Trane AHU (CLCP) for Energy Efficient Humidity Control · a traditional cooling coil. A cooling...

Transcript of Trane AHU (CLCP) for Energy Efficient Humidity Control · a traditional cooling coil. A cooling...

CDQ-PRC001-E4

Trane AHU (CLCP) forEnergy EfficientHumidity Control

CDQTM Cool Dry Quiet DesiccantDehumidification

2

3

Contents

Introduction

Application

Dimensions

Selection Procedure

Performance Data

Mechanical Specifications

4

7

8

9

11

12

4

Introduction

CDQ Benefits• Increased cooling coil latent (dehu

midification) capacity• Lower supply air dew points• Decreased need for reheat• Lower unit cooling sensible heat ratios

(SHR)• Warmer required chilled-water

temperatures• Decrease the required cooling capacity

when dehumidifying• Exhaust air is not required• All electric system - no “expensive” gas

heat needed

Lowers supply-air dew pointThe addition of the CDQ desiccant wheelto the system enhances the dehumidifi-cation performance of the traditionalcooling coil. The CDQ wheel transferswater vapor, and the cooling coil does allthe dehumidification work in the system.The latent (dehumidification) capacity ofthe cooling coil increases withoutincreasing its total cooling capacity. CDQcan achieve a lower supply-air dew pointthan the coil temperature.

Saves cooling and reheatenergyUtilizing the CDQ wheel enhances thedehumidification capabilities of a coolingcoil. In order to remove the same amountof moisture, a cool-reheat system willrequire more cooling capacity and needto reheat CDQ will generally save coolingand reheat energy, any may even allowfor downsizing of the cooling equipment.The cooling coil sensible heat ratio(SHR-the ratio of sensible cooling to totalcooling), is also lowered with CDQwithout using reheat. This helps the unitprovide significantly better part loaddehumidification (up to 200 percentbetter) and reduces the need for reheat.

Extends achievable dewpoints of traditional DX orchilled water systemsA unique benefit of the CDQ system isthat it can deliver a lower supply airdewpoint than other technology that uses

a traditional cooling coil. A cooling coil cantypically dehumidify air to a dew point thatis 50F to 100F above the temperature ofthe fluid or refrigerant that flows throughits tubes.For example, 450F chilled water (depend-ing on the flow rate and coil characteris-tics, of course) can dehumidify air to adew point of 500F to 550F. By adding aCDQ desiccant wheel to the process, thesupply-air dew point can be 00F to 100Fbelow the chilled-water temperature.This can extend the achievable dewpoints of traditional DX or chilled-watersystems.

Improves energy efficiencyA CDQ system can also improve theefficiency of chilled-water systems.Because the chillers can producewarmer water temperatures to achievelower supply-air dew points, the chillercan be more efficient. CDQ may alsoreduce the pumping power by allowingreduced chilled-water flow rates, andmay eliminate or reduce the need forglycol in the system. This allows buildingareas requiring lower dewpoints to usethe same chilled water temperature asthe rest of the facility.Finally, in low dew point applications,CDQ may reduce overall energy use byeliminating the need for a coil defrostsystem or an active (high-temperatureregenerated) desiccant system.

Reduces path noise controloptionsThe main source of sound in ahu is fan &motor unit. The CDQ is a blow-thrudesign that is sandwiched in between,which means it is significantly quieterthen a standard draw-thru unit.

5

Introduction

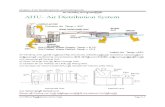

Figure 2

CA

OA

RA

SA

MAMA' WATER VAPOR

12.8oC 9.5oC DPT 12.8oC

6.1oC DPT

21.1oC 9.5oC DPT

17.8oC 11.7oC DPT

CONDENSATE

SA

TRANE CDQ WHEEL

Figure 2 : Selection Example of AHU with CDQ - Supplying lower dew point air. DPT = Dew Point Temperature

6

Introduction

What is CDQThe TraneCDQ desiccant wheel is usedto enhance the dehumidification perfor-mance of a traditional cooling coil. Thewheel is configured in series with coil(see Figure 1,2 & 3) such that the“regeneration” side of the wheel islocated upstream of the coil and the“process” side of the wheel is locateddownstream of the coil. The CDQdesiccant wheel absorbs water vapor

from the air downstream of the coolingcoil and then adds it back into the airupstream of the coil where the coilremoves it through condensation. Thisprocess is accomplished without theneed for a second regeneration airstream.

The addition of the CDQ desiccantwheel to the system enhances thedehumidification performance of the

traditional cooling coil. The CDQ wheeltransfers water vapor, and the cooling coildoes all the dehumidification work in thesystem. The latent (dehumidificattion)capacity of the cooling coil increaseswithout increasing its total coolingcapacity. The system can achieve a lowersupply-air dew point without lowering thecoil temperature. Unlike a system with acooling coil alone, the dew point of the airleaving the coil can be lower than the dry-bulb temperature leaving the coil.

