W o r l d ' s DairyI W S l y CHEESE REPORTER 31, 2017 Section 1.pdf · with organizations that...

Transcript of W o r l d ' s DairyI W S l y CHEESE REPORTER 31, 2017 Section 1.pdf · with organizations that...

Small-Scale Artisan Cheese Makers Navigate Pitfalls In Getting Products To Market

Serv

ing

theWorld's Dairy Industry W

eekly

Since 1876

CHEESE REPORTER

UK Notifies EU Of Plans to Leave; Ireland’s Dairy Industry Concerned

Vol. 141, No. 41 • Friday, March 31, 2017 • Madison, Wisconsin

“The triggering of Article 50 provides us with a definitive time-frame for the UK to exit the EU and the clock is ticking. We hope this means we can move swiftly from the realm of speculation into one where real issues are being resolved,” said Ian Wright, direc-tor general of the UK’s Food and Drink Federation (FDF).

“FDF on behalf of manufactur-ers, alongside our partners across the food chain, will work tirelessly to help government to secure the best possible outcomes on future trade, access to the right work-force, regulation and ensuring a seamless border with the Republic of Ireland,” Wright added.

Earlier this week, the FDF, Brit-ish Retail Consortium (BRC) and National Farmers Union of Eng-land and Wales (NFU) issued a joint statement to government officials highlighting core objec-tives and priorities for UK trade policy.

They called on the UK govern-ment to adopt an approach that will ensure stability and continuity for agri-food and drink businesses

• See Brexit And Dairy, p. 39

March 7-9, 2017LAMBEAU FIELD ATRIUM GREEN BAY, WISCONSIN

WINNERS, SCORES, HIGHLIGHTS

Presented by the CHEESE REPORTER and the WISCONSIN CHEESE MAKERS ASSOCIATION

March 7-9, 2017LAMBEAU FIELD ATRIUM GREEN BAY, WISCONSIN

WINNERS, SCORES, HIGHLIGHTS

Presented by the CHEESE REPORTER and the WISCONSIN CHEESE MAKERS ASSOCIATION

Vermont Creamery Acquired By Land O’Lakes; LOL Brings Resources, Expertise To Spur More GrowthWebsterville, VT, and Arden Hills, MN—Bob Reese and Allison Hooper, co-founders of Vermont Creamery, and Chris Policinski, president and CEO of Land O’Lakes, Inc., on Wednesday announced that their businesses have joined forces.

Vermont Creamery, which was known as Vermont Butter & Cheese Creamery until several years ago, will become an indepen-dently operated subsidiary of Land O’Lakes, and will continue to pro-duce its award-winning fresh and aged goat cheeses, cultured butter and fresh dairy at the creamery in Websterville, VT. Terms of the transaction will not be disclosed.

• See Vermont Creamery, p. 16

Madison—Patience and persis-tence when selecting a distribu-tor, creating a return policy for damaged products, and the poli-tics of overlapping distributors are among the many hurdles cheese makers need to overcome when bringing a product to market.

In a special webinar hosted by the American Cheese Society (ACS) Wednesday, cheese mak-ers discussed how smaller produc-ers – particularly those without a sales team and limited product – can successfully navigate work-ing with distributors, packing and shipping, connecting with end customers, and common pitfalls.

Panelists included Keith Adams of Wm. Cofield Chee-semakers, Sebastopol, CA and Alemar Cheese, Mankato, MN; Sarah Hoffmann of Green Dirt Farm, Weston, MO; and Jodi

Ohlsen Read of Shepherd’s Way Farms, Nerstrand, MN.

One of the initial steps is find-ing the right distributor. Ohlsen Read said Shepherd’s Way Farms recruited its first distributor on the basis that the owner was an acquaintance and former cheese monger.

“That was an obvious choice,” she said. “Later, when one of my cheeses won an award at ACS, that was our first introduction to the national distribution world. They came to us first.”

“Otherwise, we talk and look around and see who’s represent-ing cheeses that might be in the same family – not necessarily spe-cific competitors, but who’s rep-resenting similar artisan cheese, and look at what they’re doing,”

•See Cheese To Market, p. 8

House, Senate Bills Aim To Bring Additional Transparency, Accountability To Commodity CheckoffsWashington—Bipartisan leg-islation introduced in both the US Senate and House this week aims to bring more transparency and accountability to commodity checkoff programs.

The Opportunities for Fairness in Farming Act of 2017 (OFF Act) was introduced in the Senate by US Sens. Mike Lee (R-UT) and Cory Booker (D-NJ) and in the House by US Reps. Dave Brat (R-VA) and Dina Titus (D-NV).

Under the legislation, the term “checkoff program” means a pro-gram to promote and provide research and information for a particular agricultural commod-ity without reference to specific producers or brands, including a program carried out under, among other laws, Subtitle B of the Dairy Production Stabilization Act of 1983 (which established the dairy farmer-funded National Dairy Pro-motion and Research Board) and the Fluid Milk Promotion Act of 1990 (which established the pro-cessor-funded Fluid Milk Processor Promotion Program).

According to the legislation, although the laws establishing checkoff programs broadly prohibit the use of funds in any manner for the purpose of influencing legisla-tion or government action, check-off programs “have repeatedly been shown to use funds to influence policy directly or by partnering with organizations that lobby.”

• See Checkoff Reforms, p. 33

Cheddar Exports From Ireland To UK Already Down From Last YearBrussels, Belgium—British Prime Minister Theresa May on Wednes-day officially notified the European Council of the United Kingdom’s intention to leave the European Union (EU).

This notification follows a ref-erendum held in June 2016 and starts the withdrawal process under Article 50 of the Treaty on Euro-pean Union, which sets out the procedure for a member country to withdraw from the EU.

For the EU, the first step will now be the adoption of guidelines for the negotiations by the Euro-pean Council. These guidelines will set out the overall positions and principles in light of which the EU, represented by the European Commission, will negotiate with the UK. The negotiations them-selves are expected to last approxi-mately 18 months, from early June 2017 through October/November 2018.

The talks that are about to start between the UK and EU “will be

difficult, complex and sometimes even confrontational,” European Council President Donald Tusk said today.

The UK remains a full mem-ber of the EU and all the rights and obligations of EU membership remain in force until exit. The UK government will continue to nego-tiate, implement and apply EU law during this period.

The work on Brexit is a priority for the European Dairy Associa-tion (EDA).

“The UK dairy sector is an inter-linked part of the EU dairy chain,” the EDA noted in its “EDA Dairy Flash” newsletter. “It is vital that the dairy sector continues to work on a single market/free trade basis on both sides for UK and EU milk and dairy products.

“We hope that the European Union and the UK will apply the virtues of fairness, transparency and pragmatism as guiding prin-ciples when discussing the future dairy relationship between the European Union and the UK with the clear objective to limit any potential negative impact on our sector,” the EDA added.

Cheese Contest Booklet Inside

CHEESE REPORTERPage 2 March 31, 2017

Cheese Reporter Publishing Co. Inc. © 2017

2810 Crossroads Drive, Suite 3000Madison, WI 53718-7972

(608) 246-8430 • Fax (608) 246-8431http://www.cheesereporter.com

DICK GROVES

Publisher/Editore-mail: [email protected]

608-316-3791MOIRA CROWLEY

Specialty Cheese Editore-mail: [email protected]

608-316-3793

KEVIN THOME

Advertising & Marketing Directore-mail: [email protected]

608-316-3792

BETTY MERKES

Classifieds/Circulation Managere-mail: [email protected]

608-316-3790

REGULAR CONTRIBUTORS:Bob Cropp, Neville McNaughton,

Dan Strongin, John UmhoeferYou can e-mail our contributors at: [email protected]

The Cheese Reporter is the official publication of the following associations:

California Cheese & Butter AssociationLisa Waters,

1011 Pebble Beach Dr, Clayton, CA 94517

Central Wisconsin Cheesemakers’ and Buttermakers’ Association

Janice Norwood [email protected]

