Technical Manual for Veda Software · Technical Manual for Veda Final Report Prepared by: George...

Transcript of Technical Manual for Veda Software · Technical Manual for Veda Final Report Prepared by: George...

Technical Manual for

Veda Software

…………..

…………..

N

E

Pass No. =1

Pass No.=2

Pass No.=3321

Legend of Pass No.

IX X

VII VI II

V VI

II I IV

I II

•I, V and IX are same coordinate.•II, VI and X are same coordinate.•III and VII are same coordinate.•IV and VIII are same coordinate.

All passes data Proofing data only

Y axis (North)

X axis (East)

Lag Tolerance

Azimuth

Lag D

istan

ceLag

1Lag

2

Lag 3

Lag 4

Bandwidth

Azimuth tolerance

Y axis (North)

X axis (East)

Lag Tolerance

Azimuth

Lag D

istan

ceLag

1Lag

2

Lag 3

Lag 4

Bandwidth

Azimuth tolerance

1. Report No. MN/RC-2010-11-___

2. Government Accession No. N/A

3 Recipient Catalog No. N/A 5. Report Date August 2011

4. Title and Subtitle Technical Manual for Veda

6. Performing Organization Code N/A

7. Author(s) George Chang, Qinwu Xu, Jason Dick, and Jennifer Rutledge of the Transtec Group Inc.

8. Performing Organization Report No. N/A

10. Work Unit No. (TRAIS) N/A

9. Performing Organization Name and Address The Transtec Group, Inc. 6111 Balcones Drive Austin TX 78731

11. Contract or Grant No. Mn/DOT Contract No . 97334 13. Type of Report and Period Covered Final report (draft)

12. Sponsoring Agency Name and Address This effort is sponsored jointly by Mn/DOT and FHWA. Minnesota Dept. of Transportation Consultant Services Section, Mail Stop 680 395 John Ireland Boulevard St. Paul , Minnesota 55155

14. Sponsoring Agency Code N/A

15. Supplementary Notes 16. Abstract Intelligent compaction (IC) is an emerging technology, and for some applications it is mature enough for implementation in field compaction of pavement materials. IC data are often massive and new to DOTs and industries. Thus, it requires practical guidelines and protocol to assist DOTs and industries to properly manage the IC data in order to provide support for decision-making and quality control/acceptance (QC/QA). Therefore, there is an immediate need to develop IC Data Management Protocol to fulfill these needs, and on a local level, to assist with Minnesota’s current implementation efforts. The tool would be used by research personnel for further development and refinement of the Minnesota Department of Transportation’s (MnDOT) draft specifications and by the Inspectors for review of uniformity and assistance in the determination of areas for QA spot testing. Features are included to analyze defection data from sonic test rolling (STR). This document is a technical manual to describe in details on the methods and algorithms of the IC and STR data management tool - Veda. 17. Key words Compaction, intelligent compaction, roller, data, viewing, analysis, pavement performance.

18. Distribution Statement No restrictions. This document is available to the public through the National Technical Information Service, Springfield, Virginia 22161

19. Security Classif. (of this report) Unclassified

20. Security Classif. (of this page) Unclassified

21. No. of Pages

22. Price

i

SI* (MODERN METRIC) CONVERSION FACTORS APPROXIMATE CONVERSIONS TO SI UNITS

Symbol When You Know Multiply By To Find Symbol LENGTH

in inches 25.4 millimeters mm ft feet 0.305 meters m yd yards 0.914 meters m mi miles 1.61 kilometers km

AREA in2 square inches 645.2 square millimeters mm2

ft2 square feet 0.093 square meters m2

yd2 square yard 0.836 square meters m2

ac acres 0.405 hectares ha mi2 square miles 2.59 square kilometers km2

VOLUME fl oz fluid ounces 29.57 milliliters mL gal gallons 3.785 liters L ft3 cubic feet 0.028 cubic meters m3

yd3 cubic yards 0.765 cubic meters m3

NOTE: volumes greater than 1000 L shall be shown in m3

MASS oz ounces 28.35 grams glb pounds 0.454 kilograms kgT short tons (2000 lb) 0.907 megagrams (or "metric ton") Mg (or "t")