Coil Capacity29.3 tons (Cooling)0 MBH (Reheat)

Peak Load ConditionsFigure 3

Figure 3 : Example of AHU with CDQ System that uses highly efficient system kW. CDQ System uses lower energy.

Chiller Chiller AHU System AHU Heating (Thermal)(kW/Ton) (kW) (kW) (kW) (NaturalGas)

Cool & Reheat (1 Coil) 1.24 49.6 + 15.9 65.5 1.7 Cool & Reheat (2 Coils) 39.6 + 16.3 55..9 1.7

UpStream Coil 0.74DownStream Coil 1.24Split Dehumidifation Unit 35.1 + 16.9 52.0OA Coil 1.34RA Coil 0.74Trane CDQ 0.74 21.7 + 22.0 43.7

Heat Regenerated Desiccant 0.74 32.5 + 23.5 56.0 3.4

Note Airflow : 15,000 CFM Energy Saving 33.3%

7

CDQ ApplicationThe CDQ system can be applied in mostcommercial applications that requirehumidity control. This includes spacesthat need to be maintained between 35to 65 percent relative humidity. Thebenefit of using a CDQ system versuscool-reheat will vary by application, butthe benefits of higher latent capacity,lower achievable supply-air dew point,and reduced reheat energy will be seenthrough the range of applications.

35 to 45 Percent RelativeHumidity Spaces

The CDQ system provides the mostbenefit in 35 to 45 percent relativehumidity applications. This range ofspace relative humidity requires that thesupply-air dew point be 300F to 480F. Theprimary benefit of using a CDQ system inthese applications is the ability to usewarmer coil temperatures (warmerchilled-water temperatures or highersuction temperatures) than would berequired by another system. Dry storage/archives, hospital operating rooms, andlaboratories are just a few 35 to 45percent relative humidity applications thatmay benefit from a CDQ system.

Dry Storage/Archives

This space type has a small latent loadin the space and requires very littleventilation air to be introduced. Thechallenge for humidity control is keepingthe space humidity level at the desiredlow level. Since the mixed-air relativehumidity is low, the CDQ desiccant wheelwill be operating at its most efficientconditions to help lower the supply airdew point. This will raise the required coiltemperature and also lower the need forreheat.

Hospital Operating Rooms

Operating rooms are not only kept at alow relative humidity but also at coolertemperatures, a good fit for a CDQsystem. The improved latent removal

capacity not only reduces the requiredcooling needed but the lower supply-airdew points can eliminate the need for asecondary refrigeration coil or a heatregenerated active desiccant system.Because active desiccant systemsprovide hot air (which would then requirea significant amount of post-cooling), theuse of a CDQ system in this applicationcan produce significant energy savings.

Laboratories

A CDQ system can help achieve thelower relative humidity needed forlaboratories. Because the exhaust airoften contains contaminants, total energy(enthalpy) recovery from the exhaust air isusually not permissible. A CDQ systemcan improve energy efficiency and latentremoval from the space without the needto use the exhaust air stream.

50 to 65 Percent RelativeHumidity SpacesMost of the benefits of a CDQ system arealso realized in these applications,particularly at part load conditions. Theprimary benefit in these applications isan increased latent capacity and lowerSHR, which allows the unit to bettermatch the space dehumification require-ments. Schools and colleges, retailstores and restaurants, and officebuildings are just a few 50 to 65 percentrelative humidity applications that maybenefit from a CDQ system.

Schools and Colleges

Because of the high occupancy level ofclassrooms, the space latent load canbe high. This load occurs years can behigh. This load occurs year round, whichresults in a lower SHR at part loadconditions. A CDQ air handler can beused to help achieve the higher latentcapacity needed for classrooms. Thesystem can be either constant volume orvariable air volume (VAV). Humidity levelsin schools can elevate during weekendsand other times when the buildings areunoccupied. The same air handler canbe used as a recirculating dehumidifierto keep the humidity levels under controlduring unoccupied hours.

Office BuildingsA constant volume or VAV system can beenhanced to get better humidity control inthe space. A CDQ system can also behelpful in offices designed with under-floor air distribution. Air delivered at floorlevel is at a warmer dry-bulb temperature(typically around 650F). This can create adehumidification challenge in manyclimates. A CDQ system can deliver air at650F drybulb temperature, and at a dewpoint of 550F to 580F, without the need forovercooling and reheat (or overcoolingand mixing in bypassed return air).

