Modeling, Simulation and Control of Dimethyl Ether Synthesis in an Industrial Fixed-bed Reactor

Simulation Of Fixed Bed Processes

Transcript of Simulation Of Fixed Bed Processes

-

7/21/2019 Simulation Of Fixed Bed Processes

1/77

Abstract

The numerical simulation of fixed bed processes using the Method of Lines is analyzed from

an efficiency point of view and a discretization scheme is proposed that is easy to implement

and more efficient than conventional schemes. Biasing of the intervals used to discretize the

partial differential equations that describe bulk transport in a fixed bed process is studied.

The amount of biasing that results in the least error is derived. The effect of using unequally

biased intervals is also discussed. The improvement in accuracy that results from using

biased intervals can be used to reduce the number of equations required to get the desired

accuracy . Discretization of the diffusion and adsorption equation using a geometric grid is

studied to determine the improvement in accuracy that can be achieved using a non-linear

grid. The behavior of different adsorption isotherms on the optimal geometric grid is also

discussed.

Two test problems are simulated to validate the discretization scheme developed. The

adsorption of Cadmium on novel organo-silicates developed by Gomez-Salazar et. al.[7] is

used to demonstrate the improvement in efficiency obtained when a non-linear isotherm is

used. Using a geometric grid for discretizing the pellet equations does not result in a sig-

nificant improvement in accuracy over a linear grid because the non-linear isotherm results

in a concentration front moving through the pellet. Biased intervals in the discretization of

the bed equation are used successfully to improve the accuracy of the breakthrough curve

obtained. The adsorption of Toluene on an activated Carbon packed bed present in a room-

air cleaner is simulated assuming a linear isotherm. Discretization of the bed equation using

biased intervals does not result in significant gains in the accuracy of the solution because

the solution profiles in the bed are flat. A geometric grid is used for discretizing the pellet

equation and the solution obtained is more efficient than that obtained with conventional

methods.

-

7/21/2019 Simulation Of Fixed Bed Processes

2/77

An Efficient Numerical Method for the Simulation of Fixed-bed

Processes

by

Manuj Swaroop

BTech, Indian Institute of Technology Kanpur, 2002

Masters thesis

Submitted in partial fulfillment of the requirements for the degree

of Master of Science in Chemical Engineering in the GraduateSchool of Syracuse University

December 2004

Approved: _____________________Prof. John C. Heydweiller

Date: _____________________

-

7/21/2019 Simulation Of Fixed Bed Processes

3/77

Copyright 2004 Manuj Swaroop

All rights reserved.

-

7/21/2019 Simulation Of Fixed Bed Processes

4/77

Contents

List of Figures vii

Acknowledgements ix

1 Introduction 1

1.1 Mathematical model for a fixed bed . . . . . . . . . . . . . . . . . . . . . . 2

1.2 Numerical methods for simulation of fixed bed . . . . . . . . . . . . . . . . 6

1.3 Objective . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 The fixed-bed equation 10

2.1 Biased differencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

2.2 Integration over biased intervals . . . . . . . . . . . . . . . . . . . . . . . . . 15

2.3 Error analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

2.4 Temporal truncation error . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.4.1 Explicit scheme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.4.2 Error in trapezoidal integration . . . . . . . . . . . . . . . . . . . . . 20

2.4.3 Unequal biasing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2.5 Convection-Diffusion-Reaction equation . . . . . . . . . . . . . . . . . . . . 23

2.5.1 Error analysis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

2.6 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

2.7 Results and discussion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

2.8 APPENDIX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

v

-

7/21/2019 Simulation Of Fixed Bed Processes

5/77

CONTENTS vi

3 The pellet equation 35

3.1 Geometric grid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

3.1.1 Equation at r=0 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

3.1.2 Equation at r=1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.2 Simulation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

3.3 Results and discussion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

3.3.1 Linear isotherm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3.3.2 Non Linear isotherm . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

4 Simulation of fixed beds 49

4.1 Discretization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

4.2 Simulation procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

4.3 Cadmium adsorption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.3.1 Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

4.3.2 Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

4.4 Room air cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.4.1 Background . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

4.4.2 Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

4.5 Conclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Bibliography 66

-

7/21/2019 Simulation Of Fixed Bed Processes

6/77

-

7/21/2019 Simulation Of Fixed Bed Processes

7/77

LIST OF FIGURES viii

3.8 Average absolute error for a non linear isotherm based on amount contained

in the pores, with a linear grid and a geometric grid . . . . . . . . . . . . . 47

3.9 Average absolute error for a non linear isotherm based on surface concentra-

tion of pellet, with a linear grid and a geometric grid . . . . . . . . . . . . . 48

4.1 Breakthrough curve obtained using simple upwind differencing compared

with the benchmark and optimal biasing curves . . . . . . . . . . . . . . . . 57

4.2 Breakthrough curve obtained using central differencing compared with the

benchmark and optimal biasing curves . . . . . . . . . . . . . . . . . . . . . 57

4.3 Breakthrough curve obtained using partial upwind biasing in the spatial part

compared with the benchmark and optimal biasing curves . . . . . . . . . . 58

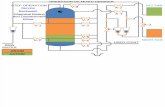

4.4 Model of the room air cleaner used for the adsorption of toluene on activated

carbon. For the numerical simulation, the bed is modeled as a thick, short

bed as shown on the right side, obtained by unfolding the cylindrical bed. . 59

4.5 Simulation results for Toluene adsorption on activated carbon in a room air

cleaner, at flow rate Q = 7.44 104cm3/s for (a), (b), and (c) and Q =2.36104cm3/s for (d) usingnb = 21 (no. of grid points in the bed), np = 10(no. of grid points in pellets) and m = 1.4 (geometric factor) . . . . . . . . 63

4.6 Concentration profiles in the first pellet in the bed at high flow rates for time

-

7/21/2019 Simulation Of Fixed Bed Processes

8/77

Acknowledgements

I would like to express my sincere gratitude and respect to my advisor, Dr. John C.

Heydweiller for his valuable guidance, motivation and patience throughout this research

work. It has been a privilege and a very good learning experience for me to work under his

supervision. I would also like to thank Dr. Tavlarides for allowing me to carry out experi-

ments in his lab and Dr. Jianshun Zhang for introducing me to some practical applications

of this research work and providing me with experimental data.

Dr. Thong Q. Dang gave me valuable insights into various numerical methods that are

applicable to this research work. I am grateful to Dr. Ashok S. Sangani for his support,

encouragement and interest in my research and for the fruitful discussions I had with him.

All the Chemical Engineering staffincluding Ms. Dawn Long and Mickey Hunter were

very helpful and supportive during my stay at Syracuse University and I would like to take

this opportunity to thank them.

I would also like to thank my friends and colleagues Nitin Agarwal, Bhushan Hole,

Francisco Nam, Shailesh Ozarkar, Wenhao Chen and Gautam Bisht for their encouragement

and assistance with this thesis.

I am very thankful to my friends, parents and brother for their friendship and love.

ix

-

7/21/2019 Simulation Of Fixed Bed Processes

9/77

Chapter 1

Introduction

Adsorption phenomena play an important role in many natural, biological and chemicalsystems. Adsorption operations are used extensively in the chemical and petrochemical

industries and are being increasingly used for biotechnology and environmental control

applications. Adsorption maybe used as a separation process or as a step in multiphase

reaction systems. The process of adsorption involves separation of a component of a mixture

from one phase and its accumulation on the surface of another phase, usually solid. The

adsorbing phase is called the adsorbent and the material adsorbed at the surface of that

phase is called the adsorbate.The most common configuration used for adsorption processes is a fixed bed. In a fixed

bed, adsorbent pellets are held together in place to form a bed, through which the incoming

fluid is made to flow. The fluid flows through interstitial spaces present in the bed and

diffuses into the pores of the adsorbent pellets. Accumulation of the adsorbate takes place

mostly on the surface inside the pores of the pellets, which provide a very large surface

area. This configuration is quite easy to accommodate in a variety of designs for different

applications. The particular application of interest in the present work is indoor room aircleaners. They consist of a fixed bed usually made of activated carbon cloth or pellets. A

fan is used to blow air from the outside into the bed. The fixed bed is usually small in length

and has a large cross-sectional area. This kind of structure results in faster adsorption of

gases.

