Ultra Deepwater Semi Submersible

-

Upload

hdyoon3379891 -

Category

Documents

-

view

226 -

download

0

Transcript of Ultra Deepwater Semi Submersible

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 1/34

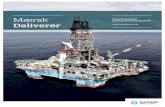

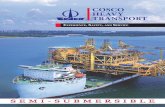

Frigstad D90 : Ultra Deepwater Semi Submersible

Simen Skaare Eriksen, CEO – Frigstad Offshore Pte Ltd

IBC Conference, London, September 2008

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 2/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 2

N O T E

THE MATERIAL CONTAINED WITHIN THIS PRESENTATION, AND THE INFORMATION UPON WHICH IT IS

BASED, IS THE PROPERTY OF FRIGSTAD ENGINEERING INC AND ITS AUTHORISED ASSIGNEES (THE

“COMPANIES”). This document must not be acted on or relied on by persons who are not relevant persons. Any

investment or investment activity to which this communication relates is available only to relevant persons and will be

engaged in only with relevant persons. This document is incomplete without reference to, and should be viewed solely

in conjunction with, the oral briefing provided by the Companies. This document is not intended to form the basis of

any investment decision and should not be considered as a recommendation by the Companies to do so. In preparing

this document the Companies has relied upon and assumed, without independent verification, the accuracy and

completeness of all information available from public sources or which was provided to it or otherwise reviewed by it.

The information contained in this document has been taken from sources deemed to be reliable. The Companies cannot represent that such information is accurate or complete and it should not be relied on as such. Any opinions

expressed herein reflect the Companies’ judgment at this date, all of which are accordingly subject to change. All

technical details and data shall be regarded as preliminary and subject to change, and should not be used for any

other purposes than mentioned in this disclaimer. Accordingly, this information is being supplied to you for information

purposes only and not for any other purpose. This communication and the information contained in it does not

constitute or form any part of an offer of, or invitation or inducement to invest in the products or services of the

Companies or any of its affiliates.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 3/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 3

Contents

Background – Frigstad group of companies

The Frigstad D90 design

• Design Philosophy

• Design Features

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 4/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 4

Background

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 5/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 5

Background : Frigstad group of companies

Established by Mr Harald Frigstad in Norway in 1980.

Operational headquarters in Singapore since 1989.

Operational experience from 15 different countries.

ISO 9001 certified in 1999.

Currently employing approx 80 staff, presence in Singapore, Norway, China.

Two primary business units:

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 6/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 6

Background : Frigstad group of companies

Frigstad Engineering

• Development of Advanced Rig Designs

• Engineering Services to offshore industry

• Inspections

• Project Support to Frigstad Offshore

Frigstad Offshore

• Offshore Drilling Contractor

• Rig & Project Management

• Construction Site Supervision

• Refurbishment, Upgrade and New-Build

• Business Development

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 7/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 7

Background : Frigstad group of companies

A unique combination of industrial capabilities

Frigstad Engineering

• Development of Advanced Rig Designs

• Engineering Services to offshore industry

• Project Support to Frigstad Offshore

Frigstad Offshore

• Offshore Drilling Contractor

• Rig & Project Management

• Construction Site Supervision

• Refurbishment, Upgrade and New-Build

• Business Development

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 8/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 8

The Frigstad D90 design

Design Philosophy

Design Features

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 9/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 9

Foundation

► The core foundation for the development of the Frigstad D90 is founder and chairman, Mr Harald Frigstad’s decision to realize his ambition todesign and build the ultimate drilling rig, making use of the practical,

hands-on experience gained during a 15-year career of workingoffshore.

► The quest for energy drives exploration activities into deeper and

deeper waters, and consequently the challenges faced by drillingcontractors change and become more demanding.

► Rising costs of large scale offshore projects means that efficiency of the drilling units has become ever important.

► Extensive research, testing and implementation of innovative andefficiency enhancing features has resulted in a rig design which istailored to meet these demands of the future.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 10/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 10

Ultra Deepwater : New Trends & Challenges

“The easy oil is gone.”

Future is in the deep waters & remote areas.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 11/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 11

Ultra Deepwater : New Trends & Challenges

► More Marine Riser and TensioningCapacity

► More Liquid Mud Capacity

► More Bulk and Sack Material

► Higher Derrick- and Crane Capacities

► More Pipe Racking Capacity in

Derrick

► More Storage Space for Consumables

► More Beds & High Quality Quarters

► More Efficient Tubular Handling

► Higher Mud Pump Volume & Pressure

► Development Drilling Capabilities

► Sub Sea Completion

► Dual Activity and Drilling Features

► More Deck Space

► Increased Capacity of Power Plant

►Increased Capacity of DP and Mooring

► Increased Space Requirement for

Mooring Equipment

“The easy oil is gone.” Future is in the deep waters & remote areas.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 12/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 12

Frigstad D90 : Responding to future demands

Most drilling rigs in operation and under construction today are

based on generic hull designs which have been made to serve

different purposes.

