Tree House Plan

-

Upload

adrian-postavaru -

Category

Documents

-

view

223 -

download

0

Transcript of Tree House Plan

-

8/13/2019 Tree House Plan

1/12

94 Cottage Life A P R I L / M A Y 2 0 0 5

Highsociety

-

8/13/2019 Tree House Plan

2/12

-

8/13/2019 Tree House Plan

3/12

96 Cottage Life A P R I L / M A Y 2 0 0 5

HEADER JOIST

24"

4412"

5512"

1934"

30

22"

BACK LEG

SIDECROSS BRACES

CROSSBAR

1"

BACKCROSS BRACE

CROSSBAR

BRIDGINGDECK JOISTS19 316" o.c.

CENTRE POST

HEADERJOIST FRONT LEG

1"

4"

TRAP DOOR

HIDEY-HOLE

1"

RAILINGPOSTS

HANDRAILS

HANDRAILS

14" BOLT

9834"

9914"

3312"

3312" 18"19316"

18"19316"

FIG. 2: Pulley support

24"

PULLEY ARM

CENTRE POST

PULLEY BRACE18"

3"

FIG. 5: Handrails and trap doorsIllustrations by Terry Dovaston and Chad Greenwood

FRONT BACK SIDE

The Support Framework

1] The spreading triangular frames, frontand back, give the treehouse a large, sta-ble footprint and help prevent racking.Start with the front assembly, bolting thecentre post to the middle of one header

joist, using two 38" x 6" carriage bolts in

predrilled 38" holes. As you work, checkregularly that your assembly is square.Tip: Sight down any structural piecesthat arent vertical including crossbars,legs, joists, and rafters and look for

any crown, or curve. Position pieces so

the hump of the curve points up; gravitywill work to straighten it out.2]Cut one end of each front leg at a30 angle, as in Figure 4. Working flat onthe ground, clamp the legs to the header

joist and, with a few 3" screws, temporar-ily secure their angled ends to the centrepost. Chamfer the crossbar ends: Marka line 1" from the ends on all four sides,and with a circular saw blade set to a 45angle, bevel the edges. Lay the crossbar

FIG. 1: Cross braces

FIG. 3:

Deck corner

detail

4"

FIG. 4: Supporting frame

-

8/13/2019 Tree House Plan

4/12

A P R I L / M A Y 2 0 0 5 Cottage Life 97

on top of the legs. Clamp in place. Drill38" holes where shown (six in all for the

header and crossbar) and secure with 6"and 8" bolts, just finger-tight for now.

Tip: Prevent scrapes and barked shins byrounding off any sharp, pointy ends. Cut

bolt ends off and file smooth; soften pro-truding wood corners by chamfering orrounding. Strategically placed foam, suchas camping pads and foam pipe wrap,can also help avoid bumps and bruises.3]Drill a 12" hole through the legs andcentre post, near the thickest part of this

joint, for the 12" x 14" bolt (substitutethreaded rod if you cant find a long bolt).

Youll be drilling through about 12" ofwood, so youll need an extra-long bitor a bit extender. Chisel a neat pocket atboth ends of the hole for the bolt head,

washer, and nut. Tighten all bolts andcut and file all exposed threaded ends.4]Assemble the back frame. It mirrorsthe front assembly, with three differ-ences: Theres no centre post, the legs

dont extend above the header joist, andthe back legs are stiffened with two diag-onal cross braces, which youll add later.

5]Cut the deck joists (six 9'9" joists).

6]Now let the fun begin! Youll need ahelper or two for a few hours to get the

frame assembly up, level, plumb, square,and the correct height above the ground.The deck surface cannot be higher than

71" above grade, or the railing must be42" high instead of 36" (according to theOntario Building Code). To get the deckto the right height, youll likely have todig in, or trim, one or more legs. Workcarefully, because youll have several heavypieces propped up with temporary braces.

A fairly level site will make this job easier.