Indoor air cleaners are used to remove volatile organic compounds (VOCs) from the air.

1

-

7/21/2019 Simulation Of Fixed Bed Processes

10/77

CHAPTER 1. INTRODUCTION 2

These gases are typically emitted from adhesives, upholstery, manufactured wood products,

cleaning supplies and some household appliances. The concentration of such gases in indoor

air is usually extremely low (measured in parts per billion). As a result, accurate isotherms

for their adsorption are not available. The low concentration of the gases also means that

the adsorbent will take a very long time to become saturated with the adsorbate. Thus,

indoor room air cleaners are designed to last for several years.

The lifespan and efficiency of an adsorber is characterized by its breakthrough curve.

This curve is a plot of the concentration of the adsorbate at the outlet of the fixed bed

versus time. The breakthrough curve is used to determine the time for which the adsorber

operated within acceptable limits. A breakthrough curve with a sharp slope implies that the

adsorber was working efficiently and has a longer lifetime. On the other hand, if the pellets

are unable to adsorb efficiently, the breakthrough occurs earlier and the slope is less steep,

so that the bed does not saturate optimally. The long life span of these adsorbers poses a

problem in proper testing and design of the fixed beds used in the air cleaner. Experiments

with the same concentrations that are present in indoor air would take too long to complete

to be of any practical use. On the other hand, if higher concentrations of gases are used, the

physics of adsorption is expected to be different and so the results may not be extrapolated

to low concentrations.

Simulation of fixed bed adsorbers for indoor air quality can be used to calculate the

values of the adsorption parameters for VOCs at very low concentrations, and that infor-

mation can be used to predict the breakthrough curve of an adsorber. However, the nature

of the adsorption isotherm at such low concentrations, combined with the variations in the

kind of flow that takes place in different regions of the bed makes it a difficult task to make

an accurate prediction of the breakthrough curve.

1.1 Mathematical model for a fixed bed

The simplified mathematical model used to simulate a fixed bed can be described as follows.

The flow through the bed is mostly convective. Hence, a one dimensional plug flow approx-

imation in the direction of the flow can be used to represent the flow in the bed. A mass

-

7/21/2019 Simulation Of Fixed Bed Processes

11/77

CHAPTER 1. INTRODUCTION 3

transfer coefficient coupled with the concentration difference between the concentration in

the bulk fluid and the surface of an average pellet in the same region is used to describe

mass transfer to the pellets. The equation for the bed flow can be written in the following

form[21]:

uscbz

+cbt

+b3kfRp

(cb c|r=R) = 0 (1.1)

cb =

0 z 0 t 0cbin z= 0 t >0

where

z = axis along the direction of flow

cb = concentration in bed along z

us = superficial bed velocity

= bed packing fraction

b = density of the bed

p = density of pellets

R = radius of pellets

kf = bulk mass transfer coefficient

This partial differential equation contains a convection term, along with a source term to

represent mass transfer from the bulk to the surface of a pellet. The source term couples

the bed equation with the pellet equations.

To solve the fixed bed equation, the bed is discretized into equal intervals. The pellets

contained in each interval are represented by a single averaged pellet in that interval (see

Figure 1.1). The total amount transferred to the pellets in a given region can be determined

using a mass balance between the bulk and the pellets. This balance is incorporated in the

source term in the bed equation.

-

7/21/2019 Simulation Of Fixed Bed Processes

12/77

CHAPTER 1. INTRODUCTION 4

Figure 1.1: Model of a fixed bed. The axial coordinate is denoted by x. The bed isdiscretized into equal intervals of size x. The concentration profile inside the pellets ineach interval is represented by a single averaged pellet.

The adsorbate that is transferred to the surface of a pellet diffuses into its pores and

then adsorbs on the surface inside the pores. The pellets are modeled as spherical particles

with identical cylindrical pores. The flow inside the pores is mostly due to diffusion. The

flow and adsorption equation for the pellets can be written as follows[21]:

p+p

q

c

c

t = De

1

r2

r

r2

c

r

+ Dsp

1

r2

r

r2

q

r

(1.2)

c= 0 for t 0; 0 r Rc

r = 0 at r= 0

Dpc

r =kf(cb c) at r= R

-

7/21/2019 Simulation Of Fixed Bed Processes

13/77

CHAPTER 1. INTRODUCTION 5

where

c = concentration inside pores of pellet

r = radial axis of pellet

p = porosity of pellet

p = density of pellet

De = effective pore diffusion coefficient

Ds = surface diffusion coefficient

q = adsorption isotherm (function of c)

The above partial differential equation is a parabolic equation in spherical coordinates and

it represents diffusion inside the pores and on the surface along with the adsorption. It is

linked to the bed equation through the boundary condition at r = R.

The averaged pellets in each interval of the bed are expected to have different concen-

tration profiles because the bulk concentration in the bed is a function of the distance along

the bed axis. The solution of the pellet equation also depends on the rate of change of

the bulk concentration in its section. Hence the pellet equation has to be solved for each

section of the bed. Thus, there is 1 PDE for the bed andnb PDEs for the pellets, where nb

is the number of intervals used in the bed, that have to be solved for a complete fixed-bed

simulation. This approach results in a nested structure of equations.

It should be noted that there are significant differences in the physics and numerical

characteristics of the bed equation and the pellet equation. They can be summarized as

follows:

The bed equation is a convective equation with a linear source term whereas the pelletequation is a diffusion equation. Typically, the spatial discretization scheme and the

time integration schemes used for these two types of equations are different.

If the isotherm to be used is non-linear, then the pellet equation becomes non-linear

and has to be solved numerically for each section with appropriate approximations.

-

7/21/2019 Simulation Of Fixed Bed Processes

14/77

CHAPTER 1. INTRODUCTION 6

The two equations are in different spatial domains. As a result, different spatial grid

spacing would be needed for each kind of equation and that would affect the size of

the time step that can be used to solve them simultaneously.

If the two equations are non-dimensionalized, it is noted that the time scale that

emerges for each is quite different. So, the solution would have to proceed at the

smaller of the two time scales and might slow down the solution procedure significantly.

A unified approach to the simulation procedure for such problems, which can solve the

equations resulting from different models simultaneously is desirable and is presented in

this study.

1.2 Numerical methods for simulation of fixed bed

Numerous studies have been published which have dealt with the problem of solving an

advective equation with high accuracy and stability[6]. Similarly, there are many good

techniques for the solution of the diffusion equation. However, not all of them meet the

requirements of an efficient numerical method suitable for simulation of fixed bed prob-

lems. High order discretization schemes are usually computationally intensive. Second

order upwind schemes lead to problems in evaluating the boundary condition. The numeri-

cal approach must also be capable of solving both the advective equation and the nonlinear

diffusion equation with similar accuracy. Hence specialized methods for either kind of equa-

tion may not be suitable and may also be difficult to implement. A suitable numerical

method would have to be able to handle different grid discretizations, be able to solve

non-linear equations, be computationally efficient and easy to implement.

A concise review of the methods that can be used to solve equations arising in fixed

beds is given by Le Lann et. al.[11]. They presented the following classification of numerical

methods used to solve partial differential equations:

Method of Lines (MOL)

Finite difference Methods

-

7/21/2019 Simulation Of Fixed Bed Processes

15/77

CHAPTER 1. INTRODUCTION 7

Weighted Residuals Methods

Finite Element Methods

Finite Volume Methods

Adaptive Grid Methods

Moving grid Methods

A more specific review of numerical methods suitable for adsorption models was presented

by Costa and Rodrigues[5]. Sun and Meunier[19] developed an improved finite difference

method for fixed bed sorption problems using a higher order implicit scheme. Solution meth-

ods based on the method of characteristics were presented by Loureiro and Rodrigues[12].Weighted residual methods may be used to solve the complete set of equations but they

are generally not suitable for problems that have sharp moving fronts. Sharp fronts or

steep gradients can arise in the bed equation as well as the pellet equations with a non

linear isotherm. Oscillations and negative values of concentrations are often observed in

such cases when weighted residual methods are used[9]. Adaptive grid and moving grid

techniques[16, 17] can be used to reduce the error and enhance stability at the cost of

computational effi

ciency but they are diffi

cult to implement when both particle and bedequations have to be solved simultaneously.