Cheese Importers Association of America 204 E St. NE, Washington, DC 20002

Eastern Wisconsin Cheesemakers’ and Buttermakers’ Association

Barb Henning, Henning’s Cheese21812 Ucker Road, Kiel, WI 53042

International Dairy-Deli-Bakery Association636 Science Drive, Madison, WI 53711

Missouri Butter & Cheese InstituteTerry S. Long, 19107 Factory Creek Road,

Jamestown, MO 65046

Nebraska Cheese AssociationEd Price, Fremont, NE 68025

New York State Cheese Manufacturer’s Assn Kathyrn Boor, 11 Stocking Hall,

Cornell University, Ithaca, NY 14853

North Central Cheese Industries AssnLloyd Metzger, SDSU, Box 2104,

Brookings, SD 57007

North Dakota Cheese Makers’ AssnChuck Knetter, Medina, ND 58467

Ohio Swiss Cheese AssociationDarlene Miller, P.O. Box 445,

Sugar Creek, OH 44681

South Dakota State Dairy AssociationHoward Bonnemann, SDSU, Box 2104,

Brookings, SD 57007

Southwestern Wisconsin Cheese Makers’ Association

Myron Olson, Chalet Cheese Coop, N4858 Cty Hwy N, Monroe, WI 53566

Wisconsin Association for Food ProtectionBob Wills

PO Box 620705, Middleton WI 53562

Wisconsin Cheese Makers’ AssociationJohn Umhoefer, 8030 Excelsior Drive,

Suite 305, Madison, WI 53717

Wisconsin Dairy Products AssociationBrad Legreid, 8383 Greenway Blvd.,

Middleton, WI 53562

CHEESE REPORTER (Publication Number: ISSN 0009-2142). Published weekly by Cheese Reporter Publishing Co. Inc., 2810 Crossroads Drive, Suite 3000, Madison, WI 53718-7972; Phone: (608) 246-8430; Fax: (608) 246-8431. Subscriptions: $140.00 per year in USA; Canada and Mexico: $195.00 per year; other foreign subscribers, please write for rates. Advertising and Editorial material are copyrighted material. Any use without publisher’s consent is prohibited. Cheese Reporter does not endorse the products of any advertiser or any editorial material. POSTMASTER: If undeliverable, Form 35579 requested. Periodicals postage paid at Madison, WI. Address all correspondence to: Cheese Reporter, 2810 Crossroads Drive, Suite 3000, Madison, WI 53718-7972

there’s an ongoing federal order issue that prompts us once again to call for a thorough review, and then reform, of federal orders. That issue concerns Class I milk, or more spe-cifically, declining Class I use and rising overall milk production.

Past Issues Read this week’s issue or past issues of Cheese Reporter on your mobile phone or tablet by scanning this QR code.

The Federal Order Class I Conundrum

D I C K G R O V E S

Publisher / EditorCheese Reportere: [email protected]: @cheesereporter

EDITORIAL COMMENT

As with any federal program that dates back to the 1930s, there are plenty of problems here in the 21st century with the federal milk mar-keting order program.

We’ll cite just a couple pieces of evidence that those problems exist. First, the 2008 farm bill called for the establishment of a Federal Milk Marketing Order Review Commission, which was supposed to conduct a comprehen-sive review and evaluation of the federal order system and consider legislative and regulatory options for, among other things, simplify-ing the federal order system, and evaluating whether that system serves the interests of dairy pro-ducers, processors and consumers.

Establishment of that commis-sion was subject to the availability of funding, which never happened. Thus, the commission was never formed.

What was formed, in 2009, was USDA’s Dairy Industry Advisory Committee. In its final report, the DIAC recommended, among other things, that the secretary of agricul-ture appoint a committee to review the implications of federal orders, including, but not limited to, end-product pricing’s impact on milk price volatility and the impact of classified pricing and pooling on processing investment, competi-tion and dairy product innovation. Again, that committee was never appointed.

Those general recommenda-tions aside, there’s an ongoing federal order issue that prompts us once again to call for a thorough review, and then reform, of federal orders. That issue concerns Class I milk, or more specifically, declin-ing Class I use and rising overall milk production.

There are a couple of recent examples of what these two trends mean for federal orders, and they concern the two largest federal orders (in terms of pooled milk). The first concerns the Upper Midwest order where, starting on April 1, shipping requirements are reduced from 10 percent to

7.5 percent, with a corresponding increase in the diversion limits from 90 percent to 92.5 percent.

These adjustments were requested in late December 2016 by two separate organizations: the Upper Midwest Marketing Agency and the Central Milk Producers Cooperative.

In their nearly identical requests, the UMMA and CMPC cited the same factors: declining Class I utilization percentage, declining monthly Class I receipts, declin-ing number of distributing plants, declining fluid milk sales, rising monthly total milk production, and the burden of depooling.

This all sounds kind of famil-iar, and there’s a simple reason why. Back in June 2016, a pool handler in the Northeast federal order, Queensboro Farm Products, requested that the order’s shipping requirements for the months of September, October and Novem-ber be lowered from 20 percent to 10 percent.

In its petition, Queensboro cited, among other things, declin-ing Class I sales, rising milk pro-duction, and declining pool distributing plant numbers. And as Erik Rasmussen, Northeast market administrator, pointed out last summer, 2016 marked the fourth consecutive year in which a handler has requested to reduce the shipping percentages for the months of September, October, and November.

Just to put this Class I issue in some historical perspective, back in 1999 (the year in which USDA issued its final rule reforming fed-eral orders; that rule became effec-tive January 1, 2000), total receipts of producer milk in all federal orders was 104.5 billion pounds, 45.2 billion pounds of which, or 43.3 percent, was used as Class I.

Last year, receipts of producer milk in all federal orders totaled 133.8 billion pounds, 41.1 billion pounds of which, or 30.7 percent, was used as Class I. The numbers are pretty clear: Class I sales are declining, the Class I utilization

percentage is declining, and milk production is increasing.

The Upper Midwest and Northeast orders are the two larg-est federal orders; last year, they accounted for almost 45 percent of all milk pooled on federal orders.

Since 2000, when these orders were formed, the amount of milk used in Class I has fallen from 4.1 billion pounds to 3.4 billion pounds on the Upper Midwest order and from 10.5 billion pounds to 8.8 billion pounds on the Northeast order.

This issue is simply not going to go away for the dairy industry. But don’t just take our word for it. Here’s how Dean Foods put it in a letter opposing the UMMA and CMPC request to reduce shipping percentages on the Upper Midwest order:

“Given the trends, it is clear that the change that the Cooperatives are requesting would merely be a short-term fix to a long-term issue. Adjust-ing the shipping percentage to 7.5% may allow for more milk to be pooled on the order today. The long-term erosion in fluid milk demand — a trend that is very unlikely to change — coupled the milk production trends in Federal Order 30, a 2.5% reduc-tion in the shipping percentage will not solve the issue. While it is not a trend we as a fluid milk company like to see, fluid milk consumption will likely con-tinue to decline in the years ahead. By not addressing the root cause of this issue which is the decline in fluid milk consumption, we will continue to face this exact issue in the years ahead.”

Dean Foods also stated that, at some point, the dairy indus-try “must stop focusing in on the short-term issues and must address the long-term structural issues fac-ing the US dairy industry. Dean feels strongly that that day is cer-tainly now.”

Class I milk continues to decline in importance in federal orders, and that decline will become more pronounced if California approves its federal order. Sooner or later, the dairy industry will have to deal more permanently with this issue.

CHEESE REPORTERMarch 31, 2017 Page 3

For more information, circle #1 on the Reader Response Card on p. 54

•

•

•

•

More Cheddar Converted To Cracker Cuts & Shreds As Flavor, Convenience In DemandMadison—A larger percentage of aged Cheddar is being converted to slices, snack sizes and shred-ded blends as consumer demand requires greater convenience with more robust flavor.

Joe Widmer, Master Chee-semaker and owner of Widmer’s Cheese Cellars, Theresa, WI, started selling two-year-old Ched-dar in his retail store back in the early 1980s.

“People loved it and came back asking for more,” Widmer said. “I decided if people really like old Cheddar, they’d probably like it even more if it was older, so I started aging it out to four- and six-years old.” Now he ages it all the way up to 12 years.

“To age Cheddar out, you have to have a relationship with a banker who understands the need for a line of credit and that every time you put another batch of cheese aside, the price of milk and labor expense to make the cheese is money you have tied up until you sell it,” Widmer said.

“We have our Old School Cheddar, which is aged five years and

the aficionados enjoy it, but it is only available in limited quantities. Not every batch of

cheese is going to age out for that long, and it’s a small portion of

our inventory.”

—Nate Formalarie, Cabot Creamery

Cheddars aged two to five years are probably the most highly in demand at the retail level, he said. They already have a sharp Ched-dar flavor profile, but don’t have the cost of an eight-, 10- or 12-year Cheddar.

Convenience is also certainly a trend we are seeing, specifically in the area of cracker cuts and Cheddar slices, said Nate Forma-larie, communications manager for Cabot Creamery Cooperative, Montpelier, VT.

“People are busy and those pre-cut items make snacking and host-ing that much easier,” Formalarie said.

The cracker cut segment is up 25 percent for the latest 52 weeks ending Feb. 18, 2017 in total US All Outlets Combined.