On the ground, mark a 12' x 10'8"rectangle. This will show approximately

where the ends of the legs sit. Measurediagonals to check your layout is square;if both diagonal corner-to-corner mea-surements are the same, its square.7]Youll need to determine which of thefour leg positions is lowest. You can dothis with a long straight board and a car-penters level, a line level, or a water level.

8] Starting at this lowest leg, stand the

corresponding assembly up, in position,and brace it so it is more or less plumb.Check that the header joist is level and the

right height from the ground (71" less

MaterialsFor a shopping list you can take to the

lumberyard, see p. 101.

PT Pressure-treated spruce

UT Untreated spruce

SPS Spruce strapping

T&G #4 pine tongue-and-groove

Newer pressure-treated wood corrodes

and weakens some metals. Always use

hardware (hot-dipped galvanized or stain-

less steel) intended for contact with it.

Support structure and deck

MATERIAL CUT TO QTY.

Centre post 4 x 4 PT 8' 1

Front legs 4 x 4 PT 12' 2

Back legs 4 x 4 PT 8' 2

Leg crossbars 4 x 4 PT 12' 2

Header joists 2 x 8 PT 8' 2

Deck joists 2 x 8 PT 9'9" 6Pulley arm 4 x 4 PT 24" 1

Pulley brace 4 x 4 PT 18" 1

Railing posts 2 x 4 PT 43" 8

Side cross braces 2 x 6 PT 12'* 4

Back cross braces 2 x 4 PT 10'* 2

Deck boards 54x 6 PT 8' 25

Bridging 2 x 8 PT 171116* 6

Ladder stringers 2 x 4 PT 8' 2

Ladder rungs 2 x 6 PT 2' x 234" 6

Handrails 2 x 4 PT 34"* 2

2 x 4 PT 8'4"* 2

Balusters PT precut 4012" 4042"

Support-structure hardware

QTY.

#8 x 2" deck screws 312lbs

#8 x 3" deck screws 4 lbs

Dock-style corner brackets 4

(Kwikdox model KD90-CN)516" x 4" lag bolts 16

38" x 4" carriage bolts 30

38" x 6" carriage bolts 15

38" x 8" carriage bolts 4

12" x 14" carriage bolt 1516" washers 1638" washers and nuts 4912" washers and nuts 1

2 x 8 joist hangers 8

Joist hanger nails 34lb

512" zinc-plated door pulls 2

Clothesline reel 1

Safety snap 1

Threaded 38" hook 1

Small dock cleat 1

14" rope 25'

*approximate length; cut to fit

-

8/13/2019 Tree House Plan

5/12

98 Cottage Life A P R I L / M A Y 2 0 0 5

the thickness of the deck boards). If not,

trim or dig in the legs to suit.9]Once thats done, stand the other frameassembly up, in position, and brace againfor plumb. Place a straight board from oneheader joist to the other, check for level,

then trim or dig in the second assembly.10]Screw two deck joists (with 3" deckscrews) between the front and back header

joists, one at each end. Double-check

that everything is square, plumb, level, andto the correct height. After a few moreadjustments, and perhaps a few expletives,the basic supports will be in place.11]Attach the diagonal side cross bracesto the legs to help strengthen and stabi-lize them (see Figure 4). Clamp them inposition to mark the excess, remove and

Materials, continued

House

.YTQOTTUCLAIRETAM

Side wallsTop and 2 x 3 UT 90" 4bottom plates

Studs 2 x 3 UT 45" 12

Window sills 2 x 3 UT 1612" 4and headers

Temporary brace 1 x 3 SPS 8' 2

Back wallTop and 2 x 3 UT 61" 2bottom plates

Studs 2 x 3 UT 45" 3

Temporary brace 1 x 3 SPS 8' 1

Front wallBottom plates 2 x 3 UT 1734" 2

Studs 2 x 3 UT 5314" 2

Girts 2 x 3 UT 1834" 4

Header 2 x 3 UT 62"* 1

Temporary brace 1 x 3 SPS 8' 1

CladdingSiding 1 x 6 300' pine cove

Corner trim 1 x 2 pine 48"* 4

1 x 3 pine 54"* 4

Flooring 14" G1S 112

plywood pces*

RoofRafters 2 x 4 UT 57"* 16

Ridge board 1 x 6 pine 8'4" 1

Back gable 2 x 3 UT 30"* 1studs 2 x 3 UT 16"* 2

Front gable 2 x 3 UT 24"* 1stud

Roof boards 1 x 10 #4 pine 150'

Side fascia 1 x 6 pine 8'6" 2

End fascia 1 x 6 pine 58"* 4

Collar ties 2 x 3 pine 32" 2

Window frames

Top and bottom 1 x 3 pine 1612" 4

Sides 1 x 3 pine 1212" 4

Window side trim 1 x 3 pine 1212" 4

Window 1 x 4 pine 21" 2bottom trim

Window top trim 1 x 6 pine 22" 2

Door frameSide jambs 1 x 4 pine 54" 2

Head jamb 1 x 4 pine 2512" 1

Door side trim 1 x 3 pine 54" 2

Door top trim 1 x 6 pine 31" 1

Door stop pine trim 12'*

.YTQOTTUCLAIRETAM

DoorOuter frame rails 1 x 3 pine 1812" 4

Outer frame stiles 1 x 3 pine 2634" 4

Inner frame rails 1 x 2 pine 2312" 4

Inner frame stiles 1 x 2 pine 2334" 4

Door panel pieces 1 x 6 T&G 2334" 8

Owl door rails 1 x 3 pine 1238" 4and stiles x 1"

Owl door panels 1 x 6 T&G 12" 2

Bunk bedsBases 12" 61" x 2

plywood 24"

Side ledgers 2 x 3 UT 2534" 4

Back ledgers 2 x 3 UT 58" 2

Rails 1 x 4 pine 61" 2

Support strips 1 x 2 pine 61" 2

Ladder stringers 2 x 3 UT 4' 2

Ladder rungs 2 x 3 UT 12" 4

*approximate length; cut to fit

ENDFASCIA

ROOFBOARDS

2014" 1612" 1612"

EDISKCABTNORF

SIDEFASCIA

CORNER TRIM

FIG. 6: Framing and siding

http://www.timbr.com/?cid=459 -

8/13/2019 Tree House Plan

6/12

A P R I L / M A Y 2 0 0 5 Cottage Life 99

trim, and then tack back in place with3" screws. Drill two 516" holes througheach end of the braces and about 1" intoeach leg. Hammer a 4" lag bolt, with

washer, into each hole and tighten. Drilltwo 38" holes where the braces intersectand secure with 4" carriage bolts.

Tip:Newer pressure-treated wood, called

Alkaline Copper Quaternary (ACQ) andCopper Azole (CA), is more corrosiveto metal, so you must use hot-dipped

galvanized or stainless-steel hardware, or

fasteners recommended by the manufac-turer, or the hardware could fail prema-turely. Check labels when you buy. Elec-troplated or Grade 2 steel just wont do.

Filling in the deck1] Now reinforce each deck corner with ametal bracket, the kind commonly used in

dock building, bolted to the inside face (seeFigure 3). For extra strength, five of therailing posts are bolted with the headers

or joists through these brackets. Making

Materials, continued

House hardware

QTY.

Shingles 3 bundles

78" roofing nails 34lb

114" ring nails 34lb

#8 x 1

1

4" wood screws 1002" finishing nails 2 lbs

4" strap hinges 2

3" butt hinges 2

2" butt hinges 4

Spring hinges 2

212" barrel bolt 1

434" door pulls 3

Screen door catch 1

Foam weatherstripping 12'

Door sweep 1

Fibreglass screening 3' x 3'

Outdoor glue

FIG. 9: Siding notch detail

FIG. 8: Framing

FIG. 7: Rafter detail

21"

18"

18" o.c.