Application Target Dewpoint or RHLaboratories 40 DPDry air storage (military) 35% RHIce rinks 25 DPDorms 47 DPElder-care facilities 47 DPHospitals (operating rooms) 40 DPMuseums, archives 35 DPLibraries 47 DPSchools 47 DPSupermarkets (freezer area) 42 DPOffice buildings 47 DPHotels 47 DPRestaurants 47 DP

Application

DPT = Dew Point Temperature (0F)

L4 L5 L3 L2 L1Nominal Fan Electric Heater Mixing/Intake

Model Airflow Motor Section Coil Section Section 2”Pre+4”Catridge 2”Pre+15”Bag SectionkW 4 R 6 R 8-2 R 1-3Steps 4Steps Filter Section Filter Section Width Height

CLCP003 0.6 0.18 - 3 1085 310 465 620 465 620 310 620 775 748 1616CLCP004 1.0 0.37 - 3 1085 310 465 620 465 620 310 620 775 1058 1616CLCP006 1.4 0.55 - 7.5 1240 310 465 620 465 620 310 620 775 1368 1616CLCP008 1.9 0.75 - 7.5 1240 310 465 620 465 620 310 620 775 1678 1616CLCP010 2.3 1.1 - 7.5 1240 310 465 620 465 620 310 620 775 1368 2236

11 - 15 1395 310 465 620 465 620 310 620 775CLCP012 3.0 1.1 - 7.5 1395 310 465 620 465 620 310 620 775 1678 2236

11 - 15 1550 310 465 620 465 620 310 620 775CLCP014 3.6 1.5 - 7.5 1395 310 465 620 465 620 310 620 775 1988 2236

11 - 15 1550 310 465 620 465 620 310 620 775CLCP016 4.1 3 - 15 1550 310 465 620 465 620 310 620 775 1678 2856

18.5 1705 310 465 620 465 620 310 620 775CLCP020 5.0 3 - 15 1705 310 465 620 465 620 310 620 775 1988 2856

18.5 - 22 1860 310 465 620 465 620 310 620 775CLCP025 6.2 5.5 - 15 1860 310 465 620 465 620 310 620 775 1988 3476

18.5 - 30 2015 310 465 620 465 620 310 620 775CLCP030 7.4 5.5 - 15 1860 465 465 620 465 620 310 620 775 1988 4096

18.5 - 30 2015 465 465 620 465 620 310 620 775CLCP035 8.7 7.5 - 22 2015 465 465 620 465 620 310 620 775 2298 4096

30 2170 465 465 620 465 620 310 620 775CLCP040 10.1 4 - 45 1860 465 465 620 465 620 310 620 775 2608 4096CLCP045 11.5 4 - 45 1860 465 465 620 465 620 310 620 775 2918 4096

8

Dimensions

Note : Electric Heater is used when dryer air is needed.

9

Selection Procedure

1 0

The CDQ performance program can beused to determine the required coilcapacity based on the required supply-airdew point, dry-bulb temperature, andairflow. Performance runs should becompleted for cooling design day,

dehumidification design day, andpossibly even a warm, rainy day. This willconfirm that the cooling equipment issized appropriately. In many comfort-cooling applications, the CDQ wheel

may may only operate at part-loadconditions. For these and other cases, itis a good idea to check the performanceat a part-load condition to highlight thebenefits of a CDQ system.

Selection Procedure

1 1

PerformanceData

AIR FLOW DRY BULB RELATIVE HUMIDITYVOLUME TEMPERATURE HUMIDITY RATIO ENTHALPY(SCFM) (F) (%) (grains/lbm) (btu/lbm)

RETURN AIR 12,000 62.0 52.0 42.9 21.5OUTSIDE AIR 3,000 100.0 29.3 84.5 37.4MIXED/REGEN.AIR 15,000 69.6 47.4 51.2 24.7LVG WHEEL (1) 15,000 66.0 65.3 62.6 25.6LVG COOLING COIL 15,000 52.8 92.2 54.7 21.1LVG WHEEL(2) 15,000 56.4 64.0 43.3 20.2

UNIT SHR = 0.73REQUIRED COIL CAPACITY 28.8 TONS, 345 MBHREDUCTION IN REQUIRED COOLING CAPACITY USING CDQ vs COOLING WITH REHEAT 14.7 TONS, 33.8%REQUIRED PREHEAT CAPACITY 0 MBHREDUCTION IN REQUIRED REHEAT USING CDQ : 195.0 MBH

12

CDQ Mechanical Specifications

1. DEHUMIDIFICATIONCASSETTE

1.1. The CDQ dehumification wheelshall be placed in the air handler asshown in the air handler unit drawings.The dehumidification wheel shall notrequire an additional regeneration airflowstream or the use of a high heat source.If any preheat is required it shall notexceed the scheedulled capacity.