Production, accommodation, drilling, heavy lift, pipe laying,

intervention, transportation, storage etc etc….

In order to respond to the new market trends and demands, the

Frigstad D90 has been developed from scratch, & with one sole

objective:

To provide an optimal tool for ultra deepwater

drilling and development operations.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 13/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 13

Frigstad D90 : Optimising rig design

So, Frigstad Engineering set out to design the ultimate drilling rig from

scratch, not depending on any existing generic hull designs.

Which gave the team the luxury of starting with a blank sheet of paper.

Certain core parameters were at the top of the priority list, such as

- Drilling performance and efficiency

- High variable load

- Large deck space

- Safe & easy logistics

- Low cost; both to build and operate.- Cover majority of the world’s deepwater areas

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 14/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 14

Frigstad D90 : Optimising rig design

- Frigstad Engineering started with what we regard as the most

important component of a drilling rig; the drilling systems.

- We worked together with Aker MH for years to further develop their Dual Ram Rig concept into a customised solution for the Frigstad D90,

focussing on certain core properties of the drilling system:

- High capacities & a user friendly man-machine interface.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 15/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 15

Frigstad D90 : Optimising rig design

The Dual Ram Rig supports our ultimate objectives and helps us achieve i.a: - Efficiency in the drilling operations; dual activity, offline pipe handling.

- Safety; equipment pushed from drill floor by hydraulic cylinders rather

than suspended by wire from top of derrick. No slip and cut.- Lower weight & lower centre of gravity; higher variable deck load.

- Cost efficient maintenance.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 16/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 16

Frigstad D90 : Optimising rig design

In short, the rig has been designed specifically to support the drilling systems

and operations.

The end result of this holistic philosophy is a solution where the various

aspects of the drilling rig can be customised to suit the purpose, thereby

avoiding many compromises and sub-optimal utilisation of resources and

equipment applications.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 17/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 17

Frigstad D90 : Optimising rig design

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 18/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 18

Frigstad D90 : Optimising rig design

All anchor winches

below deck. Frees

up large deckspace areas and

Eases equipment

maintenance

Large Open Deck

areas for handlingof many X-mas

trees and BOP.

Unobstructed

access for

assembly and

maintenance by

overhead cranes,

both Port andStarboard

Large 100 ton deck

cranes P/S will

handle heavy liftssuch as X-mas

trees and change

out of thrusters.

200 men modern

living quarters with

only 1 or 2 men

cabins, many offices,

large facilities.

Highest capacity

drilling facilities

worldwide at

present; 2 x 1000

Short TonsLarge open and

accessible pipe

rack deck.Dedicated knuckle

boom crane for

safe pipe handling

8 x 4,3 MW

thrustersReady for pre-set

mooring system

Hull with good motion

characteristics and

high transit speed.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 19/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 19

Large Capacity Drilling System

Dual Ram Rig MkII –developed together withAker MH and tailored forthe Frigstad D90

World’s highest capacitydrilling facilities.2 x 1,000 short tons load

2 hydraulic top drives1,000 tons each

Full dual capacity at bothWell centers > increasedflexibility.

Working on solutionenabling 2 x 1,250 sT.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 20/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 20

Large Vertical Racking Capacity

10,000 ft of vertical riser storage

for clip type risers in 100 ft stands.

Vertical tubular setback with capacity for

50,000ft of drill pipe in 90 ft stands.

The rig can move with full riser and drill string racked in the setback!

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 21/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 21

Large open deck area

Very large open & clean deck space - 54,000 sqft total

Facilitates onboard logistics and material handling

Increasingly important as drilling locations are becoming more remote, and advanceddevelopment operations require more equipment.

No mushrooms on deck!

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 22/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 22

Large open deck area

Large open area

for X-mas treepreparation and

deployment.

Moon pool access

via

100 mt gantrycrane

Moon pool accessvia

450 mt gantry crane

Large well test

area

Large ROV areas

(Port and STB)

Large open area for

2 complete BOP

stacks and

numerous X-mas

trees.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 23/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 23

It continues beneath the surface…

Large moon pool

opening with direct

access from maindeck from both sides

Thrusters placed in

circular formation toavoid interference

and loss of effect.