TEMPERATURE (exact degrees) oF Fahrenheit 5 (F-32)/9 Celsius oC

or (F-32)/1.8 ILLUMINATION

fc foot-candles 10.76 lux lx fl foot-Lamberts 3.426 candela/m2 cd/m2

FORCE and PRESSURE or STRESS lbf poundforce 4.45 newtons N lbf/in2 poundforce per square inch 6.89 kilopascals kPa

APPROXIMATE CONVERSIONS FROM SI UNITS Symbol When You Know Multiply By To Find Symbol

LENGTHmm millimeters 0.039 inches in m meters 3.28 feet ft m meters 1.09 yards yd km kilometers 0.621 miles mi

AREA mm2 square millimeters 0.0016 square inches in2

m2 square meters 10.764 square feet ft2

m2 square meters 1.195 square yards yd2

ha hectares 2.47 acres ac km2 square kilometers 0.386 square miles mi2

VOLUME mL milliliters 0.034 fluid ounces fl oz L liters 0.264 gallons gal m3 cubic meters 35.314 cubic feet ft3

m3 cubic meters 1.307 cubic yards yd3

MASS g grams 0.035 ounces ozkg kilograms 2.202 pounds lbMg (or "t") megagrams (or "metric ton") 1.103 short tons (2000 lb) T

TEMPERATURE (exact degrees) oC Celsius 1.8C+32 Fahrenheit oF

ILLUMINATION lx lux 0.0929 foot-candles fc cd/m2 candela/m2 0.2919 foot-Lamberts fl

FORCE and PRESSURE or STRESS N newtons 0.225 poundforce lbf kPa kilopascals 0.145 poundforce per square inch lbf/in2

*SI is the symbol for th International System of Units. Appropriate rounding should be made to comply with Section 4 of ASTM E380. e(Revised March 2003)

ii

Technical Manual for Veda

Final Report

Prepared by:

George Chang, Qinwu Xu, Jason Dick, and Jennifer Rutledge

The Transtec Group, Inc.

6111 Balcones Dr. Austin, TX 78731

For:

Minnesota Department of Transportation

Office of Materials and Road Research

395 John Ireland Blvd, St. Paul, MN 55155

And

Federal Highway Administration

Office of Pavement technology

1200 New Jersey Ave., SE

Washington, DC 20590

August 2011

This report represents the results of research conducted by the authors and does not necessarily represent the views or policies of

the Minnesota Department of Transportation. This report does not contain a standard or specified technique.

The authors and the Minnesota Department of Transportation do not endorse products or manufacturers. Trade or manufacturers’

names appear herein solely because they are considered essential to this report.

iii

TABLE OF CONTENTS

Acknowledgement ........................................................................................................................................ 1 Introduction 2 Basic Univariate Statistics ............................................................................................................................ 5

Methodology ............................................................................................................................................. 5 Implementation ......................................................................................................................................... 6

Histogram 8 Methodology ............................................................................................................................................. 8 Implementation ......................................................................................................................................... 8

Semi-variogram........................................................................................................................................... 10 Methodology ........................................................................................................................................... 10

Introduction......................................................................................................................................... 10 Algorithm of semi-variogram ............................................................................................................. 11

Implementation ....................................................................................................................................... 15 Compaction Curves..................................................................................................................................... 17

Methodology ........................................................................................................................................... 17 Implementation ....................................................................................................................................... 17

Correlation Analysis ................................................................................................................................... 19 Methodology ........................................................................................................................................... 19 Implementation ....................................................................................................................................... 20

Fixed Interval Analysis ............................................................................................................................... 22 Methodology ........................................................................................................................................... 22 Implementation ....................................................................................................................................... 22

Linear failure Analysis................................................................................................................................ 24 Methodology ........................................................................................................................................... 24 Implementation ....................................................................................................................................... 25

References 27

LIST OF TABLES

LIST OF FIGURES

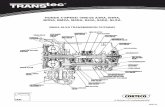

Figure 1. Time history data vs. post-processed data (Sakai America). ........................................................ 3

iv

Figure 2. All passes data and proofing data (Sakai America)...................................................................... 4 Figure 3. Basic univariate statistics report in Veda...................................................................................... 7 Figure 4. Histogram report in Veda. ............................................................................................................ 9 Figure 5. Description of a typical experimental and exponential semi-variogram and its parameters ....... 10 Figure 6. Location and lag vectors............................................................................................................. 11 Figure 7. Direction for a semi-variogram analysis..................................................................................... 12 Figure 8. Nodal data used for semi-variogram analysis within a given lag distance. ................................ 13 Figure 9. Experimental semi-variogram. ................................................................................................... 13 Figure 10. Curve fits of theoretical Semi-variogram models..................................................................... 15 Figure 11. Semi-variogram report.............................................................................................................. 16 Figure 12. Compaction Curve Report. ....................................................................................................... 18 Figure 13. Data extracted from a circular area centering a point test location. ......................................... 19 Figure 14. Correlation Report .................................................................................................................... 21 Figure 15. User-defined start/stop locations and lots................................................................................. 22 Figure 18. Linear Failure Analysis ............................................................................................................ 23 Figure 15. User-defined start/stop locations and moving average base length. ......................................... 24 Figure 16. Zoom in to user-defined start locations and moving average base length................................ 24 Figure 17. Refined segments to produce data points for moving average computation. ........................... 25 Figure 18. Linear Failure Analysis ............................................................................................................ 26

v

Acknowledgement

This document would not have been possible without the partial sponsorship from MnDOT and the FHWA.

The authors would also like to specifically acknowledge the following individuals for their contribution to this document:

• MnDOT: Glenn Engstrom, Chief Geotechnical Engineer, Terry Beaudry, Grading, Base and Aggregate Engineer, and Rebecca Embacher, Assistant Grading and Base Engineer.

• FHWA: Victor (Lee) Gallivan

1

Introduction

Veda (pronounced as "Vehda" - means "knowledge") is a generic software for viewing and analyzing

geospatial data. Currently, the applications are limited for intelligent compaction (IC) and sonic test

rolling (STR). Veda can now import data from various intelligent compaction machines and STR device,

then perform standardized data processing and reporting. Users should follow the step-by-step

instructions in the IC Data Management Guidelines and STR Data Management Guidelines to

setup/collect/export data for specific vendors' systems prior to importing data to Veda. This document

focuses on the methods and algorithm for the IC and STR analyses.

The IC and STR analyses target various types of data sets. Generally, IC-related data include post-

processed IC measurement values (ICMV) and other measurements from vendors’ software and in-situ

point test data collected with other devices. Please refer to the companion report “IC Data Management

Guidelines” and “STR Data Management Guidelines” for further details.

IC vendors often store IC data in two different forms: Time History Data and Post-Processed Data (see

Figure 1).

• Time History Data: Time history data record the raw IC data during compaction operations. They

normally include one data point at the bottom center of the drum at a point in time, usually at 10 Hz

resulting a sampling rate at approximately 1 ft/sec .

• Post-Processed Data: The Time History Data can be post-processed (sometimes in real-time for some

vendors’ solutions) to produce data in finer meshes, often by duplicating data points over the drum

width at a 1 ft. interval. Some vendors also provide users options to store the post-processed data in

all-passes or proofing form.

2

…………..

…………..

N-E coordinates of *.gps are here which is center of drum.

N-E coordinates of *.pln are here which is center of mesh.These coordinates are calculated by AithonMT using *.gps data and setting data.

N

E (Courtesy of Sakai)

Figure 1. Time history data vs. post-processed data (Sakai America).

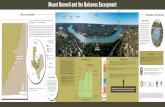

The post-processed data can be in two sub-forms: All-Passes Data and Proofing Data. These two forms

can be imported to Veda.

• All-Passes Data: As this term indicates, All-Passes Data include all passes within a given mesh

(e.g., coverage I through X in Figure 2).

• Proofing Data: The Proofing Data contain only the last passes within a given mesh (e.g., coverage

VII, VIII, IX, and X in Figure 2).

3

…………..