“This trend led Cabot to make some investments around those items,” Formalarie said. “In the last year, we have brought in equip-ment to allow Cabot to package

on sandwiches and in restaurant entrees,” Dietsche said.

The application of sharp Cheddar as an ingredient in pre-pared foods and snacks has also increased, he said. And of course, everyone enjoys a nice cold pack or cheese spread crafted with nine to 12-month old Cheddar.

At the wholesale level, demand for and sale of extra sharp and vin-tage Cheddar blocks is steady and growing, Dietsche reported.

“Oshkosh has seen truckload sales of extra sharp Cheddar in the past. However, pallet quantity orders of combined ages is more common and is very good repeat business,” he said.

The cheese industry is also experiencing the resurrection of traditional bandaged Cheddars, as seen with the number of entries in

the recent United States Champi-onship Cheese Contest.

“Another trend we have seen is the increased demand for white sharp Cheddar aged two years or more,” Dietsche said. Not too many years ago – especially in the Midwest – if an inventory of super sharp white 40-pound blocks or 640s was on the floor, it would take a long time and a lot of effort to move it.

Cheddar Made Outside Wisconsin“In my opinion, the best Ched-dar in the US is produced by Wis-consin’s talented and traditionally experienced cheese makers,” Wid-mer said.

A lot of Cheddar is made out-side of Wisconsin, with some of it

• See Cheddar Usage, p. 6

cracker cuts and Cheddar slices in-house. Those new packages are launching right now.”

It’s an exciting addition that will allow us to increase Cheddar sales in the convenience segment, he continued.

Flavor is just as important as con-venience, however. For both slices and shreds at retail and foodser-vice levels, there is a trend to offer consumers more flavor, according to Stan Dietsche, vice president of sales and procurement, Oshkosh Cheese Sales & Cold Storage.

“As a result, an increase in sharp Cheddar blends and sharp Cheddar slices are showing up on the hooks in the dairy section,

CHEESE REPORTERPage 4 March 31, 2017

from our archives

50 YEARS AGOMarch 31, 1967: Des Moines, IA—Judge Roy Stephenson placed a 10-day restraining order on members of the National Farm-ers Organization here this week at a hearing on the US Justice Department’s antitrust suit filed to force the farmer group to stop coercing others to support its milk price activities.

Washington—Dairy produc-tion standards and standards now developed for cheeses are expected to be among the first published in the Codex Alimentarius. Some standards for dairy products have already been accepted by both the US and other countries.

25 YEARS AGOMarch 27, 1992: Madison—The Wisconsin budget bill that was headed for final legislative approval this week included an amendment dealing with bovine somatotropin, but did not include a controversial phosphorus discharge limit. WCMA had opposed the bill, which would have set a blanket discharge limit of one mg/L of phosphorus discharged into sur-face waters.

Ithaca, NY—A new Cornell University study looks at the impact of manufacturing costs and profits of using milk frac-tionation and concentration processes in Cheddar cheese plants. The study is fifth in a series of publications on Ched-dar manufacturing costs, and is authored by Cornell’s Rich-ard Aplin, David Barbano, and Susan Hurst.

10 YEARS AGOMarch 30, 2007: Newark, NJ—Two former executives of the new defunct cheese com-pany Suprema Specialties, Inc., were convicted this week by a federal jury of conspiracy, bank fraud, mail fraud, wire fraud and making false statements to the US SEC.

Madison—The cost and labor involved in producing traditional hooped Cheddar has caused many cheese companies to aban-don the process, despite con-sumer appreciation and demand for specialty bandaged and waxed daisies, midgets or gems. Only and handful of US companies continue to make specialty-cut Cheddar, and most in limited production.

There is a huge ruckus about fake news in the media and online these days. Each side blames the other for using it. Neither side seems to care much about their own. The search for objective truth, long the hallmark of western civilization, has devolved into the pursuit of news that proves my opinion right. In the science of discourse called Rhetoric, referred to as a logical fallacy in service of the ancient art of the foregone conclusion.

When we in the cheese indus-try see headlines proclaiming fat is bad, our dander is up. But we have no problem at all sharing articles that “prove” cheese increases our reproductive potential, cures heart attacks and prolongs life, without even reading the article or exam-ining critically the research it is based on.

The Difference between Opinion,and Validated OpinionOpinions are emotional interpreta-tions of apparent facts. We like a fact, it is true. We don’t; it isn’t. But opinions can be wrong, utterly so! What used to separate us from the folks in the dark ages was the realization that opinions are a dime a dozen.

What turns an opinion into something useful is testing it. If your opinion accurately predicts what will happen, every time, it is validated. It is real. It is knowledge you can use, something you can

W E ’ R E K I L L I N ’ I T. . .

BRINE BENEFITS:•Brandimagesecurity•Increaseshelflife•EnhanceUFmembraneperformance&life

•Cleanbreaktechnology•Continiouscontroleliminatespasteurization&shocktreatments

LISTERIAYEAST &MOLDS

CONTACT US TODAY FOR MORE INFORMATION

®[email protected] | www.bioionix.com | 608-838-0300 ext. 288

plant your flag in. Not everything in life can be validated. Part of liv-ing is learning to live with uncer-tainty. The one thing everyone who likes cheese can agree upon is it can be delicious.

The Challenge of MarketingIn the 1300s, the King of Aqui-taine, (aka Burgundy, before there was a France), decreed that only wines made in Burgundy could be sold as “Burgundy.” It seems every-one from Africa to Never-Never Land were calling their red wine burgundy. In my day it was blue point oysters, even though it was forbidden to fish them for decades due to pollution. Every restaurant had so-called Blue Point Oysters.

In our desire to sell more, we marketers overstep the bounds of truth and common sense. When we hawk our goods as if we were selling snake oil in a carnival, don’t you think consumers perceive it, eroding their trust?

If you want to go out and vali-date whether or not eating cheese increases your potency, good luck with that. As food people, aren’t we better served by marketing based on what William Faulkner called “the old verities and truths of the heart, the old universal truths lack-ing which any story is ephemeral and doomed - love and honor and pity and pride and compassion and sacrifice,” and flavor?

The Real Moos: FlavorLife is not a dubious demographic study. We lose using fake moos. But we win on taste, especially

C h e e s e m a r k e t i n g P r a c t i c e

Fake Moos

Dan StronginASQ CMQ/OEUncorporate Consultant

if our products have some. At the dawn of Western Civilization Hip-pocrates, the father of modern medicine, laid it down as clear as a bell: (transcribed into hip Eng-lish), he advised we eat a variety of foods and not more than we need, and shake our booties with regular-ity. A simple universal truth and the pleasure of sharing food with friends. Who doesn’t smile think-ing of it?

The fixation on proving a single food is good or bad is silly, but, in marketing, it can be fatal. Com-merce in food should be based on trust. Food is the most intimate of things we sell, truly, the oldest pro-fession. People welcome our prod-ucts into their families and feed them to their children, and each other, and they are dependent on food to live.

What the Green Grocer KnewIn my childhood, every neighbor-hood had a Green Grocer. She was that guy or gal who let you pay on Friday for the food you bought today. The one who always winked at the kids, and gave a slice of apple. You could trust him.

Then, one day, a marketing executive read some stuff about cholesterol and entered into a panic. “We have to let people know our oils contain no choles-terol or we will lose our business,” he thought. So he put a statement on their label: Contains no Cho-lesterol.

What is the problem? Since Creation vegetable oils contain no cholesterol. Only foods from ani-mal sources do. When people fig-ured this out, they felt misled, the first in a long line of bogus health claims that rapidly deteriorated the bond of trust between the public and those of us who supply their

• See Strongin, p. 5

For more information, circle #2 on the Reader Response Card on p. 54

CHEESE REPORTERMarch 31, 2017 Page 5

StronginContinued from p. 4

their food. I do not drink a cold drink on a hot day because it sup-ports my immune system. I do not even know what that means. I am thirsty, it is cold, and it tastes good!

Trust is the most powerful tool in marketing. It builds loyal cus-tomers, the most lucrative of all, because they come back and seek out your products over and over again, and convince others to try it as well. But it is like a glass key, turn it too hard in the lock, and it breaks. (thank you, Dashiell Ham-mett.)

If we sell on fear, opinion, or the promise of magic pill nutri-tion, we risk breaking the glass key. But selling on flavor, enjoyment, enrichment, and the plea. DS

When searching for the latest technology and design know how for process

plant solutions, processors look to RELCO. Our range of those solutions

has broadened since RELCO teamed up with Technopak Limited of New

Zealand as The USA Distributor for their high speed automated Dry Powder

Packaging Systems.

