SCEPTER TECHNICAL BRIEF - Graver Technologies...consists of a vibrating 100 mesh (140 microns)...

Transcript of SCEPTER TECHNICAL BRIEF - Graver Technologies...consists of a vibrating 100 mesh (140 microns)...

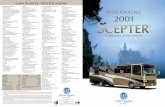

200 Lake Drive Glasgow, DE 19702 | 888-353-0303 | Fax: 302-369-0938

STB-010

SCEPTER TECHNICAL BRIEF

Caustic Recovery in Waste Streams

LIQUID FILTERS | GRAVER TECHNOLOGIES | 1-888-353-0303 | GRAVERTECH.COM

Application: Caustic Recovery

Application Detail: Recovery of Caustic from Waste Streams

Graver Product: Graver Technologies Scepter

Discussion:

Caustic recovery of CIP streams in food , pharma and the textile industry is of significant importance as caustic is expensive and its disposal creates a hazardous waste treatment problem. The contaminated dilute caustic from these processes is commonly concentrated and recovered by evaporation. However, evaporators cannot recover highly contaminated caustic. In the past, it had to be neutralized prior to disposal.

Graver Technologies patented membrane technology can clarify highly contaminated caustic for reuse. By combining its experience in polymer research, membrane technology and process engineering, Graver Technologies brings you customized solutions to your most pressing waste minimization, raw material recovery or liquid processing problems, including caustic recovery.

Graver Technologies Customized System Provides

• Cost savingsReduced waste caustic discharge

Reduced purchased caustic requirements Reduced energy requirements• Process improvements

Cleaned caustic for reuseImproved evaporator efficiencyReduced evaporator blowdownWaste treatment savings

• Low capital investment• Low operating and maintenance costs• Custom designed turnkey system• Leasing/rental options• Worldwide marketing and technical supportteam

The Technology

Graver Technologies' caustic recovery system is based on SCEPTER patented filtration technology, which combines porous stainless steel tubing and state-of-the-art, formed-in-place titanium dioxide (TiO2) membranes. This creates a smooth, foulant-resistant membrane that permits the processing of dirty or hostile fluids over a broad range of chemical conditions, pressures and temperatures, often where no other membrane device can be used.

How the System Works The contaminated caustic feed stream is pumped into one end of a membrane-lined porous stainless steel tube. Water and clean caustic will pass through the wall of the membrane-lined porous tube, where it is recovered for reuse. The concentrated contaminants flow out the other end of the tubing for further treatment or disposal.

The SystemPretreatment of the dirty caustic stream consists of a vibrating 100 mesh (140 microns) strainer to remove lint and coarse particulates. The feed is then directed through a heat exchanger where it is heated to 170oF by the 190oF permeate from the membrane system. The higher feed temperature allows for an increase in membrane flux. Every 1oF rise produces between a 1 - 1 1/2% increase in permeate flow, further reducing the system size.

The feed pump(s) supply the caustic to the first stage at a pressure of up to 55 psig. Each successive stage receives it’s feed from the previous stage. Each stage has a recirculating pump to boost the pressure of the fluid to 105 psig and provide the membrane crossflow velocity of 15 feet per second. The average transmembrane pressure in each stage is 80 psig. The final stage runs at the design recovery of 90 percent.

The concentrate flow contains all the contaminants in the feed stream greater than 0.1 micron in size. This flow is directed to waste treatment. The permeate flow, or clean caustic, is collected from each stage in a header.

Evaluation of Your Feed Stream The Graver Technologies design team is available to work with you to analyze your needs. Together we will custom-design the optimal caustic recovery system for your plant. For a preliminary analysis of your process, please contact Graver Technologies toll-free 800-249-1990 x 539 or visit our website:www.gravertech.com, e-mail:[email protected]