Renewable Energy Rothe Erde Slewing Bearings and Rings · Rothe Erde® Slewing Bearings and Rings....

Transcript of Renewable Energy Rothe Erde Slewing Bearings and Rings · Rothe Erde® Slewing Bearings and Rings....

-

ThyssenKrupp Rothe Erde

Renewable EnergyRothe Erde Slewing Bearings and Rings

-

22

Who we are what we doLeading global supplier of slewing bearings and rings

ThyssenKrupp Rothe Erde is the worlds largest manufacturer of slewing bearings and a leading player in the market for seamless rolled steel and non-ferrous metal rings. Rothe Erde slewing bearings and rings have set the industry benchmark for many years and have a proven track record in all areas of technology. ThyssenKrupp Rothe Erde is also a highly respected producer of turntables and structural elements.

-

33

In addition to its main production sites in Germany, ThyssenKrupp Rothe Erde has subsidiaries in Great Britain, Italy, Spain, France, the USA, Brazil, India, Japan and China along with a network of distribu-tors and agencies in all of the world's major industrialized nations to ensure close proximity to the customer.

All of our domestic and foreign production facilities share the same uncompromising commitment to quality. Our entire portfolio including application consultancy services, design engineering, production and comprehensive customer care are aligned with international quality standards.

Rothe Erde slewing bearings and rings are compact, high-strength connecting elements which provide an essential, sustainable contribution to climate protection and resource conservation in wind turbine systems, hydroelectric and tidal power plants and solar energy systems, all of which exploit non-depletable resources.

-

4

Wind energy turbinesOnshore and offshore

Wind turbine systems generate power without releasing CO2 emissions, which is one

reason why they are playing an increasingly important role in the energy mix. Germany is the technology leader in this market segment, and wind power is the largest alternative energy source in the country. As the world market leader in slewing bearings, ThyssenKrupp Rothe Erde has played a leading role in the industry from day one. The company has made a major investment in R&D, and its slewing bearings have a proven track record in wind turbine systems (onshore and offshore) around the world.

-

5

Rothe Erde slewing bearings absorb all radial and axial forces and the resultant tilting moments in a single self-retaining, ready-to-install bearing unit which has an excellent weight/performance ratio. Compact Rothe Erde slewing bearings have a proven track record in numerous wind turbine applications around the world. They are maintenance-friendly and easy to install, and they provide a cost-effective solution for high-performance mounting systems and optimized companion structures.

A range of surface treatment options is available to meet bearing corrosion protection requirements including conformance to Corrosion Category C5-M as defined in DIN EN ISO 12944.

-

66

Rothe Erde slewing bearings meet the most stringent requirements

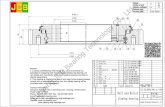

Individualized designs are needed to meet the demands placed on the different bearings in wind turbines. ThyssenKrupp Rothe Erde provides the right slewing bear-ing for each mounting situation in diameters up to 8,000 mm. Because we have many years of experience and a wealth of expertise in the design of ball and roller slewing bearings, we can supply the optimal design for any load and operating conditions.

-

7

Rothe Erde pitch bearings are given a preload with defined torque resistance values during production as a means to prevent unwanted false brinelling.

Special UV and ozone resistant double-lip-seals provide optimal protection for the raceway system.

The Rotor Bearing

ThyssenKrupp Rothe Erde uses patented production tech-nology to manufacture induction-hardened raceways with-out soft spots on rotor bearings. The process is suitable for double-row taper roller bearings and three-row cylindri-cal roller bearings with diameters up to 4,000 mm.

Rothe Erde slewing bearings configured

as three-row cylindri-cal roller bearings

or double-row taper roller bearings with

special seals

The Blade Bearing

Rotor blade pitch must be adjustable to produce maximum output from the generator. Pitch bearings in particular have to withstand the continuous load changes resulting from pulsating loads.Single and double-row four point contact ball bearing and three-row roller bearings are ideally suited for these applications.

Preloaded Rothe Erde ball and roller slewing bearings

The Yaw Bearing

The yaw (azimuth) bearing is used primarily for positional adjustment, keeping the nacelle properly oriented in the wind. Single and double row four point contact ball bearings are ideally suited for these applications. Three-row roller bearings are used on MW scale turbines.