25kg bagging at 1 - 10 bags per minute

Innovative and reliable hygienic seals

Accurate weight control

Pre and post bag fill gassing options

Design flexibility to meet the needs of any plant

USDA and 3A sanitary design

Modular design

Small footprint

Backed by RELCO’s process, installation and service integrity

To keep up with the latest in process advancements, keep looking to RELCO.

P E R F O R M A N C E D E R I V E D F R O M

Innovative Technologies for

Food Processing Equipment

T H E R E L C O ® A D V A N T A G EUSA | The Netherlands | New Zealand | Brazil | +1 320.231.2210 | www.relco.net

SANITARY PACKAGING SYSTEMS

US Regulatory Agencies Need To Prepare For Greater Quantity, Range Of Biotech ProductsThe Number of New Products Has Potential To Overwhelm AgenciesWashington— A profusion of bio-technology products is expected over the next five to 10 years, and the number and diversity of new products has the potential to overwhelm the US regulatory sys-tem, according to a recent report from the National Academies of Sciences, Engineering, and Medi-cine.

The US Environmental Pro-tection Agency (EPA), the Food and Drug Administration (FDA), the US Department of Agricul-ture (USDA), and other agencies involved in regulating biotechnol-ogy products should increase their scientific capabilities, tools, and expertise in key areas of expected growth, said the committee that conducted the study and wrote the report.

The United States biotechnol-ogy economy is growing rapidly, with the scale, scope, and com-plexity of products increasing.

More types of organisms will likely be engineered, the report noted, and the kinds of traits intro-duced with biotechnology will also increase.

Some future biotechnology products are likely to use genome-editing techniques such as CRISPR for familiar applications, such as modifying agricultural crops, the study reported.

Other future products are expected to be entirely new — plants that can serve as sentinels of environmental contamina-tion, for example, and collec-tions of microorganisms that can produce chemical compounds efficiently.

Engineered microbes, plants, and insects designed to live in the environment with little or no human management are likely to be more common. With few exceptions, products such as these have not yet been evaluated by the current regulatory system, the report said.

Current staffing levels, exper-tise, and resources available at Environmental Protection Agency, FDA, US Department of Agriculture and other agencies may not be sufficient to address the expected scope and scale of future biotechnology products, the study reported.

It is critical that the agencies involved in regulation develop and maintain scientific capabilities, tools, and expertise in key evolv-ing areas.

Examples of such areas include understanding relationships between intended genetic changes and an organism’s observable

traits, the unintended effects of genetic changes on target and non-target organisms, predicting and monitoring ecosystem responses, and quantifying the economic and social costs and benefits of bio-technologies.

To respond to the expected increase and diversity of products, the agencies should develop risk-analysis approaches tailored to the familiarity of products and the complexity of their uses, the report said.

For biotechnology products that are similar to products already in use, established risk-analysis meth-ods can be applied or modified, and a more expedited process could be used.

For products that have less-familiar characteristics or more complex risk pathways, new risk-analysis methods may need to be developed.

Regulatory agencies should build their capacity to rapidly determine the type of risk-analysis approaches most appropriate for new products entering the regulatory system, the study reported.

The Food and Drug Adminis-tration, Environmental Protection Agency and the US Department of Agriculture should identify products that could serve as pilot projects to develop new approaches to assess risks and benefits and to inform regulatory decisions, the report said.

Pilot projects could also be used by the agencies to evaluate future products as they move from labora-tory scale, to field- or prototype-scale, to full-scale operation, the study reported.

One challenge regulators will face is finding jurisdiction under existing statutes to regulate the diverse range of anticipated bio-tech products, the report said.

The current collection of stat-utes and regulations that provide the basis for agencies’ oversight, known as the Coordinated Frame-work for Regulation of Biotechnol-ogy, appears to have considerable flexibility to cover a wide range of biotechnology products, the study reported, but in some cases the agencies’ jurisdiction has been defined in ways that could leave gaps or overlaps in regulatory over-sight.

At times, Food and Drug Administration, Environmen-tal Protection Agency, and the USDA may need to make use of the flexibility under their statutes to minimize gaps in jurisdiction, the report said.

Even when statutes do allow agencies to regulate products, the current statutes may not ade-quately equip regulators with the tools to regulate the products effec-tively, the committee said.

For example, the statutes may not empower regulators to require product sponsors to share in the burden of generating information about product safety, and may place the burden of proof on regu-lators to demonstrate that a prod-uct is unsafe before they can take action to protect the public.

This implies that adequate fed-eral support for research will be crucial to protect consumer and occupational safety and the envi-ronment.

Biotech products on the horizon are likely to generate substantial public debate, the report notes. Many members of society have concerns over the safety and ethics of various biotechnologies, while others see prospects for biotech-nology addressing social or envi-ronmental problems.

CHEESE REPORTERPage 6 March 31, 2017

For more information, circle #4 on the Reader Response Card on p. 54

Cheddar UsageContinued from p. 3

destined for a mild to medium-plus application, Dietsche agreed.

“What is also happening over the years is an increase in Ched-dar made outside the Dairy State that ages very well and is enjoyed by consumers across the board,” he continued.

As a cooperative of New Eng-land and New York farmers, we are quite focused on making sure our 1,100 family farms have a home for their milk and ensuring the highest quality cheese and dairy products are made from that milk, Cabot’s Formalarie said.

“Wisconsin is obviously a big cheese state, but we don’t have much insight there,” he contin-ued. “We can say Vermont and New York Cheddar sales are grow-ing steadily along the Eastern Sea-board.”

In the last year there has been quite a bit of press about a ‘cheese glut’ in the US, Formalarie said.

“Much of this is slightly over-blown as much of that cheese is in storage aging. We can’t comment on other companies, but from where Cabot sits we are happy with our inventory levels of our naturally aging cheeses,” he said.

Currently, there’s an adequate inventory of aged Cheddar to sat-isfy demand for high-end shreds and slices, Dietsche added. At the wholesale level, Oshkosh Cheese alone is storing about 10 loads of seven- to eight-year colored Ched-dar.

The price of fresh or current Cheddar is still based on the mar-ket, plus some kind of premium, and margins can be slim, he said.

“With the vintage Cheddar, there’s a better return to reap,” he said. “But you still need to leave room in your sell cost for every-one in the supply chain to make a profit.”

Formalarie said the volatility in the market is part of the reason why Cabot is making investments in its creameries to make them more efficient and process more milk.

“The price of milk is hurting our farm families. We work to bring as much of their milk as possible into our creameries so we can turn it value-added Cheddar and dairy products,” he said.

The benefit to the farms in our co-op is that at the end of the year, Cabot returns all profits from Cheddar sales to the farms, he con-tinued.

Over the past few years, people

Nutricepts, Inc. T: 952-707-0207E: [email protected]

Nutricepts, Inc.

CrystalBanTM allows for a more precise management of moisture levels. This allows you to convert blocks into thinner cheese slices and longer shreds without fracturing the cheese.

More precise management of moisture levels No visible crystals No effect on taste Better Slicing and Shredding characteristics Increased resistance to fracture

ConvertabilityCrystalBanTM Enhances The

Quality & Body of Your Cheese

seem to be willing to pay a higher price for aged artisan Cheddar, Widmer said.

However, because older Ched-dars are still more costly, demand for less aged commodity Cheddar remains greater, he added.

“Also, more and more cheese makers are aging out Cheddars, and this makes the Cheddar more available to high-end retailers,” he said.

What Makes A Great Cheddar?As people continue down the path of Cheddar and are exposed to older Cheddars, their palates soon crave the five-year Cheddar, For-malarie said.

“We have our Old School Cheddar, which is aged five years and the aficionados enjoy it, but it is only available in limited quanti-ties. Not every batch of cheese is going to age out for that long, and it’s a small portion of our inven-tory,” he said.

We find somewhere between 10 and 18 months to be the most pop-ular amongst your average Ched-dar consumer.

Cabot Seriously Sharp is aged that long and is our best seller, For-malarie said.

According to Dietsche, most sought after Cheddar remains to be five-year colored Cheddar and white Cheddar. However, requests for six-year and older is on the rise.

“And though it’s not usually a large order, it does become the plus sale and is appreciated,” he con-tinued.

It All Starts On The FarmHigh quality Cheddar starts with high quality milk, Formalarie stressed. Our farmers work hard

to deliver the highest quality milk and our employees in turn take great care in turning that milk into award-winning Cheddar.

“To age Cheddar out, you have to

have a relationship with a banker who

understands the need for a line of credit and that every time you put another batch of cheese aside, the price of milk and labor expense to make the cheese is

money you have tied up until you sell it.