…………..

N

E

Pass No. =1

Pass No.=2

Pass No.=3321

Legend of Pass No.

IX X

VII VIIIV VI

III IVI II

•I, V and IX are same coordinate.•II, VI and X are same coordinate.•III and VII are same coordinate.•IV and VIII are same coordinate.

All passes data Proofing data only

(Courtesy of Sakai)

Figure 2. All passes data and proofing data (Sakai America).

The structure of Veda data analyses is summarized as follows:

• Proof data analysis o Basic statistics and Histogram o Fix interval report (if the start and end locations are selected and the fix lot length

is defined) o Correlation with point test data (if available) o Linear failure analysis (for STR data only) o Semi-variogram (optional)

• All-passes data analysis o Basic statistics and Histogram o Semi-variogram (optional) o Compaction curves o Correlation with point test data (if available)

The followings detail the methods and implementation of the above analyses.

4

Basic Univariate Statistics

Methodology

The basic univariate statistics for a population or data set consists of the followings:

• mean value

• variance

• standard deviation

• skewness

• Kurtosis excess

• min values

• max values

• ranges

• coefficient of variations

• counts

• lower 95% confidence limits for mean

• high 95% confidence limits for mean

• lower 95% confidence limits for variance

• high 95% confidence limits for variance

• sum of weights

The confidence intervals for the mean and variance are computed if the sample is assumed to be from a

normal population.

Definition for selected statistics reports are presented below:

The sample arithmetic mean is defined as follows:

∑=

=n

iix

nx

1

1 (1)

Where,

5

n : number of data points;

xi : data values.

Sample standard deviation is defined as follows:

∑=

−−

=n

ii xx

n 1

2)(1

1σ (2)

Where,

x : sample mean value.

Coefficient of variance is determined as follows:

xσ

=cov (3)

Sample skewness, a measure of the degree of asymmetry of a distribution is determined as follows:

( )

( )2/3

2

3

/

/

⎥⎦

⎤⎢⎣

⎡−

−=

∑

∑n

ii

n

ii

nxx

nxxSkewness (4)

Sample excess/kurtosis, the degree of peakedness of a distribution, is determined as follows:

( )

( )3

/

/

22

4

−

⎥⎦

⎤⎢⎣

⎡−

−=

∑

∑n

ii

n

ii

nxx

nxxKurtosis (5)

Currently, only selected statistics are reported including: minimum, maximum, mean, standard deviation,

coefficients of variation, and sample size.

Implementation

The basic univariate statistics function in Veda is implemented by utilizing an IMSL function call,

UVSTA (IMSL, 2007). If users setup target values for passing score, “% of Target Achieved” and

“Target Status (i.e., pass or failed)” will be included in the report. “% of Target Achieved” means the

percentage of data that meet the target values (i.e., for ICMV, it is equal or greater than the target value; it

is the opposite for sonic test rolling deflection data). “Target Status” means that whether the area of

interest is a pass or fail based on the minimum requirement of percentage of data meeting the target

6

values. An example report is illustrated as follows:

Figure 3. Basic univariate statistics report in Veda.

7

Histogram

Methodology

The histogram is a graphical display of tabular frequencies, shown as adjacent rectangles. The histogram (tabular frequency) of a specific interval is computed as the percentage of the quantity within that interval over the total quantity of observation. Table 1 shows the tabular frequency for a sample with size of 27.

Table 1. An example of histogram analysis

Interval Width Quantity (Q) Freqency0 2 2 7.41%2 3 3 11.11%5 1 4 14.81%6 3 5 18.52%9 1 6 22.22%10 5 7 25.93%

Implementation

The histogram function in Veda is implemented by utilizing an IMSL function call, OWFRQ, to tally

observations into a one-way frequency table (IMSL, 2007). An example report is illustrated as follows:

8

Semi-variogram

Methodology

Introduction

A semi-variogram is a plot of the average squared differences between data values as a function of separation distance, and is a common tool used in geostatistical studies to describe spatial variation. A typical semi-variogram plot is presented in Figure 5.

The semi-variogram is defined as one-half of the average squared differences between data values that are separated at a distance h (Isaaks and Srivastava 1989). If this calculation is repeated for many different values of lag distances (as long as the sample data will support) the result can be graphically presented as experimental semi-variogram shown as circles in Figure 5. More details on experimental semi-variogram calculation procedure are available elsewhere in the literature (e.g., Clark and Harper 2002, Isaaks and Srivastava 1989).

To obtain an algebraic expression for the relationship between separation distance and experimental semi-variogram, a theoretical model is fit to the data. Some commonly used models include linear, spherical, exponential, and Gaussian models. An exponential semi-variogram is illustrated in Figure 5 as solid line.

Separation Distance (m)

Sem

ivar

iogr

am

Range, R

Effective RangeR* (3R to 5R)(For Exponential or Gaussian models)

Scale, C

Nugget, C0

SillC + C0

Range: As the separation distance between pairs increase, the corresponding semivariogram value will also generally increase. Eventually, however, an increase in the distance no longer causes a corresponding increase in the semivariogram, i.e., where the semivariogram reaches a plateau. The distance at which the semivariogram reaches this plateau is called as range. Longer range values suggest greater spatial continuity or relatively larger (more spatially coherent) “hot spots”.

Sill: The plateau that the semivariogram reaches at the range is called the sill. A semivariogram generally has a sill that is approximately equal to the variance of the data.

Nugget: Though the value of the semivariogram at h = 0 is strictly zero, several factors, such as sampling error and very short scale variability, may cause sample values separated by extremely short distances to be quite dissimilar. This causes a discontinuity at the origin of the semivariogram and is described as nugget effect.(Isaaks and Srivastava, 1989)

Exponential Semivariogram

ExperimentalSemivariogram

Figure 5. Description of a typical experimental and exponential semi-variogram and its parameters

Three important features to construct a theoretical semi-variogram include: sill (C+C0), range (R), and nugget (C0). These parameters are briefly described in Figure 5. Arithmetic expressions and detailed descriptions of theoretical models can be found elsewhere in the literature (e.g., Clark and Harper 2002, Isaaks and Srivastava 1989).

For the semi-variogram analysis in Veda, the sill, range, and nugget values during theoretical model fitting were determined by checking the models for “goodness” using the modified Cressie goodness fit

10

method (see Clark and Harper 2002) and cross-validation process (see Isaaks and Srivastava 1989). From a theoretical semi-variogram model, a low “sill” and longer “range of influence” represent best conditions for uniformity, while the opposite represents an increasingly non-uniform condition.

Algorithm of semi-variogram

Data conversion

Spatial variability/continuity depends on the detailed distribution of the physical attributes. Attributes with highly skewed data distribution present problems in variogram calculation and the extreme values have significant impact on variogram. Therefore, raw data are transformed to the logarithmical scale prior to the semi-variogram analysis:

)(log10 zZ = (6)

Where,

z : data value such as ICMV.

Location and lag vector definition

Next, the location vector and lag vector are defined for a 2-dimentional (2-D) space (Figure 6).

Location vector (μ)

Lag vector (h)

Loca

tion

vect

or (μ

+h)

Origin

Location vector (μ)

Lag vector (h)

Loca

tion

vect

or (μ

+h)

Origin

Figure 6. Location and lag vectors.

11

Direction and model parameter definition

The direction specification for the semi-variogram analysis is then defined as shown in Figure 7. The direction (and its angle), lag number, interval for lag distance, bandwidth, and total length (distance) are specified.

Y axis (North)

X axis (East)

Lag Tolerance

AzimuthLag

Dist

ance

Lag 1

Lag 2

Lag 3

Lag 4

Bandwidth

Azimuth tolerance

Y axis (North)

X axis (East)

Lag Tolerance

AzimuthLag

Dist

ance

Lag 1

Lag 2

Lag 3

Lag 4

Bandwidth

Azimuth tolerance

Figure 7. Direction for a semi-variogram analysis.

Calculation of semi-variogram:

The semi-variogram for a lag distance is defined as the average squared difference of data values separated approximately by lag distance, for all possible locations:

[ ]{ }2)()()(2 huZuZEh +−=γ (7)

Where,

μ : location;

h : lag distance ( could be constant for the same lag area). h

The variogram can be re-expressed as follows:

[ ]∑ +−=)(

2)()()(

1)(2hN

huZuZhN

hγ (8)

Where,

)(hN : the number of pairs for lag distance h of a specific lag area

The semi-variogram is then attained as follows:

12

[∑ +−=)(

2)()()(2

1)(hN

huZuZhN

hγ ] (9)

Figure 8 shows that the nodal data used to determine the semi-variogram for a given lag distance.

Y axis (North)

Lag 1

Lag 2

Lag 3

Lag 4

Y axis (North)

Lag 1

Lag 2

Lag 3

Lag 4

Y axis (North)

Lag 1

Lag 2

Lag 3

Lag 4

Figure 8. Nodal data used for semi-variogram analysis within a given lag distance.

Model fit

The resulting semi-variogram values for lag distances are plotted as an experimental semi-variogram (in Figure 9).

Vario

gram

γ(h

)

Lag distance (h)

Increase variability

No correlation

Vario

gram

γ(h

)

Lag distance (h)

Increase variability

No correlation

Figure 9. Experimental semi-variogram.

13

Various mathematical models can be used to fit the experimental semi-variogram: including power model, exponential model, and Gaussian model, etc.

Power model: c

ahahr ⎟⎠⎞

⎜⎝⎛= .)( (10)

Exponential model:

⎥⎦

⎤⎢⎣

⎡⎟⎠⎞

⎜⎝⎛−−=

ahchr 3exp1)( (11)

Gaussian model:

⎥⎦

⎤⎢⎣

⎡⎟⎟⎠

⎞⎜⎜⎝

⎛−−= 2

29exp1)(ahchr (12)

Where,

a , : model parameters. c

Based on the geospatial data collected from intelligent compaction, it appears that the exponential model provides better fit than other models. Figure 10 shows an example of an experimental semi-variogram of IC data and fitted curves with the exponential, Gaussian, and power model, respectively. Once a theoretical semi-variogram fit is performed, the parameters such as nugget, sill, scale, and range can be found.

14

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

0 20 40 60 80 100 120 140 160

Lag distances (m)

Semi-variogram

Experimental semi-variogram

Exponential model

Gaussian model

Pow er model

Figure 10. Curve fits of theoretical Semi-variogram models.

Implementation

The semi-variogram function in Veda is implemented using an algorithm similar to the GAMV function

of the GSLIB geostatistical software library (Deutsch and Journel, 1998). The fitting of theoretical semi-

variogram is implemented by using an IMSL function, BCNLS, solving a nonlinear least-squares problem

subject to bounds on the variables and general linear constraints (IMSL, 2007). The exponential model is

used for the curve fitting. Currently, some inputs are fixed with default values as follows

Parameters Default Number of lags 10 Lag distance 4 Lag tolerance 2 Angle of direction 45 Angle tolerance 90 horizontal bandwidth 50 Dip angle 0 Dip angle tolerance 0 Vertical bandwidth 50 Standardize sills? No Tail variable 1 Head variable 1 Semivariogram type Traditional semivariogram

15

Compaction Curves

Methodology

Compaction curves indicate the trend of compaction effects versus roller passes. The optimal roller pass count can be determined from a compaction curve, e.g., data from a test strip. Compaction curves can also be produced from different stages or sections of constructions to monitor the efficiency of compaction.

To build a compaction curve, the following steps should be followed:

• Define a zone or compaction area for analysis;

• Compute mean values of ICMV for data corresponding to each roller pass;

• Plot mean ICMV values against roller pass counts;

• Fit the data points to a second-order polynomial function;

• Obtain the fitted coefficients and the R2 value.

The second-order polynomial function is defined as follows: 2ncnbaRMV ⋅+⋅+= (13)

Where,

a ,b ,and : fitted coefficients; c

n : roller pass count.

