Slewing Rings - Rotis temperature range for normal op-eration of slewing rings lies between -25°C...

Transcript of Slewing Rings - Rotis temperature range for normal op-eration of slewing rings lies between -25°C...

3

CCONTENTS

Product overview

Examples of application

Assembly

Attributes

Quality

Functioning of slewing ring

Other atributes

Mounting

Markings

4

5

6

9

10

11

16

19

25

Model 2000:Single-row axial - ball bearing slewing rings without teethSingle-row axial - ball bearing slewing rings with internal gearSingle-row axial - ball bearing slewing rings with external gear

Model 3000:Single-row axial - ball bearing slewing rings without teeth Single-row axial - ball bearing slewing rings with external gearSingle-row axial - ball bearing slewing rings with internal gear

Model 4000:Double-row axial - ball bearing slewing rings with internal gear Double-row axial - ball bearing slewing rings with external gear

Model 5000:Single-row axial - roller bearing slewing rings with internal gear Single-row axial - roller bearing slewing rings with external gear

Model 7000:Three-row axial - radial roller bearing slewing rings with internal gear Three-row axial - radial roller bearing slewing rings with external gear

27

32

38

44

48

4

PPRODUCT OVERVIEW

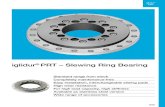

Model Typ 2000Single-row ball bearing slewing rings

Model Typ 3000Single-row ball bearing slewing rings bearings

Model Typ 4000Double-row ball bearing slewing rings

Model Typ 5000Single-row roller bearing slewing rings

Model Typ 7000Three-row roller bearing slewing rings

5

TEXAMPLES OF APPLICATION

Examples of application:

Slewing rings connections are used in different revolving con-structions with the most frequent areas of their application compris-ing:

Production of revolving construction

cranes

Shipyard cranes

Airport cranes

Cranes mounted on vehicles

Workshop cranes; Earthwork ma-

chines Excavators

Shovel loaders

Stone-crushing machines, Excavators

with shovel-shaped wheels (anten-

nas)

Telescopes and periscopes; indus-

trial and welding robots Switchover

technologies

Naval technologies

Road and track vehicles, Naviga-

tion systems for vehicles, Recycling

machines

Armoured vehicles and tanks

Artillery

6

AASSEMBLY

MATERIALS

Rotis uses a variety of steel whose

differing structural conditions (nor-

malised or tempered) allow them to

be used for the most varied of appli-

cations whereby tempered steel is far

better suited for the manufacture of

both bearings and gears subjected to

higher load conditions than is normal-

ised steel.

For the manufacture of slewing rings

ROTIS defines the materials best suit-

ed for their intended application in

its product concepts catalogue. These

materials are then manufactured from

type-tested steel.

COMPONENTS

External or internal gear

Internal ring

Holes for fastening bolts

Raceway

Seal

Rollers or balls

Filler plug

Grease nipple

7

AASSEMBLY

Each step of production undergoes

controls ensuring the quality of the

products. In the majority of cases, fine

steel with carbon additives and alloys

are selected best suited to functional

requirements.

The tempering method through

quench hardening or artificial age-

ing is then selected when the forces

which the work pieces are subjected

to make this necessary.

MATERIALS

COMPARISON OF STANDARDS IN DIF-

FERENT COUNTRIES:

The table below displays our steel

standards in comparison with stand-

ards and material designations of oth-

er countries. The listed comparative

materials are those most similar to our

materials.

ADDITIONAL MATERIALS:

For specific applications or special

functional requirements the use of

special materials is recommended:

- stainless steel,

- hardened steel or alloys

- special tempered steel in controlled

atmospheres,

- steel subjected to carburisation or

nitration

- special steel for extremely low tem-

peratures

- light alloys on an aluminium basis.

LAND

GERMANY

ITALY

SPAIN

JAPAN

SWEDEN

U.S.A.

NORM

DIN

UNI

UNE

JIS

SSSTAHL

AISI

Ck 45

C45

C45K (F1140)

S45C

1672

16B45

42CrMo4

42CrMo4

42CrMo4 (F8232)

SNB7

2244

4142

8

AASSEMBLY

HEAT TREATMENT

A slewing ring conveys the force of a

bearing part to a stationary part of a

mechanism. The resulting load arising

from contact of the rolling element on

the raceway of the bearing is calcu-

lated according to Hertz’ theories and

modern criteria of plasticity.

ROTIS carries out local tempering in

order to fulfil requirements both in

the area of surface compression and

those regarding fatigue under the

surface. Through induction hardening

the required hardness as well as an ad-

equate depth hardness is achieved.

Through systematic manufacturing

controls, quality and equability during

heat treatment of the slewing rings

and conformity with ROTIS specifica-

tions is guaranteed.

This type of local tempering can also

be carried out on teeth when the cor-

responding forces require this and

when the geometry of the part allows

for this.

Additional methods of surface hard-

ening such as carburisation, nitration,

etc. can also be carried out.

9

AATTRIBUTES

TEMPERATURE

The temperature range for normal op-

eration of slewing rings lies between

-25°C and +70°C. Slewing rings for use

at lower or higher temperatures can

likewise be manufactured whereby a

special construction by our manufac-

turing department is required.

ENVIRONMENT

In cases with especially aggressive

environmental conditions such as:

- sea-air

- sand/coal (dusty and abrasive air),

the appropriate additional protection

measures must be taken such as for

example:

- affixation of labyrinth seals,

- installation of a housing,

- application of an oil lubrication.

These measures of protective mainte-

nance are fortified in order to ensure

normal operational conditions.

IMPACTS, VIBRATIONS

When slewing rings are subjected to

constant impacts or vibrations, this

fact must be stated in the product

specification book to ensure that the

manufacturing department takes this

into account with regard to the con-

struction.

ROTATIONAL SPEED

The reliable circumferential

speed for four point bearings

to 4 m/s,

short-term up to 5.5 m/s

and

at Typ 2000 2 m/s,

short-term 2.8 m/s.

The reliable circumferential speed for

roller bearings to 2 m/s,

short-term 2.8 m/s.

10

QQUALITY

CARE FOR PRODUCT QUALITY

Product quality is systematic and

complex with the objective of best

fulfilling the requirements of custom-

ers in all areas of the manufacturing

process.

Pre-manufacturing procedure:

- Service comprising expert client con-

sultation prior to sale

- Marketing – Incorporation of market-

ing needs and developmental trends

Manufacturing:

- modern manufacturing methods,

- techniques and tools,

- new materials and heat treatment

methods,

constant innovation of control meth-

ods and means,

- inspection of products at testing sta-

tions,

- constant improvement according to

TQM principles.

Post-manufacturing:

- quality control of products in opera-

tion with regard to improving their

use attributes

- after sales service – support in the

use of our products.

11

FFUNCTIONING OF A SLEWING RING

DETERMINING LOAD

The slewing ring which allows a con-

nection between a moving and a

stationary part must possess the re-

quired capacity to transfer force from

the moving part onto the stationary

part. The corresponding definition for

this capacity requires a precise knowl-

edge of the forces arising and their

subsequent effect on the slewing ring

including forces arising due to the

mass and the inertia of the payload

and substructure.

One must in this case differentiate be-

tween fixed loads, variable loads and

forces due to dynamic loads whereby

the two latter pose fatigue loads.

The knowledge of the direction of

forces with regard to the axis of the

ball bearing is necessary. One thus

distinguishes between:

The AXIS FORCES Fa, whose direc-

tion is parallel to the axis of rotation of

the slewing ring. The resultants from

these forces are called F axial forces.

The RADIAL FORCES Fr, which run

perpendicular to the axis of rota-

tion. The resultant forces are called F

radial forces.