—Joe Widmer, Widmer’s Cheese Cellars

“Each step of the process is a delicate balance of art and sci-ence,” he said. “A lot of care goes into our products, but at the end of the day, you can’t make quality cheese if you don’t start with qual-ity milk.”

We believe that there is no ‘ideal’ Cheddar profile, so our goal in the end is to have a cheese that is free of defects and show-cases a near perfect example of the extra sharp style of Cheddar which has yielded Cabot every major award for taste, Formalarie continued.

Using old-fashioned techniques and recipes is the key to making a great aged Artisan Cheddar, Wid-mer concluded.

Colleagues Celebrate The Retirements Of Leetz And Voermans From Kraft/Heinz

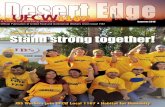

Green Bay, WI—With the announcement of their retirement from Kraft/Heinz, fellow co-workers throughout the 38 and 37 years of Donna Leetz and Jeff Voermans, respectively, gathered at Lambeau Field to honor their cheese industry colleagues. Leetz began with Kraft in 1980. Her career with Kraft started in whey management. From there she acquired responsibilities focused on planning how much bulk cheese of every type, Kraft needed to keep cheese conversion lines running at multiple Kraft plants and Kraft co-manufacturers. Voermans began his career at Kraft in Green Bay in 1979. The Kraft cheese procurement team was headquartered in Green Bay. The procurement team was supported by a “Cheese Production Technology” team, which of which Voermans was a member. This team worked with cheese suppliers to make the cheeses that Kraft desired.In the first row, from left to right are: Divya Reddy, John Scott, Dwight Krampien, Jeff Hal-let. In the middle row, from left to right are: Donna Leetz, Steve Ludy, Debbie Stanke, Mary Deneys. In the back row, from left to right are: Kirk Baldwin, Mike McCully, Marv Kovac, Jeff Voermans, Dan Huntley, Dave Volesky

CHEESE REPORTERMarch 31, 2017 Page 7

www.apt-inc.com | 877-230-5060 | Minnesota | Idaho | California

Advanced Cheese Vat (ACV)With 3 US patents, the Advanced Cheese Vat (ACV) is a signature piece of cheese equipment manufactured by APT. The patented agitator design is robust, yet gentle to allow for performance second to none with the highest quality, curd consistency, and yield customers expect and demand. APT’s Automation and Controls are designed and supported with the �exibility all cheesemakers appreciate.

Advanced Dosing System (ADS)APT’s Advanced Dosing System (ADS) is designed for accurately metering ingredients such as rennet, calcium, and color. The ADS is customized to

customer speci�cations for one or more ingredients and is CIP-able with no need for disassembly.

Advanced Finishing Vat (AFV)APT’s enclosed �nishing table, the Advanced Finishing Vat (AFV) was designed for customers that manufacture a large variety of cheeses. Multiple recipes allow for high moisture washed curd styles as well as low moisture cheeses. Automatic and semi-automatic salting systems are available. APT’s Automation and Controls allow for reduced labor, consistency and highest product quality.

Advanced Cheese Packaging (ACP)All of APT’s Advanced Cheese Packaging systems are customized. APT’s

experienced sta� will work with you on a bulk packaging system tailored to your speci�c process. APT’s Automation and Controls provide for con-

sistent and timely output of product for reduced labor.

Make your next move the right one.Providing customers with high quality cheese making equipment proven to

produce higher yields and higher consistency with higher pro�ts.

Advanced Process Technologies, Inc. serves the Dairy & Food Industry with plant concept,

design, process, electrical and mechanical engineering; along with equipment manufacturing and complete installation. We are committed to design, fabricate,

and install the best system possible for your new or existing facility.

April 4 - 6, Booth #2803 April 12, Booth #928

CHEESE REPORTERPage 8 March 31, 2017

The Specialty Cheese market is booming! Cheese is considered an indulgence and gaining popularity as a healthy snack.

CSK, with our knowledge and range of world-class cultures, can help you take advantage of this trend. Using your existing process, we will create Specialty Cheeses that meet consumers’ desire for distinctive fl avors and gourmet-quality cheese.

Go Special at BOOTH # 325

Your Ideas, Your Process, Our Cultures!

www.cskfood.com

Take the challenge! Together we will create Specialty Cheeses that make your business grow. Visit us to taste the possibilities.

Cheese To Market(Continued from p. 1)

Ohlsen Read said.It’s also important to talk with

other cheese makers and see if they’re happy with their distribu-tors, she said. If so, you can request a meeting and take it from there.

We found the Meet the Chee-semaker event at the ACS confer-ences has been an invaluable way for us to meet distributors, Hoff-mann added.

“The cost of me doing the work that a distributor would do would be equal to the amount I would spend by using a distributor.”

—Jodi Ohlsen Read, Shepherd’s Way Farms

“It’s sort of a courtship in a way,” Adams said. “You cannot will a distributor to work with you. They literally have to decide they want to sell your cheese, and there’s no amount of convincing.”

“You can give them all the information about pricing and tell them what you’re willing to do for them, but in the end, they have to make that decision,” he said.

Except for one instance where I cold-called a distributor and they said “yes” right away, it’s been an ongoing process of building up a relationship and having them commit to carrying your products, Adams said.

“We’ve had good results, and I would advise patience and persis-tence,” he continued.

It really is about the relation-ship, Ohlsen Read said. It’s not something you can force.

Regarding the expenditure of employing a distributor, Ohlsen Read said the move is cost-effec-tive.

“The cost of me doing the work that a distributor would do would be equal to the amount I would spend by using a distributor,” Ohlsen Read said.

As a rule of thumb, using a dis-tributor typically means a 15 to 20 percent mark-up from what we’re selling the cheese for, Adams said. A $10 piece of cheese would be sold at distribution for $11.50-$12.50.

If distributors are coming to you with a refrigerated truck, how cheese is packaged isn’t really an issue, Adams said.

“You basically have to put it in boxes that will keep the cheese safe,” he said. “That’s the easiest way of getting our cheese from point A to point B.”

If you’re shipping though UPS or FedEx, then you have to fig-ure out if you’re going to purchase pre-made Styrofoam containers or make something up yourself, Adams said.

For distributors, many want a consistent box and case size for cheese, Ohlsen Read added. Spe-cific case size can go into a distrib-utor’s database and can help with tracking.

“A lot of them will also need to know the number of pieces in a case, what is the size, and what’s the outreach price range,” she said.

Some distributors also require universal product codes (UPC).

“We only put UPCs on cheeses that are going to a distributor that requires them, because it’s an extra

step and more work,” Hoffmann said.

“We also have some distributors who require case UPCs, so again – more work and we only do it if the distributor requires it. We’re set up for UPCs for all of our cheeses – individual UPCs as well as case UPCs,” Hoffmann said.

Right now, we’re not using any UPCs, Adams said. Whoever we’ve been working with has done it themselves. However, if there’s incentive to do it, we will.

Devising A Return Policy For Damaged CheeseIf cheese makers have a distributor that’s taking product far from their manufacturing facility, companies may often have to deal with prod-ucts that don’t arrive in optimum condition and need to devise a return policy.

“We don’t have a lot of prob-lems with that, even though we’re sending soft-ripened cheese across the country,” Adams said. “We’ve had pretty good luck.”

In a case where something might have gone wrong, we tend to err on the side of crediting right off the bat, Adams said. If it becomes a persistent thing, we have to do something else.

“For the most part, if it’s a bad outcome, we’ll eat it a time or two,” he said.

Shepherd’s Way has a similar approach. In the beginning, one of our cheeses was very soft and we had to change the way we pack-aged it, Ohlsen Read said. The boxes we were using simply didn’t protect the cheese enough.

Once it didn’t arrive a couple of times in proper shape, that was a key to us that we had to make a change in our packaging, she said.

“It’s not common for cheese to arrive damaged, especially when using a distributor,” Ohlsen Read said. “If something does happen, the customer is always right. You take it back, and go forward from there.”

Green Dirt Farm also tries to investigate what happened as much as possible – why the failure and damage to the cheese, Hoff-mann said. We also ask the cus-tomer to send us the lot number of the cheese, and take pictures if possible if it arrived in the shipping container damaged.

“Those are all really help-ful when investigating so we can quickly correct the problem and move forward, Hoffman said.

Politics of Overlapping Distributors In Same RegionThe politics of overlapping dis-tributors can be tricky. Shepherd’s Way initially never wanted to have more than one distributor in one region because it didn’t seem fair, Ohlsen Read said.

