S6698 - Brochure for Silicone Composite Insulator 9-1-12

Transcript of S6698 - Brochure for Silicone Composite Insulator 9-1-12

8/19/2019 S6698 - Brochure for Silicone Composite Insulator 9-1-12

http://slidepdf.com/reader/full/s6698-brochure-for-silicone-composite-insulator-9-1-12 1/4

s

Answers for energy.

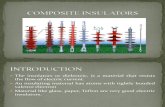

Silicone Composite Insulatorwww.siemens.com/energy

8/19/2019 S6698 - Brochure for Silicone Composite Insulator 9-1-12

http://slidepdf.com/reader/full/s6698-brochure-for-silicone-composite-insulator-9-1-12 2/4

Siemens with its state-of-the-art manufacturing facilitiesstands out as one of the leading quality manufacturer ofsilicone composite insulators. Siemens offers excellent,reliable and highest quality standard Silicone composite

insulators adapted for high voltage applications in outdoorservice. We are a powerful partner for our customers anda competent supplier of reliable products and solutions atcompetitive prices with the high standard of quality thatSiemens is known for. We comply with our customers’demands for reliability, safety and cost-effectiveness andserve them throughout the world. We provide the bestsolution for your requirements every time.

The excellent performance of silicone composite Insulatorsunder all climates and diverse polluted environment hasproven their capabilities over conventional porcelaininsulators. Silicone composite insulators are known andaccepted worldwide for high voltage applications. We arecurrently providing hollow silicone composite insulators in

the voltage from 145kV-800kV.

Bene ts of Silicone Composite Insulator:

Explosion/Shatter proof with higher safety for both personnel and substation equipment.

Non-brittle and minimum risk of vandalism.

Easy to repair even if sheds are intentionally damaged.

Ideal for heavily polluted atmosphere.

Freedom from cleaning (Hot line washing)

Hydrophobic.

High mechanical strength and adjustable exibility.

Superior seismic performance.

Excellent ash over resistance under humidity and contamination.

Light weight and minimum risk for handling, transport and installation damages.

2

8/19/2019 S6698 - Brochure for Silicone Composite Insulator 9-1-12

http://slidepdf.com/reader/full/s6698-brochure-for-silicone-composite-insulator-9-1-12 3/4

Construction:Siemens’ silicone composite insulators are made of Fiber-Reinforced Plastic (FRP) tube, ange and silicone rubbersheds conforming to international standards and are highlysuitable for outdoor applications. The FRP tube is made ofe-glass roving and epoxy resin using a winding technique.The winding of the ber onto the mandrel ensures highdimensional stability and mechanical strength. The strengthto weight ratio of FRP composite tube is higher than that ofsteel, results in maintaining its shape and function undersevere mechanical and environmental stresses.

The anges are tted with the FRP tube by shrink t processthat results in extremely strong and leak-proof joint. The

FRP tube associated with ange involves casting of siliconeshed on the tube sprayed with a thin layer of chemicalprimer, and the process ensures a perfect bonding betweensilicon rubber and the FRP tube. The silicone rubber is hightemperature vulcanized, low viscosity LSR formulationand with hydrophobic characteristics offers an excellentpollution performance under extreme climate conditions.The nished silicone composite insulator undergoes a

nishing for removal of ns followed by water pressure testto the rated pressure. Siemens silicone composite insulatorsare designed, type and routine tested in accordance withinternational standards.

Technical details:

Voltage Level LengthFlashoverDistance

Inner Tube(Dia.)

Outer Shed(Dia.)

Alternating shed pro le

d D p1 p2 s

[kV] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

145 1400 1200 240 370 50 35 50

245 2600 2350 340 470 50 35 50

420 3650 3400 340 470 50 35 50

800 6048 5600 586 708 44 29 48

p1

s

p2

3

8/19/2019 S6698 - Brochure for Silicone Composite Insulator 9-1-12

http://slidepdf.com/reader/full/s6698-brochure-for-silicone-composite-insulator-9-1-12 4/4

ET-01-001-002

Product upgradation is a continuousprocess. Hence, data in this brochure issubject to change without prior notice. Forthe latest information, please get in touchwith our Sales Of ces.

Siemens Ltd.Energy Sector - Energy TransmissionAurangabad WorksE76 – MIDC WalujAurangabad - 431136, India.Tel: +91 240 2565 191Fax: +91 240 2554 701

www.siemens.com/energy

Western Region

Mumbai 3rd Floor, R&D Tech CentreOpposite Airoli Railway StationThane Belapur RoadThane - 400 601, Maharashtra (India)Tel.: +91 22 27600001/6Fax: +91 22 27600030

Vadodara3rd Floor, OHM Business ParkOpp. Balaji HospitalEllora Park (East), SubhanpuraVadodara - 390 023, Gujarat (India)Tel.: +91 265 6692111Fax: +91 265 6692190

PuneVasant Vihar, Shirole RoadPune - 411 004, Maharashtra (India)Tel.: +91 20 25706000Fax: +91 20 25706060

Eastern Region

Kolkata43, Shanti PalliRasbihari Bypass ConnectorKolkata - 700 042, West Bengal (India)Tel.: +91 33 30939302Fax: +91 33 30939012

Northern Region

Delhi3rd Floor, Tower - BPlot No. 6 - A, Sector - 18Maruti Industrial Area, HUDAGurgaon - 122 015, Haryana (India)Tel.: +91 124 3836002Fax: +91 124 3836024

Southern Region

Chennai144, Mahatma Gandhi Road,P.O. Box No. 3323Chennai - 600 034, Tamil Nadu (India)Tel.: +91 44 30474444Fax: +91 44 30474450

For more information, please contact: