Replacement Inhibitors for Tank Farm Cooling Coil Systems (U)

Mechanical System Redesign Dedicated Outdoor Air System ... · Figure 7 displays the coil selection...

Transcript of Mechanical System Redesign Dedicated Outdoor Air System ... · Figure 7 displays the coil selection...

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

17

Mechanical System Redesign

Dedicated Outdoor Air System

Design Criteria

The outdoor air conditions used were for Philadelphia, Pennsylvania IAP at a

0.4% occurrence. The supply air conditions were developed using an exhaustive search

method that optimized the cooling capacity of the ventilation air and the capacity of the

cooling panels at the same time. With these supply air conditions, the room air

conditions provide a high level of thermal comfort. Because the cooling panels transfer

heat through radiation and convection, the room feels comfortable even at a higher dry

bulb temperature.

Table 3-Outdoor and Space Conditions

Dry Bulb (° F) Humidity Ratio (gr/lbm)

Dew Point (° F) (for supply air)

Outdoor Air Conditions 92 104 - Supply Air Conditions 58 55.9 51 Room Air Conditions 78 57.3 -

Because the building originally had four AHUs, each serving one quadrant of the

building, four new AHUs will each serve the same quadrants. The design criteria for the

Pinnacle units, described in the next section, are as follows:

Table-4-AHU Criteria

Unit Name Pinnacle Unit Designation

Quadrant Served Airflow rate (cfm)

AHU-1 PVS-09 Northwest 4,000 AHU-2 PVS-09 Southwest 5,600 AHU-3 PVS-18 Northeast 9,700 AHU-4 PVS-09 Southeast 6,650

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

18

The specific size of AHU is based on air flow rate. Refer to appendix for the

Pinnacle Unit Selection Table used to determine the size of each AHU.

Refer to appendix for calculations of ventilation air. The amount of ventilation air

is calculated using ASHRAE Standard 62-2001 minimum outdoor air requirement. The

airflows are different from the original design because the multiple spaces equation of

Standard 62 is not used in this design. Table 3 summarizes these requirements:

Table 5-Ventilation Rates

Space Occupancy Load Ventilation

People /1000 ft2 CFM/Person

Conference room 50 20

Office space 7 20

Cafeteria Seating Area 100 20

Reception Area 60 20

The airflow rate of AHU-3 is higher than the other units because it serves the

servery/dining room. Additionally, a flat maximum occupancy of 120 people is used in

the dining room in modeling the building.

Pinnacle Ventilation System

The SEMCO Pinnacle Ventilation System AHU (PVS) was used to replace the existing

AHUs. This is because the Pinnacle System can produce low dew point space

temperatures economically regardless of the temperature of the chilled water suuplied to

the cooling coils. The PVS is comprised of a total energy wheel, a cooling coil, a passive

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

19

dehumidification wheel, a post-cooling coil, a supply fan, and a return fan. Because the

PVS has two energy recovery wheels, it is advantageous to use in this

application. The AHU components are described below, but the actual design was

performed by selection software provided by SEMCO.

The passive dehumidification wheel removes moisture more effectively than

dessicant-based cooling or even a dual-wheel energy recovery system. Thus, it can

produce the low dew point space temperature that is needed to decouple the space

sensible and latent loads. Figure 5 demonstrates its dehumidification capacity as a

function of wheel speed. This shows that the amount of dehumidification can be altered

by controlling the speed at which the wheel rotates.

Figure 5

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

20

The cooling coil, though part of the overall system, was selected using the USA

Coil software. The conditioning of the air in the PVS is not dependent on the chilled

water temperature. This makes it ideal for this particular application because the chilled

water system serves two buildings. The controls are much simpler if the chilled water

temperature is uniform throughout the system. Figure 6 displays the cooling coil

selection for AHU-1. Refer to the appendix for the cooling coils of the other three

AHUs.