“There are times...when we’d get written

up or win an award and we’d think the phone

would start ringing and never stop. That is not the case. You have to go out and earn the

business, you have to make cheese, you have to tell the story, and

you have to keep at it every day.”

—Keith Adams Wm. Cofield Cheesemakers

“Sometimes, distributors get purchased by other distributors or they expand and the distribu-tor that once had one region may suddenly be overlapping another distributor’s region,” she said.

We have some arrangements where they have exclusives – particularly in our home region, she said. In other places, I think some of our distributors are very understanding that those regions sometimes shift and suddenly they overlap.

“It’s a careful dance,” she con-tinued.

Green Dirt operates in much the same way, in the sense that initially, when we first establish a relationship with the distributor, we try really hard to make sure that there’s not overlapping sales, Hoff-mann said.

“It’s not always possible, and sometimes it happens inadver-

• See Cheese To Market, p. 20For more information, circle #6 on the Reader Response Card on p. 54

CHEESE REPORTERMarch 31, 2017 Page 9

Expansion, Just Two Years After Plant Opened, Will Increase Filling Capacity, Expand Product VarietiesVerona, VA—Shamrock Farms this week announced the expan-sion of its milk processing facility in Verona (Augusta county), VA.

The expansion, which is expected to be completed by late 2018, comes just two years after the facility opened its doors and will more than double its produc-tion capacity.

The plant expansion will sig-nificantly increase filling capac-ity and expand product varieties, sizes and formats, Shamrock Farms said. Among the technology addi-tions is the ability to produce shelf-stable products using convenient plastic single-serve bottles, which the company said makes it one of only a handful of dairy brands in the US with the capability.

“As a company we’re always looking for ways to grow and inno-vate,” said Ann Ocana, chief mar-keting officer at Shamrock Farms. “The expansion gives us the capac-ity and the technology to meet growing demand, expand our offer-ings and propel milk-based bever-ages into the future.”

Shamrock Farms’ products are available in more than 50,000 quick service restaurants and 36,000 grocery and convenience stores across the US. The exist-

ing product portfolio includes the Shamrock Farms ready-to-drink mmmmilk line and Rockin’ Refuel protein beverages.

Also, the company recently launched Cold Brew Coffee and Milk, capitalizing on the rapid growth of the ready-to-drink cof-fee category.

Shamrock Farms is invest-ing more than $40 million into the project, and will receive a $400,000 performance-based grant from the Virginia Investment Part-nership (VIP) program, along with a $400,000 grant from the Gov-ernor’s Agriculture and Forestry Industries Development (AFID) Fund, administered by the Vir-ginia Department of Agriculture and Consumer Services.

The expansion will cre-ate more than 70 new jobs in Augusta county, and once com-pleted Shamrock Farms will employ more than 120 people at that location.

“We’re thrilled to be expand-ing just two years after opening our doors in Virginia,” Ocana said. “We’re poised for further growth and product innovation, and are thankful for our employees and the support we’ve received from the community and the Common-wealth.”

“Shamrock Farms has become an incredible asset to the agriculture economy in the Shenandoah Val-ley,” said Basil Gooden, Virginia’s agriculture secretary. “Shamrock’s

Shamrock Farms Announces $40 Million VA Expansion; Will More Than Double Capacity

PlateCheck™

SEEING IS BELIEVING™

lateChecChecC kSEEING IS BELIEVING

FRAME CONDITION

PIN HOLES

GASKET CONDITION

PLATE CORROSION/

WEAR

CIP RESPONSE

www.agcheattransfer.comEASTERN

10129 Piper Lane I Bristow, VA 20136703.257.1660 I 800.825.8820

WESTERN9109 SE 64th Ave. I Portland, OR 97206

503.774.7342 I 800.715.8820

CENTRAL8400 Lakeview Pkwy, Suite 700 I Pleasant Prairie, WI 53158

847.301.6890 I 888.489.8820

Building the Best,Servicing the Rest

THE ALL INCLUSIVE TESTThe PHE inspection that fully meets 3A Sanitary Standards. We assess CIP response and the condition of plates, gaskets, and frame making PlateCheckTM the most comprehensive testing method available. Done right the first time.

• Pinpoint specific plates which are leaking.• Report provided with a grade for each area inspected and recommended action.• Helps with accurately budgeting for repairs and replacement costs.

For more information, circle #7 on the Reader Response Card on p. 54

continued investment in Virginia, and commitment to quadruple the amount of milk purchased from Virginia farmers, is evidence of the company’s intent to be a long-term corporate citizen and partner in agriculture.”

“Virginia has established itself as a leader in the food and bever-age sector, and Shamrock Farms’ rapid growth in just two years in the Shenandoah Valley is a testa-ment to Virginia’s business advan-tages and dominant standing in this thriving industry,” said Vir-ginia Gov. Terry McAuliffe.

“Since 2007, food and bever-age companies have announced plans to invest more than $2.25 billion and create 7,500 new jobs in Virginia,” said Todd Haymore, Virginia’s secretary of commerce and trade.

“Shamrock Farms is a corner-stone in Mill Place Commerce Park and a strong asset to the agri-cultural community of the Com-monwealth,” said Tracy Pyles, chairman of the Augusta County Board of Supervisors. “As exclu-sive purchasers of milk through the Maryland/Virginia Milk Produc-ers Cooperative, Shamrock Farms supports our dairy farmers and provides high-tech manufacturing jobs to our citizens.”

Shamrock Farms, which has facilities in both Arizona and Vir-ginia, is a division of Shamrock Foods Company, a family-owned and -operated business founded in 1922 in Tucson, AZ.

For more information, visit www.shamrockfarms.net.

Americold Breaks Ground On Expansion Of Clearfield, UT, SiteAtlanta, GA—Americold has offi-cially broken ground in Clearfield, UT, to expand its site there.

The project will add 6.5 million cubic feet of temperature-con-trolled warehouse space to Ameri-cold’s current 11.2 million cubic foot facility on the site.

Americold’s new building will feature ammonia-free, self-con-tained, refrigeration units with no engine room requirement. The system offers significant energy efficiency gains, zero water usage, and is air-cooled, the company said.

“We are excited to be able to provide the additional capacity in Salt Lake City that our customers have requested. The new build-ing should be operational in time for our peak volumes during the fourth quarter of 2017,” said Fred Boehler, Americold’s president and CEO.

Americold is a global leader in temperature-controlled warehous-ing and logistics to the food indus-try.

Based in Atlanta, GA, Ameri-cold owns and operates over 165 temperature-controlled ware-houses, with more than 1 billion cubic feet of storage, in the US, Australia, New Zealand, China, Argentina and Canada. Americold serves more than 2,500 custom-ers and employs 11,000 associates worldwide.

CHEESE REPORTERPage 10 March 31, 2017

E-mail: [email protected]

Canada Should Use Supply Management For Dairy As Bargaining Chip In New NAFTA TalksMontreal, Quebec—With the US on the verge of reopening the North American Free Trade Agreement (NAFTA), Canada should seize this opportunity to open its dairy and other agricultural markets, and in return ask for full access to US markets for its softwood lumber, according to an “Economic Note” published recently by the Montreal Economic Institute (MEI).

Supply management will “in all likelihood” be at the heart of the next trade negotiations between the US and Canada, the note pre-dicted.

A US government document points out, among other things, the grievances of US producers with regard to this system, which governs the marketing of dairy, eggs and poultry by establishing production quotas and import tar-iffs, and by fixing prices.

Tariffs in particular are a source of friction, as they triple or quadru-ple the price of certain commodi-ties, thereby closing the Canadian market to US producers for all practical purposes, the note said.

“Canadian farmers also lose under supply management, since it deprives them of access to billions of consumers around the world, which means that they have not been able to benefit from increased

global food consumption over the past decade,” the note stated.

When it comes to milk, Can-ada’s current production level is comparable to what it was in the 1960s, the note pointed out. Demand for dairy products in developing countries is expected to grow over the coming years, but supply management will prevent Canadian producers from benefit-ing from this growth.

Further, the funds required to purchase quotas limits the ability of farmers to invest in their facili-ties and equipment to increase the productivity of their farms, accord-ing to the note. For example, a British Columbian dairy farmer has to pay $43,000 (US$32,470) just to acquire the right to produce and sell what corresponds to the production of approximately one cow, even before owning a single animal.

In Quebec, where the price of quotas is fixed at $24,000 (US$18,123), these production permits represent 42 percent of the value of the average dairy farm, the note said.

“Supply management, by con-tributing to underinvestment in farms, thus traps producers in a vicious cycle,” the note stated. “Paradoxically, the low produc-

tivity of certain farms is used to justify the maintenance of this sys-tem, whereas it is itself responsible for the situation. Yet larger farms would allow Canadian producers to be more productive and more competitive on local and global markets.”