24"

14"

BIRDS MOUTH

NOTCHfits

over top

plate and

siding

Top edge of

siding trimmed

to align with

top of rafter

214"

BIRDS MOUTHNOTCH

318"

318"

90

45

50"

434"

434"

18"o.c.

TOPPLATES

BOTTOMPLATES

RIDGE BOARD

COLLAR TIE

RAFTERS

FRONTGABLE STUD

HEADER

BACKGABLESTUDS

HEADER

For clarity, window

on opposite wall

not shown

WINDOWFRAME

SILL

Header

and girts

are notched

GIRTS

SIDE

JAMBS

HEADJAMB

21"

24"

STUD

BOTTOMPLATE

18"o.c.

18"o.c.

18"o.c.

18"

1 x2CORNER

TRIM

1 x3CORNER

TRIM

-

8/13/2019 Tree House Plan

7/12

100 Cottage Life A P R I L / M A Y 2 0 0 5

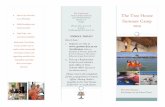

tree dwellersCottagers are building up and branchingout

1

2 3

4

5

-

8/13/2019 Tree House Plan

8/12

A P R I L / M A Y 2 0 0 5 Cottage Life 101

6sure the posts are plumb, drill 38" holesand install with the 38" x 4" carriage bolts.2] Use joist hanger nails, not deck screws,to attach joist hangers to the front andrear header joists at 19316" on centre

(o.c.). Slide the deck joists down into thehangers, screw through the header joistsinto the deck joists with 3" deck screws,

and nail the hangers.3]Cut the deck boards to 96". Tempo-rarily screw one across the middle of thedeck framework to hold each joist inplace. Starting at the back, nail or screw(with 2" hardware) the first deck board

flush to the edge. The next three boardsneed to be cut to leave a space for the trapdoor (see Figure 5), which is 19316" wide.Mark these cuts to line up with the joistcentres, so when the trap door is closed,both sides will be supported. Likewise, cut

the eighth, ninth, and tenth boards toleave an opening for the secret hidey-hole.

Tip:For screws going into the ends

of the deck boards, drill clearance holesfirst to prevent splitting.4]When you reach halfway, remove thetemporary brace. At this point, cut the2 x 8 bridging pieces to fit between the

joists; note that a piece of bridging formsthe front of the box for the hidey-hole,and an extra bridging piece forms theback. Screw pieces of 2 x 2 around the

inside bottom edges of the hidey-hole tomake a ledge; then screw down 12" ply-

wood for the bottom. Secure the remain-ing deck boards to the joists; you willlikely have to rip the last one to fit.5]Attach the 2 x 4 cross braces to theback legs, trimming off any excess length.Secure the braces with 38" x 4" carriagebolts at their intersection, at bottom

through the legs, and at top through theheader joist. One brace has its end boltedthrough the 2 x 4 railing post as wellas the header joist, requiring a 6" bolt.

Add the ladder and pulley1]For the ladder rungs, I ripped pressure-treated 2 x 6s in half to 234". Screw tworungs to the stringers to square the ladder

up. Position it at the same angle as thelegs, fitting between the two railing posts(see Figures 15 and 16). Screw the ladderstringers into the deck joist. Starting fromthe top, screw the first rung to the string-ers with four 3" screws. Ensure its top edgeis flush with the deck surface to avoid

a tripping hazard. Add the other rungs

24" apart. You can adjust this distanceso the last rung is high enough to helpkeep very young children off the struc-ture. On the right side of the ladder, screwthrough the railing post into the stringer;

on the left side, cut the stringer flush withthe railing post; again, this minimizes thetrip factor. Two door pulls, attached to

the railing posts, make climbing easier.2]Cut the pieces for the optional pulleystructure and drill 516" holes for the bolts.Use two 516" x 8" lag bolts to secure thehorizontal piece to the centre post andfour 516" x 4" lag bolts to attach the sup-

port piece. Add a 38" threaded hook, a

clothesline pulley, about 25' of rope witha snap, and a cleat to tie the rope off. >>

1Kalley Libera and her dad, Steve,inspect the family treehouse on

Harris Lake near Pointe au Baril. Built

by Kalleys Uncle Markus, its a work

in progress: Trap door and cottage-

to-treehouse delivery system

(a clothesline) are complete, while

new railings are to come.