Normally, a sensible wheel is used to recover sensible heat from the return air to

increase the supply air temperature. The supply air temperature needs to be increased

because overcooling can occur if the space loads are too small. This can happen when

the space is unoccupied. When a space is unoccupied, the humidity can be controlled by

reheating the air after it leaves the cooling coil. However, the PVS passive

Figure 6

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

21

dehumidification wheel must raise the temperature of the supply air to achieve the

desired humidity ratio. Consequently, the system needs a sensible cooling coil to post-

cool the supply air. The post-cooling coil was also selected using the USA Coil software.

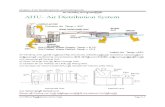

Figure 7 displays the coil selection for the post-cooling coil for AHU 1. Refer to

the appendix for the post-cooling coils of the other three AHUs.

Air System Modeling

Cooling loads for the building are modeled using Carrier’s Hourly Analysis

Program (HAP). The air system is modeled as a two-pipe fan coil unit with common

ventilation. The ventilation rates were those calculated in the appendix. This HAP

model provided the total sensible load for each space. This information was used to

design the radiant panel system discussed in the next section. The program also

calculated the cooling load on the chillers in the central plant. Refer to the energy

comparison section for a discussion on the reduction of cooling load on the chillers.

Figure 7

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

22

The most important HAP output is the breakdown of the total cooling load into

sensible and latent components. Refer to the appendix for the DOAS air system output.

This shows that the air system can adequately handle the entire modeled latent load using

the specified supply air conditions.

There are several ways that the AHU could be modeled using the SEMCO

modeling software, but because the space latent load is handled entirely by the DOAS,

the air system is modeled to determine the performance data for peak space latent loads.

Figure 8 shows the model of AHU-1. Refer to appendix for the models of AHU-2, AHU-

3, and AHU-4. It is clear that the PVS is capable of producing the required supply air

and room conditions. Figure 8 also shows the energy savings that are achieved using the

PVS. While this shows that the PVS saves energy, it compares the DOAS system to a

conventional system with the same supply air and room conditions. The current system

uses a supply air condition of saturated 55° F air, and a room condition of 75° F and 55%

RH. Because of the difference in conditions, more accurate energy savings are predicted

using HAP. Refer to the energy comparison section.

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

23

Refer to appendix for AHU-1 schematic.

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

24

Radiant Cooling Panel System

Radiant cooling panels are used in every space in the building to remove sensible

space loads that the DOAS cannot handle. Invensys Building System panels are selected

using their Magic 6 product selection software. Because the reflected ceiling plan of the

building is already set up in a 2’×4’ grid, 2’×4’ panels are selected. To maximize the

panels’ cooling capacity, the panels are free-hanging at 8’-0”, or 1’-6” below the original

ceiling line. The radiant panel system is also designed to take up at most 50% of the total

ceiling area to allow for other ceiling fixtures, such as lights, diffusers, and sprinkler

heads. For each quadrant, a pump delivers water to the radiant panel control closets on

each floor. In the control closets, one control valve for each zone controls the inlet

temperature of the water in one of the spaces.

Design

The total space sensible load is calculated using the HAP model. A Microsoft

Excel spreadsheet (see appendix) is used to determine how much of the space sensible

load could be handled by the DOAS system. The remainder of the sensible load is met

by the radiant panels.

The radiant panel inlet water temperature is chosen somewhat arbitrarily, but the

mean temperature difference is chosen to provide maximum capacity for each panel.

Table 4 summarizes the radiant panel design choices. Refer to appendix for Magic 6

software selection outputs.

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

25

Table 6-Radiant Panel Design Criteria

Room Dry Bulb Temperature ( ° F) 78 Panel Inlet Temperature (° F) 52 Panel Outlet Temperature (° F) 60 Mean Panel Temperature Difference (° F) 22 Total Capacity (Btu/ft2) 33.6 Pressure Drop (psi) 2.8 Water Velocity (fpm) 85

The air side temperature difference (∆T) is only 20° F, compared to a normal

DOAS ∆T of about 30° F. This means that the DOAS cooling capacity is relatively

small, because the cooling load is directly proportional to the ∆T of the standard air by

the equation Q=1.08×scfm×∆T. Consequently, the radiant panels have to remove more

of the space latent load. The way that the building envelope is currently designed allows

more sensible solar and envelope load into the space than can be handled by the DOAS

system and an appropriate amount of radiant panel area (<50% of the total floor area).

To overcome this problem, half of the windows in the exterior private and open offices

were replaced with spandrel panels that were modeled as equal in performance with the

wall construction. This exchange is discussed in the cost comparison section.

This envelope alteration did not completely solve the problem in the exterior

offices. In the perimeter spaces, more panel area, about 60% of the ceiling area, was able

to completely handle the sensible load. In corner offices and some of the perimeter

offices, the amount of air supplied to the space was increased slightly to overcome the

sensible load. Refer to the appendix for the complete design of every space.

To demonstrate that the radiant panel system can work in every space, figures 9

through 13 show sample radiant panel layouts for each type of space. These select spaces

are on the second floor and are served by either AHU-1 or AHU-2. In each figure, the

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

26

blue 2’×4’ panels are the radiant panels.

The radiant panels in the interior offices are able to handle the sensible load,

utilizing less than 50% of the ceiling area.

Figure 9

Figure 10

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

27

The percentage of ceiling area that the radiant panels cover is about 55%, but

there is still adequate room for other ceiling fixtures. The ventilation air is increased to

30 cfm.

The radiant panel area in the corner office is about 60% of the ceiling area, but

there is still adequate room for other ceiling fixtures. The ventilation air in this room is

increased to 60 cfm. This is a large increase, but the office is oriented to the southwest,

has a large envelope area, and thus receives a higher solar load.

Figure 11

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

28

The radiant panels in the conference room are able to handle the space sensible load. The

panels take up less than 50% of the ceiling area. This is very important in the conference

room, because there are extra ceiling fixtures, such as dimmable lights and a projector.

Figure 12

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

29

The radiant panels in the open office area are able to handle the space sensible

load, utilizing less than 50% of the ceiling area.

Panel Piping

For modeling purposes, the building is split into four main zones that correspond

to the areas that each AHU serves. These zones are divided into “mini-zones” that

correspond to a particular use group, such as perimeter enclosed offices with south-facing

exposure. The purpose of this grouping is to separately control the radiant panel water

flow to each mini-zone. Each mini-zone has its own control valve in a control closet that

Figure 13

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

30

can easily be manually adjusted and maintained. The location of the control valves is not

only advantageous to maintenance. If the control valves were located above the ceiling

in the space, a leak could drip into the space. Locating the control valves in a central

closet, however, reduces the risk of a leak developing above the space. Figure 14 on

page 32 shows the location of the control closet for AHU-2 on the second floor. The

valves are shown outside of the closet for clarity. One pump serves the control closets of

each AHU, and these pumps are located in the basement. It would be optimal to place

them in the same quadrant on one of the floors to be closer to the control closets, but the

pumps take up floor space and have the potential to leak.

While detailed controls for the piping system are out of the scope of this report, it

is necessary to discuss the basic control sequence. The water for the panels comes from

the chilled water system, which supplies chilled water at 44° F. A three-way valve is

used to mix returning 60° F water with the chilled water supply to maintain the required

52° F inlet water temperature.

One concern about locating chilled water piping in a space is what happens when

the air system that normally controls condensation is turned off at night and humidity is

allowed to build up. In this case, condensation would occur when 52° F water was

initially pumped back into the system in the morning. To prevent this, the three-way

valve can control the water temperature to ensure that is above the dew point of the

space.

Another control valve is placed farther down the supply line and is controlled by a

temperature sensor located at the inlet of the panel system of a typical space. Condensate

sensors in each room sense any condensation from the panels in the room. The

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

31

condensate sensors are located at the inlet of the piping, near the ceiling, to prevent

tampering. If the condensate sensor is tripped, the control valve in the control closet for

that mini-zone shuts down the flow to that mini-zone. Figure 15 on page 33 gives an

example of how one mini-zone could be controlled.

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

32

Figu

re 1

4

Pi

ctur

e no

t ava

ilabl

e du

e to

secu

rity

reas

ons.

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

33

Figu

re 1

5 Pi

ctur

e no

t ava

ilabl

e du

e to

secu

rity

reas

ons.

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

34

Mechanical System Energy Analysis

The new DOAS/Radiant system was compared to the current VAV system in

terms of monthly electrical energy usage and chiller plant load. The load breakdown of

each system was also compared. Table 7 summarizes the chiller plant load of each

system from the Phase 2 building only. The “original VAV” system serves the original

building.

Table 7-Chiller Plant Loads System Chiller Plant Load (tons) Original VAV System 541 DOAS/Radiant Parallel System 122

Figure 16 shows the cooling load breakdown of the original VAV system. Note how

small the envelope load is in comparison to the Outdoor Air Load. Figure 17 shows the

cooling load breakdown of the DOAS/Radiant System. Here, the envelope load

(including solar load) is a much higher percentage of the overall load because the OA

load does not factor in to the cooling load estimate. This also demonstrates why

eliminating one-half of the office windows contributes so strongly to the overall load on

the panels.

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

35

VAV System Cooling Load BreakdownEnvelope 3%

Occupant 9.74%

Electric 32%

OA Load 55%

DOAS/Radiant Cooling Load Breakdown

Total Electric67%

Occupant13%

Envelope20%

Figure 17

Figure 16

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

36

Mechanical System Cost Comparison

The first cost and monthly operating costs of the original VAV and DOAS system

were compared. These estimates do not take into account parts of the mechanical system

that did not change with the DOAS/Radiant system redesign. Because the chiller plant

serves both Phase 1 and Phase 2 buildings, the central plant configuration cannot be

altered. However, because the DOAS/Radiant system reduces the Phase 2 building

cooling load by so much, one of the water cooled electric chillers can be downsized from

650 tons to 350 tons. This also means that one of the cooling towers can be downsized to

match the condenser water flow from the smaller chiller.

The main first cost savings, however, come from the reduction in ductwork.

Table 8 shows a summary of the first costs of each system and the amount of savings that

the DOAS/Radiant system produces.

Table 8-First Cost Comparison

Item Unit Cost-VAV Units-VAV VAV Unit Cost-Parallel Units-Parallel Parallel Savings650 tonAbs Chiller $321,000 1 $353,100 $321,000 1 $353,100 $0650 ton WC Chiller $229,500 3 $757,350 $229,500 2 $504,900 $252,450350 ton WC Chiller N/A N/A $132,000 1 $145,200 -$145,200650 ton CT $26,796 4 $117,902 $26,796 3 $88,427 $29,476350 ton CT N/A N/A $16,433 1 $18,076 -$18,076Ductwork1 $4/ft2 186000 $744,000 $1/ft2 186000 $186,000 $558,000AHU-1 $77,808 1 $85,589 $24,378 1 $26,816 $58,773AHU-2 $77,808 1 $85,589 $26,366 1 $29,003 $56,586AHU-3 $77,808 1 $85,589 $35,903 1 $39,493 $46,096AHU-4 $77,808 1 $85,589 $28,372 1 $31,209 $54,380Radiant Panels1 N/A N/A N/A $13/ft2 44528 ft2 $636,750 -$636,750

$255,733All cost estimates are from RS Means, 2003, unless noted otherwise

1: Cost estimate from Mumma. "Ceiling Panel Cooling Systems," ASHRAE Journal: ASHRAE, November 2001.