The Method of Lines (MOL) converts each Partial Differential Equation (PDE) into a

set of Ordinary Differential Equations (ODEs) in time by discretizing the spatial variable.

The collection of ODEs resulting from each PDE can be combined to form a set of ODEs

that represent the complete problem. The resulting of equations can be solved simulta-

neously using an ODE solver. The ODE solver integrates the equations in time using a

specified numerical scheme. The advantage with this method is that well established in-tegration routines may be used for solving large sets of ODEs with good accuracy. These

include algorithms that can solve stiffas well as non stiffsystems of equation and feature

automatic step size adjustment and integration-order selection to maintain a user-specified

error tolerance and to solve the equations with high efficiency. The main drawback is that

non-stiffODE solvers may have problems with estimating and controlling the impact of the

-

7/21/2019 Simulation Of Fixed Bed Processes

16/77

CHAPTER 1. INTRODUCTION 8

space discretization scheme on the overall numerical scheme. Finite element, finite volume

or finite difference methods may also be incorporated in the MOL for the spatial discretiza-

tion. Only the spatial discretization needs to be done by the user when using the MOL and

as a result the MOL requires less effort on the part of the user as compared to a full finite

element simulation.

The nature of the adsorption problem is such that as the solution proceeds, the time

derivative decreases in magnitude. So a numerical method in which the size of the time

increments can be increased as the solution proceeds is desirable[22]. The MOL can be used

with sophisticated algorithms for controlling the time step, and so it is suitable for such

applications. The method of lines can also be used to simultaneously solve sets of PDEs

which require different kinds of spatial differencing schemes as all of them will result in

ODEs in time, which can be solved together.

The MOL when used with the proper spatial discretization and a reasonably fast and

accurate (depending on the problem) numerical integration scheme turns out to be a very

suitable and convenient method for fixed bed applications. The present work attempts to

formulate a simple and easy to use numerical method based on the MOL, which can be used

to simulate fixed bed adsorbers. The numerical scheme formulation should be more efficient

than conventional methods used in fixed bed simulations. This can be done by reducing

the number of equations required to get the same accuracy as compared to conventional

methods. The numerical scheme should allow solution of advection and diffusion equations

simultaneously. It should also be independent of grid spacing and time step so that it can

be implemented easily in different problems.

1.3 Objective

The goal of the present work is to develop an easy to implement and reasonably fast and

accurate method based on the MOL for the simulation of fixed bed adsorber problems.

This study builds on the ideas presented by Heydweiller and Patel[10] about upwind biased

discretization schemes and attempts to present an in-depth analysis of the problem, leading

to an improved numerical scheme based on biased intervals and the MOL. Other techniques

-

7/21/2019 Simulation Of Fixed Bed Processes

17/77

CHAPTER 1. INTRODUCTION 9

to make the solution more efficient, like using a non-linear grid for discretization of the

pellet equations have also been investigated. The resulting techniques have been applied to

predict the breakthrough curve of a room air cleaner and also to investigate the adsorption

isotherms of the VOCs adsorbed on it.

The following chapter describes a general scheme for deriving the biasing matrices based

on certain parameters. The non-dimensionalized advection equation is used to demonstrate

the technique throughout the derivation. An error analysis of the resulting set of equations

is done and is used to find the best values for the biasing parameters. This analysis also

shows how different biasing for the temporal and the spatial part can be used to improve

the accuracy further. The amount of biasing would also depend on the particular numerical

scheme used for time integration. The derivation is then generalized to include equations

with diffusion and source terms.

The pellet equations are also solved with the MOL using a non-linear grid in the next

chapter. The effect of different non-linear grids on the accuracy of the solution is investigated

and the grid that results in the least error for the same number of grid points is used. The

optimal geometric grid was determined for various grid sizes for a linear and a non-linear

isotherm[7].

The last chapter deals with applying the numerical schemes developed in this study to

the simulation of two fixed-bed problems. The bed equation and the pellet equations are

solved simultaneously and the solution profiles and the breakthrough curve are presented.

The first problem is the simulation of adsorption of Cadmium on novel organo-ceramic

adsorbents developed by Gomez-Salazar et. al.[7]. The results for this setup were already

available and were used to check the derived numerical scheme for efficiency. Simulation of

adsorption of toluene on activated carbon in a room-air cleaner at very low concentrations

is also performed. The results are then compared with experimental data to examine theimprovements obtained in efficiency.

-

7/21/2019 Simulation Of Fixed Bed Processes

18/77

Chapter 2

The fixed-bed equation

Diff

erent spatial discretization schemes can be used with the method of lines for solvingdifferent kinds of PDEs. Second-order centered finite differences yield stable and efficient

solutions for parabolic equations. However, using central differencing for hyperbolic equa-

tions results in an unstable solution procedure. Backward differencing can be used with

hyperbolic equations to make the solution procedure stable but the relative inaccuracy of

first order backward differencing results in an inefficient solution as a large number of grid

points are needed to reduce the numerical dissipation that is introduced by this scheme.

Second order backward diff

erencing can also be used but it is more diffi

cult to implementat boundaries. There are several other schemes available for the solution of hyperbolic

equations[6] including explicit, implicit and several semi implicit schemes. However, only a

few of them are suitable for use with the MOL.

A discretization scheme to be used with the MOL should be based on spatial discretiza-

tion only, as the time discretization is handled by the ODE solver. If the same numerical

scheme is used discretize the time domain as well as the spatial domain for different kinds

of equations, then the temporal discretization should yield an accurate and stable solutionfor all the ODEs being solved simultaneously. This renders many conventional numerical

schemes unusable with the MOL if more than one kind of PDE is being solved.

Discretization schemes that have been proposed for solving the hyperbolic equation using

10

-

7/21/2019 Simulation Of Fixed Bed Processes

19/77

CHAPTER 2. THE FIXED-BED EQUATION 11

the method of lines will be discussed using the advection equation:

ut = c0ux (2.1)

Carver and Hinds[3] proposed the following formula, which incorporates biased differencing

of the spatial domain while also using a spatially biased time derivative:

1

6

1 +

3

2

(ut)i1+ 4(ut)i+

1 3

2

(ut)i+1

= c02 x[(1 )ui+1+ 2ui (1 +)ui1] (2.2)

The parameter was determined empirically using numerical experiments such that the

total error was minimized. Although the solution of the advective equation with c0 =1was stable and accurate with the parameter set to 0.3, the computation time required was

50% greater than the time required using either backward or upstream biased differences.

Using eq. (2.2) necessitates the solving of a matrix problem at each time step even though

a non-stiff integrator is employed.

Heydweiller and Patel[10] formulated an upstream biased differencing scheme for the

solution of hyperbolic PDEs. This scheme does not involve a mass matrix, i.e., the time

derivative at only one grid point is used in any given ODE that results from the spatial

discretization. Hence, it is computationally more efficient than the scheme proposed by

Carver and Hinds. The biased differencing results in a stable solution for hyperbolic equa-

tions which have smooth solutions. It also permits sets of coupled hyperbolic and parabolic

equations to be solved simultaneously by the method of lines. This kind of coupling is very

common in mathematical models used by chemical engineers. The parameters used in the

difference formula are functions of the grid spacing and can give accuracy between first and

second order. The biased upwind differencing can be written in the form

(ux)i=aui+1+ cui bui1

2x + C

(x)p

P (uxx)i+

(x)2

6 (uxxx) (2.3)

-

7/21/2019 Simulation Of Fixed Bed Processes

20/77

CHAPTER 2. THE FIXED-BED EQUATION 12

or

(ux)i=ui+1 ui1

2 x + Dcui+1 2ui+ ui1

(x)2 (2.4)

where Dc =C(x)p/P , C = (c0/ |c0|) and p and P are parameters independent of

the grid spacing x. They also showed that single values of the parameters (p = 1.5 and

P= 1.0) could be used for most problems on a normalized spatial domain.

The idea of discretizing the equations over biased intervals on the spatial grid has been

investigated in detail in the present study. The analysis has been used to formulate an

efficient and easy to use method for solving fixed bed problems, based on the improvements

in accuracy that result from using biased intervals.

An integral formulation for discretizing PDEs in a particular domain has been used in the

present work. This method is essentially a simplified form of the finite volume technique.

