Wellhead Brochure_low Res

-

Upload

philip-albert-hutapea -

Category

Documents

-

view

234 -

download

0

Transcript of Wellhead Brochure_low Res

-

8/13/2019 Wellhead Brochure_low Res

1/12

Subsea wellhead systems

1

Subsea wellheadsystems

The next generation inAker Solutions wellhead family

-

8/13/2019 Wellhead Brochure_low Res

2/12

2

Subsea wellhead systems

Illustration of a subsea wellhead

-

8/13/2019 Wellhead Brochure_low Res

3/12

Subsea wellhead systems

3

Aker Solutions is a global leading supplier of engineering,

manufacturing, installation and life-of-field support of

subsea wellheads to the oil and gas industry worldwide.

We pride ourselves on delivering leading edge technology

and solutions to our customers.

Aker Solutions, in co-operation with our customers, develop

solutions that focus not only on cost efficient products and

tools, but also on optimisation of wellhead designs, drilling

and operational cost.

Aker Solutions views quality, simplicity and reliability in

design as fundamentals to the success of our business.

Our products and services include:

Wellheads

Hangers

Pac-offs

Tooling

Drilling connectors

Products and

services

-

8/13/2019 Wellhead Brochure_low Res

4/12

Subsea wellhead systems

4

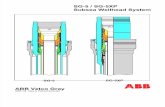

Subsea wellheads

Advanced wel lhead

technology

Aker Solutions is a world

leader in the design andmanufacture of subsea

wellhead systems

Key accreditations

Aker Solu tions holds

certificates of accreditation

for the use of American

Petroleum Institute 6A, 16Aand 17D, ISO 9001:2000and ISO 14001:2004.

Aker Solutions wellhead system is unique

amongst its peers.

It has an innovative hanger system which makes

it suitable for exploration and production in the

most extreme conditions and water depths.

The standard H4 prole wellhead complete with aVX/HX Inconel 625 gasket seal area, offers a fast,reliable well installation with exceptional load

carrying characteristics.

System features

High load capacity

Each casing load transferred directly to housingnot through single lower shoulder

Each pack-off can transfer 5.0 M.lbs loaddirectly into the housing

Total load capacity 10.7 M.lbs, the highest load capacity in the industry

Preferred load path method greatly reducesstack-up tolerances

System gives positive hanger lock down, essentialfor high temperature and production wells

Metal to metal annulus sealing system

High pressure capacity (15 000 psi)

Gas tight sealing

Does not rely on elastomer seal

Positive indication that seal is set prior to tool recovery

-

8/13/2019 Wellhead Brochure_low Res

5/12

85

Subsea wellhead systems

5

Oceanuswellhead system(ultra rapid system)

The Oceanus wellhead system is based on

Aker Solutions standard field-proven design.

This system offers sufficient flexibility to

accommodate many specific needs and

applications regardless of pressure rating,

capacity and casing programmes. It utilises

pre-configured components and standard

rental tooling package.

Oceanus is specically designed for all explorationwells in water depth applications of around 80 to800 metres (2 625 feet).

The Oceanus fast-track wellhead is suitable for themost robust drilling programmes for both exploration,

appraisal and production turn-key developments.

Oceanus is supported by a dedicated manufacturingstocking programme, which means lead times and

project risks are reduced.

Key advantages

Short delivery time (8 weeks) as

part of the RapidSolutionTM

stocking programme

Dedicated manufacturing slots

Field-proven technology

Competitively priced

Supported with global rental tools

Oceanus

rapid

Nereus

deepsocket

Triton

RLD

Pontus

drill thru

Aegir

annulus B

18 18 18 13 18

Working Pressure rating, H2S trim 15,000 psi 15,000 psi 15,000 psi 15,000 psi 15,000 psi

Gasket profile VX/HX VX/HX VX/HX VX/HX VX/HX VX/HX

Temperature rating 250F / 35F 250F / 35F 250F / 35F 250F / 35F 250F / 35F

Bending capacity* 4MM ft-lbs 4MM ft-lbs 6.7MM ft-lbs 5.5MM ft-lbs 4MM ft-lbs

M to M sealing Yes Yes Yes Yes Yes

Mandrel H4-27size H4-27size H4-27"size H4-27size H4-27"size

Single hanger load 1MMlbs 1MMlbs 1MMlbs 1MMlbs 1MMlbs

Number of hanger slots 3-4 3-4 3-5 1 3

Conductor OD size 30 36" 36" 36 30

Conductor pressure rating 2000 psi 2000 psi 2000 psi 2000 psi 2000 psi

Conductor return flow-by 26in 30.6in 133.8in & shut-off 30.6in 26in

Pre-load wellhead to conductor none none 2,000,000lbs none none

Total load capacity 10.7 MMlbs 10.7 MMlbs 10.7 MMlbs 7.4MMLBS 7.4MMLBS

Oceanus was

the god of the

world-ocean

*Note: The bending capacity limited to the actual capacity of the blow-out prevention (BOP) connector

Wellhead comparison table

-

8/13/2019 Wellhead Brochure_low Res

6/12

6

Subsea wellhead systems

Nereus wellhead system

Nereus is a deep socket wellhead system.

