourgroup fabricated 2,6-diamino-3,5-dinitropyrazine-1-oxide(LLM-105) microtubes with a distinctive rectangular cross-section architecture by using ionic liquid 1-butyl-3-methylimidazolium trifluoromethanesulfonate ([Bmim]CF3SO3) as good solvent and water as poor solvent [55]. Inaddition, other various structures and morphologies of ultra-fine RDX have also been reported, such as murphy-like, cube-like, and spherical [56]. It is found that the morphologies andsizes of the obtained structures can be controlled by adjustingthe experimental parameters.

2.1.3. Nozzle-assisted solvent/nonsolvent processThe above mentioned solvent/nonsolvent method has been

used to synthesize the energetic compounds with desired sizeand special morphology, but it suffers with an issue of processscale-up. Therefore, an instrument with high-pressure jet,which can lead to a rapid nucleation in continuous reactionand crystallization, producing the nanoscale energetic particleswith high yield and mass production, was developed in thepast few years.

Wang and his coworkers reported the fabrication of sub-micron HMX and RDX by spraying a solution of the nitr-amine explosive into water at different process parameters[57]. Recently, they also prepared the high-purity HNSnanocrystals with high specific surface area and narrow par-ticle size distribution by using a prefilming twin-fluid nozzle-

assisted precipitation method [58,59]. In our laboratory, thelarge-scale TATB nanoparticles were obtained by atomizingthe objective compound to the small droplets through a nozzleat high speed [60,61]. TEM and atomic force microscopy(AFM) images show that the resulting nano-TATB particleshave the shape of sphere or ellipsoid with size of about 60 nm(Fig. 4). Bayat and coworkers used a similar method to preparethe submicron particles of HMX and systemically investigatedthe influence of the experimental parameters, such as anti-solvent temperature, compressed air flow rate, and nozzlediameter [62], on the size of HMX particle, while Shokrolahiand coworkers obtained the crystalline nanoparticles of keto-derivative of RDX (K-6) [63].

2.1.4. Ultrasound-assisted solvent/nonsolvent processUltrasound-assisted solvent/nonsolvent is an effective and

safe technology for preparing the micro/nanoparticles of en-ergetic materials [64,65]. It is generally used to control thenucleation process [66]. Sivabalan et al. combined the ultra-sound technology with the solvent/nonsolvent method tocontrol the size and morphology of 2,4,6,8,10,12-hexanitro-2,4,6,8,10,12-hexaazaisowurtzitane (CL-20) [67]. The resultsreveal that the sonication process offers a uniform morphologywithout any agglomeration, and the particle size of sonicatedCL-20 sample obtained is about 5 mm with a narrow particlesize distribution. Bayat and his coworkers introduced thesonication into spaying-assisted precipitative crystallization toprepare the spherical or ellipsoidal CL-20 nanoparticles withan average size of 95 nm [68]. They pointed out that thenanoparticles tend to agglomerate due to their smaller size.Wang and his coworkers also demonstrated that ultrafine CL-20 was synthesized with ethyl acetate as solvent and heptaneor n-hexane as non-solvent by using an ultrasound- and spray-assisted precipitation [69].

2.2. Spray drying strategy

2.2.1. Spray dryingBesides the above re-precipitation method, a simple spay

drying technology, which has been widely used to preparethe submicrometer- or nanosized inorganic and polymericnanoparticles [70e72], is utilized to prepare the nanostructures

Fig. 3. SEM and TEM images of sample prepared by solvent/nonsolvent

method. Concentration of HMX acetone solution: (a) 2 mmol/L, (b) 5 mmol/L,

and (c) 10 mmol/L [10].

62 B. HUANG et al. / Defence Technology 9 (2013) 59e79

of energetic materials. For example, Castro-Rosario and hiscoworkers prepared RDX nanoparticles with an average size of405 nm by exposing the glass substrate surfaces to an aerosoljet containing RDX [73]. Ultra-fine HNS explosive withspherical morphology was acquired with the aid of spray dryingprocess by Wang’s group, and there was no phase transition inthe process of preparation [74]. Recently, Qiu and his co-workers assessed the feasibility of single-step preparation ofHMX-based nanocomposite particles with polymeric binder byusing spray drying [75]. It was found that the microparticlesconsist of small crystals uniformly and discretely dispersed in abinder. This facile method may be suitable for the preparationof a wide range of insensitive explosive compositions. Zhigachet al. demonstrated that ultrafine nitramine (RDX, HMX andCL-20) powders with an average crystal size of about 1 mm andaluminized nanocomposites were produced [76]. Our groupextended this technology to coreeshell binary energetic system.For instance, we prepared and characterized a new type ofcomposite particles with a coreeshell structure by injecting atetrahydrofuran (THF) suspension containing NTO and HMXinto a spray dryer. After THF evaporation, NTO crystallized inthe shape of small particles on the surface of HMX micropar-ticles, and the coreeshell structure of HMX/NTO compositeparticles was obtained [77]. The surface of the composite par-ticles was “potholed”, while that of HMX particles was smooth.Moreover, the ultrafine TATB/benzotrifuroxan (BTF) coree-shell composite particles can also be synthesized by using thespay drying method [78].

2.2.2. Electrospray crystallizationElectrospray crystallization is one of the effective methods

to achieve the nano- and submicron-sized crystals [79]. Withthe aid of high potential difference, the electrostatic forcescould overcome the surface tension, and any flow arriving atthe tip of the nozzle is directly emitted as a jet of liquiddroplets. As a result, a mist of ultrafine solution droplets isgenerated, and the subsequent solvent evaporation leads to theformation of submicron-sized crystals [80]. For example,Radacsi’s group developed an electrospray crystallizationmethod (Fig. 5) to prepare the agglomerated RDX hollowspheres with the size of around 4 mm and spherical particleswith a size ranging from 200 to 600 nm under the differentpotential differences [81]. Reus and his coworkers preparedthe encapsulated RDXetrinitrotoluene (TNT) sphericalnanoparticles by using the elecrospray technique, and thecomposition of the particles needs further investigation [82].

2.2.3. Ultrasound-assisted spray dryingUltrasonic-assisted spray drying, as one of various atomi-

zation techniques, is a favored method because of its excellentenergy-efficiency and the inherently low velocity of initialdroplets [83]. Accordingly, this outstanding technique hasbeen employed for the preparation of energetic materials withmicro/nanostructures.

Spitzer and his coworkers reported the first use of the at-omization process for the continuous crystallization ofexplosive submicrometer- and nano-energetic compounds

Fig. 4. (a) TEM and (b) AFM images of nano-TATB [60].

63B. HUANG et al. / Defence Technology 9 (2013) 59e79

[84,85]. More inspiringly, RDX or 2,2-bis[(nitroxy)methyl]-1,3-propanediol (PETN) nanoparticles can be produced from 1to 10 g/h by using a reactor containing one ultrasonic piezo-electric transducer, and even can be scaled up using severaltransducers. Qiu et al. reported that RDX- or CL-20-basednanocomposite consisting of explosive crystals with nano-esubmicron size range can be obtained by ultrasonic sprayfrom an explosive/polyvinyl acetate binder/acetone dilute

Fig. 5. Process scheme of electr

solution [86e88]. Recently, Koo and his coworkers also uti-lized this technology to achieve ultrafine RDX with size of0.8e2.6 mm [89,90]. It could be observed from Fig. 6 thatRDX concentration and furnace temperature play an importantrole in controlling the crystal size and habit. They alsoconcluded that a nucleation inhibitor could be utilized as ahabit modifier and the onset time of nucleation is an importantfactor to improve the crystal shape.

2.3. Spray freeze-drying technique

Spray freeze-drying (SFD) technique, which is consideredas one of the advanced ways for the fabrication of nano-particles, has been widely used for the synthesis of nano-structures of biological medicaments and inorganic materials[91e93]. The particles obtained by this method generallypossess the intriguing advantages, such as molecular scalehomogeneity because of flash freezing in the cryogen, andminimal agglomeration because of the sublimation of thewater ice in the low-temperature vacuum drying condition[94,95]. So far, this system has been used to synthesize thenanostructures of energetic materials.

