Sg Iron Production

-

Upload

shreyashri-nayak -

Category

Documents

-

view

216 -

download

0

Transcript of Sg Iron Production

-

8/3/2019 Sg Iron Production

1/20

SEMINAR ON SPHEROIDAL

GRAPHITE PRODUCTION

BYSHREYASHRI NAYAK

ROLL- 27604

GUIDED BY:- MRS SWARNALATA BEHERA

-

8/3/2019 Sg Iron Production

2/20

overview:IntroductionBase iron compositionSteps in production of s.g ironPropertiesDefectsAdvantages and disadvantagesApplicationsConclusion

-

8/3/2019 Sg Iron Production

3/20

introduction It is a type of cast iron. It is also known as ductile, nodular or

spherulitic iron. It has graphite in form of spheroids embedded

in a steel matrix, mainly ferrite or pearlite. It is produced by treating the molten alloy with

magnesium and cerium which causespheroidal graphite to grow duringsolidification. After that ferro-silicon is addedas inoculant.

-

8/3/2019 Sg Iron Production

4/20

Base iron composition

A typical chemical analysis of this material: Iron

Carbon 3.3 to 3.4% Silicon 1.5- 1.7% Manganese 0.1 to 0.5% Phosphorus 0.005 to 0.04% Sulphur 0.007 to 0.012%

http://en.wikipedia.org/wiki/Ironhttp://en.wikipedia.org/wiki/Carbonhttp://en.wikipedia.org/wiki/Siliconhttp://en.wikipedia.org/wiki/Manganesehttp://en.wikipedia.org/wiki/Phosphorushttp://en.wikipedia.org/wiki/Sulfurhttp://en.wikipedia.org/wiki/Sulfurhttp://en.wikipedia.org/wiki/Phosphorushttp://en.wikipedia.org/wiki/Manganesehttp://en.wikipedia.org/wiki/Siliconhttp://en.wikipedia.org/wiki/Carbonhttp://en.wikipedia.org/wiki/Iron -

8/3/2019 Sg Iron Production

5/20

S.G IRON COMPOSITION

C- 3.3-3.5% Si 2.5% Mn- 0.1- 0.5% S- 0.001-0.010% P- 0.004-0.01% Other elements such as copper or tin may be added to

increase tensile and yield strength while

simultaneously reducing elongation. Improvedcorrosion resistance can be achieved by replacing 15%to 30% of the iron in the alloy with varying amounts of nickel , copper , or chromium .

http://en.wikipedia.org/wiki/Copperhttp://en.wikipedia.org/wiki/Tinhttp://en.wikipedia.org/wiki/Ironhttp://en.wikipedia.org/wiki/Nickelhttp://en.wikipedia.org/wiki/Copperhttp://en.wikipedia.org/wiki/Chromiumhttp://en.wikipedia.org/wiki/Chromiumhttp://en.wikipedia.org/wiki/Copperhttp://en.wikipedia.org/wiki/Nickelhttp://en.wikipedia.org/wiki/Ironhttp://en.wikipedia.org/wiki/Tinhttp://en.wikipedia.org/wiki/Copper -

8/3/2019 Sg Iron Production

6/20

Steps involved in production of s.giron

Desulphurisation : sulphur helps to form graphite as flakes. So raw material should have low sulphur content(

-

8/3/2019 Sg Iron Production

7/20

Innoculation : As magnesium is a carbide former ferrosillicon is

added as innoculant as it prevents formation of carbide and helps in nucleation of graphite.

Inoculation of ductile iron requires greater

amounts of treatment agent than grey iron. Formation of rounded , even nodules is essential to

obtain the best properties. Ferrosilicon gives satisfactory nodule counts and iron

properties in many medium castings. Addition of Mg followed by FeSi makes the growth

rate of graphite to be approximately same in all

directions so that a spherical shape results.

-

8/3/2019 Sg Iron Production

8/20

Effect of iron composition on Mg- FeSi alloy selection

Siliconcontent

0.5- 1.5% Use 5% Mg-FeSi alloy

1.5- 1.8%10% M g-FeSi alloy

Sulphurcontent

-

8/3/2019 Sg Iron Production

9/20

Properties of sg iron castings

Sg iron castings have high tensile strength(400-

700 MPa), ductility, toughness, good machinability,damping capacity, high wear resistance,reasonable castability, elongation between (10-18%)

It has a yield strength of 270-290 MpaThey do not suffer from defect such such as firecrazes when used at elevated temperatures andare less section sensitive.

-

8/3/2019 Sg Iron Production

10/20

Complete ferritic matrixhaving a maximun 10%

pearlite possess maximumductility, toughness andmachinability.