The solution domain is divided into intervals, usually of equal size. The equation to be

discretized is integrated over the discretization variable in each interval. The resulting set

of equations are independent of the discretization variable. Numerical integration formulas

can be used to approximate terms that cannot be integrated directly. The accuracy of the

resulting equations depends on the method used for numerical integration. This method

can be used to discretize a variety of equations along with their boundary conditions in a

consistent manner. Several finite difference methods run into problems at a boundary if

one or more imaginary point is needed to incorporate the boundary condition. The integral

method does not have this problem as it can be integrated over a partial interval at the

boundary, within the solution domain.

The integral method can be used very effectively for discretizing equations over a biased

interval. In this chapter, the idea of discretizing PDEs over a biased interval to improve the

accuracy has been explored further using the integral method.

2.1 Biased differencing

The upstream-biased difference scheme presented by Heydweiller and Patel (eq. 2.3) can be

derived by integrating the partial differential equation for each grid point over an interval

xshifted upstream (see Figure 2.1) by an amount defined by biasing parameters, a and b.

-

7/21/2019 Simulation Of Fixed Bed Processes

21/77

CHAPTER 2. THE FIXED-BED EQUATION 13

Figure 2.1: An upwind-biased interval about a grid point, (c0< 0)

The parameter a represents the part of the interval to the right of the point xi that forms

part of the integration domain while the parameter b represents the part of the interval to

the left ofxi that is used. The advection equation (eq. 2.1) has been used to illustrate the

integration method.

The advection equation can be integrated over a biased interval as follows:

xi+(ax/2)xi(bx/2)

u

tdx= c0

xi+(ax/2)xi(bx/2)

u

xdx (2.5)

The parameters a and b are chosen such that a+b = 2, in order to have non-overlapping

intervals of length x each. Using the trapezoidal rule for the integral on the left hand

side (l.h.s.) of the equation and making suitable approximations, the following difference

equation was obtained:

duidt

=c0

aui+1+ (b a)ui bui1

(a + b)x

(2.6)

The right hand side (r.h.s.) of this equations is the same as eq. (2.3). At the boundaries,

integration is done over a partial interval and the same approximations are used as above

so that the order of accuracy is maintained throughout and the boundaries can be handled

-

7/21/2019 Simulation Of Fixed Bed Processes

22/77

CHAPTER 2. THE FIXED-BED EQUATION 14

conveniently. The integration formula at the left boundary is given by:

x0+(ax/2)x0

u

tdx= c0

x0+(ax/2)x0

u

xdx (2.7)

wherex0 denotes the leftmost grid point in the bed. The formula for the right boundary is

given by: xIxI(bx/2)

u

tdx= c0

xIxI(bx/2)

u

xdx (2.8)

wherexIdenotes the rightmost grid point in the bed.

The numerical integration used to obtain the r.h.s. of eq. (2.6) is of order (x)2 as the

value ofuiat the two ends of the biased interval was obtained using the lever rule. However,

the integration scheme used for evaluating the l.h.s. results in a larger truncation error. Ingeneral, higher order integration techniques can be used to evaluate both sides of eq. (2.5)

to improve the accuracy of the resulting equations. The number of grid points involved in

the resulting equation for each interval depends on the order of accuracy of the integration

scheme used. If a higher order scheme is to be used for integration, then the integration

domain should encompass more grid points, resulting in a larger interval. However, this

approach can run into problems at the boundary. The number of points available for the

last interval would be less than the number of points available for the adjacent interval.This would result in a difference between the order of accuracy of the integration used in

the two intervals and can lead to numerical errors.

The resulting set of equations can be expressed with the help of a l.h.s. and a r.h.s.

-

7/21/2019 Simulation Of Fixed Bed Processes

23/77

CHAPTER 2. THE FIXED-BED EQUATION 15

matrix as follows:

Ll1 Ll2

Lc1 Lc2 Lc3

Lc1 Lc2 Lc3

Lr1 Lr2

u1/t

u2/t

un1/t

un/t

=c0

Rl1 Rl2

Rc1 Rc2 Rc3

Rc1 Rc2 Rc3

Rr1 Rr2

u1

u2

un1

un

(2.9)

2.2 Integration over biased intervals

The advection equation (eq. 2.1) has been used to demonstrate the integration over biased

interval formulation used in this study. The trapezoidal rule is used to integrate terms

that cannot be integrated algebraically. The lever rule is used to calculate the value of any

expression in between grid points. Both these methods are second order accurate. Hence

the order of accuracy of the resulting equation is second order.

Consider a pointxi in the space domain. The equation is integrated over an interval of

length x around xi. The interval is upwind -biased as shown in Figure 2.1. The biasing

parametersa and b are used to define the amount of biasing. Since the size of the interval

is kept constant over the entire domain (a+ b = 2), only one of them is an independent

parameter (a in the present study). The integration technique used to derive the set of

equations also plays an important role in determining the accuracy of the solution, along

with the amount of biasing.

-

7/21/2019 Simulation Of Fixed Bed Processes

24/77

CHAPTER 2. THE FIXED-BED EQUATION 16

Integration of the spatial derivative results in the following expression:

c0

xi+(ax/2)xi(bx/2)

u

xdx = c0

u|xi+(ax/2) u|xi(bx/2)

= c0bui1+ (b a)ui+ aui+1a + b (2.10)

The discretization of the spatial part obtained with this method is the same as that presented

by Heydweiller and Patel (eq. 2.6).

The integration of the time derivative is evaluated as the area under the two trapezoids

ABEF and BCDE in Figure 2.1 (assuming that ui/t is used instead ofui).

xi+(ax/2)

xi(bx/2)

u

t

dx = EF

u

t

dx + DE

u

t

dx

=

b2

ui1t

+ (2ab + 4)uit

+ a2ui+1t

x

8 (2.11)

The complete discretized equation can be written as:

b2

ui1t

+ (2ab + 4)uit

+ a2ui+1t

1

8 = c0

bui1+ (b a)ui+ aui+1(a + b)x

(2.12)

The equations obtained using this method of integration are more accurate than eq.

(2.6) but the solution requires the solution of an additional matrix problem at each time

step. In this respect, the set of equations is similar to eq. (2.2). The difference is that

there is no empirical correlation used to derive the biasing parameters. The equations have

been obtained by simply improving the accuracy of the integration. The only independent

parameter is the amount of biasing and an optimum value for this parameter will be de-

termined using an error analysis. The accuracy of the solution can be improved by using

a more accurate scheme of integration, although it will reduce the efficiency of solution if

more than three adjacent grid points are used per solution point.

This method also makes handling of the boundary condition a simple task. The null

boundary condition can be handled by integrating over the partial interval left at the end:

b2

uI1t

+ (ab + 2b)uIt

1

8 = c0

buI1+ (2 a)uI(a + b)x

(2.13)

-

7/21/2019 Simulation Of Fixed Bed Processes

25/77

CHAPTER 2. THE FIXED-BED EQUATION 17

wherexI is the last grid point in the spatial domain.

2.3 Error analysis

A complete error analysis was done for the spatially discretized equations. The coefficients

of each term were treated as independent parameters so that the results can be used to find

the truncation error in equations derived using different integration schemes by replacing

the coefficients with their corresponding expressions. The error analysis does not take into

account the truncation error arising from discretization of the time derivative. This is

intentional because the numerical integration in time is done by the ODE solver. Further,

a simple explicit or implicit scheme might not be appropriate for solving all the equations

being solved simultaneously. Hence the time discretization is best left to the ODE solver,

which can use sophisticated algorithms to do the integration in time efficiently. However,

an explicit scheme was analyzed in order to provide a comparison.

After integrating the advection equation over a biased interval for use with the method

of lines as shown in the previous section, it can be expressed in the following manner:

k(ut)i1+ (1 (k+ l))(ut)i+ l(ut)i+1= c0x

(pui1 (p + q)ui+ qui+1) (2.14)

The actual value of the biasing parameters is a function of the amount of biasing and the

scheme used for integration. Only schemes using three grid points for a single equation

have been considered in this case. The results from this analysis can therefore be used to

evaluate the truncation error using all the integration schemes used in this study.