In the early years, our group reported the fabrication of three-dimensional (3D) nano-network structures of NTO [96]. Sincethe formed ice limits the aggregation of small particles, theobtained NTO particles have an elongated shape and the size ofthe particles is in the range of 70e90 nm. With a similar tech-nique, 1,1-diamino-2,2-dinitroethylene (FOX-7) 3D gridnanostructures with different unit sizes were also prepared bythe freeze-drying technique mentioned above [97]. The prepa-ration process of FOX-7 3D grid nanostructures is shown inFig. 7(a). The typical SEM images in Fig. 7(b), (c) indicate thatthe resulting FOX-7 3D structures are constructed from one-dimensional nanostructures. The size and reticular structuresof the as-resulting nano-FOX-7 could be easily controlled byadjusting the concentration of the aqueous solution of raw ma-terials. The further investigation on a possible formationmechanism of this structure reveals that a high degree of super-cooling under the liquid nitrogen conditions leads to a highnucleation rate, and the small particles and ice are rapidlyformed due to the rapid heat transfer between the aqueous so-lution and the cryogen. After the sublimation of ice, the small

ospray crystallization [81].

Fig. 6. SEM images of RDX particles prepared from (a) 0.5 wt% and (b) 4.0 wt% RDX/acetone solution at the furnace temperature of 175 �C; SEM images of

RDX particles prepared from 1.0 wt% RDX/acetone solution at furnace temperatures of (c) 75 �C and (d) 175 �C [89].

64 B. HUANG et al. / Defence Technology 9 (2013) 59e79

particles with a relatively high energy start to aggregate by self-assembly, leading to the formation of 3D grid structures. Ascheme of this growth process is summarized in Fig. 7(d). Moreimportantly, this facile synthesis strategy may represent a gen-eral approach for the preparation of nanostructures of otherwater-solubility energetic compounds.

2.4. Sol-gel processing

Sol-gel processing is a feasible way to prepare the inor-ganic/organic nanocomposites under mild conditions[98e102]. The stoichiometry and homogeneity of the nano-composites can be easily controlled by using this method,and therefore this method could dramatically improve currentstate-of-the-art technology. Moreover, the solegel chemistryhas the ability to construct the nanostructured materials withspecial shapes, such as uniform net-shape geometric solids,fibers, films, and powders with nanoscale size [103,104].

Tillotson’s group used the solegel processing to preparethe composite nano-energetic materials [105]. In this process,RDX or PETN was first loaded into the pores of the wetmonolithic gel and then was kept there upon supercriticalsolvent extraction drying, which helps restrain the growth ofthe explosive particle beyond the nanometer and submicronscale. Brill and his coworkers prepared various unusual ener-getic composites, in which CL-20 nanoparticles were uni-formly coated with energetic polymer gels using solegelmethod [106e108]. Ingale et al. demonstrated that the silicaxerogels incorporated with nanocrystalline PETN or PETN/TNT were synthesized, in which the content of energetic

materials ranges from 50% to 90% (w/w) [109,110]. Ourgroup used this strategy to prepare laminate-like structuredHMX/ammonium perchlorate (AP)/resorcinol-formaldehyde(RF) aerogel with uniform pores [111], as shown in Fig. 8(a),(b). The XRD results show that the mean size of HMX crystalsis less than 100 nm and the mixture of HMX and AP is uni-form in nano-scale. The specific surface area of HMX/AP/RFis 27 m2/g, which is much less than that of RF aerogel. Themesopores and micropores of HMX/AP/RF composites mainlydistribute in the range of 2e20 nm and 0.6e1.6 nm, respec-tively. Besides HMX/AP/RF, we also prepared RDX/RF gel bymeans of emulsion process and solegel technique [112]. SEMimages are given in Fig. 8(c)e(e), which clearly show that theparticle size of RDX/RF composites is controlled by adjustingthe composition of the surfactant system and the temperatureof growth solution. Recently, Luo and his coworkers reportedthe preparation of an AP/RDX/SiO2 nanocomposite energeticmaterials [113]. They found that the distance between the SiO2

colloidal particles was enlarged due to the presence of RDXand AP, which is contributed to the lower crosslinking struc-ture and the bigger pores.

2.5. Supercritical fluid precipitation processes

Supercritical fluids have been used as solvents for a widevariety of applications in the field of organic and inorganicmaterials [114e116]. On the basis of above fluids, varioussupercritical fluid-based precipitation methods have beendeveloped and have attracted extraordinary attention due tounique micronization processes compared with conventional

Fig. 7. (a) Flow chart of FOX-7 quasi-three-dimensional grids fabricated via SFD technique; (b) low magnification; (c) high magnification of SEM images of FOX-

7 nanostructures prepared with CFOX-7 ¼ 0.1 g/L; (d) a probable formation process of FOX-7 network structures under the same supercooling rate [97].

65B. HUANG et al. / Defence Technology 9 (2013) 59e79

crystallization techniques, such as milling, crushing, spraydrying, and crystallization from liquid solution [117,118]. Thesupersaturation and nucleation rates, and the size andmorphology of micro/nanoparticles can be easily controlled byvarying the process parameters. To date, the supercritical fluidprocesses, mainly including rapid expansion supercritical so-lutions (RESS) process and supercritical anti-solvent (SAS)process [19,119], have been used for explosives.

Fig. 8. (a), (b) SEM micrographs of HMX/AP/RF aerogel [111]. SEM images of th

the surfactant, respectively; (c) 70 �C, 5%; (d) 90 �C, 5%; (e) 70 �C, 2% [112].

2.5.1. Rapid expansion of supercritical solutions (RESS)RESS, which is to saturate a supercritical fluid with the

objective compound and then depressurize this solution into alow pressure chamber through a heated nozzle, is a simpleprocess for explosive that enables the growth of micro/nano-particles without the need for a drying process [19]. Morrismeasured the solubility of RDX in carbon dioxide (CO2) at303e353 K and 6.9e48.3 MPa, and confirmed a maximum

e as-obtained RDX/RF composite at different temperatures and proportions of

66 B. HUANG et al. / Defence Technology 9 (2013) 59e79

solubility of about 0.25 mg of RDX/g of CO2 [120]. Subse-quently, Krober et al. reported that TNT and NTO can bemicronized by the RESS process [121]. RDX was precipitatedto the ultrafine particles with spherical morphology by usingcompressed liquid dimethyl ether (DME) as a solvent [122].Krasnoperov’s group produced RDX nanocrystals by RESS[123]. The experiments were performed by expanding thesupercritical solution of RDX in carbon dioxide through sap-phire nozzles, as shown in Fig. 9(a). SEM images indicate thatthe tunable particle size of resulted RDX nanocrystal is in therange of 110e220 nm with a narrow size distribution(Fig. 9(b)e(d)). Moreover, they also further investigated theoptimized conditions and initiation sensitivity [20,124e126].The significant change of properties of nano-RDX comparedwith that of the bulk material will be discussed in Section 3.

2.5.2. Supercritical anti-solvent process (SAS)In the SAS process, a compressed gas or supercritical fluid

is used as an anti-solvent that causes the precipitation of solidraw material dissolved initially in a liquid solvent. This pro-cess offers several advantages, such as control of particle size,size distribution, crystal structure and crystal phase [127].Therefore, the SAS process is also adopted in micronization ofexplosives as a promising crystallization method.

In recent years, Lee’s group prepared micronized RDX byusing a SAS process and systemically investigated the in-fluence of different solvents on morphology, size, and sizedistribution [128]. Fig. 10 shows the SEM images of therecrystallized RDX particles obtained in different solvents. It

Fig. 9. (a) Schematic representation of the RESS setup; SEM images of RDX partic

(c) 363 K and pressure 15.0 MPa, using heatable nozzle (ID ¼ 100 mm); and (d)

can be seen from Fig. 10 that the morphology and size ofrecrystallized RDX are dependent on the used solvent. Inaddition, they proved that the SAS technique is an effectivemethod for the preparation of size- and morphology-controllable HMX particles [129,130]. Similar results werealso found by Lee and his coworkers when they tried toprepare the microparticles of nitroamine explosives (RDXand HMX) [131e133]. With the aid of the SAS process,Pourmortazavi et al. successfully synthesized HMX nano-particles by employing Taguchi robust design as a statisticaloptimization method to optimize the experimental variables[134].

2.6. Template technique

The template technique is a straight forward approach tofabricate micro/nanostructures by inducing the target materialsto grow according to the patterns of the templates. Thisstrategy provides a simple way for the synthesis of micro/nanomaterials with desired shape and size, and has beenwidely applied in the construction of different dimensionalmicro/nanostructures. The templates adopted in this methodcan be generally divided into two sorts: rigid and soft ones.

2.6.1. Rigid templateThe rigid template method for the preparation of micro/

nanostructures has been developed independently in variousfields of nanotechnology. It has become one of the mostcommon methods in the fabrication of inorganic, organic and

les produced at (b) 348 K and 28.0 MPa, using heatable nozzle (ID ¼ 100 mm);

363 K and pressure 15.0 MPa, using heatable nozzle (ID ¼ 150 mm) [123].

Fig. 10. SEM images of the recrystallized RDX particles obtained in different solvents: (a) CHN; (b) DMSO; (c) ACN; (d) AC; (e) DMF; (f) NMP [128].