1.2. The CDQ dehumidification wheelshall not utilize exhaust air. The CDQwheel shall have no exhaust air tranfer.

1.3. Cassettes can be designed witheither a vertical (side by side) or ahorizontal (over/under) airflow arrange-ment as per requirements. The cas-settes shall be mounted upright.

1.4. Cassettes casing shall beconstructed of heavy duty G90 galvanixedsteel. Cassettes up to 7000 cfm shall besingle face panel construction for easyservice access to the wheel drive motorand belt. Larger cassettes shall bedouble face panel with removable sidepanel for access to belt and drive motor.Small amounts of casing deflection shallhave no significant impact on wheelperformance or life. Casings shall have a1” - 1 1/2” perimeter flange to facilitateinside AHU cabinet with self-tappingsheet metal screws. Alternatively,cassettes may be mounted using“safeoff” blanking to the side, top, andbottom of the cassette.

1.5. The CDQ dehumidification wheelsshall be constructed of synthetic matrixwith an adsorbent integrally bound intothe matrix. The adsorbent shall beselected for its high affinity for water vaporat the CDQ operating conditions. Theadsorbent shall be a type III desiccant.Construction of the wheel shall becorrugated, fluted design, which providesdistinct passageways and preventsinternal wheel bypass. The desiccant isintimately, permanently bound anduniformly dispersed throughout thewheel matrix. Because the dessiccant isnot applied as a glued on surfacecoating, it is not susceptible to erosion,abrasion, or de lamination of the desic-cant. The wheel matrix shall be rigid andglued layer-to-layer, and not susceptibleto sagging or separation of the layers.The wheel shall be structurally reinforced

with a spoking system to minimize wheeldeflection. Because the product isnonmetallic, it offers complete resistanceto corrosion. The media shall meet theflammability requirements governing thisclass of products and be UL recognizedcomponents in accordance to UL 1812and UL1995.

1.6. All cassettes shall include both acircumferential seal as an air block-offaround the perimeter, and an innerdiametric seal separating regenerationand supply sides. Seals shall be fullcontact nylon brush seals, whichminimizes leakage. Seals are factory setand field adjustable and make intimatecontact with the wheel on all surfaces.CDQ cassette, wheel ans seal configu-ration allows for operation at highdifferential pressures. Seal replacementshould not be necessary during the life ofthe product.

1.7. The drive system shall consist of aheavy-duty fractional horsepower A/Cgear motor mounted in the cassette andcooled by the Ahu air stream. Motorlocation shall be as required. All motorshave permanently lubricated bearings.Minimal amp draw will be reuired and allmotors shall be 115V/1PH/60Hz or 230V/1PH/60Hz. Drive belts shall be highperformance v-belt multilink belts. Themultilink belt allows for replacement ofindividual links (1” each) if a section ofbelt becomes worn or breaks. Belts areinstalled under tension, require nomechanical tensioner, and do not requireadjustment after startup. The rotationspeed of the wheel shall not exceed thescheduled value.

1.8. The wheel matrix shall be clean-able by vacuuming or pressurized airblowing, or alternatively with low tem-

perature steam, hot water, light detergent.

1.9. Cassettes shall be provided withbearings which support rotation of thewheel around a center shaft driven by aperimeter belt. The bearings shall beinternal ball bearings press fitted into thebored wheel hub for all wheels up to andincluding 72” diameter. Internal bearingsare permanently lubricated, no mainte-nance bearings which support fixed shaftoperation of the wheel assembly.Flanged or pillow block bearings whichsupport rotating shaft operation of thewheel assembly are used for all unitslarger than 72” diameter. Outboardbearings are provided with grease fittingsfor periodic lubrication. L10 bearing life isgreater than 400,000 at design condi-tions.

1.10. The wheel cassette shall becontinuous operation over ambienttemperatures ranging from -40F to 200Fat any relative humidity without adverselyaffecting wheel performance or life.

1.11. Performance shall be as predictedby CDQ selection software as sched-uled. The performance shall be basedon testing conducted on the wheelcassette installed in the air handlerconfiguration as shown in the AHUdrawings. Performance based on stand-alone desiccant wheel cassette or testswith two independent air streams areunacceptable. Performance data shallbe from tests of a complete unit per-formed by an ISO 9000 certified labora-tory. Temperature measurements shallbe taken using instrumentation whosecalibration is traceable to NIST stan-dards. Dry bulb and wet temperaturemeasurements shall be accurate to +/-0.1 Deg F. Performance prediction for theCDQ air handler shall be available formultiple conditions as required.

Literature Order Number

File Number

Supersedes

Stocking Location

Trane has a policy of continuous product and product data improvement and reserves the right to change design andspecifications without notice.

Tranewww.trane.com

For more information, contact your local district

office

CDQ-PRC001-E4 (February 2008)

New

Malaysia