Using the Taylor series expansion foru, the r.h.s. can be written as

RHS=

c0

(qp)(ux)i+ (p + q) (x)

2 (uxx)i+ (qp) (x)

2

6 (uxxx)i+ (p + q)

(x)324

(uxxxx)i+

(2.15)

Comparing with eq. (2.1), qp= 1. Substituting in the above expression and replacingui

-

7/21/2019 Simulation Of Fixed Bed Processes

26/77

CHAPTER 2. THE FIXED-BED EQUATION 18

with u gives

RHS=c0ux+ c0(p + q)(x)

2 uxx+ c0

(x)26

uxxx+ c0(p + q)(x)3

24 uxxxx+ (2.16)

Similarly, using the Taylor series for ut, the l.h.s. can be written as:

LHS = ut+ (l k)(x)utx+ (l+ k) (x)2

2 utxx+ (l k) (x)

3

6 utxxx+ (2.17)

LHS = ut (l k)(x)uxx (l+ k) (x)2

2 uxxx (l k) (x)

3

6 uxxxx+ (2.18)

using relations from eq. (2.59).

The complete equation can now be written as:

ut = c0ux+ (x)

c0uxx

(p + q)

2 (l k)

+(x)2

c0uxxx

1

6 (l+ k)

2

+(x)3

c0uxxxx

(p + q)

24 (l k)

6

+ (2.19)

Substituting the values of the coefficients ofut and u from eq. (2.12), the error terms can

be written as:

ET{O[(x)]} (p + q)2

(l k) = a 12

a 12

= 0

ET{O[(x)2]} 1

6 (l+ k)

2 =

a2 2a +2

3

(2.20)

The first order error term is identically zero if either both sides of the equation are integrated

over the same interval or if both sides are integrated over a centered interval ( l = k and

p + q= 0). The second order term can be reduced to zero by using a root of the quadratic

expression in that term as the value ofa. The resulting value of the biasing parameter a is:

a= 1 13

0.423 (2.21)

This value of the biasing parameter would yield a third order accurate discretization in

-

7/21/2019 Simulation Of Fixed Bed Processes

27/77

CHAPTER 2. THE FIXED-BED EQUATION 19

space. However, the truncation error derived here does not include the error due to time

discretization. In the actual solution, there would be some error added to the first and

second order error terms depending on the numerical scheme used for time integration. In

principle, if a third order accurate scheme is used for integration in time, the solution would

also be third order accurate.

Caveat: The derivative relations (eq. 2.59) used to obtain this result are applicable only

if the profile ofuis continuous and differentiable at all points. If there is any discontinuity

in the first derivative ofu, none of the derivatives are defined at that point and hence those

relations are not valid there. The solution is expected to be less accurate at and adjacent

to the points where u is non-differentiable but the accuracy should be unaffected at the

remaining grid points.

2.4 Temporal truncation error

The left hand side can be discretized using a first order time discretization scheme as follows:

LHS= k

un+1i1 uni1

t

+ [1 (k+ l)]

un+1i uni

t

+ l

un+1i+1 uni+1

t

(2.22)

where the superscript ndenotes the current time step.

2.4.1 Explicit scheme

The r.h.s for an explicit scheme can be written as:

RHS=c0unx+ c0(p + q)

(x)

2 unxx+ c0

(x)26

unxxx+ c0(p + q)(x)3

24 unxxxx+ (2.23)

Let t = r(x). This substitution enables us to consolidate the truncation error in

the temporal and spatial domains and hence, to obtain the overall truncation error. The

variable r can be considered to be the velocity of the numerical solution. Replacinguni with

-

7/21/2019 Simulation Of Fixed Bed Processes

28/77

CHAPTER 2. THE FIXED-BED EQUATION 20

u and using the Taylor series expansion of the terms on the left hand side gives:

ut = c0ux+ (x)

c0

(p + q)

2 uxx r

2utt (l k)utx

+(x)2

c01

6 uxxx r2

6uttt (k+ l)

2 utxx (l

k)r

2 uttx

+(x)3

c0(p + q)

24 uxxxx (l k)

6 utxxx r

3

24utttt (k+ l)r

4 uttxx (l k)r

2

6 utttx

+ (2.24)

Substituting the relations given in the appendix for derivatives ofu in eq. (2.24), the

following expression is obtained:

ut = c0ux+ (x)uxx

c0 (p + q)2 c20 r2 c0(l k)

+(x)2uxxx

c0

1

6 c30

r2

6 c0 (k+ l)

2 c20

(l k)r2

+(x)3uxxxx

c0

(p + q)

24 c0 (l k)

6 c40

r3

24 c20

(k+ l)r

4 c30

(l k)r26

+ (2.25)

2.4.2 Error in trapezoidal integration

The expressions for the biasing variables k , l, pand qfor integration of equations using the

trapezoidal rule can be obtained by comparing eq. (2.14) to eq. (2.12).

k = b2

8

l = a2

8

p = b2

q = a

2 (2.26)

Substituting these expressions in eq. (2.25) and simplifying, we get the total error using

the trapezoidal integration on biased intervals.

-

7/21/2019 Simulation Of Fixed Bed Processes

29/77

CHAPTER 2. THE FIXED-BED EQUATION 21

Explicit scheme:

ET{O[(x)]} 12

c20r (2.27)

ET{O[(x)2]}

1

12c0+

1

4c0a

1

8c0a

2 +1

4c20r

1

6c30r

2 (2.28)

ET{O[(x)3]} c0

24c0a

24 +

c20ra

8 c

20r

8 c

20ra

2

16 c

30r

2a

12 +

c30r2

12 c

40r

3

24 (2.29)

These results clearly show that the spatial discretization is second order accurate. The

time discretization is first order accurate, so the first order error is non-zero and is directly

proportional to the size of the time step relative to the grid size. Hence smaller time steps

will result in better accuracy. However, for a given value ofr, a suitable value of the biasing

parametera can be chosen, such that the second order error is identically zero. This results

in improved accuracy of the overall solution. The accuracy would be better if a higher order

time discretization was used.

2.4.3 Unequal biasing

It should be noted in the preceding error analysis that the first order error term could not

be eliminated because the terms resulting from the l.h.s. and r.h.s. which contained the

biasing parameter, canceled out. If the biasing were diff

erent on the two sides, it wouldprovide an additional degree of freedom that can be used to eliminate the first order error

term. This is the reason for using different biased intervals for the temporal and spatial

parts of the equation.

Using unequal biasing for the l.h.s. and the r.h.s., the biasing variables can be written

as:

k = b2

8

l = a2

8

p = b

2

q = a

2 (2.30)

-

7/21/2019 Simulation Of Fixed Bed Processes

30/77

CHAPTER 2. THE FIXED-BED EQUATION 22

where a is the biasing factor for the l.h.s. of the equation with b = 2 a and a is thebiasing factor for the r.h.s. of the equation with b = 2 a. Substituting these expressionsin eq. (2.25) and simplifying, the following truncation error are obtained:

ET{O[(x)]} c0a + c0a c20r

2 (2.31)

ET{O[(x)2]} 1

12c0+

1

4c0a 1

8c0a

2 +1

4c20r

1

6c30r

2 (2.32)

ET{O[(x)3]} (c0a

2c0a + c0)24

+c20ra

8 c

20r

8 c

20ra

2

16 c

30r

2a

12 +

c30r2

12 c

40r

3

24

(2.33)

The above expressions have three degrees of freedom, including the time step. This

implies that, in principle, the two biasing parameters and a suitable time step can be

chosen to eliminate the error up to the third order. However, if a limit is imposed on the

time step, for example due to stability considerations, the error can be eliminated up to

the first order and the second order error can be minimized. In the case of a fixed bed

simulation, the time step may also be limited by the time scale of the pellet equations.

The results for unequal intervals are applicable only if the time step is fixed. A similar

analysis can be done for an implicit scheme or any other time discretization scheme and

equations can be formulated for minimizing the truncation error. In most problems involving

fixed beds, a fixed time step is not suitable for solving all the equations simultaneously. As

a result, this approach has not been investigated further in this study. The above analysis

has been presented to illustrate how using different biasing for integration of the two sides

of an equation can be used to improve the accuracy. Even when an ODE solver is used,

there may be first or second order error terms resulting from the time discretization used

by the ODE solver, and slightly different biasing for the integration intervals can be used

to reduce that error. The actual difference in biasing needed depends on the problem and

the ODE solver used and may need to be determined by experimentation.