67B. HUANG et al. / Defence Technology 9 (2013) 59e79

polymeric micro/nanomaterials [135e138]. Now thecommonly used templates include ordered porous membranes[139], silica [140], nanochannel glass [141], monodispersecolloids [142], and iontrack-etched polymers [143].

During the past several years, this technique has alsobeenusedto prepare the energetic nanocomposites. Smeug et al. investi-gated the confinement of energetic molecules inside carbonnanostructures by molecular structure and total energy calcula-tions [144]. The calculation results predict that each energeticmolecule, including FOX-7, RDX, HMX, 3,6-di-(hydrazino)-1,2,4,5-tetrazine (DHT), 3,6-diazido-1,2,4,5-tetrazine (DiAT),3,30-azo-bis(6-amino-1,2,4,5-tetrazine) (DAAT), and N-oxidesofDAAT(DAATOn,n¼ 1e5) could be stabilizedby32e53kcal/mole if a carbon nanotube (CNT) with appropriate size isselected. Recently,Hu and his coworkers achieved the fabricationof KNO3@CNTs nano-energetic materials by combining thewetchemical-assistant electrophoretic deposition (EPD) with rigidtemplate method (Fig. 11(a)) [145]. The TEM images ofKNO3@CNTs nanocomposites are shown in Fig. 11(b)e(d). Itcan be seen that the hollow cavities of CNTs are homogeneouslyfilled with crystalline KNO3 without any impurities attached onthe outer surface.

Several host-guest nanocomposites, such as 2,4,6-trinitrophenol (PA)/mesoporous carbon FDU-15, FOX-7/FDU-15 and CL-20/mesoporous silica SBA-15, were preparedbased on self-assembly of energetic molecules in nanometer-scale channels of an ordered mesoporous material[146e148]. The design and synthesis of these kinds of mate-rials are beneficial to understand the reaction characteristics ofenergetic ordered arrays and further fabricate the micro/nano-devices with high performance and efficiency. Similarly, FOX-7 immobilized in the pores of silica MFI-type zeolite nano-crystals was fabricated by Mintova and his coworkers [149].Choosing a porous chromium (III) oxide (Cr2O3) matrix pro-duced by the combustion of ammonium dichromate as atemplate, the RDX/Cr2O3 nanocomposites were obtained via afacile solvent evaporation process by Spitzer and his co-workers [150,151]. The method may be suitable for thepreparation of a wide range of sensitive explosive composi-tions embedded in the porous materials.

2.6.2. Wet chemical-assisted soft templateSo-called soft templates can be dissolved in the liquid

phase, mainly including surfactant micelles and copolymers[152e154]. It is well-known that the surfactant micelles andinverse micelles with different shapes (spherical, rod-like, andso on) are formed in the solutions when their concentrationsreach the critical micelle concentration (CMC) [155]. Thus,these micelles can then be used as the soft templates for thefabrication of organic and inorganic micro/nanostructures.

It iswell-known that TATB is not soluble in themost commonsolvents due to significant intra- and inter-molecular hydrogenbonds [156,157], and thus most of methods commonly used inthe synthesis of organic nanomaterials, such as solvent volatil-ization, rigid template, and vapor deposition, are not suitable forthe fabrication of TATB nanostructures. In our recent work, aternary microemulsion system of water/dioctyl sulfosuccinatesodium salt (AOT)/toluenewas developed to directly synthesizeone-dimensional (1D) twinned TATB nanobelts [158]. A seriesof experiments confirm that the urea as an aminating reagentplays a key role in the formation of highly crystalline nanobeltswith perfect mirror symmetry, because the aminating reactioncould be easily controlled by adjusting the hydrolysis rate ofurea. By using this route, besides twinned nanobelts, variousTATB micro/nanostructures, such as particles, leaves, bananaleaves, and wedge-shaped ribbons with different sizes, could bedirectly prepared by changing the experimental parameters.

Subsequently, we developed a facile surfactant-assistedself-assembly technique for constructing 3D dendritic 2,6-diamino-3,5-dinitropyrazine (ANPZ) microstructures innontoxic ethanol solvent using urea as the aminating reagent(Fig. 12(a)e(d)) [159]. With the assistance of surfactantPluronic P123 block copolymer, the size and morphology ofANPZ micro/nanostructures can be easily tailored by varyingthe operating conditions. Moreover, the growth mechanism ofANPZ dendrites was also proposed on the basis of a detailedtime-dependent morphology evolution study, as illustrated inFig. 12(e). Recently, Mandal and his coworkers synthesizedthe spherical particles of FOX-7 by using the concept of amicelle-based nanoreactor [160]. The diameters of thesespherical particles are in the range of nanometer to

Fig. 11. (a) Schematic model of EPD. The Cu thin-film microbridge on the glass substrate was set as cathode and Pt plate as anode. The distance between the

cathode and the anode was adjusted to be 1 cm. (b)e(d) TEM images of the KNO3@CNTs nEMs achieved by wet chemical method [145].

68 B. HUANG et al. / Defence Technology 9 (2013) 59e79

submicrometer. Significantly, the size and shape of FOX-7particles can be adjusted by varying the wateresurfactantmolar ratio in the microemulsion system.

2.7. Physical vapor deposition (PVD)

PVD is a simple and outstanding method for preparingnanomaterials, and has achieved great success in the synthesisof inorganic nanostructures and polymeric thin films[161e163]. The morphology, size, and dispersity of theproducts are easily controlled by tuning the experimentalconditions, such as saturation level, temperature, and time.

Frolov et al. reported the first synthesis of nano-RDX,nano-HMX, nano-NH4NO3, or their composites by employ-ing vacuum sublimation and condensation process[21,164e166]. The obtained energetic particles have anaverage diameter of about 50 nm. Although this technique hasa low yield, it provides useful information for the design andfabrication of energetic molecule micro/nanostructures. Zhangsynthesized PETN films with desired surface morphology in acontrollable and reproducible way by thermal evaporation ondifferent substrates [167,168]. Recently, 2D one-molecule-thick single-crystalline nanosheets of LLM-105 supported onhighly oriented pyrolytic graphites (HOPG) were prepared byvapor self-assembling method at 220 �C and atmosphericpressure (Fig. 13) [169]. The nanosheet with rectangular shapeand lateral dimension, which is very sensitive to electricity and

force stimuli, provides an opportunity to write optional pat-terns and fabricate high-sensitive force sensor.

2.8. Inkjet printing

It is noteworthy that inkjet printing technique has beenrecently extended as a low-cost processing method in the fieldof energetic materials due to its advantages of excellent ac-curacy and surface finishes. For example, this technology wasexplored as a new way to directly deposit and pattern energeticmaterials for trace explosive detection application [170,171].Lee reported the inkjet-print RDX crystals, which weredispersed in a cellulose acetate butyrate (CAB) matrix bydirect-phase transformation from organic solvent-based all-liquid inks. They found that a variety of crystal morphologiescould be obtained by changing the ink deposition parameters[172,173]. They also reported that this effective strategy isused to control the droplet coalescence during inkjet printing,and consequently to tailor the nanoscale morphology oforganic composites [174]. They found that the decrease incoalescence increased the evaporation rate of solvent, the su-persaturation of the solutes, and the nucleation density of theorganic crystals. Utilizing this method, the average size ofPETN crystals dispersed in an adhesive binder [poly(vinylacetate) or a chlorinated wax] matrix from 0.2 to 100 mm waseasily tailored (Fig. 14). In addition, the inkjet technique wasalso used to prepare other energetic samples (HMX, TNT and

Fig. 12. (a)e(c) SEM images of the as-prepared ANPZ sample; (d) TEM images of a single microrod. (e) Schematic illustration of the possible growth process of

dendritic ANPZ microstructures and their building blocks [159].

69B. HUANG et al. / Defence Technology 9 (2013) 59e79

NH4NO3) with controlled size and distribution by Hernandez-Rivera and coworkers [175].

3. Properties

Besides the exploration of the construction strategies, mucheffort has also been focused on investigating the significantchange of properties of micro/nano-energetic materials ob-tained by above technologies, In this section, we give anoverview of present studies on the unique properties of micro/nano-energetic materials. First, the size-dependent thermalproperties are discussed, then more attention is paid to varioussensitive characteristics, and finally the combustion/detonationperformance and compaction behavior are also introducedbriefly.