TILTING MOMENT Mk

On the level parallel to the axis

of rotation. The resulting moment is

called MT and relates to the level on

which the axis of rotation lies.

ROTATIONAL MOMENT Md

Creates a shift in position of the

movable ring.

12

FFUNCTIONING OF A SLEWING RING

QUESTIONNAIRE

Client:

Applications:

Loads: Operating load Test load

normal maximum

F axial kN

F radial kN

Mk of 1 kNm

Mk of 2 kNm

Mgk (3+4) kNm

Axial load: overlying Position of rotational horizontal

suspended axis: vertical

variable from

Rotational speed: maximal to

normal

Operating and environmental temperatures: Environment: special seal

minimal against

maximal strong impacts or vibrations

Desired dimensions:

Outer diameter Dz Borehole Lz m:

Inner diameter Dn na z2:

Height H Borehole Ln x2:

Teeth inner outer nn k2:

Pinion teeth: Number of pinions:

m: Design of pinions: normalized

z1: tempered

x1: hardened

k1: smooth

Tooth load: Fz/Md1/Md2 incl. impact factor Operating hours/year:

normal Operation time/day:

maximum Desired lifetime:

Client: Processor: Date:

/if yes:

13

FFUNCTIONING OF A SLEWING RING

FIXATION FUNCTION

In order to transfer the aforemen-

tioned forces an adequately dimen-

sioned mechanical fixation of the

slewing ring onto the corresponding

framework must be defined so that

the slewing ring remains permanently

and firmly affixed to the substructure.

A number of fixation methods are

possible with the most reliable being

the connection with screws and nuts.

Welding methods are absolutely un-

reliable. The correct definition of the

screwing connection and its expert

execution determine the correct func-

tioning of the slewing ring ensuring

safety of operations.

QUALITY OF THE SCREW CONNECTION

The standard ISO 898-1 defines the

quality classes of screw connections

for the assembly of constructions such

as slewing rings. ROTIS recommends

the quality class 10.9. In exceptional

situations, the quality classes 8.8 or

12.9 can be used.

The nuts must correspond or be high-

er than the quality of screws used. For

screws with a diameter of d, nuts with

a length of 1 x d are recommended.

Hexagonal screws are recommended

over cylinder screws whenever possi-

ble. ROTIS recommends using paired

and pre-lubricated screw sets (screw

+ nut) with guaranteed mechanical

characteristics so a more constant

and confessed coefficient of friction is

present. The surface stress should not

lead to embrittlement through the

screwing.

8.810.912.9

80010401220

640940

1100

404040

CLASS TENSILE STRENGTH (Mpa)

YIELD POINT (Mpa)

RESISTANCE TO WEAR (Mpa)

exceptionrecommendedexception

Minimal mechanical characteristics

14

FFUNCTIONING OF A SLEWING RING

FIXATION FUNCTION

CALCULATING THE FIXATION

The rules of calculation have been

designed by ROTIS so that all valid

standards and rules as well as numer-

ous results from research and testing

are taken into consideration. These

calculations are especially based on

the VDI - Guideline 2230 (1988).

One must distinguish between over-

lying and suspended loads. ROTIS

should be consulted regarding sus-

pended loads. Normal bases of calcu-

lation are:

Overlying loads act as compressive

forces.

Screws should be placed evenly

over the circumference of the pitch

circle.

Slew rings and connecting struc-

tures made of steel.

SUSPENDED AXIAL LOAD

FA

SUPPORTED AXIAL LOAD

FA

Slew rings according to our rules:

thickness, stiffness, parallel (see the

chapter on additional constructions

on page 20).

Use of centring to avoid shearing

power on the screw connection when

large radial forces are present.

Splicing of the slew ring is also

advised when large radial forces are

present.

The length of the screw connec-

tion should be at least equal to five

times the diameter: LK ≥ 5 x d.

15

FFUNCTIONING OF A SLEWING RING

Track diameter (in mm) 500

25

750

30

1000

35

1250

40

1500

45

2000

55

2500

65

3000

80Minimum thickness(in mm)

16

OOTHER ATTRIBUTES

PRECISION – TOLERANCES

The general tolerances of standard

slewing rings are defined in the stand-

ards ISO 286- 1 and -2. For use entail-

ing higher precision requirements

such as for industrial robots, radar sys-

tems, etc. a higher degree of quality

can be achieved. The tolerance values

are evaluated according to the design

of the slewing ring. For slewing rings

with larger diameters and smaller

cross sections as well as for weaker

radial stiffness, these values must be

considered upon mounting on the

connecting structure in order to guar-

antee radial run-out.

GEOMETRYThe following criteria must be ad-

hered to:

All diameters: Js 13

All external centrings: f9

All internal centrings: H9

Total height: ± 1 mm

FIXATIONThe pitch circle diameters must fall

within class Js10 and have a minimum

tolerance of ± 0,2 mm.

TOOTH SYSTEMThe maximum radial run out error

is given in the diagram. The degree

of deviance for K teeth with the cor-

responding tolerance is also defined

in the drawing. This number also in-

cludes a proportion for tooth engage-

ment play.

TABLE OF GENERAL TOLERANCES (in compliance with ISO 286-2)

Diameter from(in mm) toInner centring H9 (in µm)Outer centring f9 (in µm)Diameter Js10 (in µm)Diameter Js13 (in µm)

180 250 315 400 500 630 800 1000 1250 1600 2000 2500250 315 400 500 630 800 1000 1250 1600 2000 2500 3150

+115 +130 +140 +155 +175 +200 +230 +260 +310 +370 +440 +540

-50 -56 -62 -68 -76 -80 -86 -98 -110 -120 -130 -145-165 -185 -202 -223 -251 -280 -316 -358 -420 -490 -570 -685

±92 ±105 ±115 ±125 ±140 ±160 ±180 ±210 ±250 ±300 ±350 ±430

±0,36 ±0,405 ±0,445 ±0,485 ±0,55 ±0,625 ±0,70 ±0,825 ±0,975 ±1,15 ±1,4 ±1,65

17

OOTHER ATTRIBUTES

RACEWAY AND RINGS

The PLANNED RUN-OUT ERROR of

the bearing surface is measured with

the aide of a dial gauge. The slewing

ring is rotated 360 degrees. The refer-

ence level is shown in the diagram on

the right.

The RADIAL ECCENTRICITY of the

centrings is also measured during the

rotation (see the diagram below).

These measurements are carried out

by placing the magnet base of the

dial gauge on the fixed ring whereby

the test prod touches the element

to be measured. The values are

measured during the rotation of the

rotating ring.

DL DL HO-DL

HO-DL

The TILTING PLAY under load

conditions is measured using the

following method: a normal force of

F is placed on a point on one of the

two rings right next to the bearing

race while the other ring remains

fixed on the rigid substructure. A dial

gauge with a rigid base is placed on

the other ring. In this way the screw

values under a force of F can be read.

This tilting play under load conditions

is measured for each slewing ring in

the work piece. These values are then

compared to permitted threshold

values and recorded.

18

OOTHER ATTRIBUTES

INSPECTION

If an excessive loss of lubricant is ob-

served upon subsequent

lubrication, the following should be

checked:

Whether the protective seal is still

in place,

Whether the seal is damaged (cuts,

tears, wearing),

Whether it warrants the due func-

tioning of the slewing ring.

This seal can be reinserted or re-

placed.

CORROSION PROTECTION

For special types of use, ROTIS can ap-

ply a corrosion protector on the sur-

faces, e.g.:

1. Galvanisation or galvanisation/bi-

chrome treatment

2. Phosphate coating

3. Chemical nickel plating

4. Paint coating

5. through 9. various treatments such

as chromisation, high temperature

galvanising, anodic oxidation, etc.