-

7/21/2019 Simulation Of Fixed Bed Processes

31/77

CHAPTER 2. THE FIXED-BED EQUATION 23

2.5 Convection-Diffusion-Reaction equation

The technique used above to calculate the biasing parameters can be applied to a typical

convection-diffusion-reaction equation. In an adsorption problem, the reaction term would

be replaced with a mass transfer term. In general, this term can be called the source term.

The non-dimensional equation can be written as:

u

t =c0

u

x+

1

P e

2u

x2+ f(u) (2.34)

The parameters in this equation could have been reduced further by including c0 in the

non-dimensional time but in some practical applications, the time scale used for non-

dimensionalization may belong to another set of equations (like the ones for particles inthe bed) and in that case, the c0 term will remain as it is. The source term actually

used for computation is usually the linearized form of the actual source term, so that

f(u) =constant and f(u) = 0.

Integrating this equation over a biased spatial interval, we get:

xi+(ax/2)xi(bx/2)

u

tdx

=c0

xi

+(a

x/2)

xi(bx/2)

ux

dx + 1P e

x

i

+(a

x/2)

xi(bx/2)

2ux2

dx +

xi

+(a

x/2)

xi(bx/2)f(u)dx (2.35)

The temporal and spatial parts have been integrated over differently biased intervals. The

biasing parameter for the temporal part is a and for the spatial part it is a. Using the

trapezoidal rule for integration, we get:

xi+(ax/2)xi(bx/2)

u

tdx =

b2

ui1t

+ (2ab + 4)uit

+ a2ui+1t

x

8

c0

xi+(a

x/2)

xi(bx/2)

ux

dx = c0

bui1+ (b a)ui+ aui+1a + b

-

7/21/2019 Simulation Of Fixed Bed Processes

32/77

CHAPTER 2. THE FIXED-BED EQUATION 24

1

P e

xi+(ax/2)xi(bx/2)

2u

x2dx =

1

P e

u

x

xi+(ax/2)

ux

xi(bx/2)

= 1

P e

ui1 2ui+ ui+1

x

xi+(ax/2)xi(bx/2)

f(u)dx =

b

2f(ui1) + (2a

b

+ 4)f(ui) + a

2f(ui+1) x

8 (2.36)

It should be noted that integrating over a biased interval results in the same formula for

the parabolic term as a regular finite difference approximation over a centered interval.

The regular approximation for the diffusion term is second order accurate and so trying to

increase the order of accuracy of the integration using biased intervals does not affect its

discretization. Also note that the coefficients of the discretized source term have the same

form as the coefficients of the temporal part. The only difference is that they are based on

different biasing parameters.

2.5.1 Error analysis

In general, the discretized equation can be written as:

k(ut)i1+ (1 (k+ l))(ut)i+ l(ut)i+1 = c0x

[pui1 (p + q)ui+ qui+1]

+

1

P e(x)2[ui1 2ui+ ui+1]+

kf(ui1) + [1 (k + l)]f(ui) + lf(ui+1)

(2.37)

The error terms resulting from the convective term have already been derived in Section

2.3. The truncation error of the diffusion term is well known. It can be written as:

ETdiff=

1

12P e (

x)2

uxxxx+ O[(

x)4

] (2.38)

The source term can be written using a Taylor series expansion as:

f(ui1) = f(ui) + (u)f(u)

u

i

+(u)2

2

2f(u)

u2

i

+

where u= ui1 ui (2.39)

-

7/21/2019 Simulation Of Fixed Bed Processes

33/77

CHAPTER 2. THE FIXED-BED EQUATION 25

The source term f(u) has been linearized, hence only the first order error term in u is

considered without any loss of accuracy. A Taylor series expansion (2.55) can be used to

write:

f(ui1) = f(ui) +x(ux)i+(x)

2

2 (uxx)i (x)

3

6 (uxxx)i+

f(ui)

f(ui+1) = f(ui) +

x(ux)i+

(x)22

(uxx)i+(x)3

6 (uxxx)i+

f(ui) (2.40)

An error analysis similar to that done in the previous sections can be done to write:

ut = c0ux+ 1

P euxx+ f(u)

+(

x)c0(p + q)

2 uxx (l k)utx + ux(l k)f(ui)+(x)2

c06

uxxx (k+ l)2

utxx

+ uxxf

(ui)(k + l)

2 +

uxxxx12P e

+(x)3

c0(p + q)

24 uxxxx (l k)

6 utxxx

+ uxxxf

(ui)(l k)

6

+ (2.41)

Using the relations derived from the generalized equation (eq. 2.34) ( given in eq. 2.60),

the above equation can be written as:

ut = c0ux+ 1P e

uxx+ f(u)

+(x)

uxxc0

(p + q)

2 (l k)

+ uxf

(l k) (l k) (l k) uxxxP e

+(x)2

uxxxc0

1

6 (k+ l)

2

+ fuxx

k + l

2 k+ l

2

+

uxxxxP e

1

12k + l

2

+ (2.42)

The error terms in the above equation contain different derivatives ofu. There is no obvious

way to compare the coeffi

cients of these terms, hence each should be minimized separately.

-

7/21/2019 Simulation Of Fixed Bed Processes

34/77

CHAPTER 2. THE FIXED-BED EQUATION 26

This results in the following equations for improving the accuracy of the solution:

(p + q)

2 (l k) = 0 (2.43)

(l

k)

(l

k) = 0 (2.44)

(l k) = 0 (2.45)1

6 (k+ l)

2 = 0 (2.46)

k + l

2 k+ l

2 = 0 (2.47)

1

12k+ l

2 = 0 (2.48)

Equation (2.43) implies that the biased interval should be the same for the time derivative

term and the convective term. Equation (2.44) implies that the biased interval should

be the same for the time derivative term and the source term. Equation (2.45) means

that the interval of integration should be centered. These three equations are sufficient

to determine the biasing parameters (a = a = 1) and they yield a second order accurate

spatial discretization.

However, if the diffusion (uxx) term is not present or is very small relative to the con-

vective term in the original equation, as is the case in many fixed bed problems, a more

accurate discretization can be achieved. Equation (2.46) can be used to determine the value

of the biasing parameter instead of equation (2.45). This equation gives the same value of

a as eq. (2.21) (a = 0.423). Equation (2.47) would be satisfied automatically as equation

(2.44) has already been satisfied if the interval of integration for the source term is the

same as that for the time derivative term. The last equation would be negligible since the

diffusion term is negligible. This formulation would result in a third order accurate spatial

discretization.

2.6 Conclusion

The results obtained in Section 2.4 and Section 2.5 are subject to the same caveat as the

results in Section 2.3. These results are applicable only if the solution is differentiable at

all points. The biasing parameters derived here may still be used for solutions which have

-

7/21/2019 Simulation Of Fixed Bed Processes

35/77

CHAPTER 2. THE FIXED-BED EQUATION 27

a discontinuity in the derivative but the solution may show oscillations in the region of

discontinuity. However, this restriction does not preclude the simulation of fixed bed ad-

sorbers using the above method because the concentration profile along the bed is observed

to be smooth for the most part. The profile has a discontinuity at very short times but it

smoothes out quickly.

The analysis done above resulted in a very straightforward approach to solving a fixed

bed equation using the method of lines. If an ODE solver that controls the time step is to be

used then the values of the biasing parameters are predetermined. They do not depend on

the physical parameters or the spatial or temporal grid. The only factor that they depend

on is the nature of the equation being solved. If the equation is convection dominated

then the appropriate biasing parameter is given by eq. (2.21). If the equation is diffusion

dominated then no biasing is necessary and the interval should be centered about a grid

point. The actual discretized equations can be obtained by integrating over the biased or

non-biased interval. On the other hand, if a fixed time step is to be used, which can be

controlled by the user, then the method for deriving the appropriate biasing factors has

been presented. The biasing factor has been determined for an advective equation to be

solved using an explicit scheme as an example.