3.1. Size-dependent thermal properties

It is well addressed that small particles in the nanometersize regime exhibit unique physical and chemical propertiesthat differ markedly from those of the bulk material. The size-dependent properties of nanomaterials were establishedinitially from inorganic materials [176,177]. Subsequently, thesize-dependent properties can also be observed in micro/nano-energetic compounds, such as HMX [10,52,179], HNS [18],TATB [60,178], RDX [63,123], CL-20 [69], and nitrocellulose(NC) [180]. In our previous work, FOX-7 nanoparticles withaverage diameters ranging from 100 to 800 nm were obtainedby SFD technique [97]. We systematically investigated thethermal properties of prepared FOX-7 nanostructures. Asshown in Fig. 15(a), the differential scanning calorimetry(DSC) patterns of both the FOX-7 nanostructures and the

Fig. 13. (a) Topographical image of a LLM-105 nanosheet in contact mode. (b) High-magnification current image of LLM-105 nanosheet with size of

20 nm � 20 nm under the conductive AFM mode with load of 0.2 nN, bias of 0.2 V, and scanning rate of 0.5 Hz. (c) The logo pattern of our institute, ICM, wrote

on an explosive nanosheet of LLM-105. (d) Dynamic force microscope (DFM) topographical of LLM-105 nanosheet on HOPG, the dark squares in nanosheet in

regions of 50 nm � 50 nm and 200 nm � 200 nm were scanned at bias value of 5 V with conductive AFM [169].

70 B. HUANG et al. / Defence Technology 9 (2013) 59e79

micro-sized raw material display two exothermal peaks withthe maximum in the range of 240e256 �C and 280e298 �C,respectively. It can be clearly seen that the first exothermalpeak shifts to higher temperature with the decrease in FOX-7particle size. This phenomenon can be explained by the theoryof topochemical reactions that the small-sized FOX-7 particle

Fig. 14. (a) Surface morphology of a single layer deposition printed under maximum

multilayer deposition printed under minimum coalescence-like conditions using

morphology in areas labeled “c” and “d”, respectively, in (b) [174].

generally requires a higher decomposition temperature due toits less lattice defects and smaller internal stress [181]. For thesecond exothermal peak, it shifts to lower temperature with thedecrease in the particle size, and there is a shift of approximate13 �C to lower temperature compared to FOX-7 raw material.This regular shift is considered to result from the increased

coalescence-like conditions using a d1,2 of 5 mm; (b) surface morphology of a

a d1,2 of 100 mm (c) and (d) higher magnification images of characteristic

Fig. 15. DSC (a) and TGA (b) curves of FOX-7 nanostructures prepared with

different CFOX-7 (a: 0.1 g/L; b: 0.2 g/L; c: 1 g/L; d: 2 g/L) and FOX-7 raw

material (e) between 40 �C and 500 �C at a heating rate of 10 �C/min [97].

71B. HUANG et al. / Defence Technology 9 (2013) 59e79

ratio of surface atoms to interior atoms when the particle sizedecreases. Thermogravimetry (TG) curves in Fig. 15(b)exhibit a distinct weight loss and no evident inflexion fornanoparticles. It is suggested that nano-sized FOX-7 has amuch higher decomposition rate, which is in accordance withthe results of DSC.

In addition, our group also reported the thermal propertiesof other micro/nano-energetic materials [159]. We preparedANPZ micro/nanoparticles with different morphologies via afacile surfactant-assisted solvothermal process. It is interestingto note that the morphology evolution from 2D nanosheets to3D hierarchically self-assembled dendrites was accompaniedby a regular change in decomposition temperature, whichexhibited a unique morphology-dependent thermal effect. Thatmay be due to the fact that the size changes from nanometer tomicrometer as the morphology evolves from nanosheets todendrites. Therefore, the ratio of surface atoms to interioratoms significantly decreases as the particle size increases.The ANPZ dendritic microstructures have a lower surface

energy and are more difficult to be stimulated under thermalinitiation than small-sized nanostructures. On the basis ofabove analysis, the ANPZ micro-/nanostructures exhibited aseeming morphology-dependent thermal effect that is actuallysize-dependent.

Very recently, Mohammadi and coworkers studied thethermal decomposition of RDX nanoparticles with varioussizes produced by a wet ball milling technique in hexanesolvent [182]. The results show that the thermal decompositiontemperature of RDX and its decomposition activation energyare significantly enhanced as the particle size of RDX isincreased. The activation energy for micro-RDX is 1.5 timeshigher than that for nano-RDX, which was ascribed to thedecrease in reactivity and localized hotspots. Furthermore,based on calculated kinetic data, the gradual increase in thecritical ignition temperature of RDX samples was also foundin the order: 180 nm RDX < 250 nm RDX < 300 nmRDX < 50 mm RDX, which is in good accordance with theDSC results.

Furthermore, the catalytic behavior of inorganic nano-materials on the thermal decomposition of high-energy ex-plosives attracted some attention in the past years because ofimproved thermal efficiency. As a consequence, the consid-erable efforts have been devoted to the controllable con-struction of inorganic nanoparticles, such as metals [183,184]and metal oxides [185e189], in order to obtain higher cata-lytic activity, in which micro-sized explosives are selected ascatalytic targets. However, there has been scarcely any reportso far on the catalytic thermal decomposition of ultrafine ex-plosives. Zhigach and coworkers developed a convenientapproach for preparing the alumined nanocomposites by spraydrying of a suspension of Al nanoparticles in as solution ofnitramine (RDX, HMX and CL-20) [76]. SEM images revealthat the nitramine powders with an average crystal size ofabout 1 mm were obtained and nano-sized Al particles wereuniformly distributed in the energetic matrix of compositematerials. Unfortunately, there is no report on the catalyticthermal decomposition of alumined nanocomposites.

3.2. Tunable sensitivity characteristics

3.2.1. Impact sensitivityThe impact sensitivity of energetic materials to unintended

initiation is an important safety factor during their uses. Ingeneral, the reduction in particle size leads to the decrease inimpact sensitivity. For instance, NTO nanoparticles with a sizeof 70e90 nm were prepared by spray freezing drying tech-nology [96], and the mechanical sensitivity measurement showthat the determined H50 for micro-NTO and nano-NTO are26.2 and 35.5 cm, respectively. This result shows that the as-synthesized ultrafine powder has lower impact sensitivitythan that of the NTO raw material. It was proposed that theaverage pore diameter of ultrafine particles was too small tobecome a hot spot under the impact stimulus, thus leading tothe decrease in impact sensitivity. Wang and his coworkersalso investigated the effect of particle size on the impactsensitivity of energetic materials. As mentioned above, a

Fig. 16. Shock sensitivity of uncoated samples of Class 1, 4.8 micron, Type A

nano-RDX (a specific surface area around 15e20 m2/g), and Type B nano-

RDX (a specific surface area around 5e6 m2/g) [125].

72 B. HUANG et al. / Defence Technology 9 (2013) 59e79

nozzle-assisted solvent/nonsolvent method was developed forthe preparation of nanoparticles from HNS and CL-20 [58,69].The impact test indicates that both nano-HNS and nano-CL-20are less sensitive than that of their raw material. In particular,the impact sensitivity of composite energetic materials wasalso studied by Brill’s group and Luo’s group [107,113]. Thetunable impact sensitivity characteristics of these nano-composites were confirmed.

3.2.2. Friction sensitivityAs expected, the particle size of energetic materials has an

important effect on friction sensitivity, but the reported resultsare controversial. Recently, Robmann et al. reported that theultrafine HMX particles were synthesized by using a beadmilling technology [190]. It was revealed that the frictionsensitivity of HMX decreased greatly as the crystal size wasreduced from 4.5 mm to 171 nm. Radacsi and his coworkersalso performed the friction sensitivity tests at the highestpossible load (360 N) and found that the friction sensitivity ofthe submicron-sized RDX particles is much lower than that ofthe conventional RDX crystals [81]. The author assumed thatthe decrease in the friction sensitivity was mainly attributed tothe defect and internal quality of the energetic crystals. Li andhis coworkers fabricated three kinds of HMX samples with

Fig. 17. Burning rate dependency on the pressure of the RDX monopropellant.

RDX particle sizes: A 50 nm; : 5 mm and - 50 mm [166].

spherical, needle-like and polyhedral microstructures by wetmilling, solvent/nonsolvent and riddling methods, respectively[52]. It is interesting to note that the friction sensitivity in-creases gradually as particle size decreases for spherical b-HMX particles, but the friction sensitivity of needle-like g-HMX linearly increases with the increase in particle size from2.98 to 16.1 mm. However, for polyhedral b-HMX sample, itsfriction sensitivity did not display some rule as a function ofparticle size. The above results show that the safety of HMX isdependent strongly on the size and structure of HMX particles.This phenomenon can be explained by the “hot spot” growthmechanism [191].