Total thruster power

46,000 hp!

Distance between well

centers allows riser

and BOP to be parked

in the middle,

increasing flexibility.

“Trip saver” with

skiddable DAT

system.

Estimated transit

speed 8-10 kts, with

The horizontal

bracings above sea

level

Large distance

between well centers

allows BOP and riser

to be parked in the

middle.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 24/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 24

High Capacity Deck Cranes

The rig is equipped with 2 x 100 tonnes

deck cranes.

Cranes are designed to enable change

out of thrusters.

Draft of a large DP semi submersiblemakes it virtually impossible to get

alongside for repair & maintenance

(without removing thrusters)

Single unit lift – Reduced weatherdependency.

No need for external barge support.Less waiting time & less cost.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 25/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 25

Large Accommodation

High quality quarters, with large office space and accommodation for 200

persons, all in 1 or 2 bed cabins

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 26/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 26

Anchor winches below deck

The Frigstad D90 is designed with DP-3 system, and prepared for pre-set

mooring spread. In addition, the rig can be equipped for a conventionalchain/wire mooring system.

All the anchor winches have been placed below deck. This saves deck space,eases maintenance and reduces wear and tear on equipment.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 27/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 27

Easy Handling and Access

Forklift “ring-road” on lower decks Maintenance tunnel inside pontoons.Gives access to manifolds, pumps etc.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 28/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 28

Summary : Key Design Features

► Large deck Space - 3 Full Decks

► Clean Design – Easy to Fabricate

► Equipment Placed Indoor – Low Corrosion► Reduced Need for Water Tight Upper Hull, Big Savings in Outfitting

► Bulk Storage Tanks Located Next to Mud Mixing Area – Short Transport Distance

► Vertical Riser Storage – Easy Handling

► Lay Down Area for Riser Inspection

► Large Area for BOP/LMRP and Christmas Tree Holding

► Tunnel in Pontoons – Exposed and Accessible Manifolds

► Dual Drilling Capable Derrick

► Can Perform Many Dual Operations

► Space for Two BOP stacks on Deck.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 29/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 29

5

2

2

1

1

3

22

24

27

Frigstad D90 : Geographical Coverage

1

1

Location: Units:

USGOM 27

West Africa 22

South America 24

NW Europe 5

India 3

Latin America 1

South East Asia 2

Australia/NZL 2

Mediterranean 1

Caspian Sea 1

Far East 1

Total working: 89

* Designates location of deep water rated units not necessarily working in deep water

The Frigstad D90 isdesigned to cover95% of the world’s

deep water E&P areas.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 30/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 30

Frigstad D90 : Design Verification

► Motion, Acceleration and Air Gap Analysis:

using WADAM and SESAM computer programs

► Global strength and fatigueby Sesam Program, Aker Brevik.

► Stability Analysisusing AutoHydro computer program.

► Design approved by DnV in 2007

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 31/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 31

Frigstad D90 : Market Acceptance

► March 2006 - April 2007: Frigstad Discoverer Invest Ltd secured financing for theconstruction of a Frigstad D90, and listed the company on the main board at the Oslo

Stock Exchange.

► The first Frigstad D90 rig is currently under construction at the Yantai Raffles

Shipyard in China.

► October 2007: Frigstad Discoverer Invest Ltd acquired by Saipem S.p.A, at a premium

of more than USD 140 million above the construction cost.

► November 2007: Eni awards a 5 year, USD 860 million drilling contract to the first

Frigstad D90.

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 32/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 32

Frigstad D90 : Best in Class

Deeper

12,000 feet water depth

50,000 feet drilling depth

Larger 24,000 bbl liquid mud/brine

4,000,000 lbs combined hook load

3,200,000 lbs total riser tensioning capacity

8,100 mt variable deck load

54,000 sqft deck space

Large, clean deck layout

62,000 BHP power plant

200-bed quarters

More efficient

Dual operations (2 x 1000 s.t.) Significantly more efficient than single derrick operations,

considerably reducing non-productive time

50,000 ft vertical drill pipe set-back

10,000 ft vertical riser set-back

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 33/34

8/2/2019 Ultra Deepwater Semi Submersible

http://slidepdf.com/reader/full/ultra-deepwater-semi-submersible 34/34

© Frigstad Engineering | Frigstad D90 - Experience meets Innovation | London, September 2008 34

Contacts

Frigstad Offshore Pte LtdFrigstad Engineering Pte Ltd

9 Temasek Boulevard#44-02 Suntec Tower 2

Singapore 038989

Tel: +65 6223 1277

Fax: +65 6223 3906

www.frigstad.com