Please consult with the technical de-

partment.

SEALS

ROTIS slewing rings all have protec-

tive seals on both sides of the bearing

raceway. The protective seals func-

tions as:

Protection of the bearing raceway

against foreign particles from the out-

side,

Preservation of the lubricant inside

the bearing raceway.

CASING (METAL HOUSING)

For very difficult conditions of use and

in order to limit risks posed by the fol-

lowing foreign bodies:

filings,

frictional splinters,

welding grains,

splinters.

dirt,

sand,

sea water,

cutting fluids ...,

ROTIS strongly recommends the ap-

plication of effective protection. Also

when cleaning with solvents or when

using high pressure cleaners, it is rec-

ommended to avoid their application

to the protective seals.

19

MMOUNTING

INSPECTION – CONTROLS

Following the final tightening of all

fixation screws:

rotate the slewing ring at least

three times.

examine the value of the tooth

play over the complete perimeter

once more.

determine the tilting play with a

known load with regard to the meas-

uring points.

Methods:

Place the measuring instrument

between the two rings closest to the

bearing raceway on the main axle of

the load using a measuring accuracy

of at least 0.1 mm.

Set the calibration with the cali-

brated load to zero.

Place the load on the measure-

ment fixture.

Read the tilting play at the meas-

uring point.

A number of measurements

must be taken at various previously

marked points during continuous

operation.

The unevenness of the substruc-

ture and the tension force loss of the

screws depending on the position of

the measuring instrument must be

taken into consideration.

TRANSPORT

Because of the unstable construc-

tion of the rings, large anti-friction

bearings measuring 300 to 3500 mm

in various shapes must be especially

carefully transported.

Special boreholes have been pro-

vided for the conveyance of larger

bearings for retaining screws by

which the bearings can be clamped

and thus transported.

The bearings may only be trans-

ported and stored horizontally on an

even supporting area. Impacts on the

bearing especially radially should be

avoided. For longer storage periods,

it is recommended that bearings be

stored in dry and dust-free rooms

with a room temperature of between

-20º und 50º C. All bearings are pro-

tected against corrosion for a period

of approximately 12 months and the

raceway system has been greased

with the prescribed quality grease.

The tooth system is not greased and

must thus be greased immediately

upon its mounting.

20

MMOUNTING

ASSEMBLY

A large anti-friction bearing must be

installed in the connecting structure

very carefully and only by knowledge-

able workers – fitters. The instructions

of the manufacturer and general valid

requirements for the assembly of ex-

acting machine elements must be ob-

served.

It is extremely important to ensure

that the connecting structure remain

level and that assembly is performed

with a minimum of plan variance (the

permitted plan variances are defined

in Tables 1 and 2).

Run diameter

(DL)

mm

Reliable planned run-out error of each support surface

Double-row ball bearing

supported slewing ring

Single-row ball bearing sup-

ported slewing ring

900up to 1300up to 2000up to 3000

0,160,200,300,35

0,120,160,200,25

Table 1

Run diameter

(mm)

Maximal bend

(mm)

900up to 1300up to 2000up to 3000

0,50,70,91,5

Maximum allowed axial deflection of the supporting surface at maximum opera-tional load.

Table 2

The connecting structure and the

bearing should be cleaned of all im-

purities. Paint dabs, oil rests and pre-

servatives must be removed while

paying attention that the seals are

not damaged during cleaning and do

not come into contact with aggressive

media.

Regarding the maximum resultant

moment on the bearing, the bearing

must be installed so that the red mar-

ket points on the bearing lie within the

area of minimum resultant moment.

21

MMOUNTING

The point at which the largest devia-

tion of the partial arc of the circle on

the gear wheel is marked in a green

colour. The bearing and as the case

may be, the gear wheel must be in-

stalled so that the lateral play amounts

to approximately 0.03 modules.

Extremely important during assembly

is the expert fixation of the bearing

onto the connecting structure. When

selecting screws, nuts and washers,

the recommendation of the manufac-

turer must be observed. The required

fixation of the screws and nuts are ap-

parent from the technical calculation

supplied with each offer and rendered

based on data of the requirements

and loads supplied to us by the buyer.

When the buyer fails to supply data

on the loads the bearing will bear, the

manufacturer can not warrant for the

correct choice of bearing. All screws

must be gradually and cross-wise

tightened using the prescribed tight-

ening torque.

The screws, nuts and washers should

be greased and only lightly oiled prior

to being tightened. Strongly lubri-

cated screws, nuts and washers have

a lower friction coefficient leading to a

larger resilience of the screws with the

same tightening torque.

In this case, the screws should be

tightened below the limiting value of

the prescribed tightening torque (Ta-

ble 3).

The screws are tightened using the

appropriate torque wrench. The tight-

ening torque value is listed in Table 3

together with the MA value.

For the tightening of screws with

threads exceeding M 30, we recom-

mend a special hydraulic tightening

device which can be ordered together

with the bearing.

Backlash

22

MMOUNTING

DK (mm) – Outer diameter of the head surface area or respectively nut surface area (wrench size)

DI (mm) – Inner diameter of the head or respectively nut service area (bore diameter)

A1 (mm2) – nominal cross-section of the screw

A3 (mm2) – the core of the cross section of the screw

As (mm2) – the cross tension of the screw thread

FSp (N) – bolt force at the minimum limit value

MSp (Nm) – theoretical torque tightening

MA (Nm) – torque tightening value for the torque wrench (MA = 0,9 * MSp)

M12

M14

M16

M18

M20

M22

M24

M27

M30

µm0,148,8

10,98,8

10,98,8

10,98,8

10,98,8

10,98,8

10,98,8

10,98,8

10,98,8

10,9

A1(mm2)113,1

153,9

201,1

254,5

314,2

380,1

452,4

572,6

706,9

As(mm2)

84,3

115,4

156,7

192,5

224,8

303,4

352,5

459,4

560,6

A3(mm2)

76,2

104,7

144,

175,1

225,2

281,5

324,3

427,1

519,0

DI(mm)13,5

15,5

17,5

20

22

24

26

30

33

DK(mm)

19

22

24

27

30

32

36

41

46

Fsp(N)

3850054100528007430072700

10230088400

124300113600159800142000199700163600230100215500303000261800368200

Msp(N)89

124141198216303298419422593570802727

10221077151514602053

MA(Nm)

79112126178194273268377379533513721653919969

136313141847

Table 3

23

MMOUNTING

OBSERVATION

Since the fixation of the large anti-

friction ring onto the connecting

structure with mounting screws is an

extremely important task, we would

once again like to emphasise that

this task only be carried out by expert

and trained fitters. The quality of the

screws and nuts as well as the torque

tension prescribed by the manufac-

turer should be strictly observed!

A retightening of the screws is re-

quired after 100 hours of operation

and should be subsequently checked

every 3 months.

BEARING MAINTENANCE

Once installed the bearing should be

greased on all grease points with the

prescribed lubricant until a fat collar

made of fresh grease builds up on the

entire circumference of the opening

of the bearing or respectively on the

seals. After inspecting the run systems

(correct lateral tooth play), the tooth

system should also be greased.

Lubricants can be used from lubricant

manufacturers recommended for spe-

cific operating conditions.

We recommend the following lubri-

cants:

The bearing should be correspond-

ingly greased according to defined

greasing periods. When regreasing

turn the bearing. In general, regrease

the bearing after every 100 hours of

operation. In more humid conditions,

strong temperature variations and

constant rotation, regreasing should

be repeated in shorter time intervals.

The manufacture of large anti-friction

bearings warrants a long life under

normal operating conditions and reg-

ular maintenance. Operational safety

is affected when bearing play during

a longer operational period increases.