3.2.3. Electrostatic spark sensitivityIt was mentioned in Section 2 that our group presented a

facile strategy for the construction of 3D FOX-7 nano-structures and investigated the response of nanoparticles toignition stimulus under the electrostatic discharge conditions[97]. The results of electrostatic spark sensitivity of nano-FOX-7 indicate that its 50% critical ignition voltage (V50)and 50% critical ignition energy (E50) are 13.19 kVand 2.65 J,respectively, which are lower than those of FOX-7 raw ma-terial, 16.42 kV and 4.11 J. The decrease in ignition energymay be explained by the fact that the FOX-7 nanostructureswith higher surface energy are easy to be stimulated.

3.2.4. Shock sensitivityIn order to produce the safe munitions which are capable of

withstanding the unwanted mechanical stimuli, such as shocksfrom explosions, it is necessary to substantially reduce theinitiation sensitivity of energetic materials. A great number ofexperimental data prove that energetic materials withdecreased particle size have great changes in safety under thecondition of shock initiation stimuli. The prior studies havedemonstrated that the shock initiation sensitivity of some ex-plosives, such as HNS, HMX, RDX and TATB, has beeneffectively lowered [192e195]. In the case of RDX, thenanoparticles generated by the RESS process show differentshock behaviors compared to the bulk material [125], asillustrated in Fig. 16. The RDX with the size of 4.8 mm showsthat the small scale gap test result is 19.6 kbar, while the bulkmaterial exhibits higher sensitivity. However, the shocksensitivity results of Types A nano-RDX and Types B nano-RDX are 20.6 and 26.1 kbar, respectively. The above dataclearly show that the shock sensitivity decreases as the crystalsize is reduced down to the nano-scale, meaning that long-pulse shock sensitivity can be tuned by changing the particlesize. Similarly, Stepanov and Qiu also found that the RDX-based nanocomposites exhibited lower shock sensitivity,which is attributed to small crystal size as well as small voidsize. [87,88] Additionally, Wang and his coworkers developeda novel technique to prepare the ellipsoidal HNS nanocrystalswith high specific surface and narrow particle size distribution[58]. The obtained HNS samples were subjected to small scalegap test, and the results indicate that crystalline HNS nano-particles are less sensitive to shock stimuli than micro-sizedHNS (50 mm).

73B. HUANG et al. / Defence Technology 9 (2013) 59e79

It is worth noting that a completely opposite result can beobtained if the test of shock sensitivity is carried out under theslapper initiation stimuli. Gifford and coworkers studied thebehavior of short duration shock of PETN with different sizesand found that there were no changes when PETN micropar-ticles were initiated using laser-driven flyer though somelimited reaction. In contrast the ultrafine PETN particle wasreadily initiated at flyer velocities of around 5 mm ms�1 [196].Wang et al. also reported that the ultrafine HNS is more sen-sitive to short duration shock wave than its conventionalcounterpart [74]. These studies show that the initiation formplays an important role in determining test results of small-sized explosives. For the small scale gap test, its shock waveis low pressure-long pulse, and the relative shock sensitivity iscontrolled by ignition process [197], but oppositely, the shockwave is high pressure-burst pulse and the sensitivity iscontrolled by detonation buildup for the slapper initiation test[198].

3.3. Improved combustion and detonation performance

Nano-scaled energetic materials have attracted wide in-terest by virtue of their unusual combustion and detonationperformance. Therefore, there have been a number ofexperimental and theoretical studies on these properties ofnano-energetic materials and nanocomposite propellants[199,200]. Pivkina’s work shows that there was a significantdifference in burning rate of pure RDX nanopowders incomparison to micron-sized component [166]. As shown inFig. 17, a monopropellant of RDX nanoparticles with thesize of about 50 nm, prepared by a vacuum condensationtechnique, exhibits burning rate twice greater than conven-tional powder at an elevated pressure of 10 MPa, indicatingthat the size has considerably important influence on themechanism of RDX combustion. Muravyev and coworkersalso investigated the combustion parameters of HMX as amonopropellant [201]. It was shown that although combus-tion velocity is almost same for micro-HMX and ultrafineHMX, the combustion of the ultrafine HMX is more com-plete than that of micro-HMX. To fulfill the control of thecombustion performance of high explosives, the solidifica-tion of energetic phases in a porous matrix (Cr2O3) is used tofabricate and stabilize the nano-scale explosive particles(RDX) [151]. The studies show that the combustion rate isremarkably increased by decreasing the size of the reactants,and the highest rates can be obtained with the mixtures inwhich each reactant is structured at nano-scale.

Additionally, Wang et al. tested the detonation performanceof each formulation by probe method and found that thedetonation velocity of superfine explosives (HMX and RDX)is obvious higher than that of the coarse particles [57]. This isprobably because the superfine particles with high specificsurface area can burn faster than the conventional counterpartand hence more energy is transferred to the detonation reac-tion zone. Gogulya’s group achieved the similar result whenthey used a pulverization drying method to synthesize theultrafine HMX particles [202].

3.4. Unique compaction behavior

In addition to the properties mentioned above, thecompaction behavior of small-sized energetic materials hasalso been reported in the past few years. For example, Loweet al. investigated the relationship between particle size andcompaction behavior of granular bed [203,204]. Theydesigned a modeling and experimental method to study thecompaction behaviors of two types of granular HMX: coarseHMX (mean diameter of 40 mm) and microfine HMX (meandiameter of less than 5 mm). The results show that the granularbed of the microfine HMX with the particulate structure ismore strength than the coarse bed. Agarwal and coworkersprepared fine TATB particles (2�5 mm) with the assistance ofreprecipitation and found that its mechanical strength/com-pressed strength was significantly improved in comparison tocoarse TATB (55 mm) alone in plastic bonded explosive (PBX)formulations [47].

4. Conclusions and future perspective

In this paper, a review of recent research on controllablepreparation of micro/nano-energetic materials with specialstructures and sizes was presented. We introduced variousadvanced strategies for the construction of structure- and size-controlled micro/nano-energetic materials. Besides the prep-aration of 0D energetic nanoparticles, we focused on theconstruction of 1D twinned nanobelts, 2D nanosheets andbanana-like nanoleaves, 3D nanogrids, dendritic micro/nano-structures and hierarchical microspheres. The structures andsizes of energetic materials are easily controlled by means ofmolecular design and synthetic strategies. More emphasis isplaced on the unique properties of structure- and size-controlled micro/nano-energetic materials. The size-dependent thermal properties of several kinds of high-energyexplosives are first introduced, and then the sensitive proper-ties, such as impact sensitivity, friction sensitivity, shocksensitivity, and electrostatic spark sensitivity, are reviewed,and finally the combustion, detonation, and compaction be-haviors are also briefly presented.

Currently, the research on micro/nanomaterials based onenergetic compounds is still in its infancy, and there is a lot ofwork to do in this area. In our opinion, several research di-rections should be paid more attention in the future. Firstly, itis still necessary to develop the methods for the design andcontrollable construction of micro/nano-energetic materialswith large scale, special dimensions, desired structures andsizes [190,205e207], although some progress has been madeto date. At the same time, the development of better charac-terization methods is equally important to further understandthe nature of the nano-energetic materials at the molecularlevel. Secondly, we think that the systematic study, especiallyfor relationship between detailed structures/shapes and variousfundamental properties, should be carried out [169]. Thirdly, itis necessary to explore and improve the stability, safety andreliability of micro/nano-energetic materials [208,209]. Inaddition, as to the great potential application of micro/nano-

74 B. HUANG et al. / Defence Technology 9 (2013) 59e79

energetic materials, the micro-electromechanical systems(MEMS) has proved to be a promising direction for micro/nano-scale energetic materials with specific structures [210],and the fabrication of thin films and patterns composing of thenanostructured building blocks on solid substrates, such asglass, ceramic, and crystalline silicon, is essential for therealization of practical devices [211e214].

Acknowledgment

This work was supported by National Natural ScienceFoundation of China (21231002, 21276026, 21271023,21173021, 91022006, 11202193, 11172276, and 11072225),the 111 Project (B07012), the Program of Cooperation of theBeijing Education Commission (20091739006), and Special-ized Research Fund for the Doctoral Program of Higher Ed-ucation (SRFDP, 20101101110031).

References

[1] Jenekhe SA, Chen XL. Self-assembly of ordered microporous materials

from rod-coil block copolymers. Science 1998;279:1903e8.

[2] Whitesides GM, Grzybowski B. Self-assembly at all scales. Science

2002;295:2418e21.