Rothe Erde ball and roller slewing bearings with special seals

-

8

3 4

21

Rothe Erde rings for wind turbines

[ 1 ] Foundation Bottom Flange

[ 2 ] Tower Flange

[ 3 ] Top Flange and Slewing Bearing

[ 4 ] Top Flange and Yaw Top

ThyssenKrupp Rothe Erde has more than one hundred years of experience in the steel forming industry. Today, we are one of the leading producers of seamless rolled rings. Our manufacturing plants in Germany, China and the USA produce everything from ring forgings to finished parts which are ready to install. We deliver top-quality products on time to customer specification. The seamless rolled rings have a homogeneous material structure. They withstand high mechanical stress and are available in a wide range of dimensions. Close production tolerances enable us to optimize allowances and achieve significant weight reductions.

-

9

1

2

3 | 4

We are a certified producer of rings for: wind turbine towers and

foundation sections, gear units, shaft/hub connections

(rings for shrink rings) and brake disks.

The rings are suitable for use in all known onshore and offshore applications. They comply with all applicable standards and customer specifications.

On request, rings up to an OD of around 15,000 mm can be machined on state-of-the-art CNC systems and delivered ready to install.

-

10

1

1

Hydroelectric and tidal power stations generate energy from the predictable forces of the changing tides

Corrosion protection is especially important in hydroelectric and tidal power stations to prevent damage caused by seawater. ThyssenKrupp Rothe Erde uses special sealing systems with mating surfaces made of stainless steel, which have an extensive track record in the offshore industry.

Hydroelectric power stations produce electricity at flow rates as

low as 2 - 2.5 m per second. The rotor which drives a generator

has a very low rotational frequency.

Three-row roller slewing bearing

-

11

Rothe Erde slewing bearings absorb all radial and axial forces and the resultant tilting moments in a single self-retaining, ready-to- install bearing unit with an excellent weight/performance ratio.

Compact design, an excellent weight/performance ratio, an open center and integrated gearing make Rothe Erde slewing bearings the ideal choice for tidal power stations.

Rothe Erde slewing bearings are supplied as yaw, blade or rotor bearings depending on the application. Integrated sealing systems can be provided as well.

-

12

1

2

Focusing the power of the sunto generate new energy

Efforts continue to make better use of existing potential of solar power systems, and ThyssenKrupp Rothe Erde is a major contributor. On PV systems, Rothe Erde slewing bearings and slew drives ensure optimal solar tracking performance. Slewing bear-ings and slew drives also position the mirrors which focus the suns rays at solar thermal stations, producing heat which is converted to electricity in a conventional power station.

-

13

1

2

Slewing bearings featuring proven designs and compact slew drives which are supplied ready to install deliver absolute precision to maximize system efficiency.

The slew drive offers the advantages of a slewing bearing and a worm drive gear in a single unit. It withstands high axial and radial forces and tilting moments. The Rothe Erde slew drive eliminates the need for a brake, and due to the geometry of the gearing the drive is self-locking.

Rothe Erde slewing bearings and slew drives deliver dependable operation without the need for extensive maintenance. Rothe Erde slew drives are not complicated to install, and the rugged design ensures many years of low-maintenance operation.

Slew drive for solar tracker

Slewing bearing for solar tracker

-

14

Creating the futureDevelopment and design

New bearing designs are subjected to rigorous trials under extremely demanding conditions using leading-edge technology at the ThyssenKrupp Rothe Erde research and test center. The R&D team works on next-generation products and turns its expertise, experience and new ideas into solutions which meet market and customer needs.

-

A state-of-the-art FEM-based engineering tool developed by ThyssenKrupp Rothe Erde provides the basis for a sustained devel-opment partnership between the customer and the manufacturer.

Using this new technology, the product development teams are able to conduct a rigorous in-depth analysis of the entire system including the slewing bearing and companion structure to produce a cost-effective solution which is based on a sophisticated mechanical design.

-

16

Rothe Erde MaQUSQuality, Eco and Safety Management

Quality assurance, environmental protection and safety are key success factors in the ThyssenKrupp Rothe Erde business model. Customers gain a multiplicity of benefits from the companys uncompromising commitment to its MaQUS policies.

Professional quality management ensures that a system is in place for planning, controlling and monitoring all organizational, business and engineering activities which have an impact on the quality of the end product.

We are equally committed to environmental protection, resource conservation and uncompromising standards of occupational safety in our production opera-tions. Compliance with government regulations and other requirements is fully embedded into our day-to-day activities.

-

17

Integrated Management SystemThe ThyssenKrupp Rothe Erde Integrated Management System complies with the fol-lowing standards: Quality

as defined in DIN EN ISO 9001:2008, Environmental protection

as defined in DIN EN ISO 14001:2004 and Occupational health and safety

as defined in OHSAS 18001:2007.

The management system is based on documentation of all processes and workflows in the form of procedures and work instructions which reflect legal and regulatory requirements as well as require-ments which are set out in guidelines, specifications and agreements.

The production processAll of the standard quality assurance break-points starting with verification of input materials and continuing through all stages of production, final inspection, packing and shipment to the customer are an integral part of the manufacturing process. Environmental protection and occupational health and safety are also major factors in the production process.

Mission statementOur declared goal is to maintain and intensify customer relationships, deliver quality which is second to none, minimize the impact on the environment, avoid harmful effects on humans and equipment, conserve resources and continually improve our processes and workflows.

Our assetsA highly motivated workforce is absolutely essential for the success of our quality assurance, environmental protection and occupational safety efforts. Information sharing is an integral part of our day-to-day activities, and through our training and continual professional development programs we promote professionalism and responsibility at all levels of the company.

-

18

ThyssenKrupp Rothe Erde worldwide

Subsidiaries FranceRoballo France [email protected]

Great BritainRoballo Engineering Co. [email protected]

ItalyRothe Erde-Metallurgica Rossi [email protected]

SpainRoteisaRothe Erde Ibrica [email protected]

ChinaXuzhou Rothe Erde SlewingBearing Co., [email protected]

Xuzhou Rothe Erde SlewingRing Mill Co., Ltd. [email protected]

IndiaRothe Erde India Private [email protected]

JapanNippon Roballo Co., [email protected]

BrazilRobrasaRolamentos EspeciaisRothe Erde Ltda.vendas.robrasa@ thyssenkrupp.comwww.robrasa.com.br

USARotek [email protected]

BerlinThyssenKrupp Rothe Erde GmbHGeschftsstelle [email protected]

Branch offices in Germany

NorthThyssenKrupp Rothe Erde GmbHGeschftsstelle [email protected]

SouthThyssenKrupp Rothe Erde GmbHGeschftsstelle [email protected]

Lippstadt plantThyssenKrupp Rothe Erde GmbHBeckumer Strasse 87 59555 Lippstadt, GermanyTelephone +49 (29 41) 7 41-0Fax +49 (29 41) 7 41-33 20

Dortmund plantThyssenKrupp Rothe Erde GmbHTremoniastrasse 5-11 44137 Dortmund, GermanyTelephone +49 (2 31) 1 86-0 Fax +49 (2 31) -25 00

Headoffice DortmundThyssenKrupp Rothe Erde GmbHTremoniastrasse 5-11 44137 Dortmund, GermanyTelephone +49 (2 31) 1 86-0 Fax +49 (2 31) -25 [email protected]

Plants

Headoffice

Eberswalde plantThyssenKrupp Rothe Erde GmbHHeegermhler Strasse 64 16225 Eberswalde, GermanyTelephone +49 (33 34) 2 06-4 00Fax +49 ( 33 34) 2 06-4 90

Individual details of this information shall only then be considered a quality or durability guarantee when each such case is expressly confirmed by us in writing. This publication may not be reproduced in whole or in part without permission. All rights reserved. Printed in Germany.

-

GB

-7.1

1-EE

-V2-

2.0-

B

ThyssenKrupp Rothe Erde GmbH

Tremoniastrasse 5-11 44137 Dortmund Germany

Telephone +49 (2 31) 1 86-0 Fax +49 (2 31) 1 86-25 00

www.rotheerde.com [email protected]