Ship, grind and press – ceramics in the making...A SACMI Imola PH 7500 hydraulic press being...

Transcript of Ship, grind and press – ceramics in the making...A SACMI Imola PH 7500 hydraulic press being...

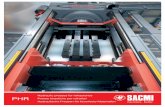

A SACMI Imola PH 7500 hydraulic press being unloaded from a multi-axle low bed trailer in Brazil.

2018-02-14 15:10 CET

Ship, grind and press – ceramics in themaking

Panalpina Energy and Project Solutions did it again with another#MajorMove. This time by handling two port-to-door shipments for one ofBrazil’s leading ceramics makers with an output of over 30 million squaremeters of tiles per year. The tiles are produced for a global market and usedin architecture and interior design.

The move included ocean and overland transportation of an industrial milland a hydraulic press from Genoa, Italy’s busiest port by cargo tonnage, to

Paranaguá, one of the main gateways in southern Brazil, as well as theinstallation of both machines in Tijucas, Santa Catarina.

Made in Italy by industry leader Sacmi, the 176-ton state-of-the-art hydraulicpress Imola PH 7500 was dismantled into its two main components andpacked separately for transport. The main unit (7.63x3.89x2.59 m) had aweight of 120 tons, while its press motion system (3.17x2.66x0.90 m) was 56tons. Hydraulic presses are used for the forming of ceramics powder.

The second machine was a fully-assembled 32-ton Sacmi MTD drum mill(8.0x3.62x3.67 m) designed for the wet grinding of ceramic clays and glazefrits. These units are generally used for the production of porcelainizedstoneware.

“Although the parts had a long way to go, the main challenge was to navigatethe last few corners inside the warehouse at project site. The narrow doors,warehouse columns, internal structures, and machines surrounding the pointsrequired a very detailed analysis and complex execution. The handlingrequired several maneuvers to have both press and mill positioned for finallifting,” says Anderson Antonio, Panalpina’s country head of Energy andProject Solutions, Brazil. “One of the reasons why Panalpina was chosen forthis move was our ability to provide this kind of last-mile service foroversized cargo, which is essential for the high-output globalized economywe live in,” concludes Anderson.

Both machines are now an integral part of the customer’s production plant.For the final touches, the tiles go through big burners for drying andsintering, and after more production steps the finished products are thenshipped out to countries on five continents, mainly through the same port ofParanaguá that saw the press and mill arrive in Brazil.

Learn more about Panalpina’s knowledge, experience and global force of skilledprofessionals to craft a transportation solution for any heavy or oversized move.

Photo gallery

The heavy drum mill is escorted into the plant premises at destination inTijucas, Santa Catarina, Brazil.

Finally at installation point.

This is how 32 tons of drum mill look after final lifting.

The 176-ton state-of-the-art hydraulic press Imola PH 7500 is reassembled atdestination.

DSV Panalpina A/S

We provide and manage supply chain solutions for thousands of companiesevery day – from the small family run business to the large globalcorporation.

Our reach is global, yet our presence is local and close to our customers.75,000 employees in more than 90 countries work passionately to delivergreat customer experiences and high-quality services.

Read more at www.dsv.com

Kontaktpersoner

Maiken Riise AndersenPressekontaktHead of Corporate [email protected]+45 43 20 30 74

Christian KrogslundPressekontaktSenior Director, Corporate Marketing & [email protected]+45 28 44 22 35