2.7 Results and discussion

The formula obtained in the previous section was tested on the following advection equation:

u

t = u

x

for 0 x 1

Boundary condition u(0, t) =u0(0); t

0

Initial condition u(x, 0) =u0(x) (2.49)

The exact solution, given byu(x, t) =u0(x t) is shown with a dashed line in all the figuresat t = 0.5. A stiffODE solver was used for the simulation in all cases. The simulation

was done in MATLAB r[13] using the ode15sODE solver. The results obtained using the

-

7/21/2019 Simulation Of Fixed Bed Processes

36/77

CHAPTER 2. THE FIXED-BED EQUATION 28

biased interval formulation were compared to the results using a simple backward difference.

A smooth sinusoidal initial condition was used for the comparison to avoid any errors that

could be introduced by discontinuities in the derivative. The following initial condition was

used:

u0(x) =

1+cos(+ x0.2

2)

2 0 x 0.20 0.2 x 1

(2.50)

It is evident from Figure 2.2 that a drastic improvement in accuracy can be achieved by

using the proper biasing. A biasing parameter different from the one obtained in Section

2.3 results in larger oscillations either leading or trailing the wave depending on the value of

the parameter. This behavior shows that numerical dissipation can be eliminated to a great

extent by using equally biased intervals . However, improper biasing can lead to instability

similar to that observed with using central differencing. The correct biasing can mitigate

both dissipation and dispersion error to a large extent.

The simulation was also carried out for the following initial conditions:

Smooth front:

u0(x) =

1+cos( x0.2

)

2 0 x 0.20 0.2 x 1

(2.51)

Triangular wave:

u0(x) =

x0.1 0 x 0.1

1 (x0.1)0.1 0.1 x 0.20 0.2 x 1

(2.52)

Step input:

u0(x) =

1 x= 0

0 0< x 1(2.53)

The results of these simulations are shown in Figure 2.3. The smooth front represents

the kind of solution profile that is encountered typically in fixed beds. It is evident from

the figure that there is very little dissipation and dispersion in the solution to the smooth

front. The triangular wave and the step input have at least one discontinuity in their spatial

derivative and as such the solution is not expected to be very accurate. This can be verified

-

7/21/2019 Simulation Of Fixed Bed Processes

37/77

CHAPTER 2. THE FIXED-BED EQUATION 29

in Figure 2.3. There is some numerical dissipation in the overall solution and some dispersion

near the points of discontinuity. However, the solution obtained using biased intervals is

more accurate than that obtained by using a simple backward or central difference with the

same value ofx.

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0

0.2

0.4

0.6

0.8

1

x

u

deltax=0.01 time=0.5 no mass matrix aRHS=0

(a) Simple backward difference

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0

0.2

0.4

0.6

0.8

1

x

u

deltax=0.01 time=0.5 aLHS=0.423 aRHS=0.423

(b) Equally biased intervals with a=0.423

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0

0.2

0.4

0.6

0.8

1

x

u

deltax=0.01 time=0.5 aLHS=0.2 aRHS=0.2

(c) Equally biased intervals with a=0.2

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0

0.2

0.4

0.6

0.8

1

x

u

deltax=0.01 time=0.5 aLHS=0.8 aRHS=0.8

(d) Equally biased intervals with a=0.8

Figure 2.2: Advection equation for a smooth function using biased intervals

-

7/21/2019 Simulation Of Fixed Bed Processes

38/77

CHAPTER 2. THE FIXED-BED EQUATION 30

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0

0.2

0.4

0.6

0.8

1

x

u

deltax=0.01 time=0.5 aLHS=0.423 aRHS=0.423

(a) Sinusoidal wave

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0

0.2

0.4

0.6

0.8

1

x

u

deltax=0.01 time=0.9 aLHS=0.423 aRHS=0.423

(b) smooth front

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0

0.2

0.4

0.6

0.8

1

x

u

deltax=0.01 time=0.5 aLHS=0.423 aRHS=0.423

(c) Triangular wave

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0

0.2

0.4

0.6

0.8

1

x

u

deltax=0.01 time=0.5 aLHS=0.423 aRHS=0.423

(d) Step input

Figure 2.3: Simulation results with different initial conditions using equally biased intervals

To show that the above formulation gives reasonable solutions for a range of values of

x, (eq. 2.49) was solved for x = 0.04, 0.02, 0.01 and 0.005 using the initial condition

given in (eq. 2.50). The results are shown in Figure 2.4. It can be seen that there is greater

dissipation and dispersion error with larger values ofx, although the solution remains

stable.

The above results show that the biased intervals formulation can be used very effectively

for typical fixed bed equations. It can reduce the error to a great extent in smooth solution

profiles as compared to backward differencing or central differencing. Even for profiles with

-

7/21/2019 Simulation Of Fixed Bed Processes

39/77

CHAPTER 2. THE FIXED-BED EQUATION 31

discontinuous derivatives, the solution obtained is better. It is be appropriate to mention

here that there are other numerical schemes available for solving the advective equation[6].

Some of them can also capture regions with discontinuous derivatives with little or no

oscillations. However, these schemes are specific to the advection equation and most of

them also use a fixed time step.

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0

0.2

0.4

0.6

0.8

1

x

u

deltax=0.04 time=0.5 aLHS=0.423 aRHS=0.423

(a) dx=0.04

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0

0.2

0.4

0.6

0.8

1

x

u

deltax=0.02 time=0.5 aLHS=0.423 aRHS=0.423

(b) dx=0.02

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0

0.2

0.4

0.6

0.8

1

x

u

deltax=0.01 time=0.5 aLHS=0.423 aRHS=0.423

(c) dx=0.01

0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1

0

0.2

0.4

0.6

0.8

1

x

u

deltax=0.005 time=0.5 aLHS=0.423 aRHS=0.423

(d) dx=0.005

Figure 2.4: Simulation results with different grid sizes using equally biased intervals

The emphasis in the present study was to develop a consistent and easy to implement

numerical scheme that can be used for solving the advection equation along with a source

term and a diffusion term. It should also be independent of the time step used. The biased

-

7/21/2019 Simulation Of Fixed Bed Processes

40/77

CHAPTER 2. THE FIXED-BED EQUATION 32

interval scheme developed above provides a straightforward approach to solving this kind

of problems. This scheme is also easy to implement if the advection equation is coupled

with a parabolic equation. The parabolic equation can be discretized over intervals different

from those used for the advection equation without affecting the solution of the advection

equation. There is no optimum time stepping required to get the desired accuracy for a

given discretization, hence the ODE solver can solve both equations simultaneously without

losing any more accuracy.

2.8 APPENDIX

Evaluating the terms in the integration of eq. (2.5).

Terms occurring in the spatial part:

u|xi(bx/2) = bui1+ aui

a + b

u|xi+(ax/2) = bui+ aui+1

a + b

u|xi+(ax/2) u|xi(bx/2) = bui1+ (b a)ui+ aui+1

a + b (2.54)

Terms occurring in the temporal part:

u

t

xi(bx/2)

= b

ui1t + a

uit

a + b

u

t

xi+(ax/2)

= bui

t + aui+1t

a + bF E

u

tdx =

ut

xi(bx/2)

+ uit

2

bx

2

=

b2 ui1

t + (2a + b)buit

4(a + b)

x

ED

u

tdx =

ut

xi+(ax/2)

+ uit

2

ax

2

=

a2

ui+1t + (2b + a)a

uit

4(a + b)

x

-

7/21/2019 Simulation Of Fixed Bed Processes

41/77

CHAPTER 2. THE FIXED-BED EQUATION 33

Taylor series expansion of variables:

ui1 = ui x(ux)i+(x)2

2 (uxx)i (x)