Please consult with the manufacturer

regarding more details on maximum

reliable bearing play.

We ask you to consult with the manu-

facturer regarding all special wishes.

We are available for consultation and

help at all times.

BEARING RACEWAYSPHEEROL EPL2ALVANIA EP2MOBILITH 460 SHC (for low temperatures)

MANUFACTURERCASTROLSHELLMOBIL

Our slewing rings are normally filled with the grease of type KP2N-20 (DIN 51825). We use one of the below mentioned grease, depends on the application of the slewing rings or requirements of our customers. Of course there can be used any other type of grease, if requested so.

24

MMAINTENANCE

INSPECTION OF THE POWER UNIT

When cleaning prior to relubrication

of the tooth system:

Ensure that no foreign particles are

in the tooth depth, slewing ring or on

the gear.

Check the regularity of the contact

area of the gear throughout the entire

tooth length

of the slewing ring and if needed cor-

rect the alignment of the axes.

Also check the value of tooth play.

MMARKINGS

DESIGNATION

Each slewing ring is labelled with:

serial number,

drawing No.

LUBRICATION QUANTITY

Bearing raceway:

The lubrication quantity is determined

by the manufacturing department

when designing the slewing ring. For

a fixed slewing ring, a practical formu-

la for determining the required mini-

mum amount Mm in cm3 is:

Mm= 0,0045/3 x D x H

D= central diameter of the slewing

ring in mm.

H = height of the slewing ring in mm.

In all cases, the new lubricant must

leak out from under the seal lips.

Tooth system:

The lubricant must be sprayed or ap-

plied with a paint brush onto all sides

of the gear and slewing ring.

25

26

MMARKINGS

Description of terms used in the measurement tables

DzDnHLzLnnBMOU

H1H2HuHodmz

x.mbTt

Zuhu

Drawing No.Outer diameterInner diameter Overall heightExternal bolt circle diameterInternal bolt circle diameterNumber of bolt holes per hole circleBolt hole diameterBolt sizeDiameterDiameterRing heightRing heightDistance at bottom Outer ring / inner ringDistance at top Outer ring / inner ringGear P. C. D.ModuleNumber of teethAddendum modification sign per DIN 3960 October, 1976Tooth widthweightthread depthDiametertooth height

27

DDRAWING NUMBER COMPOSITION

2000. 10. 20. 0 - 0 0414. 00

INTERNAL

CHARACTERISTICS

PITCH CIRCLE - DIAMETER

NUMBER OF VARIATIONS

INTERNAL CHARACTERISTICS

ANTI-FRICTION BEARINGS DIAMETER

PRODUCT GROUPS

2000 – single-row ball bearing slewing rings

3000 – single-row ball bearing slewing rings

4000 - double-row ball bearing slewing rings

5000 – single-row roller bearing slewing rings

7000 - three-row roller bearing slewing rings

TOOTH SYSTEM

10 – without teeth

20 – inner teeth

30 – external teeth

29

Drawing Nr.

2000.10.20.0-0.0414.00

2002.10.20.0-0.0544.00

2004.10.20.0-0.0644.00

2006.10.20.0-0.0744.00

2008.10.20.0-0.0844.00

2010.10.20.0-0.0944.00

2012.10.20.0-0.1094.00

DL

(mm)

414

544

644

744

844

944

1094

Dz

(mm)

518

684

748

848

948

1048

1198

Dn

(mm)

304

434

534

634

734

834

984

H

(mm)

56

56

56

56

56

56

56

Lz

(mm)

490

620

720

820

920

1020

1170

Ln

(mm)

332

462

562

662

762

862

1012

nz

8

10

12

12

14

16

16

B/M

(mm)

18

18

18

18

18

18

18

nn

12

14

16

16

18

20

20

B/M

(mm)

18

18

18

18

18

18

18

t

(mm)

-

-

-

-

-

-

-

O

(mm)

412,5

542,5

642,5

742,5

842,5

942,5

1092,5

U

(mm)

415,5

545,5

645,5

745,5

845,5

945,5

1095,5

A

(mm)

453

583

683

783

883

983

1133

C

(mm)

375

505

605

705

805

905

1055

Hu

(mm)

10,5

10,5

10,5

10,5

10,5

10,5

10,5

Ho

(mm)

10,5

10,5

10,5

10,5

10,5

10,5

10,5

d

(mm)

-

-

-

-

-

-

-

m

(mm)

-

-

-

-

-

-

-

z

-

-

-

-

-

-

-

b

(mm)

-

-

-

-

-

-

-

T

(kg)

23,4

31,0

36,4

42,8

47,8

53,1

61,9

Drawing Nr.

2028.20.20.0-0.0414.00

2030.20.20.0-0.0544.00

2032.20.20.0-0.0644.00

2034.20.20.0-0.0744.00

2036.20.20.0-0.0844.00

2038.20.20.0-0.0944.00

2040.20.20.0-0.1094.00

DL

(mm)

414

544

644

744

844

944

1094

Dz

(mm)

518

648

748

848

948

1048

1198

Dn

(mm)

326,5

445,2

547,2

649,2

737,6

841,6

985,6

H

(mm)

56

56

56

56

56

56

56

Lz

(mm)

490

620

720

820

920

1020

1170

Ln

(mm)

375

505

605

705

805

905

1055

nz

8

10

12

12

14

16

16

B/M

(mm)

18

18

18

18

18

18

18

nn

12

16

18

20

20

22

24

B/M

(mm)

M 12

M 12

M 12

M 12

M 12

M 12

M 12

t

(mm)

20

20

20

20

20

20

20

O

(mm)

412,5

542,5

642,5

742,5

842,5

942,5

1092,5

U

(mm)

415,5

545,5

645,5

745,5

845,5

945,5

1095,5

A

(mm)

453

583

683

783

883

983

1133

C

(mm)

-

-

-

-

-

-

-

Hu

(mm)

10,5

10,5

10,5

10,5

10,5

10,5

10,5

Ho

(mm)

-

-

-

-

-

-

-

d

(mm)

335

456

558

660

752

856

1000

m

(mm)

5

6

6

6

8

8

8

z

67

76

93

110

94

107

125

b

(mm)

45,5

45,5

45,5

45,5

45,5

45,5

45,5

T

(kg)

27,1

36,9

43,7

51,1

61,6

65,8

80,7

Drawing Nr.

2014.30.20.0-0.0414.00

2016.30.20.0-0.0544.00

2018.30.20.0-0.0644.00

2020.30.20.0-0.0744.00

2022.30.20.0-0.0844.00

2024.30.20.0-0.0944.00

2026.30.20.0-0.1094.00

DL

(mm)

414

544

644

744

844

944

1094

Dz

(mm)

505

642

744

840

952

1048

1200

Dn

(mm)

304

434

534

634

734

834

984

H

(mm)

56

56

56

56

56

56

56

Lz

(mm)

455

585

685

785

885

985

1135

Ln

(mm)

322

462

652

662

762

862

1012

nz

10

14

16

18

18

20

22

B/M

(mm)

M 12

M 12

M 12

M 12

M 12

M 12

M 12

nn

12

14

16

16

18

20

20

B/M

(mm)

18

18

18

18

18

18

18

t

(mm)

20

20

20

20

20

20

20

O

(mm)

412,5

542,5

642,5

742,5

842,5

942,5

1092,5

U

(mm)

415,5

545,5

645,5

745,5

845,5

945,5

1095,5

A

(mm)

-

-

-

-

-

-

-

C

(mm)

375

505

605

705

805

905

1055

Hu

(mm)

10,5

10,5

10,5

10,5

10,5

10,5

10,5

Ho

(mm)

-

-

-

-

-

-

-

d

(mm)

495

630

732

828

936

1032

1184

m

(mm)

5

6

6

6

8

8

8

z

99

105

122

138

117

129

148

b

(mm)

45,5

45,5

45,5

45,5

45,5

45,5

45,5

T

(kg)

29,3

39,5

47,6

53,5

65,1

69,6

83,0

grease nipple (according to customer request) filler plug

Drawing Nr.