Because the prices of prod-ucts under supply management are determined by the costs of production, the low productivity of small farms also increases the retail price of these foods, the note said. Although direct subsidies for Canadian producers were abol-ished in the early 2000s, keeping prices artificially high represents an indirect subsidy for producers. It is therefore Canadian consumers who “subsidize” these farmers.

The abolition of Canadian dairy quotas should be conditional on the elimination of US subsidies, the note said.

A US producer receives the equivalent of 7.46 cents for each liter of milk produced, which rep-resented 15 percent of total gross revenue in 2015.

According to the note, the US Department of Commerce is cur-rently evaluating the possibility of imposing tariffs on Canadian soft-wood lumber imports that could go as high as 25 percent. Under the last softwood lumber deal, which was in effect from 2006 to 2015, a tax was applied to Canadian soft-wood lumber when its price fell below a certain level.

US farmers’ access to Canadian sectors under supply management would open up for them a market with revenues for production and processing that total over $36 bil-lion (US$27 billion), two-thirds of which comes from the dairy sector.

One study estimates that the complete, immediate abolition, with no financial compensation, of supply management would put

Processing & Packaging Equipment

The IVARSON 640 BLOCK CUTTING SYSTEM is the newest develop-ment from IVARSON in the cheese packaging industry. Designedspecifically for feeding today’s high output cutting, slicing and shredlines, the 640 BCS is designed with simplicity and sanitation in mind.IVARSON’s reputation for quality assures you the equipment isconstructed with quality materials that stand up to the harshestenvironment, and the equipment is backed by the best service and guarantee in the business.

ADVANTAGES- Process a 640 pound block in less than 4 minutes

- Cuts bars and loaves with consistent width and height with no trim

- Automated system, requiring only one operator to lad the block

- Cut slabs from 1.5 inches to 7 inches, accurate to a thirty second of an inch

- Quick change cutting harps allow multiple formats on same production run

THE IVARSON640 BCS

Milwaukee, Wisconsin

A CUT ABOVETHE REST!

Visit us on line and see the IVARSON 640 BLOCKCUTTING SYSTEM in action at www.ivarsoninc.com/640cutter.php

www.ivarsoninc.com

The IVARSON 640 BCS will deliver loaves and bars to your slice andchunk lines with consistent dimensions without any trim. This meanshigher efficiency, better yield and increased thru-put for your production lines. Consider the IVARSON 640 BLOCK CUTTING SYSTEM to improve your efficiency.

For more information, circle #9 on the Reader Response Card on p. 54

40 percent of Canadian dairy pro-duction at risk, which could cause the disappearance of from 4,500 to 5,000 farms. This is due to the much smaller size of Canadian farms, which entails relatively higher operating costs than in the US.

“Such a scenario is excessively pessimistic since a period of tran-sition, including financial com-pensation for the value of quotas, would allow dairy producers to increase the size of their farms and thus reduce their operating costs,” the note said.

Certain farmers could indeed decide to cease their activities after having received compensation, the note continued.

The prospect for growth, how-ever, will be more favorable for those who remain.

The liberalization of the dairy industry would thus lead to an increase in Canadian production of from 75 percent to 150 percent over a period of 10 years.

This change would also benefit the processing sector, by provid-ing it with less expensive inputs and making Canadian products more competitive on the global market.

In all, liberalization could create over 8,500 jobs in the dairy pro-duction and processing sectors, the note said.

The example of New Zealand speaks volumes: that country nearly tripled its production after having liberalized its dairy indus-try, becoming the biggest dairy exporter in the world.

“It is therefore entirely plau-sible that, following the opening up of the Canadian dairy market, American producers could meet a portion of Canadian demand with-out leading to a reduction in total Canadian production,” the note said.

“Trade barriers have never made more than a small minority of people richer, at the expense of the vast majority,” the note said. “Eliminating those that persist in the agricultural sectors under sup-ply management and in the soft-wood lumber sector, and making sure not to erect new ones, would be good both for consumers and for producers.”

“Trade between Canada and the United States having stagnated since the early 2000s, eliminating supply management and softwood lumber tariffs would be a good way of breathing new life into the eco-nomic partnership,” commented Alexandre Moreau, public policy analyst at the MEI and author of the note.

“Putting supply management on the table would be a good negotiat-ing tactic that could convince the American government to drop the idea of imposing tariffs on Cana-dian softwood lumber,” Moreau continued.

CHEESE REPORTERMarch 31, 2017 Page 11

A TRUSTED NAME IN DAIRY IS NOW A NAME TO TRUST FOR TRANSPORTATION.Jacoby Logistics combines proven 3PL solutions with decades of dairy industry experience,

providing customers a one-stop solution to meet their logistic needsfrom start to finish – and every point in between.

FREE QUOTE REQUEST

1-314-822-59681-314-822-5960

MULTIPLE TRANSPORTATION METHODS TO SERVE YOUW I T H D E C A D E S O F E X P E R I E N C E & R E L I A B I L I T Y

SHIPPER TECHNOLOGY FOR TODAY’S MARKET

Refrigerated Truckload

Dry Van Truckload

IntermodalTransportation

LTL FreightManagement

L e a r n m o r e a t WWW. J ACO BY LO G I ST I C S .CO M

Freight Tracking TransportationManagement

ReportingFreight Audit

Report Outlines Actions US Government Can Take To Hike Donations Of Safe Surplus FoodActions Include Allowing Sale Or Donation Of Foods After Quality Date, Standard Date Labels, Tax IncentivesCambridge, MA—A report released earlier this month by the Harvard Law School Food Law and Policy Clinic (FLPC) and the National Resources Defense Coun-cil (NRDC) presents actions the US government can take to better align federal laws and policies with the objective of increasing dona-tion of safe surplus food to address the dual issues of food waste and food insecurity facing the US.

For example, if an entire manu-facturing run of yogurt has a mis-print with the wrong number of ounces on it, currently a company would not benefit from the liabil-ity protections or tax incentives meant to encourage food donation unless every container is relabeled, the FLPC and NRDC noted. These types of hurdles do nothing to pro-tect consumers and everything to discourage food donations.

The report, Don’t Waste, Donate: Enhancing Food Donations Through Federal Policy offers 16 actionable recommendations span-ning five key areas of federal policy that the FLPC and NRDC said can go a long way toward promoting food donation and helping the fed-eral government meet its goal of a 50-percent reduction in food waste by 2030.

The report recommends the fol-lowing policy changes to enhance food donation:

Enhance liability protections for food donations. The Bill Emerson Good Samaritan Food Donation Act provides a federal baseline of civil and criminal lia-bility protections for food donors and the nonprofits that receive and redistribute those donations. The protections afforded by the Emer-son Act are significant and have enabled many food donations, but numerous existing and prospective donors remain unaware of these protections. Further, several provi-sions in the Emerson Act should be broadened to better align with the current food recovery landscape.

Recommendations include: Congress should delegate an

executive agency to be in charge of implementing and interpreting the Emerson Act. Congress should amend the

Emerson Act to provide liability protection to nonprofit organiza-tions that either give food away for free or charge a reduced fee. The Emerson Act should be

amended so that foods must only comply with (or be reconditioned to comply with) federal, state and local safety standards or safety-related labeling standards.

farms, in lieu of the enhanced deduction. Federal tax incentives should

be strengthened by adding a deduc-tion or credit to cover the cost of transporting donated food. Congress should foster the

development of innovative, sus-tainable food recovery models by repealing the “no-charge” provi-sion that prevents the enhanced deduction from being claimed if donated food is “transferred by the donee in exchange for money, other property, or services.” Congress should amend

the enhanced deduction to only require compliance with safety standards and safety-related label-ing Food, Drug, and Cosmetic Act requirements.

Standardize and clarify expi-ration date labels. There is no federal system regulating the “sell by,” “best by,” “use by” and other date labels used on food. Instead, each state decides whether and how to regulate date labels, lead-ing to a patchwork of inconsistent regulations.

Manufacturers have broad dis-cretion on how the dates on foods

• See Food Donations, p. 14

The Emerson Act should explicitly provide liability protec-tion for the donation of past-date food.

Improve federal tax incen-tives for food donations. Federal tax incentives exist to encourage food donations. Food donors are eligible for either a general deduc-tion (deducting the basis value of the charitable contribution) or an enhanced deduction (substantially higher than the general deduc-tion) for qualified food donations.

The enhanced tax deduction was modified and permanently expanded in December 2015 to apply to all businesses that donate food, so long as the donation meets certain criteria. The 2015 changes took a significant step to incentiv-ize donations, but there are addi-tional ways to further improve the federal tax incentives available for food donations.