[3] Tian ZR, Voigt JA, Liu J, Mckenzie B, Mcdermott MJ, Rodriguez MA,

et al. Complex and oriented ZnO nanostructures. Nat Mater

2003;2:821e6.

[4] Park S, Lim JH, Chung SW, Mirkin CA. Self-assembly of mesoscopic

metal-polymer amphiphiles. Science 2004;303:348e51.

[5] Colfen H, Mann S. Higher-order organization by mesoscale self-

assembly and transformation of hybrid nanostructures. Angew Chem

Int Ed 2003;42(21):2350e65.

[6] Yamamoto Y, Fukushima T, Suna Y, Ishii N, Saeki A, Seki S, et al.

Photoconductive coaxial nanotubes of molecularly connected electron

donor and acceptor layers. Science 2006;314:1761e4.

[7] Fardy M, Yang PD. Materials science: lilliputian light sticks. Nature

2008;451:408e9.

[8] Heo JS, Park NH, Ryu JH, Suh KD. Novel light-emitting diodes using

organic electroluminescent nanocapsules. Adv Mater 2005;17(7):822e6.

[9] Schwab AD, Smith DE, Bond-Watts B, Johnston DE, Hone J,

Johnson AT, et al. Photoconductivity of self-assembled porphyrin

nanorods. Nano Lett 2004;4(7):1261e5.

[10] Zhang YX, Liu DB, Lv CX. Preparation and characterization of retic-

ular nano-HMX. Propellants Explos Pyrotech 2005;30(6):438e41.

[11] Gagliardi FJ, Chambers RD, Tran TD. Small-scale performance testing

for studying new explosives. In: 6th VACENT technical international

conference, Milpitas, CA, United States June 4, 2005.

UCRLeCONFe212196.[12] Saw CK. Kinetics of HMX and phase transitions: effects of grain size

at elevated temperature. In: Proceedings of the 12th international

detonation symposium, San Diego, CA August 11–16, 2002.

UCRLeJCe145228.[13] Gash A, Barbee T, Cervantes O. Stab sensitivity of energetic nano-

laminates. In: 33rd international pyrotechnic seminar, Fort Collins, Co,

United States July 16e21, 2006. UCRLePROCe221604.

[14] Khasainov BA, Ermolaev BS, Presles HN, Vidal P. On the effect of

grain size on shock sensitivity of heterogeneous high explosives. Shock

Waves 1997;7:89e105.

[15] Manaa MR, Reed EJ, Fried LE, Goldman N. Nitrogen-rich heterocycles

as reactivity retardants in shocked insensitive explosives. J Am Chem

Soc 2009;131(15):5483e7.

[16] Zhang CY, Wang XC, Huang H. p-stacked interactions in explosive

crystals: buffers against external mechanical stimuli. J Am Chem Soc

2008;130(26):8359e65.

[17] Gokcınar E, Klapotke TM, Bellamy AJ. Computational study on 2,6-

diamino-3,5-dinitropyrazine and its 1-oxide and 1,4-dioxide de-

rivatives. J Mol Struct Theochem 2010;953(1e3):18e23.

[18] Kaur J, Arya VP, Kaur G, Gupta YP, Verma MM, Lata P. Determination

of solvent contamination and characterization of ultrafine HNS particles

after solvent recrystallization. Propellants Explos Pyrotech

2010;35(5):487e93.

[19] Prourmortazavi SM, Hajimirsadeghi SS. Application of supercritical

carbon dioxide in energetic materials processes: a review. Ind Eng

Chem Res 2005;44(17):6523e33.

[20] Matsunaga T, Chernyshev AV, Chesnokov EN, Krasnoperov LN. In situ

optical monitoring of RDX nanoparticles formation during rapid

expansion of supercritical CO2 solutions. Phys Chem Chem Phys

2007;9:5249e59.

[21] Frolov Y, Pivkina A, Ulyanova P, Zavyalov S. Nanomaterials and

nanostructures as components for high-energy condensed Systems. In:

Proceedings of 28th international pyrotechnic seminar, Adelaide,

Australia November 4e9, 2001. p. 311e4.

[22] Gong XC, Milic T, Xu C, Batteas JD, Drain CM. Preparation and

characterization of porphyrin nanoparticles. J Am Chem Soc

2002;124(48):14290e1.

[23] Kasai H, Kamatani H, Okada S, Oikawa H, Matsuda H, Nakanishi H.

Size-dependent colors and luminescences of organic microcrystals. Jpn

J Appl Phys 1996;35:L221e3.

[24] Li SY, He LM, Xiong F, Li Y, Yang GQ. Enhanced fluorescent emission

of organic nanoparticles of an intramolecular proton transfer compound

and spontaneous formation of one-dimensional nanostructures. J Phys

Chem B 2004;108(30):10887e92.

[25] Hu JS, Guo YG, Liang HP, Wan LJ, Jiang L. Three-dimensional self-

organization of supramolecular self-assembled porphyrin hollow hex-

agonal nanoprisms. J Am Chem Soc 2005;127(48):17090e5.

[26] Zhang XJ, Zhang XH, Shi WS, Meng XM, Lee CS, Lee ST. Single-

crystal organic microtubes with a rectangular cross section. Angew

Chem Int Ed 2007;46(9):1525e8.[27] Chaudhuri D, Li DB, Che YK, Shafran E, Gerton JM, Zang L, et al.

Enhancing long-range exciton guiding in molecular nanowires by H-

aggregation lifetime engineering. Nano Lett 2011;11(2):488e92.

[28] Chiu JJ, Kei CC, Perng TP, Wang WS. Organic semiconductor nano-

wires for field emission. Adv Mater 2003;15(16):1361e4.

[29] Al-Kaysi RO, Bardeen CJ. General method for the synthesis of crys-

talline organic nanorods using porous alumina templates. Chem Com-

mun 2006:1224e6.[30] Zhao YS, Fu HB, Peng AD, Ma Y, Liao Q, Yao JN. Construction and

optoelectronic properties of organic one-dimensional nanostructures.

Acc Chem Res 2010;43(3):409e18.[31] Cui QH, Jiang L, Zhang C, Zhao YS, Hu WP, Yao JN. Coaxial organic

p-n heterojunction nanowire arrays: one-step synthesis and photoelec-

tric properties. Adv Mater 2012;24(17):2332e6.

[32] Zhang XJ, Zhang XH, Zou K, Lee CS, Lee ST. Single-crystal nano-

ribbons, nanotubes, and nanowires from intramolecular charge-transfer

organic molecules. J Am Chem Soc 2007;129(12):3527e32.

[33] Zhang CY, Zhang XJ, Zhang XH, Fan X, Jie JS, Chang JC, et al.

Facile one-step growth and patterning of aligned squaraine nano-

wires via evaporation-induced self-assembly. Adv Mater

2008;20(9):1716e20.

[34] Kim JW, Kim JK, Kim HS, Koo KK. Application of internal

seeding and temperature cycling for reduction of liquid inclusion in

the crystallization of RDX. Org Process Res Dev 2011;15(3):602e9.

[35] Han TYJ, Pagoria PF, Gash AE, Maiti A, Orme CA, Mitchell AR, et al.

The solubility and recrystallization of 1,3,5-triamino-2,4,6-

trinitrobenzene in a 3-ethyl-1-methylimidazolium acetateeDMSO co-

solvent system. New J Chem 2009;33:50e6.

[36] Daniel MA, Davies PJ, Lochert IJ. FOX-7 for insensitive boosters.

Weapons Systems Division Defence Science and Technology Organi-

sation; August, 2010. DSTOeTRe2449.

[37] vander Heijden AEDM, Bouma RHB, vander Steen AC. Physico-

chemical parameters of nitramines influencing shock sensitivity. Pro-

pellants Explos Pyrotech 2004;29(5):304e13.

75B. HUANG et al. / Defence Technology 9 (2013) 59e79

[38] Vijayalakshmi R, Radhakrishnan S, Rajendra PS, Girish GM, Arun SK.

Particle size management studies on spherical 3-nitro-1,2,4-triazol-5-

one. Part Part Syst Charact 2012;28(3e4):57e63.

[39] Kim KJ, Kim KM. Growth kinetics in seeded cooling crystallization of

3-nitro-1,2,4-triazol-5-one in watereN-methylpyrrolidone. Powder

Technol 2002;122(1):46e53.

[40] Kim KJ, Kim KM. Nucleation kinetics in spherulitic crystallization of

explosive compound: 3-nitro-1,2,4-triazol-5-one. [J] Powder Technol

2001;119(2e3):109e16.

[41] Kim KJ. Spherulitic crystallization of 3-nitro-1,2,4-triazol-5-one in

water þ N-methyl-2-pyrrolidone. J Cryst Growth 2000;208:569e78.

[42] Kim KJ, Kim KM, Lee JM, Kim HS, Park BS, Lee JW. Scale-up of

crystallizer for producing spherical crystals of NTO. In: 31st interna-

tional annual conference of ICT, Karlsruhe, Federal Republic of Ger-

many June 27e30, 2000. p. 121/1–5.

[43] Kim KJ, Lee JM, Kim HS, Park BS. Seeded batch cooling crystalli-

zation of 3-nitro-1,2,4-triazol-5-one. In: 32nd international annual

conference of ICT, Karlsruhe, Federal Republic of Germany July 3e6,

2001. p. 125/1–7.

[44] Jung JW, Kim KJ. Effect of supersaturation on the morphology of

coated surface in coating by solution crystallization. Ind Eng Chem Res

2011;50(6):3475e82.

[45] Kim KJ, Kim HS. Agglomeration of NTO on the surface of HMX

particles in watereNMP solvent. Cryst Res Technol 2008;43(1):87e92.

[46] Nalwa HS, Kasai H, Kamatani H, Okada S, Oikawa H, Matsuda H, et al.

Fabrication of organic nanocrystals for electronics and photonics. Adv

Mater 1993;5(10):758e60.[47] Talawar MB, Agarwal AP, Anniyappan M, Gore GM, Asthana SN,

Venugopalan S. Method for preparation of fine TATB (2e5 mm) and its

evaluation in plastic bonded explosive (PBX) formulations. J Hazard

Mater 2006;137(3):1848e52.

[48] Nandi AK, Kasar SM, Thanigaivelan U, Ghosh M, Mandal AK,

Bhattacharyya SC. Synthesis and characterization of ultrafine TATB. J

Energ Mater 2007;25(4):213e31.[49] Yang L, Ren XT, Li TC, Wang SW, Zhang TL. Preparation of ultrafine

TATB and the technology for crystal morphology control. Chin J Chem

2012;30(2):293e8.

[50] Xu JJ, Tian Y, Liu Y, Zhang HB, Shu YJ, Sun J. Polymorphism in

hexanitrohexaazaisowurtzitane crystallized from solution. J Cryst

Growth 2012;354(1):13e9.

[51] Wang Y, Song XL, Song D, Jiang W, Liu HY, Li FS. Dependence of the

mechanical sensitivity on the fractal characteristics of octahydro-

1,3,5,7-tetranitro-1,3,5,7-tetrazocine particles. Propellants Explos

Pyrotech 2011;36(6):505e12.

[52] Song XL, Wang Y, An CW, Guo XD, Li FS. Dependence of particle

morphology and size on the mechanical sensitivity and thermal stability

of octahydro-1,3,5,7-tetranitro-1,3,5,7-tetrazocine. J Hazard Mater

2008;159(2e3):222e9.

[53] Lee KY, Moore DS, Asay BW, Llobet A. Submicron-sized gamma-

HMX: 1. Preparation and initial characterization. J Energ Mater

2007;25(3):161e71.

[54] Moore DS, Lee KY, Hagelberg SI. Submicron-sized gamma-HMX: II.

Effect of pressing on phase transition. J Energ Mater 2008;26(1):70e8.[55] Chen J, Qiao ZQ, Wang LL, Nie FD, Yang GC, Huang H. Fabrication of

rectangular 2,6-diamino-3,5-dinitropyrazine-1-oxide microtubes. Mater

Lett 2011;65(6):1018e21.[56] Qiao ZQ, Tang YP, Zeng GY. Study of preparation of different crystal

shape fine particle size RDX. Chin J Energ Mater 2004;12:116e8.

[57] Zhang SH, Zhang JL, Wang JY. Preparation and properties of sub-

micron nitramine explosives. In: 35th international annual conference

of ICT, Karlsruhe, Federal Republic of Germany June 29eJuly 2, 2004.

p. 100/1e4.

[58] Wang JY, Huang H, Xu WZ, Zhang YR, Lu B, Xie RZ, et al. Prefilming

twin-fluid nozzle assisted precipitation method for preparing nano-

crystalline HNS and its characterization. J Hazard Mater

2009;162(2e3):842e7.

[59] Huang H, Wang JY, Xu WZ, Xie RZ. Effect of habit modifiers on

morphology and properties of nano-HNS explosive in prefilming twin-

fluid nozzle-assisted precipitation. Propellants Explos Pyrotech

2009;34(1):78e83.

[60] Yang GC, Nie FD, Huang H, Zhao L, Pang WT. Preparation and

characterization of nano-TATB explosive. Propellants Explos Pyrotech

2006;31(5):390e4.[61] Nie FD, Yang GC, Zeng GY, Qiao ZQ, Huang H. Preparation and

properties of ultrafine TATB particles. In: 10th international semi-

nardnew trends in research of energetic materials, Pardubice, Czech

Republic April 25e27, 2007. p. 452e7.

[62] Bayat Y, Eghdamtalab M, Zeynali V. Control of the particle size of

submicron HMX explosive by spraying in non-solvent. J Energ Mater

2010;28(4):273e84.[63] Shokrolahi A, Zali A, Mousaviazar A, Keshavarz MH,

Hajhashemi H. Preparation of nano-K-6 (nano-Keto RDX) and

determination of its characterization and thermolysis. J Energ Mater

2011;29(2):115e26.[64] Teipel U, Mikonsaari I. Size reduction of particulate energetic material.

Propellants Explos Pyrotech 2002;27(3):168e74.

[65] Patil MN, Gore GM, Pandit AB. Ultrasonically controlled particle size

distribution of explosives: a safe method. Ultrason Sonochem

2008;15(3):177e87.

[66] Koo KJ, Kim KM, Lee JM. Microparticle formation of 1,3,5,7-tetranitro-

1,3,5,7-tetraazacyclooctane by crystallizations with ultrasound. In: 32nd

international annual conference of ICT, Karlsruhe, Federal Republic of

Germany July 3e6, 2001. p. 124/1–5.

[67] Sivabalan R, Gore GM, Nair UR, Saikia A, Venugopalan S, Gandhe BR.

Study on ultrasound assisted precipitation of CL-20 and its effect on

morphology and sensitivity. J Hazard Mater 2007;139(2):199e203.

[68] Bayat Y, Zeynali V. Preparation and characterization of nano-CL-20

explosive. J Energ Mater 2011;29(4):281e91.[69] Wang JY, Li JL, An CW, Hou CH, Xu WZ, Li XD. Study on ultrasound-

and spray-assisted precipitation of CL-20. Propellants Explos Pyrotech

2012;37(6):670e5.

[70] Ma CA, Sheng JF, Brandon N, Zhang C, Li GH. Preparation of tungsten

carbide-supported nano platinum catalyst and its electrocatalytic ac-

tivity for hydrogen evolution. Int J Hydrog Energy

2007;32(14):2824e9.

[71] Anal AK, Stevens WF, Remunan-Lopez C. Ionotropic cross-linked

chitosan microspheres for controlled release of ampicillin. Int J

Pharm 2006;312(1e2):166e73.

[72] Freitas C, Muller RH. Spray-drying of solid lipid nanoparticles

(SLNTM). Eur J Pharm Biopharm 1998;46(2):145e51.

[73] Mercado L, Torres PM, Gomez LM, Mina N, Hernandez SP, Lareau R,

et al. Synthesis and characterization of high-energy nanoparticles. J

Phys Chem B 2004;108(33):12314e7.[74] Wang JY, Huang H, Jiao QJ, Lei L, Hua J, Yun N, et al. Modification of

ultrafine HNS explosive by spray drying process. In: 40th international

annual conference of ICT, Karlsruhe, Federal Republic of Germany

June 23e26, 2009. p. 59/1–12.[75] Qiu HW, Stepanov V, Chou T, Surapaneni A, Di Stasio AR, Lee WY.

Single-step production and formulation of HMX nanocrystals. Powder

Technol 2012;226:235e8.

[76] Zhigach AN, Leipunskii IO, Berezkina NG, Pshechenkov PA,

Zotova ES, Kudrov BV, et al. Aluminized nitramine-based nano-

composites: manufacturing technique and structure study. Combust

Explo Shock Waves 2009;45(6):666e77.[77] Yang GC, Nie FD. Preparation and characterization of core/shell

structure of HMX/NTO composite particles. Sci Tech Energ Mater

2006;67(2):77e81.

[78] Yang GC, Nie FD, Zeng GY. Preparation of fine TATB-BTF core-shell

composite particles. Chin J Explos Propellants 2005;28(2):72e4.

[79] Jaworek A. Micro- and nanoparticle production by electrospraying.