2

At Kasshabog Lake, north of

Peterborough, Lelia MacDonald and

son Andrew (right) designed a tree-

house with a trap door, translucent

roof panels, and drop-down table.

Lelias neighbour Peter Puky (lower

left) helped build it; Andrews grand-

mother Sybil (top right) is one of

many visitors to the treehouse.

3The two-storey, 18-window tree-house (sleeps six) that Mark Allen

built for his children, Marah and

Quentin, overlooks Red Bay on LakeHuron, perfect for sunset-watching.

4Raven Treehouse, as the Hick-ling family calls their retreat on Paint

Lake, near Dorset, Ont., sits on a

white pine stump. Before it fell, the

long-dead tree housed two noisy

ravens who have since resettled in

a nearby hemlock.

5Severn River cottager HarveyPresement built a breezy treehouse

for his grandchildren, Adam and

Alexa, in three weekends. Stencilled

moon and stars, and dollar-store

decor giant snakes, butterflies, and

insects add a whimsical touch.

6To avoid damaging trees onhis Fairbank Lake property, west of

Sudbury, Brian Yanchuk had a scrap

utility pole dropped in to support a

hexagonal treehouse. Its shared by

his three children, Caleb, Clara, and

Christian, who occasionally invite

adults up for colouring sessions.

SIZE LENGTH QTY.

2 x 4 8' 6

2 x 4 10' 2

2 x 4 12' 2

2 x 6 8' 1

2 x 6 12' 4

2 x 8 8' 2

2 x 8 10' 7

4 x 4 8' 2

4 x 4 12' 5

54x 6 8' 25

2 x 2 42" 40

2 x 3 8' 25

2 x 4 10' 8

1 x 3 10' 4

Pine 1 x 2 8' 2 1 x 2 10' 1

1 x 3 8' 4

1 x 3 10' 2

1 x 4 10' 1

1 x 4 12' 1

1 x 6 8' 1

1 x 6 10' 5

Pine cove 1 x 6 300'

1 x 6 10' 2

Pine door stop 12'#4 roof boards 1 x 10 150'

14" G1S plywood 4' x 8' 114" G1S plywood 4' x 4' 1 4' x 8' 1

Pressure-treatedspruce

Lumber shopping listWith careful layout and cutting, this is

enough wood to build the treehouse.

Pressure-treatedprecut balusters

Untreatedspruce

Pine tongue-and-groove

12" spruceplywood

Spruce strapping

-

8/13/2019 Tree House Plan

9/12

The wee houseTo give myself room to work on thedeck, I installed the handrails and balus-ters after I finished building and shin-gling the house. For safety, temporarilyclamp some boards in place as railings,and watch your step.

The untreated 2 x 3 lumber that framesthe house is usually sold only in 8' lengths,

so it requires some careful layout work to

minimize waste.1]On the ground, assemble the side

wall framing as shown in Figure 8. Tem-porarily attach a piece of 1 x 3 sprucestrapping as a diagonal brace across theinside of each wall to keep it square.Bring one wall up and screw the bottomplate to the deck, flush to the outside

and back edges. If its windy, you mighthave to brace it to the floor.2]Assemble the back wall, which consistsof a top and bottom plate and three inside

studs. Youll note there arent studs on the

ends of this wall; the front and back wall

share corner studs with the sides. Carrythe back wall assembly up onto the deckand screw the bottom plate to the deck,flush to the back edge and tight to thebottom plate of the side wall. Bringup the other side wall and screw it to thedeck, being careful to keep it parallel tothe other side wall. Toenail (or screw) the