2066.20.30.0-0.0955.00

2068.20.30.0-0.1055.00

2070.20.30.0-0.1155.00

2072.20.30.0-0.1255.00

2074.20.30.0-0.1355.00

2076.20.30.0-0.1455.00

DL

(mm)

955

1055

1155

1255

1355

1455

Dz

(mm)

1100

1200

1300

1400

1500

1600

Dn

(mm)

812

912

1012

1112

1212

1312

H

(mm)

90

90

90

90

90

90

Lz

(mm)

1060

1160

1260

1360

1460

1560

Ln

(mm)

894

994

1094

1194

1294

1394

nz

30

30

36

42

42

48

B/M

(mm)

22

22

22

22

22

22

nn

30

30

36

42

42

48

B/M

(mm)

M 20

M 20

M 20

M 20

M 20

M 20

t

(mm)

40

40

40

40

40

40

O

(mm)

956,5

1056,5

1156,5

1256,5

1356,5

1456,5

U

(mm)

953,5

1053,5

1153,5

1253,5

1353,5

1453,5

A

(mm)

1017

1117

1217

1317

1417

1517

C

(mm)

-

-

-

-

-

-

Hu

(mm)

19

19

19

19

19

19

Ho

(mm)

-

-

-

-

-

-

d

(mm)

830

930

1030

1130

1230

1330

m

(mm)

10

10

10

10

10

10

z

83

93

103

113

123

133

b

(mm)

71

71

71

71

71

71

T

(kg)

156

176

192

208

226

243

30

MMODEL 2000

Drawing Nr.

2066.20.30.0-0.0955.00

2068.20.30.0-0.1055.00

2070.20.30.0-0.1155.00

2072.20.30.0-0.1255.00

2074.20.30.0-0.1355.00

2076.20.30.0-0.1455.00

DL

(mm)

955

1055

1155

1255

1355

1455

Dz

(mm)

1100

1200

1300

1400

1500

1600

Dn

(mm)

812

912

1012

1112

1212

1312

H

(mm)

90

90

90

90

90

90

Lz

(mm)

1060

1160

1260

1360

1460

1560

Ln

(mm)

894

994

1094

1194

1294

1394

nz

30

30

36

42

42

48

B/M

(mm)

22

22

22

22

22

22

nn

30

30

36

42

42

48

B/M

(mm)

M 20

M 20

M 20

M 20

M 20

M 20

t

(mm)

40

40

40

40

40

40

O

(mm)

956,5

1056,5

1156,5

1256,5

1356,5

1456,5

U

(mm)

953,5

1053,5

1153,5

1253,5

1353,5

1453,5

A

(mm)

1017

1117

1217

1317

1417

1517

C

(mm)

-

-

-

-

-

-

Hu

(mm)

19

19

19

19

19

19

Ho

(mm)

-

-

-

-

-

-

d

(mm)

830

930

1030

1130

1230

1330

m

(mm)

10

10

10

10

10

10

z

83

93

103

113

123

133

b

(mm)

71

71

71

71

71

71

T

(kg)

156

176

192

208

226

243

Drawing Nr.

2042.10.30.0-0.0955.00

2044.10.30.0-0.1055.00

2046.10.30.0-0.1155.00

2048.10.30.0-0.1255.00

2050.10.30.0-0.1355.00

2052.10.30.0-0.1455.00

DL

(mm)

955

1055

1155

1255

1355

1455

Dz

(mm)

1100

1200

1300

1400

1500

1600

Dn

(mm)

805

905

1005

1105

1205

1305

H

(mm)

90

90

90

90

90

90

Lz

(mm)

1060

1160

1260

1360

1460

1560

Ln

(mm)

845

945

1045

1145

1245

1345

nz

30

30

36

42

42

48

B/M

(mm)

22

22

22

22

22

22

nn

30

30

36

42

42

48

B/M

(mm)

22

22

22

22

22

22

t

(mm)

-

-

-

-

-

-

O

(mm)

956,5

1056,5

1156,5

1256,5

1356,5

1456,5

U

(mm)

953,5

1053,5

1153,5

1253,5

1353,5

1453,5

A

(mm)

1017

1117

1217

1317

1417

1517

C

(mm)

893

993

1093

1193

1293

1393

Hu

(mm)

19

19

19

19

19

19

Ho

(mm)

19

19

19

19

19

19

d

(mm)

-

-

-

-

-

-

m

(mm)

-

-

-

-

-

-

z

-

-

-

-

-

-

b

(mm)

-

-

-

-

-

-

T

(kg)

131

145

159

172

186

200

Drawing Nr.

2054.30.30.0-0.0955.00

2056.30.30.0-0.1055.00

2058.30.30.0-0.1155.00

2060.30.30.0-0.1255.00

2062.30.30.0-0.1355.00

2064.30.30.0-0.1455.00

DL

(mm)

955

1055

1155

1255

1355

1455

Dz

(mm)

1098

1200

1300

1400

1500

1600

Dn

(mm)

805

905

1005

1105

1205

1305

H

(mm)

90

90

90

90

90

90

Lz

(mm)

1016

1116

1216

1316

1416

1516

Ln

(mm)

845

945

1045

1145

1245

1345

nz

30

30

36

42

42

48

B/M

(mm)

M 20

M 20

M 20

M 20

M 20

M 20

nn

30

30

30

30

30

30

B/M

(mm)

22

22

22

22

22

22

t

(mm)

40

40

40

40

40

40

O

(mm)

956,5

1056,5

1156,5

1256,5

1356,5

1456,5

U

(mm)

953,5

1053,5

1153,5

1253,5

1353,5

1453,5

A

(mm)

-

-

-

-

-

-

C

(mm)

893

993

1093

1193

1293

1393

Hu

(mm)

19

19

19

19

19

19

Ho

(mm)

-

-

-

-

-

-

d

(mm)

1080

1180

1280

1380

1480

1580

m

(mm)

9

10

10

10

10

10

z

120

118

128

138

148

158

b

(mm)

71

71

71

71

71

71

T

(kg)

165

183

200

216

234

250

grease nipple (according to customer request) filler plug

31

33grease nipple (according to customer request) filler plug

Drawing Nr.

3032.30.20.0-0.0414.00

3034.30.20.0-0.0544.00

3036.30.20.0-0.0644.00

3038.30.20.0-0.0744.00

3040.30.20.0-0.0844.00

3042.30.20.0-0.0944.00

3044.30.20.0-0.1094.00

Dz

(mm)

505

642

744

840

952

1048

1200

Dn

(mm)

342

472

572

672

772

872

1022

H

(mm)

56

56

56

56

56

56

56

Lz

(mm)

455

585

685

785

885

985

1135

Ln

(mm)

368

498

598

698

798

898

1048

n

20/24

28/32

32/36

36/40

36/40

40/44

44/48

B

(mm)

13,5

13,5

13,5

13,5

13,5

13,5

13,5

M

(mm)

12

12

12

12

12

12

12

t

(mm)

20

20

20

20

20

20

20

O

(mm)

412,5

542,5

642,5

742,5

842,5

942,5

1092,5

U

(mm)

415,5

545,5

645,5

745,5

845,5

945,5

1095,5

H1

(mm)

45,5

45,5

45,5

45,5

45,5

45,5

45,5

H2

(mm)

45,5

45,5

45,5

45,5

45,5

45,5

45,5

Hu

(mm)

10,5

10,5

10,5

10,5

10,5

10,5

10,5

d

(mm)

495

630

732

828

936

1032

1184

m

(mm)

5

6

6

6

8

8

8

z

99

105

122

138

117

129

148

x.m

(mm)

-

-

-

-

-

-

-

b

(mm)

45,5

45,5

45,5

45,5

45,5

45,5

45,5

T

(kg)

31

43

52

59

71

77

91

Ho

(mm)

10,5

10,5

10,5

10,5

10,5

10,5

10,5

Drawing Nr.