It utilises a simple two point contact arrangement combined with a

C-ring at the lower end of the housing. This provide transfer of theexternal bending loads to the 36 conductor pipe. Rigid lock down forthe system is not required as the system has been field-proven for

deep water applications and fatigue analysis.

It transfers loads from the hangers and bending loads from the

blow-out preventor (BOP) and riser into the 36 conductor housing.This is achieved by a two point close clearance socketing arrangementbetween the 36 housing and the 18 wellhead housing.

Nereus is capable of installing the jetting base, 36 conductor housingand conductor pipe in a single trip.

Nereus was the old man of the sea, and the god of the seas rich

bounty of harvest

Triton wellhead system

Triton wellhead system is a rigid lock down (RLD) system.

The LD system is the most robust Wellhead system within the Akersolutions portfolio.

Wellhead is pre-loaded to connector with 2 000 000 lbs RLD.

The 36 conductor housing joint provides the structural foundation forthe wellhead system. It allows the wellhead to be pre-loaded to the

conductor housing using the RLD mechanism on the wellhead.

Triton is a mythological Greek god, the messenger of the deep

-

8/13/2019 Wellhead Brochure_low Res

7/12

Subsea wellhead systems

7

85

8 85

8

Pontus wellhead system

Pontus is a drill through wellhead system.

It allows the top hole section to be drilled and the subsea tree landed,

locked and tested prior to the drilling out of the production 9 casing section.

Guideline-less and suitable for deep water application where water depth isbetween 914 to 2 286 metres (3 000 to 7 500 ft). The drill through 10 / 9 casing hanger with associated pack-offs are rated for 15 000 psi (1 030 bar)working pressure.

The drill through casing hanger can be run simultaneously with thepack-off by the single trip multi-purpose tool, or it can be run

independently by the casing hanger running tool.

The drill through casing hangers are locked in place by pack-off which is energised by weight and pressure load

The pack-off has a metal-to-metal seal for all permanently installedseals in the wellhead

Emergency seal assembly is available in case a seal cannot beestablished in the wellhead

Pontos (or Pontus) was the divinity of the sea, one of the rst born gods

Aegir wellhead system

Aegir wellhead system to monitor B-annulus.

This is achieved by the porting conguration through the 18 wellheadbody into the B-annulus section between the 13 and 9 casinghangers and pack off seals.

Flow is controlled through this porting by a 1 gate valve assemblywhich is housed integrally to the wellhead body. This valve wouldbe operated by an ROV.

The porting continues up through the wellhead body and back into thebore in a location above the 10 casing hanger pack-off seal

assembly, but below the wellhead gasket.

In production mode, with the tree installed this will allow

communication directly to the B-annulus section via the VX cavitywhen the 1 valve is opened.

Bleed down of the B-annulus section could also be carried out usingthis route.

Aegir is the king of the sea in Norse mythology

-

8/13/2019 Wellhead Brochure_low Res

8/12

85

8

Subsea wellhead systems

8

Standard casing hangers

P13 / 9 casing hanger.

The casing hanger centralises and suspends a casing stringinside the 18 wellhead housing. It also provides a sealingsurface for the pack-off assembly to isolate the casing annulus.

Features:

15 000 psi system capacity

Hanging weight capacity of minimum rated load

capacity of 3 000 000 lbs

[13 300 kN] of which 1 000 000 lbs (4 400 kN)

due to casing load

Generous ow-by

Maximum particle size 0.750 (19.05mm)

2

85

8

Optional casing hangers

13 / 9 piggyback hanger.

The piggyback hanger is used when the 13 pack-off is unable to sealdue to damage to the pack-off seal surface in the wellhead.

26, 24 and 16 sub-mud line hangers.

Used to provide additional casing string for shallow formations the

landing sub can be positioned at any position.