back wall top plate to the top plates of

the side walls. Attach a temporary braceto the inside of the back wall to keep theside walls plumb. Dont worry about anygable studs for now.3]The front is assembled without theheader or the gable stud (both will beadded once the rafters are in place). Cutstuds, girts, and bottom plates to length,notching the outside ends of the horizon-

tal girts to wrap around the side-wall studs(see Figure 8). Screw the pieces togetherand carry both halves of the wall up onto

the deck and screw in place. Add braces

102 Cottage Life A P R I L / M A Y 2 0 0 5

FIG. 10: Bunk bed detail

RAILBASE

SUPPORT STRIP

-

8/13/2019 Tree House Plan

10/12

104 Cottage Life A P R I L / M A Y 2 0 0 5

Build for lessI left the lumberyard with about

$2,200 worth of materials for the

treehouse, including the lookout

tower, but there are easy ways to cut

that cost. The treehouse might not

look quite as deluxe as this one, but

it will still be safely and solidly built:

SUBSTITUTE WAFER BOARDfor the

pine roof boards.

REPLACE THE PINE COVE SIDING

with 12" plywood, or a less expensive

siding (but dont use wafer board

here; its not strong enough to hold

up to kids or weather).

USE LEFTOVER WOOD OR PAINT

from another project.

BUILD A SIMPLER DOOR,or recycle

an old door.

SKIP THE BUNKS (and add collar ties).

TRIM THE WINDOWS AND DOORS

with less-expensive wood, such as

pressure-treated deck boards.

to the inside so that the two front studs areplumb and aligned, and the wall is stable.4]I selected 1 x 6 pine cove siding for the

walls. Start at the bottom of the back wall

and work up until you are one piece shortof the top plates (use 2" finishing nails).5]Proceed in the same manner with theside walls, leaving openings for the win-

dows. The last course of siding on eachside is notched to accept the rafters (seeFigure 9). Tack this course in place tomark the notches; their sides line up withthe side-wall studs and the bottoms align

with the top plates. Remove, cut, and tackthem up again, since youll need to ripthem to match the height of the rafters.6]Cut the rafters as in Figure 7; 12 have

birds mouth notches while four, for thegable ends, dont. These notches includeextra width so they fit overthe siding.This unusual detail makes it easier to nes-tle the siding in tight to the roof and keepout bugs. Position one of the rafters in asiding notch. Mark the siding at the topedge of the rafters, remove and rip the last

course of siding. With this cut, the roofboards will seal snugly with the siding.Nail this last course of siding in place.7]Lay out the locations for the rafters

on the ridge board. Position each rafter

in a notch cut in the siding and over asidewall stud; secure each with a 3"screw through the narrowest part of thebirds mouth, into the top plate. Slide

the ridge board up between the rafters;position the rafters on one side andscrew or nail in from the opposite side

(naturally, youll have to shift one set ofrafters out of the way). Move the remain-ing rafters into place and toenail from theopposite side. Check that the rafters areplumb and attach a brace across one sideof the roof to stabilize it. Finish fasten-ing the rafters to the top plate with twoadditional screws for each rafter.8]Add 2 x 3 studs to fill in the gable endof the back wall as in Figure 8. To avoid

complex notching to fit them aroundthe rafters, I turned the two short studs90 so theyre flush with the back of thebuilding. Finish siding the back wall.9]Notch the front wall header to f itaround the rafters. Screw it to both thedoor frame studs and to the rafters. Addthe gable stud and finish siding the front.Remove all the braces.10]Beginning at the roofs leading edge,nail or screw 1 x 10 rough-sawn pineboards to the rafters. The roof is 8'6" long,

so lay the boards out carefully to minimize

FIG. 11: Pattern

for owl cutout

1 square = 1 inch

-

8/13/2019 Tree House Plan

11/12

-

8/13/2019 Tree House Plan

12/12

108 Cottage Life A P R I L / M A Y 2 0 0 5

Inside the house1]Inside the building, I installed 14" ply-

wood (with 114" ring nails ) over thedeck boards to keep the darned bugs out.