The report recommends: Federal tax incentives should

be expanded to include an alterna-tive tax credit that can be used by low-margin businesses, like many

siggi’s Launches New Triple Cream Yogurt In Three Popular FlavorsNew York—Icelandic-style yogurt manufacturer siggi’s has just rolled out its new Triple Cream yogurt line in Raspberry, Vanilla and Lemon flavors.

siggi’s Triple Cream yogurt is packaged in a 4-ounce cup and contain 9 percent milkfat. Made with whole milk and pasteurized cream, the yogurt also features 9 grams of protein and 8 grams of sugar per serving.

“In creating this new line of yogurts, we were inspired by a simple dessert my mom used to make when I was a kid that mixed together yogurt, whipped cream and fruit,” said siggi’s founder Siggi Hilmarsson.

“We wanted to offer our fans this wholesome snack which com-bines indulgence and satiety at the same time,” Hilmarsson said. “

siggi’s Triple Cream yogurt debuted at select retailers nation-wide last month, with greater dis-tribution starting in July. For more information, visit www.siggisdairy.com.

For more information, circle #10 on the Reader Response Card on p. 54

CHEESE REPORTERPage 12 March 31, 2017

Per Capita US Milk Production Increased 1.1% In 2016, But Declined In A Majority Of StatesLenexa, KS—Per capita milk pro-duction in the US last year was 657.4 pounds, up 7.4 pounds, or 1.1 percent, from 2015, according to the Central federal milk market-ing order’s February 2017 Market-ing Service Bulletin.

Per capita milk production is a data series presented annually in the Bulletin. A comparison of per capita milk production to per cap-ita consumption data may reflect the aggregate supply and demand balance for individual states and regions throughout the US.

A map included in the Bulletin depicts per capita milk production by state for 2016. The 300 and 600 pound levels for per capita pro-duction selected for the map are arbitrary divisions; the 600-pound level roughly approximates annual per capita consumption of all dairy products on a milk equivalent basis, while the 300-pound level reflects average annual consump-tion of Class I and Class II products (fluid and soft manufactured prod-ucts), plus reserve requirements.

In 2016, 23 states reported annual per capita production increases, with South Dakota (up 7.0 percent) posting the larg-est gain. Three other states had a per capita milk production increase greater than 5 percent last year: Michigan, up 5.9 per-cent; Nebrasks, up 6.3 percent; and Maine, up 5.9 percent.

Arkansas recorded the largest per capita production decline in 2016, with per capita output down 13.7 percent from 2015.

Eight additional states recorded per capita production declines of 5 percent or more last year compared with 2015, including: Utah, down 7.5 percent; Tennessee, down 7

percent; South Carolina, down 5.4 percent; Mississippi, down 12.7 percent; Louisiana, down 10.4 per-cent; Alabama, down 9.1 percent; and Rhode Island, down 11.9 per-cent.

Per Capita Changes Since 2011US per capita milk production increased by 28.0 pounds, or 4.4 percent, between 2011 and 2016.

Some 26 states recorded increases in per capita milk pro-duction between 2011 and 2016, led by South Dakota’s 29.5 percent gain.

Another 12 states increased per capita production by 10 percent or more comparing 2016 with 2011, including Wisconsin, up 14.2 per-cent; Iowa, up 13.2 percent; Kan-sas, up 27.1 percent; Michigan, up 27.6 percent; New York, up 13.7 percent; Nebraska, up 15.2 per-cent; Colorado, up 20.9 percent; Indiana, up 14.8 percent; Wyo-ming, up 10.1 percent; Georgia, up 20.1 percent; Connecticut, up 13.4 percent; and Hawaii, up 22.6 percent.

Alaska recorded the largest per capita production decrease between 2011 and 2016, at 50.6 percent. Six additional states posted declines of more than 20 percent, including: Oklahoma, down 27.6 percent; Mississippi, down 29.6 percent; Louisiana, down 28.8 percent; Arkansas, down 45.3 percent; Alabama, down 37.4 percent; and Rhode Island, down 28.9 percent.

Another four states reported per capita production declines between 10 percent and 20 percent between 2011 and 2016, includ-ing Tennessee, down 17.4 percent; West Virginia, down 13 percent; South Carolina, down 15.6 per-

cent; and New Jersey, down 11.1 percent.

ProductionLeadersA total of 19 states had per capita milk pro-duction above 600 pounds last year, unchanged from 2015.

Idaho last year once again ranked first in per capita produc-tion, at 8,712.9 pounds, up 2 percent from 2015 and 4.1 percent higher than in 2011, when US per capita produc-tion totaled 629.4 pounds.

Wisconsin again ranked second in per capita milk production last year, at 5,212.8 pounds, up 3.6 per-cent from 2015 and 14.2 percent higher than in 2011. Ranking third was Vermont, at 4,361.2 pounds, up 2.4 percent from 2015 and 7.7 percent higher than in 2011.

Two additional states had 2016 per capita milk production of over 2,000 pounds: New Mexico, at 3,705.4 pounds, down 1.6 percent from 2015 and 5.8 percent lower than in 2011; and South Dakota, at 2,941.8 pounds, up 7 percent from 2015 and 29.5 percent higher than in 2011.

Another five states had per capita milk production above 1,000 pounds in 2016: Minnesota, 1,751.1 pounds, up 1.5 percent from 2015 and 5.4 percent higher than in 2011; Iowa, 1,605.9 pounds, up 3.6 percent from 2015 and 13.2 percent higher than in 2011; Kan-sas, 1,145.1 pounds, up 4.8 percent from 2015 and 27.1 percent higher than in 2011; Michigan, 1,095.5 pounds, up 5.9 percent from 2015 and 27.6 percent higher than in

2011; and California, 1,031.1 pounds, down 1.7 percent from 2015 and 6.3 percent lower than in 2011.

The other nine states with per capita milk production above 600 pounds last year were: Washington, 912.5 pounds, down 1.1 percent from 2015 but up 0.9 percent from 2011; Pennsylvania, 846.4 pounds, up 0.2 percent from 2015 and up 2.3 percent from 2011; New York, 747.8 million pounds, up 4.8 per-cent from 2015 and 13.7 percent higher than in 2011; Nebraska, 733.6 pounds, up 6.3 percent from 2015 and up 15.2 percent from 2011; Colorado, 708.1 pounds, up 2.7 percent from 2015 and 20.9 per-cent higher than in 2011; Arizona, 690.8 pounds, down 0.5 percent from 2015 but 1.3 percent higher than in 2011; Utah, 686.6 million pounds, down 7.5 percent from 2015 but 4.3 percent higher than in 2011; Oregon, 633.4 pounds, down 0.1 percent from 2015 and down 1.2 percent from 2011; and Indiana, 625.8 pounds, up 2.8 per-cent from 2015 and 14.8 percent higher than in 2011.

Nine of the 19 states with per capita milk production above 600 pounds last year are also among the top 10 states in total milk pro-duction. Per capita production in Texas, which ranked sixth nation-ally in milk production last year, was 386.6 pounds, up 3 percent from 2015 and 3.5 percent higher than in 2011.

Three states had per capita milk production above 300 pounds last year: Ohio, 476.3 pounds, up 0.6 percent from 2015 and up 6.9 percent from 2011; Maine, 473.2 pounds, up 5.9 percent from 2015 and up 5.1 percent from 2011; and North Dakota, 455.2 pounds, up 3.8 percent from 2015 but down 9.6 percent from 2011.

At the other end of the spec-trum are 12 states with 2016 per capita production under 100 pounds: North Carolina, 95.1 pounds; West Virginia, 73.2 pounds; South Carolina, 50.4 pounds; Mississippi, 48.2 pounds; Louisiana, 36.1 pounds; Massachu-setts, 31.6 pounds; Arkansas, 26.4 pounds; Hawaii, 24.4 pounds; Ala-bama, 18.9 pounds; New Jersey, 13.6 pounds; Rhode Island, 13.3 pounds; and Alaska, 4.7 pounds.

-10

-5

0

5

10

15

20

25

30

CA WI

ID NY

MI

PA KS NM

CO IN SD MN

OR

Per Capita Milk ProductionPercent Changes in Select States

2016 vs. 2011

For more information, circle #11 on the Reader Response Card on p. 54

CHEESE REPORTERMarch 31, 2017 Page 13

Ask for IMAC’sMost Reliable Starter Mediaand Cultures for Mozzarellaand Spray Dried Natural Color Anti-Caking agent without any Cellulose for applicationin colored shredded or diced cheese.(International Media and Cultures)