Implementation

The compaction curve function in Veda is implemented using the SVIGP function (group data for each

pass count), the UVSTA function (obtain mean values via univariate statistics) and the RCURV function

(perform polynomial curve fit) (IMSL, 2007). An example report is illustrated as follows:

17

Correlation Analysis

Methodology

The correlation between the in-situ point measurements (e.g. density, deflection) and the ICMV is expressed with linear function fit following the steps.

• Extract ICMV data points within a circular area (typical 1 m of radius) centering the location

of a point test. (Figure 13)

• Compute mean values of ICMV from the extracted data.

• Plot mean values of extracted IC data vs. point test values.

• Perform linear fit to the above data points and report fitted equations and R2.

2 m2 m2 m

Figure 13. Data extracted from a circular area centering a point test location.

The least square method was used for the linear fit between ICMV (Y) and spot measurements (X):

XbaY ⋅+= (14)

Where,

a : intercept of linear function;

b : slope of the linear function.

19

)(),(

xVaryxCovb = =

∑∑

−

−−

ii

iii

xx

yyxx

2)(

))(( (15)

xbya ⋅−= (16)

Where,

Cov is the covariance

2)()( xxVar σ= .

The R2 value is used to rate the goodness of fit:

tot

err

SSSSR −=12 (17)

Where

∑ −=i

itot yySS 2)( is the total sum of squares;

∑ −=i

iierr fySS 2)( is the residual sum of squares;

if : estimated data;

iy : observed data.

Implementation

The correlation analysis in Veda is implemented using an algorithm similar to the

CIRCLE_IMP_CONTAINS_POINT_2D function of the Geopak software library to extract data (Joes, B.

1993) and the IMSL RCURV function to perform polynomial curve fit (IMSL, 2007). An example report

is illustrated as follows:

20

Fixed Interval Analysis

Methodology

The fixed interval analysis is to analyze data in a linear lot-by-lot fashion. Based on user-defined start

and stop location as well as the lot length, this analysis will produce analysis results for lots along the data

stream (e.g. road ways).

Figure 15. User-defined start/stop locations and lots.

The data stream is divided into lots, and data within each lot are analyzed. Based on user-defined failure

criteria for the measurement values, percentage of failure segments is computed. Pass or fail will then be

determined similar to that for the basic stats.

Implementation

The fixed interval analysis in Veda is implemented using an algorithm described above. An example

report is illustrated as follows:

22

Linear failure Analysis

Methodology

The linear failure analysis is to analyze data in a linear moving average fashion. Based on user-defined

start and stop location as well as the moving average base length, this analysis will produce moving

averaged values vs. linear distance along the data stream (e.g. road ways).

Figure 17. User-defined start/stop locations and moving average base length.

Figure 18. Zoom in to user-defined start locations and moving average base length.

24

The data stream is divided into fine segments, and data values with fine segments are average to produce

mean values for subsequent moving average. Based on user-defined failure criteria for the measurement

values, percentage of failure segments is computed. Pass or fail will then be determined based on user-

defined threshold for percentage of failed segments.

Figure 19. Refined segments to produce data points for moving average computation.

Implementation

The linear failure analysis in Veda is implemented using an algorithm described above. Currently, linear

failure analysis is only available to analyze sonic test rolling data. An example report is illustrated as

follows:

25

References

Clark, I., and W. Harper. Practical Geostatistics 2000. 3rd edition, Ecosse North America Llc, Columbus,

OH, 2002.

Deutsch, C. V., and Journel, A.G. GSLIB: Geostatistical Software Library and User’s Guide, second

edition, 1998.

Isaaks, E.H., and R.M Srivastava. An Introduction to Applied Geostatistics. Oxford Univ. Press, New

York, 1989.

Joe, B., GEOMPACK Users’ Guide, 1993.

27

Contact Information

Glenn Engstrom, P.E. Mn/DOT

395 John Ireland Blvd, St. Paul, MN 55155 (651) 366-5531

George Chang, P.E., PhD The Transtec Group, Inc

6111 Balcones Dr. Austin, TX 78731 (512) 451-6233 Fax (512) 451-6234

Report Prepared by

George Chang, P.E., PhD Qinwu Xu Jason Dick

Jennifer Rutledge The Transtec Group, Inc.