3018.10.20.0-0.0414.00

3020.10.20.0-0.0544.00

3022.10.20.0-0.0644.00

3024.10.20.0-0.0744.00

3026.10.20.0-0.0844.00

3028.10.20.0-0.0944.00

3030.10.20.0-0.1094.00

Dz

(mm)

486

616

716

816

916

1016

1166

Dn

(mm)

342

472

572

672

772

872

1022

H

(mm)

56

56

56

56

56

56

56

Lz

(mm)

460

590

690

790

890

990

1140

Ln

(mm)

368

498

598

698

798

898

1048

n

24

32

36

40

40

44

48

B

(mm)

13,5

13,5

13,5

13,5

13,5

13,5

13,5

M

(mm)

12

12

12

12

12

12

12

t

(mm)

-

-

-

-

-

-

-

O

(mm)

412,5

542,5

642,5

742,5

842,5

942,5

1092,5

U

(mm)

415,5

545,5

645,5

745,5

845,5

945,5

1095,5

H1

(mm)

45,5

45,5

45,5

45,5

45,5

45,5

45,5

H2

(mm)

45,5

45,5

45,5

45,5

45,5

45,5

45,5

Hu

(mm)

10,5

10,5

10,5

10,5

10,5

10,5

10,5

d

(mm)

-

-

-

-

-

-

-

m

(mm)

-

-

-

-

-

-

-

z

-

-

-

-

-

-

-

x.m

(mm)

-

-

-

-

-

-

-

b

(mm)

-

-

-

-

-

-

-

T

(kg)

29

37

44

52

60

67

77

Ho

(mm)

10,5

10,5

10,5

10,5

10,5

10,5

10,5

Drawing Nr.

3046.20.20.0-0.0414.00

3048.20.20.0-0.0544.00

3050.20.20.0-0.0644.00

3052.20.20.0-0.0744.00

3054.20.20.0-0.0844.00

3056.20.20.0-0.0944.00

3058.20.20.0-0.1094.00

Dz

(mm)

486

616

716

816

946

1016

1166

Dn

(mm)

326,5

445,2

547,2

649,2

737,6

841,6

985,6

H

(mm)

56

56

56

56

56

56

56

Lz

(mm)

460

590

690

790

890

990

1140

Ln

(mm)

375

505

605

705

805

905

1055

n

24

32

36

40

40

44

48

B

(mm)

13,5

13,5

13,5

13,5

13,5

13,5

13,5

M

(mm)

12

12

12

12

12

12

12

t

(mm)

20

20

20

20

20

20

20

O

(mm)

412,5

542,5

642,5

742,5

842,5

942,5

1092,5

U

(mm)

415,5

545,5

645,5

745,5

845,5

945,5

1095,5

H1

(mm)

45,5

45,5

45,5

45,5

45,5

45,5

45,5

H2

(mm)

45,5

45,5

45,5

45,5

45,5

45,5

45,5

Hu

(mm)

10,5

10,5

10,5

10,5

10,5

10,5

10,5

d

(mm)

335

456

558

660

752

856

1000

m

(mm)

5

6

6

6

8

8

8

z

67

76

93

110

94

107

125

x.m

(mm)

-

-

-

-

-

-

-

b

(mm)

45,5

45,5

45,5

45,5

45,5

45,5

45,5

Ho

(mm)

10,5

10,5

10,5

10,5

10,5

10,5

10,5

T

(kg)

31

42

50

58

69

76

91

35grease nipple (according to customer request) filler plug

Drawing Nr.

3060.30.25.0-0.0764.00

3062.30.25.0-0.0980.00

Dz

(mm)

862,8

1078,4

Dn

(mm)

670

886

H

(mm)

82

79

Lz

(mm)

800

1015

Ln

(mm)

706

922

n

24

30

B

(mm)

17,5

17,5

M

(mm)

16

16

O

(mm)

765

981

U

(mm)

763

979

H1

(mm)

65

67

H2

(mm)

61

58

Hu

(mm)

21

21

Ho

(mm)

17

12

m

(mm)

6

8

z

142

133

x.m

(mm)

+0

+0

b

(mm)

56

62

T

(kg)

98

123

t

(mm)

24

24

d

(mm)

852

1064

Zu

(mm)

833

1024

hu

(mm)

9

5

Drawing Nr.

3064.30.20.0-0.0400.00

3066.30.20.0-0.0450.00

3068.30.20.0-0.0560.00

3070.30.20.0-0.0630.00

3072.30.20.0-0.0710.00

Dz

(mm)

499

554

670,8

742,8

820,8

Dn

(mm)

325

369

479

543

623

H

(mm)

55

55

55

55

55

Lz

(mm)

448

500

610

682

762

Ln

(mm)

352

400

510

578

658

n

16

16

20

20

24

B

(mm)

13,5

15,5

15,5

17,5

17,5

M

(mm)

12

14

14

16

16

O

(mm)

401

451

564

631

711

U

(mm)

399

449

559

629

709

H1

(mm)

46

46

46

46

46

H2

(mm)

46

46

46

46

46

Hu

(mm)

9

9

9

9

9

Ho

(mm)

9

9

9

9

9

m

(mm)

5

5

6

6

6

z

97

108

109

121

134

x.m

(mm)

+2,5

+2,5

+3,0

+3,0

+3,0

b

(mm)

46

46

46

46

46

T

(kg)

35

39

53

61

67

d

(mm)

485

540

654

726

804

Drawing Nr.

3074.30.25.0-0.0764.00

3076.30.25.0-0.0980.00

3078.30.25.0-0.1120.00

3080.30.25.0-0.1250.00

Dz

(mm)

886,8

1110,4

1278

1408

Dn

(mm)

671

887

1013

1143

H

(mm)

63

63

79

79

Lz

(mm)

823

1039

1183

1313

Ln

(mm)

706

922

1057

1187

n

24

30

30

36

B

(mm)

17,5

17,5

22

22

M

(mm)

16

16

16

16

O

(mm)

765

981

1121

1251

U

(mm)

763

979

1119

1249

H1

(mm)

54

54

70

70

H2

(mm)

54

54

54

54

Hu

(mm)

9

9

25

25

Ho

(mm)

9

9

9

9

m

(mm)

6

8

10

10

z

145

136

125

138

x.m

(mm)

+3,0

+4,0

+5,0

+5,0

b

(mm)

54

54

70

70

T

(kg)

95

124

182

221

d

(mm)

870

1088

1250

1380

Drawing Nr.

3082.30.30.0-0.1180.00

3084.30.30.0-0.1320.00

3086.30.30.0-0.1500.00

Dz

(mm)

1338

1497,6

1677,6

Dn

(mm)

1068

1208

1388

H

(mm)

76

89

89

Lz

(mm)

1248

1388

1568

Ln

(mm)

1112

1252

1432

n

36

42

48

B

(mm)

22

22

22

M

(mm)

20

20

20

O

(mm)

1181

1321

1501

U

(mm)

1178

1318

1498

H1

(mm)

70

80

80

H2

(mm)

63

63

63

Hu

(mm)

16

26

26

Ho

(mm)

9

9

9

m

(mm)

10

12

12

z

131

122

137

x.m

(mm)

+5,0

+6,0

+6,0

b

(mm)

70

80

80

T

(kg)

227

298

338

d

(mm)

1310

1464

1644

Drawing Nr.

