Welds Ex 1

-

Upload

nikhil-saggi -

Category

Documents

-

view

215 -

download

0

Transcript of Welds Ex 1

-

8/6/2019 Welds Ex 1

1/4

ENG 7704 Design of Steel Structures(CAN/CSA-S16-01)

Dr. Seshu M.R. Adluri

Welding Ex.1.p

WWeellddeedd ccoonnnneeccttiioonn:: EExxaammppllee 11

Ex: Design a welded connection to carry the full tension capacity of

2PL10x200.

Solution:

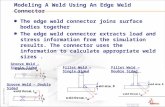

AAlltteerrnnaattiivvee 11:: AAssssuummee aa llaapp jjooiinntt aanndd ffiilllleett wweellddss aalloonngg tthhee wwiiddtthh..

DDaattaa: Fy = 345 MPa (350W Steel), Fu = 450 MPa

It is customary to choose the weld metal to have a matching strength

with plate metal. Choose E49XX electrode to match the weld metal

to the plate metal.

Xu=490 MPa (E49XX)

b = 200 mm, t = 10 mm max weld size D < t-2mm

Weld line angle with the direction of force = 90oOverlap = 50 mm (5t, 25 mm)

PPllaattee ccaappaacciittyy::

PPaatthh 11--11: Yielding of gross c/s

Tr = AgFy = resistance factor for steel = 0.9Ag = gross c/s area = bt

Tr = 621 kN

Welding practice

Han

Table 3-22, Hand

Cl. 13.2 (a)(i)

Cl. 13.1(a)

D / 2

D

D

t-2

t

Table 6-3, Handb

-

8/6/2019 Welds Ex 1

2/4

ENG 7704 Design of Steel Structures(CAN/CSA-S16-01)

Dr. Seshu M.R. Adluri

Welding Ex.1.p

PPaatthh 22--22: Rupture of net c/s. No net section for this case.

There is no shear lag effect since the ends of the plate are welded.

Hence the entire plate width receives the force uniformly.

WWeelldd ddeessiiggnn::

In the present case, the required size of the weld is unknown. We do

not know if the weld needs to be placed on both the overlap lines for

the entire width of the plate. We will assume that the weld is placed

on the full width and compute the size. If the size comes out to be

too small, we can increase the weld size and reduce the weld length.

If the weld size comes out to be too great for the thickness of the

plate, we need to increase the length of the weld by creating other

lines of weld. The welds are in fillet weld configuration.

WWeelldd mmeettaall ccaappaacciittyy::

w = 0.67Angle between weld line and applied force, = 90oWeld size, D (=?)

Total fillet weld length, Lw = 2b

Area of effective weld throat, Aw = LwD/2

Cl. 13.1 (h)

TfTf

t

b

overlap

2

2

1

1

DD

-

8/6/2019 Welds Ex 1

3/4

ENG 7704 Design of Steel Structures(CAN/CSA-S16-01)

Dr. Seshu M.R. Adluri

Welding Ex.1.p

Vr = 0.67w Aw Xu(1 + 0.5 sin1.5) > Tr of the plateVr = 0.67x0.67 (2x200xD/2) 490 (1+0.5 sin

1.5

90) =93322D > 621000

BBaassee mmeettaall ccaappaacciittyy::

Area of effective weld contact with base metal, Am = LwD

Vr = 0.67wAm Fu > TfVr = 0.67x0.67 (2x200xD) 450 = 80802D > 621000

Base metal capacity governs.

Solving, D > 7.69 mm. Use 8 mm weld (=t-2 O.K)

NNoottee: we need not have done this calculation for weld metal since for

350W steel with matching electrodes, weld metal strength governs

only if weld line angle is less than 45o

with the direction of the

applied force.

If we needed extra capacity than this, we may need to provide longer

fillet weld lines. A possible scheme is shown below.

AAlltteerrnnaattiivvee 22:: TTrryy ffuullll ppeenneettrraattiioonn wweelldd bbuutttt jjooiinntt

Weld area for both base metal and weld metal, Aw = Am = bt

Vr = 0.67w AmFu = 404.1 kN < Tr Not O.K.This complete penetration weld does not result in the required capacity

unless a longer path is provided through slots, plugs, etc.

Cl. 13.13.2.2

Cl. 13.13.2.2

overlap

TfTf

t

cp

Cl. 13.13.2.2

-

8/6/2019 Welds Ex 1

4/4

ENG 7704 Design of Steel Structures(CAN/CSA-S16-01)

Dr. Seshu M.R. Adluri

Welding Ex.1.p

AAlltteerrnnaattiivvee 33:: wweelldd jjooiinntt uussiinngg sspplliiccee ppllaatteess

Splice plates allow the main plates to be in the same plane and avoid

any eccentricity. The splice plate will have a combined area equal to the

c/s area (or greater) of the base plate. Thus the splice plates will have

enough tensile strength to carry the plate force. All calculations are as inthe case of fillet weld alternative 1. The only difference is that we need

extra plates and two extra welds of the same size. Because of the weld

size, the splice plates have to remain 10mm thick. Otherwise, splice

plates can have t/2 each. The length of the splice plate can be 50mm

similar to the lap length.

Use 2PL10x50x200 with 8mm fillet welds.

TfTf

t

88

88