Casing hangers metal to metal sealing pack-off

The unique metal-to-metal pack-off has the followingdesign features:

Hydrostatic and gas testing

Forms integral part of load sharing mechanism

Gives positive lock-down for each hanger

Ensures accurate space-out for next hanger

Cannot be left in a partially set condition

All components of the pack-off can be serviced on site

Full metal-to-metal sealing

Has a lockdown capacity of 4 million lbs

Seal assembly is protected during running operations

HP/HT 15 000 psi, 250F / 35F (121C / 1C)

-

8/13/2019 Wellhead Brochure_low Res

9/12

Subsea wellhead systems

9

Wellhead system tooling

A complete range of tools is availab le for all the Aker Solutions

wellhead systems, covering requirements for shipping, installation,

test and retrieval. These tools have been developed to providemaximum reliability while minimising the number of trips.

30 / 36 drill-ahead tool

Used to run the 36 and 30 conductor joint. The tool uses left handrotation to lock the tool in the conductor joint. Right hand turn on the

drill string will release the mandrel from the drill-ahead tool allowing the

drill string to continue with drilling operations for the 20 casing string.

The main feature is saving critical path rig time.

Single trip multi-purpose tool

Used to run, set and test the casing hangers with a pack-off in a single

trip. After the casing is cemented in place, the tool hydraulically sets the

pack-off. If the pack-off should fail to hold pressure, it can be retrieved bythe tool. There is a wash-out facility within the tool, all the sealing areascan be thoroughly washed prior to setting the seal assembly.

The main features are guaranteed sealing and saving critical path rig time.

-

8/13/2019 Wellhead Brochure_low Res

10/12

Subsea wellhead systems

10

Facilities worldwide

We are present in allmajor oil and gas regions

around the world,ensuringtimely, efficient and

effective product and

service delivery.

Sales/engineering centre

Manufacturing and assembly

Service base

Additional products

18 wellhead drilling and

subsea tree connector

18 wellhead drilling and subsea

tree connector

The 18 H4 wellhead HPHT (high pressure/hightemperature) connector is eld proven with a highbending load capacity design, hydraulically

operated, metal to metal sealing VX/HX gasketprofile. It is extensively used to rigidly fasten the

BOP stack and the subsea production subseatree to the wellhead.

Features High load capacity

15 000 psi working pressure

3 000 psi / 5 000 psi function pressure

3.5 to 5.5 Mlbsf pre-load

11.5 Mlbsf leak tight capacity

Parallel connector

H4 prole

NORSOK compliant

-

8/13/2019 Wellhead Brochure_low Res

11/12

to be the preferred partner for solutions in

the energy and process industries...

Subsea wellhead systems

11

Our vision

to be the preferred partner for

solutions in the energy and process

industries...

-

8/13/2019 Wellhead Brochure_low Res

12/12

Subsea wellhead systems

12

Contact Aker Solutions:

2008 Aker Solutions

North America

3600 Briarpark drive, HoustonTexas 77042USA

Tel: +1 713 685 5700Fax: +1 713 685 5707

South America

Rua da Ajuda, 35-21 andar, CentroRio de Janeiro - RJ CEP 20.040-915BrazilTel: +55 (21) 2122 44 01Fax: +55 (41) 2122 44 02

Headquarters

Snaryveien 36, 1364 FornebuP.O. Box 94, 1325 LysakerNorway

Tel: +47 67 82 60 00Fax: +47 67 82 64 00

United Kingdom

Howe Moss Ave.Kirkhill Industrial Estate, Dyce

Aberdeen AB21 0NAUKTel: +44 (0)1224 255 000Fax: +44 (0)1224 255 100

Africa

SONILS OSCRua 6 - I.L., Boavista, Luanda

Angola

Tel: +47 51 88 87 00Fax: +47 67 82 64 00

Asia Pacific

Level 20, Menara HLA No. 3Jalan Kia Peng 50450 Kuala LumparMalaysiaTel: +6 (0) 3 2381 8388Fax: +6 (0) 3 2381 3560

Australia

4-6 Anderson PlacePerth Airport,Western Australia 6105Tel: +61 (0)8 9262 9300

![TMHFR FR BT Staxio Family [749852-040] Brochure_low Res](https://static.fdocuments.in/doc/165x107/577c7a751a28abe054954815/tmhfr-fr-bt-staxio-family-749852-040-brochurelow-res.jpg)

![TMHFR FR BT Vector Family [749618-040] Brochure_low Res](https://static.fdocuments.in/doc/165x107/577c7a751a28abe05495481f/tmhfr-fr-bt-vector-family-749618-040-brochurelow-res.jpg)

![TMHFR FR BT Optio Family [749630-040] Brochure_low Res](https://static.fdocuments.in/doc/165x107/577c7a751a28abe054954820/tmhfr-fr-bt-optio-family-749630-040-brochurelow-res.jpg)