Powder Technol 2007;176(1):18e35.

[80] Taylor GI. Disintegration of water drops in an electric field. Proc R Soc

Lond Ser A 1964;280(1382):383e97.

[81] Radacsi N, Stankiewicz AI, Creyghton YLM, van der Heijden AEDM,

ter Horst JH. Electrospray crystallization for high-quality submicron-

sized crystals. Chem Eng Technol 2011;34(4):624e30.

76 B. HUANG et al. / Defence Technology 9 (2013) 59e79

[82] Reus M, Stankiewicz A, ter Horst J, van der Heijden A. Electrospray

crystallization of encapsulated sub-micro particles of energetic mate-

rials. In: 43rd international annual conference of the Fraunhofer ICT,

Karlsruhe, Federal Republic of Germany June 23e29, 2012. p. 37/1–12.

[83] Bang JH, Suslick KS. Applications of ultrasound to the synthesis of

nanostructured materials. Adv Mater 2010;22(10):1039e59.

[84] Spitzer D, Baras C, Schafer MR, Ciszek F, Siegert B. Continuous

crystallization of submicrometer energetic compounds. Propellants

Explos Pyrotech 2011;36(1):65e74.

[85] Spitzer D, Baras C, Ciszek F, Schafer MR. Continuous crystallization of

submicron energetic compounds. In: 37th international annual confer-

ence of ICT, Karlsruhe, Federal Republic of Germany June 27e30,2006. p. 144/1e13.

[86] Stepanov V, Qiu HW, Di Stasio AR, Lee WY. Preparation and prop-

erties of nanostructured RDX/polymer compositions. In: 41st interna-

tional annual conference of ICT, Karlsruhe, Federal Republic of

Germany June 29eJuly 2, 2010. p. 26/1–6.

[87] Stepanov V, Qiu HW, Surapaneni A. Production and characterization of

novel energetic compositions by spray drying. In: 43rd international

annual conference of the Fraunhofer ICT, Karlsruhe, Federal Republic

of Germany June 23e29, 2012. p. 38/1e6.

[88] Qiu HW, Stepanov V, Di Stasio AR, Chou T, Lee WY. RDX-based

nanocomposite microparticles for significantly reduced shock sensi-

tivity. J Hazard Mater 2011;185(1):489e93.

[89] Kim JW, Shin MS, Kim JK, Kim HS, Koo KK. Evaporation crystalli-

zation of RDX by ultrasonic spray. Ind Eng Chem Res

2011;50(21):12186e93.[90] Kim JK, Jo CH, Kim JW, Kim HS, Koo KK. Preparation of RDX

particles by ultrasonic atomization. In: 13th international seminardnew

trends in research of energetic materials, Pardubice, Czech Republic

April 21e23, 2010. p. 513e7.

[91] Maa YF, Nguyen PA, Sweeney T, Shire SJ, Hsu CC. Protein inhalation

powders: spray drying vs spray freeze drying. Pharm Res

1999;16(2):249e54.[92] Kaluza S, Muhler M. On the precipitation mechanism and the role of

the post-precipitation steps during the synthesis of binary ZnOeAl2O3

composites with high specific surface area. J Mater Chem

2009;19:3914e22.[93] Engstrom JD, Simpson DT, Lai ES, Williams III RO, Johnston KP.

Morphology of protein particles produced by spray freezing of

concentrated solutions. Eur J Pharm Biopharm 2007;65(2):149e62.

[94] McGrath PJ, Laine RM. Theoretical process development for freeze-

drying spray-frozen aerosols. J Am Ceram Soc 1992;75(5):1223e8.

[95] Rigterink MD. Advances in technology of the cryochemical process.

Am Ceram Soc Bull 1972;51(2):158e61.[96] Yang GC, Nie FD, Li JS, Guo QX, Qiao ZQ. Preparation and charac-

terization of nano-NTO explosive. J Energ Mater 2007;25(1):35e47.

[97] Huang B, Qiao ZQ, Nie FD, Cao MH, Su J, Huang H, et al. Fabrication

of FOX-7 quasi-three-dimensional grids of one-dimensional nano-

structures via a spray freeze-drying technique and size-dependence of

thermal properties. J Hazard Mater 2010;184(1e3):561e6.

[98] Morel A, Nikitenko SI, Gionnet K, Wattiaux A, Lai-Kee-Him J,

Labrugere C, et al. Sonochemical approach to the synthesis of

Fe3O4@SiO2 core-shell nanoparticles with tunable properties. ACS

Nano 2008;2(5):847e56.

[99] Yi DK, Lee SS, Papaefthymiou GC, Ying JY. Nanoparticle architectures

templated by SiO2/Fe2O3 nanocomposites. Chem Mater

2006;18(3):614e9.

[100] Scheubert U, Husing N, Lorenz A. Hybrid inorganic-organic materials

by sol-gel processing of organofunctional metal alkoxides. Chem Mater

1995;7(11):2010e27.

[101] Tillotson TM, Gash AE, Simpson RL, Hrubesh LW, Satcher Jr JH,

Poco JF. Nanostructured energetic materials using sol-gel methodolo-

gies. J Non-Cryst Solids 2001;285(1e3):338e45.[102] Tappan BC, Brill TB. Very sensitive energetic materials highly loaded

into RF matrices by the sol-gel method. In: 33rd international annual

conference of ICT, Karlsruhe, Federal Republic of Germany June

25e28, 2002. p. 38/1e10.

[103] Tappan BC, Brill TB. Thermal decomposition of energetic materials 85:

cryogels of nanoscale hydrazinium diperchlorate in resorcinol-formal-

dehyde. Propellants Explos Pyrotech 2003;28(2):72e6.

[104] Clapsaddle BJ, Zhao LH, Prentice D, Pantoya ML, Gash AE,

Satcher Jr JH, et al. Formulation and performance of novel energetic

nanocomposites and gas generators prepared by sol-gel methods. In:

36th international annual conference of ICT & 32nd international py-

rotechnics seminar, Karlsruhe, Federal Republic of Germany June

28eJuly 1, 2005. p. 39/1–11.

[105] Tillotson TM, Hrubesh LW, Simpson RL, Lee RS, Swansiger RW,

Simpson LR. Sol-gel processing of energetic materials. J Non-Cryst

Solids 1998;225:358e63.[106] Tappan BC, Brill TB. Thermal decomposition of energetic materials 86.

Cryogel synthesis of nanocrystalline CL-20 coated with cured nitro-

cellulose. Propellants Explos Pyrotech 2003;28(5):223e30.

[107] Li J, Brill TB. Nanostructured energetic composites of CL-20 and

binders synthesized by sol gel methods. Propellants Explos Pyrotech

2006;31(1):61e9.

[108] Tappan BC, Brill TB. Cryogel synthesis of nanocrystalline CL-20

coated with cured nitrocellulose. In: 34th international annual confer-

ence of ICT, Karlsruhe, Federal Republic of Germany June 24e27,

2003. p. 29/1e10.

[109] Ingale SV, Sastry PU, Patra AK, Tewari R, Wagh PB, Gupta SC. Micro

structural investigations on TNT and PETN incorporated silica xerogels.

J Sol-Gel Sci Technol 2010;54(2):238e42.

[110] Ingale SV, Wagh PB, Sastry PU, Patra AK, Tewari R, Singh IK, et al.

Nanocrystalline pentaerythritoltetranitrate using sol-gel process.

Defence Sci J 2011;61(6):534e9.

[111] Nie FD, Zhang J, Guo QX, Qiao ZQ, Zeng GY. Sol-gel synthesis of

nanocomposite crystalline HMX/AP coated by resorci-

noleformaldehyde. J Phys Chem Solids 2010;71(2):109e13.

[112] Zhang J, Yang GC, Nie FD. Preparation of RDX/RF nanocomposite

energetic particles by emulsion-sol-gel technique. Chin J Energ Mater

2010;18(6):643e7.[113] Chen RJ, Luo YJ, Sun J, Li GP. Preparation and properties of an AP/

RDX/SiO2 nanocomposite energetic material by the sol-gel method.

Propellants Explos Pyrotech 2012;37(4):422e6.

[114] Pourmortazavi SM, Sefidkon F, Hosseini SG. Supercritical carbon di-

oxide extraction of essential oils from Perovskia atriplicifolia benth. J

Agric Food Chem 2003;51(18):5414e9.

[115] Pourmortazavi SM, Ghadiri M, Hajimirsadeghi SS. Supercritical fluid

extraction of volatile components from Bunium persicum Boiss. (black

cumin) and Mespilus germanica L. (medlar) seeds. J Food Compos

Anal 2005;18(5):439e46.