3

6 (uxxx)i+

(x)424

(uxxxx)i+

ui+1 = ui+

x(ux)i+

(

x)2

2 (uxx)i+

(

x)3

6 (uxxx)i+

(

x)4

24 (uxxxx)i+ (2.55)

un+1i =uni + (t)(ut)

ni +

(t)2

2 (utt)

ni +

(t)3

6 (uttt)

ni +

(t)4

24 (utttt)

ni + (2.56)

un+1i1 = uni1+ (t)(ut)

ni1+

(t)2

2 (utt)

ni1+

(t)3

6 (uttt)

ni1+

(t)4

24 (utttt)

ni1+

= uni (x)(ux)ni +(x)2

2 (uxx)

ni

(x)3

6 (uxxx)

ni +

(x)4

24 (uxxxx)

ni +

+(t) (ut)n

i(x)(u

tx)n

i +

(x)2

2 (u

txx)n

i(x)3

6 (u

txxx)n

i +

+(t)2

2

(utt)

ni (x)(uttx)ni +

(x)2

2 (uttxx)

ni +

+(t)3

6 [(uttt)

ni (x)(utttx)ni + ] +

(t)4

24 [(utttt)

ni + ] + (2.57)

un+1i+1 = uni+1+ (t)(ut)

ni+1+

(t)2

2 (utt)

ni+1+

(t)3

6 (uttt)

ni+1+

(t)4

24 (utttt)

ni+1+

= uni + (x)(ux)ni +

(x)2

2

(uxx)ni +

(x)3

6

(uxxx)ni +

(x)4

24

(uxxxx)ni +

+(t)

(ut)

ni + (x)(utx)

ni +

(x)2

2 (utxx)

ni +

(x)3

6 (utxxx)

ni +

+(t)2

2

(utt)

ni + (x)(uttx)

ni +

(x)2

2 (uttxx)

ni +

+(t)3

6 [(uttt)

ni + (x)(utttx)

ni + ] +

(t)4

24 [(utttt)

ni + ] + (2.58)

The following relations can be derived from the hyperbolic equation (eq. 2.1). They are

used to simplify the error expression for the equation:

-

7/21/2019 Simulation Of Fixed Bed Processes

42/77

CHAPTER 2. THE FIXED-BED EQUATION 34

ut = c0ux

utt = (c0ux)t = (c0ut)x= c20uxx

utx = (c0ux)x = c0uxx

uttt = (utt)t= (c20uxx)t = c

20(utx)x= c

30uxxx

uxxt = (uxx)t= (utx)x= c0uxxx

uttx = (utt)x= c20uxxx

utxxx = (ut)xxx = (c0ux)xxx = c0uxxxx

utttt = (uttt)t = (c30uxxx)t= (c

30uxxt)x= c

40uxxxx

uttxx = (uttx)x= c20uxxxx

utttx = (uttt)x= c30uxxxx (2.59)

The following set of relations are used to simplify the terms in the convection diffusion

reaction equation (eq. 2.34):

ut = c0ux+ 1

P euxx+ f(u)

utx = c0uxx+ 1

P euxxx+ f

(u)ux

uxxt = c0uxxx+ 1

P euxxxx+ f

(u)uxx

utt = c0uxt+ 1

P euxxt+ f

(u)ut

= f f + 2c0fux+

c0+

2f

P e

uxx+

2c0P e

uxxx+ 1

P e2uxxxx (2.60)

-

7/21/2019 Simulation Of Fixed Bed Processes

43/77

Chapter 3

The pellet equation

The mass transfer inside pellets in a fixed bed is usually dominated by diff

usion. The solutediffuses from the pellet surface into the pores and gets adsorbed on the surface inside the

pores. The pore structure has been approximated with cylindrical pores arranged radially

in the pellet for the purpose of simulation. The pore diffusion constant was calculated using

the average pore diameter that was determined from experiments. This results in a simple

diffusion equation in spherical coordinates. The pellet is assumed to be symmetric, hence

the equation has spatial dependence only in r. The resulting equation can be written in

non dimensional form as follows:

c

= (c)kp

2c

r2+

2

rc

r

(3.1)

c = 0 for 0; 0 r 1c

r

r=0

= 0

c

r

r=1

=Bi(cbc|r=1)

where (c) represents the adsorption term, which may be a constant (in the case of a

linear isotherm) or a function of c (in the case of a non linear isotherm). A non-linear

term inc/rresulting from the surface diffusion term was not used in this analysis for the

sake of simplicity. The non-linear term disappears in both the fixed-bed problems that are

simulated in the last chapter and hence, the results are not affected by this omission.

35

-

7/21/2019 Simulation Of Fixed Bed Processes

44/77

CHAPTER 3. THE PELLET EQUATION 36

The non dimensional parameters used in this equations are:

c = c/cb in

r = r/R

= t/

= time scale used for non dimensionalization

Bi = Rkf

Dp

kp = Dp

R2

where

cb in = inlet concentration

R = radius of pellet

kf = bulk mass transfer coefficient

Dp = pore diffusion coefficient

As the adsorbate starts diffusing from the surface of a pellet into an empty pore, the

concentration gradient near the boundary is very steep. In order to capture this part of

the process using the method of lines, a very fine grid is needed near the external bound-

ary. However, towards the center of the pellet, the concentration profile becomes flatter in

accordance with the boundary condition of zero slope at the center. This characteristic of

mass transfer in pellets suggests that a non-linear grid with more points near the external

boundary and fewer towards the center would be able to capture the concentration profile

near the surface with greater accuracy than a linear grid using the same number of grid

points. The non linear grid would be more computationally efficient than a linear grid as the

number of equations required for obtaining the same accuracy as a linear grid is reduced.

Hence, a geometric grid was used for simulating the pellet equations.

-

7/21/2019 Simulation Of Fixed Bed Processes

45/77

CHAPTER 3. THE PELLET EQUATION 37

Figure 3.1: Two adjacent intervals in a geometric grid

3.1 Geometric grid

A geometric grid is made of grid elements whose size is defined by a geometric progression.

For a pellet, the smallest grid element is near the external boundary (r = 1) while the

largest one is near the center (r = 0). The length of any two adjacent intervals has a

predefined ratiom such that the length of an interval is m times the length of its adjacent

outer interval. Two adjacent grid elements are shown in Figure 3.1. The geometric factor

m that gives the most efficient and accurate solution depends on several factors including

the number of grid points used and the adsorption isotherm. The optimal value ofm to be

used in a simulation can not be derived but rather has to be determined for each problem

by numerical experimentation. However, using a geometric grid does improve the efficiency

of the simulation by reducing the number of equations required to be solved in order to

obtain the same degree of accuracy as that obtained with a linear grid.

The difference approximations for the first and second derivatives at rj are obtained

from the Taylor series expansions ofcj1 and cj+1 aboutcj :

cj = q2cj1 (p2 q2)cj+ p2cj+1

p2q+pq2

cj = 2qcj1 2(p + q)cj+ 2pcj+1

p2q+pq2 (3.2)

-

7/21/2019 Simulation Of Fixed Bed Processes

46/77

CHAPTER 3. THE PELLET EQUATION 38

where p = mn+1r and q=mnr (see Figure 3.1) and n = 0 for the outermost interval.

The base interval r is defined as:

1

r

=1 m(np1)

1 m (3.3)

where np is the number of grid points in the pellet. Substituting the above expressions in

eq. (3.1), the following discretized pellet equation is obtained:

cjt

=(cj )kp

2q

1 qr

cj1 2(p + q)

1 + pqr

cj+ 2p

1 + pr

cj+1

p2q+pq2

(3.4)

3.1.1 Equation at r=0

The zero-slope boundary condition at the center of the pellet leads to an indeterminate form

for the last term on the r.h.s. of eq. (3.1). This term can be converted to a determinate

form using the LHospital rule as follows:

limr0

2

r

c

r = 2

2c

r2

r=0

(3.5)

Substituting this expression into eq. (3.1), the following equation is obtained at the center

of the pellet:c

=(c)kp

32c

r2

(3.6)

This equation can be discretized using eq. (3.2) to get the spatial derivative as:

cj01 = (p2 q2)cj0+ p2cj0+1

q2

cj0 = 6

q2(cj0+ cj0+1) (3.7)

wherej0 denotes the grid point at the center of the pellet. Substituting in eq. (3.6)

cj0t

=(cj0)kp

6

q2(cj0+ cj0+1)

(3.8)

-

7/21/2019 Simulation Of Fixed Bed Processes

47/77

CHAPTER 3. THE PELLET EQUATION 39

3.1.2 Equation at r=1

The derivative boundary condition at the surface of the pellet is discretized using an imag-

inary point on the geometric grid outside the pellet. Using eq. (3.2):

cJ+1 = Bi(p2q+pq2)

p2 c +

1 q

2

p2 Bi(p

2q+pq2)

p2

cJ+

q2

p2cJ1

cJ = 2

p2cJ1+

2

p2 2Bi

p

cJ+

2Bi

p c (3.9)