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

37

The DOAS/Radiant system also saves operating costs. An energy analysis is

performed for both VAV and DOAS/Radiant systems using the HAP which shows that

the DOAS/Radiant system also has a lower operating cost. Table 9 summarizes these

figures, while Figure 18 compares each system visually. Table 9 also compares the

energy usage for each system.

Table 9-Monthly Electric Operating Costs

Month DOAS VAV Month DOAS VAVJan $37,569 $45,143 Jan 540,757 606,443Feb $36,159 $41,649 Feb 517,403 579,503Mar $41,326 $49,954 Mar 609,632 687,669Apr $42,668 $52,720 Apr 616,664 714,326May $45,969 $56,471 May 654,107 764,653Jun $52,421 $64,663 Jun 768,431 911,262Jul $56,219 $68,312 Jul 839,679 952,718

Aug $54,478 $67,740 Aug 805,920 935,599Sep $51,367 $63,633 Sep 744,782 886,787Oct $44,134 $53,844 Oct 630,335 734,301Nov $42,248 $51,454 Nov 599,605 683,471Dec $40,651 $48,280 Dec 596,817 670,487

Total $545,207 $663,860 Total 7,924,132 9,127,219$118,653 Savings 1,203,087

Electric Cost

Savings

Electric Usage (kWh)

The spandrel panels that take the pace on about one-half the windows in the office

spaces could present a higher first cost. However, a comparison of costs from Means

2003 Facilities Construction Cost Data shows that the cost of an insulated spandrel panel

is about the same as a tinted, doubled glazed window.

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

38

Electric Operating Cost Comparison

$0

$5,000

$10,000

$15,000

$20,000

$25,000

$30,000

$35,000

$40,000

$45,000

$50,000

$55,000

$60,000

$65,000

$70,000

$75,000

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

Dol

lars

DOAS/Radiant System

VAV System

Figure 18

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

39

Conclusions

Because the mechanical system for this building cannot adequately meet the

intent of ASHRAE Standard 62-2001, a DOAS system, coupled with radiant cooling

panels was implemented in the building. This new system reduces the cooling load on

the chiller plant, reduces first cost and reduces electric operating cost. Because of these

savings, this new system should be implemented.

The DOAS system provides the correct amount of fresh air to each space to meet

the intent of ASHRAE Standard 62-2001 and provide a comfortable indoor air

environment. Four SEMCO PVS AHUs are used to condition the outdoor air using the

common chilled water temperature so that the central chiller plant does not have to be

altered. The DOAS system is able to completely handle the space latent load and some

of the space sensible load, so that the radiant ceiling panels only have to take care of the

excess sensible load.

Radiant panels in every space of the building take care of the excess sensible load

while usually taking up less than one-half of the ceiling area, leaving the rest of the

ceiling for other ceiling fixtures such as lights, diffusers, and A/V equipment. The

radiant panel chilled water flow is controlled at control closets on each floor of the

building in every quadrant. Each control closets contain valves for “mini-zones” that the

closet maintains. These control closets utilize space that was formerly vertical duct space

and provide a maintenance friendly area for control.

Though the DOAS/Radiant system saves money in both first and operating costs,

there are a few reservations with the system. First of all, in some spaces, namely the

Rebecca Rubert NWI EnterprisesMechanical Option Frazer, PA

40

corner offices, the radiant panels take up so much of the ceiling that the ceiling height

should be lowered to the panel height of 8’-0” so that the ceiling has a more uniform

height. This is a workable solution, but the occupants of the corner offices may feel that

their offices are smaller because of the lower ceiling height. Additionally, in these areas

it may be difficult to locate a ceiling position for the sprinkler heads because the lights,

diffusers, and panels take up most of the ceiling space. Integrating the fire suppression

system with the radiant panel piping system may solve this problem, but that is out of the

scope of this redesign.

Overall, this DOAS/Radiant system provides a thermally comfortable, cost

effective mechanical system.