3088.30.40.0-0.1400.00

3090.30.40.0-0.1600.00

3092.30.40.0-0.1800.00

Dz

(mm)

1593,6

1803,2

1999,2

Dn

(mm)

1266

1466

1666

H

(mm)

94

94

94

Lz

(mm)

1482

1682

1882

Ln

(mm)

1318

1518

1718

n

36

40

44

B

(mm)

26

26

26

M

(mm)

24

24

24

O

(mm)

1401

1601

1801

U

(mm)

1398

1598

1798

H1

(mm)

85

85

85

H2

(mm)

81

81

81

Hu

(mm)

13

13

13

Ho

(mm)

9

9

9

m

(mm)

12

14

14

z

130

126

140

x.m

(mm)

+6,0

+7,0

+7,0

b

(mm)

85

85

85

T

(kg)

404

479

531

d

(mm)

1560

1764

1960

Drawing Nr.

3094.30.50.0-0.1900.00

3096.30.50.0-0.2130.00

3098.30.50.0-0.2355.00

3100.30.50.0-0.2645.00

Dz

(mm)

2139,2

2380,8

2604,8

2892,8

Dn

(mm)

1729

1959

2184

2474

H

(mm)

109

109

109

109

Lz

(mm)

2005

2235

2460

2750

Ln

(mm)

1795

2025

2250

2540

n

36

48

54

60

B

(mm)

33

33

33

33

M

(mm)

30

30

30

30

O

(mm)

1902

2132

2357

2647

U

(mm)

1898

2128

2353

2643

H1

(mm)

100

100

100

100

H2

(mm)

99

99

99

99

Hu

(mm)

10

10

10

10

Ho

(mm)

9

9

9

9

m

(mm)

14

16

16

16

z

150

146

160

178

x.m

(mm)

+7,0

+8,0

+8,0

+8,0

b

(mm)

100

100

100

100

T

(kg)

820

931

1024

1142

d

(mm)

2100

2336

2560

2848

37

Drawing Nr.

3102.20.25.0-0.0886.00

3104.20.25.0-0.1077.00

Dz

(mm)

980

1170

Dn

(mm)

784

960

H

(mm)

77

84

Lz

(mm)

944

1134

Ln

(mm)

850

1040

n

36

36

B

(mm)

17,5

17,5

M

(mm)

16

16

O

(mm)

885

1076

U

(mm)

887

1078

H1

(mm)

67

66

H2

(mm)

56

64

Hu

(mm)

21

20

Ho

(mm)

10

18

m

(mm)

8

10

z

100

98

x.m

(mm)

-0

-0

b

(mm)

62

61

T

(kg)

109

148

t

(mm)

24

24

d

(mm)

800

980

Zu

(mm)

820

1010

hu

(mm)

5

5

grease nipple (according to customer request) filler plug

Drawing Nr.

3130.20.40.0-0.1500.00

3132.20.40.0-0.1700.00

Dz

(mm)

1634

1834

Dn

(mm)

1308

1498

H

(mm)

94

94

Lz

(mm)

1582

1782

Ln

(mm)

1418

1618

n

40

44

B

(mm)

26

26

M

(mm)

24

24

O

(mm)

1498

1698

U

(mm)

1501

1701

H1

(mm)

85

85

H2

(mm)

81

81

Hu

(mm)

13

13

Ho

(mm)

9

9

m

(mm)

12

14

z

110

108

x.m

(mm)

-6,0

-7,0

b

(mm)

85

85

T

(kg)

410

475

d

(mm)

1320

1512

Drawing Nr.

3134.20.50.0-0.1800.00

3136.20.50.0-0.2000.00

3138.20.50.0-0.2240.00

3140.20.50.0-0.2490.00

3142.20.50.0-0.2800.00

Dz

(mm)

1971

2171

2411

2661

2971

Dn

(mm)

1554

1764

1984

2240

2544

H

(mm)

109

109

109

109

109

Lz

(mm)

1905

2105

2345

2595

2905

Ln

(mm)

1695

1895

2135

2385

2695

n

36

40

48

54

60

B

(mm)

33

33

33

33

33

M

(mm)

30

30

30

30

30

O

(mm)

1798

1998

2238

2488

2798

U

(mm)

1802

2002

2242

2492

2802

H1

(mm)

100

100

100

100

100

H2

(mm)

99

99

99

99

99

Hu

(mm)

10

10

10

10

10

Ho

(mm)

9

9

9

9

9

m

(mm)

14

14

16

16

16

z

112

127

125

141

160

x.m

(mm)

-7,0

-7,0

-8,0

-8,0

-8,0

b

(mm)

100

100

100

100

100

T

(kg)

762

827

961

1053

1205

d

(mm)

1568

1778

2000

2256

2560

Drawing Nr.

3106.20.20.0-0.0400.00

3108.20.20.0-0.0450.00

3110.20.20.0-0.0560.00

3112.20.20.0-0.0630.00

3114.20.20.0-0.0710.00

Dz

(mm)

475

531

641

717

797

Dn

(mm)

300

345

450

516

594

H

(mm)

55

55

55

55

55

Lz

(mm)

448

500

610

682

762

Ln

(mm)

352

400

510

578

658

n

16

16

20

20

24

B

(mm)

13,5

15,5

15,5

17,5

17,5

M

(mm)

12

14

14

16

16

O

(mm)

399

449

559

629

709

U

(mm)

401

451

561

631

711

H1

(mm)

46

46

46

46

46

H2

(mm)

46

46

46

46

46

Hu

(mm)

9

9

9

9

9

Ho

(mm)

9

9

9

9

9

m

(mm)

5

5

6

6

6

z

61

70

76

87

100

x.m

(mm)

-2,5

-2,5

-3,0

-3,0

-3,0

b

(mm)

46

46

46

46

46

T

(kg)

33

38

51

59

68

d

(mm)

305

350

456

522

600

Drawing Nr.

3116.20.25.0-0.0886.00

3118.20.25.0-0.1077.00

3120.20.25.0-0.1180.00

Dz

(mm)

980

1169

1287

Dn

(mm)

752

930

1020

H

(mm)

63

63

63

Lz

(mm)

944

1134

1243

Ln

(mm)

827

1017

1117

n

36

36

36

B

(mm)

17,5

17,5

22

M

(mm)

16

16

20

O

(mm)

885

1076

1179

U

(mm)

887

1078

1181

H1

(mm)

54

54

60

H2

(mm)

54

54

54

Hu

(mm)

9

9

15

Ho

(mm)

9

9

9

m

(mm)

8

10

10

z

95

94

103

x.m

(mm)

-4,0

-5,0

-5,0

b

(mm)

54

54

54

T

(kg)

111

140

185

d

(mm)

760

940

1030

Drawing Nr.

3122.20.30.0-0.1120.00

3124.20.30.0-0.1250.00

3126.20.30.0-0.1400.00

3128.20.30.0-0.1600.00

Dz

(mm)

1232

1362

1512

1712

Dn

(mm)

960

1090

1224

1428

H

(mm)

79

79

89

89

Lz

(mm)

1188

1318

1468

1668

Ln

(mm)

1052

1182

1332

1532

n

36

40

44

48

B

(mm)

22

22

22

22

M

(mm)

20

20

20

20

O

(mm)

1118

1248

1398

1598

U

(mm)

1121

1251

1401

1601

H1

(mm)

70

70

80

80

H2

(mm)

63

63

63

63

Hu

(mm)

16

16

26

26

Ho

(mm)

9

9

9

9

m

(mm)

10

10

12

12

z

97

110

103

120

x.m

(mm)

-5,0

-5,0

-5,0

-5,0

b

(mm)

70

70

80

80

T

(kg)

206

231

296

334

d

(mm)

970

1100

1236

1440

39

Drawing Nr.