Austenitic ductile matrix hasgood corrosion resistancegood creep resistance at high

temperature and are used forapplications such astransport of sulphuric acid,handling of alkali, etc

-

8/3/2019 Sg Iron Production

11/20

defects

various defects associated with production of Sg iron are:-

1.Fading of nodularity in ductile iron:- when properly treatedand inoculated ductile iron is held for prolonged time, itresults in deterioration of nodule shape of graphite. It ismainly due to either fading of Mg or fading of inoculation.

FADING OF MAGNESIUM- when Mg is lost to liquid metalsurroundings either due to loss of residual Mg content in theiron or a pick-up of sulphur or oxygen from the surroundingsresults in poor nodules formation referred to as compactedgraphite.

-

8/3/2019 Sg Iron Production

12/20

Possible cures inoculant fading consists of:-addition of more inoculantavoiding high holding temperatures and long holding time.use a second, late addition of a powerful speciality postinoculant material

INNOCULANT FADING EFFECT When the metal is held for prolonged times after addition of

post inoculant effect of inoculant gradually fade . As a resultthere is a loss in nodule count and nodules will lose theirspherical shape and irregular shape nodules result.

-

8/3/2019 Sg Iron Production

13/20

Magnesium slag defect in ductile iron

Magnesium containing reaction products act as source for inclusion

defects in ductile iron. Slag inclusion are found beneath the surface as aresult of improper separation during liquid metal processing.

Magnesium defects may also arise from turbulent mould filling and oftenappear as dross in areas where the metal is deadlocked.

Possible remedies extending hold time between treatment and skimming

to allow proper slag separation. Avoid high Ca and Mg alloys.

-

8/3/2019 Sg Iron Production

14/20

advantages

Nodular iron is a major engineering material as itcombines the engineering advantage of steel withthe processing economics of cast iron so it has hightensile strength and elongation.

Nodules of graphite weakens steel matrix to alesser extent than gray iron flakes.It does not suffer from firecrazes when used atelevated temperature.

It does act very much as stress raiser as they haveno sharp ends like graphite flakes hence increasedstrength.

-

8/3/2019 Sg Iron Production

15/20

disadvantage

Stirring of molten alloy after addition of nodulisingelement evolves a lot of gas which gets dissolved inliquid alloy and forms blow holes in castings.

Contraction during solidification of nodular cast iron

castings is much greater than grey iron castingswhich needs careful design of moulds to avoidshrinkage cavities in solidification casting.

Inspite of these drawbacks nodular cast iron isreplacing gray cast iron and steel in applications.

-

8/3/2019 Sg Iron Production

16/20

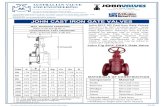

applications

Much of the annual production of ductile iron is inthe form of ductile iron pipe , used for water andsewer lines. It competes with polymeric materialssuch as PVC, HDPE, LDPEand polypropylene , whichare all much lighter than steel or ductile iron.

Ductile iron is specifically useful in many automotivecomponents, where strength needs surpass that of

aluminum but do not necessarily require steel. Othermajor industrial applications include off-highwaydiesel trucks, class 8 trucks, agricultural tractors, andoil well pumps.

http://en.wikipedia.org/wiki/Ductile_iron_pipehttp://en.wikipedia.org/wiki/Polymerhttp://en.wikipedia.org/wiki/PVChttp://en.wikipedia.org/wiki/HDPEhttp://en.wikipedia.org/wiki/LDPEhttp://en.wikipedia.org/wiki/Polypropylenehttp://en.wikipedia.org/wiki/Polypropylenehttp://en.wikipedia.org/wiki/LDPEhttp://en.wikipedia.org/wiki/HDPEhttp://en.wikipedia.org/wiki/PVChttp://en.wikipedia.org/wiki/Polymerhttp://en.wikipedia.org/wiki/Ductile_iron_pipe -

8/3/2019 Sg Iron Production

17/20

Conclusion Hence spheroidal graphite are a range of cast irons

having superior mechanical and physical properties .they are of much interest to engineers because of their useful combination of strength, ductility andtoughness.

Hence it is finding wide application in variousindustries because of its superior properties.

-

8/3/2019 Sg Iron Production

18/20

References

Technical information By elkem, L&T.Physical metallurgy- vijendra singh.http:/ www.istikamet.com.tr/en/ default.asp

http:/www.wikimediafoundation.org/wiki/Privacy_policy.

http://www.istikamet.com.tr/en/http://www.istikamet.com.tr/en/ -

8/3/2019 Sg Iron Production

19/20

Thank you

-

8/3/2019 Sg Iron Production

20/20

Any queries?????

![Iron steel production[1]](https://static.fdocuments.in/doc/165x107/551f41414979592e5b8b4ba2/iron-steel-production1.jpg)