Cut holes for the trap door and the hidey-hole. Screw two 1 x 2 scraps to the bot-tom of the three short pieces of deckboard that make up the lids. Nail the ply-

wood pieces on top. The trap door is fas-tened with 4" strap hinges to the floor;add a door pull to ease opening. Sincekids dont want just anyone accessing

their secrets, I decided not to give awaythe hidey-holes location with a pull for

its lid. It needs small, persistent fingers,or something similar, to pry it open.2]I built two bunks inside, but you couldeasily install a table, benches, shelves, or

whatever suits your kids. The bunks arereally just 24"-deep shelves of 12" ply-

wood, installed 20" and 40" above thefloor. Theyre supported on the sides and

back with 2 x 3 ledgers, and finished onthe front with a simple lip (see Figure 10).

A short ladder, built of 2 x 3s, providessupport and access. Position the ladder

near the centre of the bunk so its stringersalso act as a safety barrier (if small childrensleep up top, add a full-length guardrail).

The bunks help stabilize the walls, so ifyou leave them out, add a collar tie or two.

The door1]I opted for a dutch door for the play-house more fun, but also more compli-cated to construct than a full door. Theouter frame of both halves consists of1 x 3, with 1 x 2 inner frames glued andscrewed to them (114" screws). If you

prefer, you can use other joinery optionshere, such as biscuits or pocket-hole joints.2]With the last tongue planed off, four1 x 6 tongue-and-groove pieces fit almost

perfectly in these frames. Fasten with 114"ring nails. Enlarge the owl template (Fig-ure 11) to 11" high with a photocopier,or by hand. Centre the owl on the upperhalf and cut out with your jigsaw.3]Make the frame for the owl doors, asin Figure 14, so the inside of the framemeasures 1238" x 1038". I ripped someleftover trim pieces to a width of 1" for

this. Remember to staple some screening

under the frame before you secure it.4]Two 12" pieces of 1 x 6 tongue-and-groove tongues planed off serve wellas inside owl doors. Drill two 1" holes eyes for the owl, peepholes for the kids and mount these doors to the frame withfour 2" hinges. A scrap of wood screwed to

the frame forms a simple pivoting latch.5]Attach spring hinges surface mounted to the bottom half of the door. Locatethis half in the door opening and screwthe spring hinges in place, using one

screw each for now (I substituted #8 x114" screws for the dinky ones in the pack-age). Position the 3" butt hinges on the tophalf. This can get tricky, because all four

hinge pins, top and bottom, must alignor the door wont close smoothly. I mor-tised the butt hinges into the doors edge.Locate the top half in the opening andattach the hinges (again, one screw fornow). A helper is a definite asset here. Besure both doors swing properly. Add a bar-

rel bolt to the doors and check the doorsoperation again. If everything works,finish screwing the hinges to the frames.

6]Nail doorstop to the jamb so the doorcloses flush with the trim. For extra bug-proofing, I added foam weatherstrippingand a door sweep. Screw 434" door pullsto both the inside and outside of the tophalf of the door. Add a spring-loadedscreen door catch and youre done! Done,

that is, until the kids start asking for a look-out tower. For plans and constructiondetails, go to www.cottagelife.comandclick on Whats new in the Workshop.

FinishingI used Para Paints Refined Melody(P2710-2) for the outside walls and LaCloche Gold (P2711-2) for the trim

(three litres of blue and one litre of gold).To give the pressure-treated lumber andthe interior floor a rich cedar look, I usedParas Timber Care Raincoat (V223 #2).

Youll need about five litres.L

Wayne Lennox is the author of CottageEssentials, an eclectic and extensive how-tobook published by Whitecap Books.

FIG. 15: Front

FIG. 16: Side FIG. 17: Side FIG. 18: Back

71"

A treehouse gave us a sense of independenceand adventure, elevated as we were above the world