4072.20.40.0-0.2199.00

4074.20.40.0-0.2622.00

4076.20.40.0-0.2950.00

4078.20.40.0-0.3300.00

Dz

(mm)

2350

2770

3100

3450

Dn

(mm)

1920

2336

2646

3006

H

(mm)

156

156

156

156

Lz

(mm)

2295

2715

3045

3395

Ln

(mm)

2065

2485

2815

3165

n

52

60

60

66

B

(mm)

33

33

33

33

M

(mm)

30

30

30

30

O

(mm)

2168

2590

2918

3268

U

(mm)

2164

2587

2915

3265

H1

(mm)

117

117

117

117

H2

(mm)

150

150

150

150

Hu

(mm)

6

6

6

6

Ho

(mm)

39

39

39

39

m

(mm)

16

16

18

18

z

121

147

148

168

x.m

(mm)

-8,0

-8,0

-9,0

-9,0

b

(mm)

117

117

117

117

T

(kg)

1238

1495

1764

1935

d

(mm)

1936

2352

2664

3024

Drawing Nr.

4066.20.35.0-0.1960.00

4068.20.35.0-0.2500.00

4070.20.35.0-0.2690.00

Dz

(mm)

2090

2630

2820

Dn

(mm)

1722

2254

2432

H

(mm)

138

138

138

Lz

(mm)

2045

2585

2775

Ln

(mm)

1850

2385

2580

n

52

66

72

B

(mm)

26

26

26

M

(mm)

24

24

24

O

(mm)

1926

2466

2656

U

(mm)

1931

2471

2661

H1

(mm)

104

104

104

H2

(mm)

132

132

132

Hu

(mm)

6

6

6

Ho

(mm)

34

34

34

m

(mm)

14

14

16

z

124

162

153

x.m

(mm)

-7,0

-7,0

-8,0

b

(mm)

104

104

104

T

(kg)

851

1112

1225

d

(mm)

1736

2268

2448

Drawing Nr.

4054.20.30.0-0.1381.00

4056.20.30.0-0.1630.00

4058.20.30.0-0.1800.00

4060.20.30.0-0.1995.00

4062.20.30.0-0.2330.00

4064.20.30.0-0.2538.00

Dz

(mm)

1500

1750

1920

2115

2450

2660

Dn

(mm)

1164

1416

1568

1764

2100

2228

H

(mm)

120

120

120

120

120

120

Lz

(mm)

1455

1705

1875

2070

2405

2615

Ln

(mm)

1275

1525

1695

1890

2225

2430

n

36

40

48

48

54

60

B

(mm)

26

26

26

26

26

26

M

(mm)

24

24

24

24

24

24

O

(mm)

1352

1602

1771

1966

2301

2509

U

(mm)

1358

1610

1777

1972

2307

2515

H1

(mm)

91

91

91

91

91

91

H2

(mm)

114

114

114

114

114

114

Hu

(mm)

6

6

6

6

6

6

Ho

(mm)

29

29

29

29

29

29

m

(mm)

12

12

14

14

14

16

z

98

119

113

127

151

144

x.m

(mm)

-6,0

-6,0

-7,0

-7,0

-7,0

-8,0

b

(mm)

91

91

91

91

91

91

T

(kg)

474

558

643

716

839

963

d

(mm)

1176

1428

1582

1778

2114

2304

Drawing Nr.

4050.20.25.0-0.1360.00

4052.20.25.0-0.1600.00

Dz

(mm)

1460

1700

Dn

(mm)

1180

1404

H

(mm)

102

102

Lz

(mm)

1425

1665

Ln

(mm)

1270

1510

n

36

42

B

(mm)

22

22

M

(mm)

20

20

O

(mm)

1337

1577

U

(mm)

1342

1582

m

(mm)

10

12

d

(mm)

1190

1416

H1

(mm)

76

76

H2

(mm)

96

96

Hu

(mm)

6

6

Ho

(mm)

26

26

x.m

(mm)

-5,0

-6,0

z

119

118

T

(kg)

336

405

b

(mm)

76

76

Drawing Nr.

4000.20.18.0-0.0748.00

4002.20.20.0-0.0895.00

4004.20.20.0-0.1085.00

4006.20.20.0-0.1360.00

Dz

(mm)

823

971

1161

1440

Dn

(mm)

648

784

960

1210

H

(mm)

77

82

90

82

Lz

(mm)

798

944

1134

1410

Ln

(mm)

705

850

1040

1300

n

24

30

36

54

B

(mm)

17,5

17,5

17,5

17,5

M

(mm)

16

16

16

16

O

(mm)

710

854

1044

1319

U

(mm)

734

879

1069

1342

H1

(mm)

54

58

66

58

H2

(mm)

74

78

78

78

Hu

(mm)

3

4

12

4

Ho

(mm)

23

24

24

24

m

(mm)

6

8

10

10

z

110

100

98

122

x.m

(mm)

-0,0

-0,0

-0,0

-5,0

b

(mm)

45

50

55

58

T

(kg)

90

118

154

213

t

(mm)

30

35

35

35

d

(mm)

660

800

980

1220

Zn

(mm)

678

820

1010

-

hu

(mm)

9

8

11

-

grease nipple (according to customer request) filler plug

Drawing Nr.

4082.20.50.0-0.2559.00

4084.20.50.0-0.3520.00

4086.20.50.0-0.3739.00

4090.20.50.0-0.3839.00

Dz

(mm)

2725

3685

3905

4005

H

(mm)

185

185

185

185

Lz

(mm)

2670

3630

3850

395

Ln

(mm)

2410

3370

3590

3690

N

60

78

84

84

B

(mm)

33

33

33

33

M

(mm)

30

30

30

30

O

(mm)

2522

3482

3701

3801

U

(mm)

2524

3485

3704

3804

H1

(mm)

138

138

138

138

H2

(mm)

178

178

178

178

Hu

(mm)

7

7

7

7

Ho

(mm)

47

47

47

47

m

(mm)

18

20

20

20

z

126

161

172

177

x.m

(mm)

-9,0

-10,0

-10,0

-10,0

b

(mm)

138

138

138

138

T

(kg)

1892

2657

2823

2905

d

(mm)

2268

3220

3440

3540

Dn

(mm)

2250

3200

3420

3520

Drawing Nr.

4080.20.45.0-0.2940.00

4088.20.45.0-0.3400.00

Dz

(mm)

3100

3560

Dn

(mm)

2656

3080

H

(mm)

175

175

Lz

(mm)

3045

3505

Ln

(mm)

2800

3260

N

66

72

B

(mm)

33

33

M

(mm)

30

30

O

(mm)

2903

3363

U

(mm)

2900

3358

m

(mm)

16

20

d

(mm)

2672

3100

H1

(mm)

132

132

H2

(mm)

168

168

Hu

(mm)

7

7

Ho

(mm)

43

43

x.m

(mm)

-8,0

-10,0

z

167

155

T

(kg)

1950

2435

b

(mm)

132

132

41

Drawing Nr.

4008.30.20.0-0.0755.00

4010.30.20.0-0.0971.00

4012.30.20.0-0.1220.00

4014.30.20.0-0.1385.00

Dz

(mm)

862,8

1078,4

1342,4

1502,4

Dn

(mm)

679

895

1140

1305

H

(mm)

82

82

82

82

Lz

(mm)

800

1015

1270

1435

Ln

(mm)

706

922

1170

1335

n

24

30

48

54

B

(mm)

17,5

17,5

17,5

17,5

M

(mm)