RGU_FRP Software- ADO

-

Upload

auto-design-online -

Category

Documents

-

view

21 -

download

2

description

Transcript of RGU_FRP Software- ADO

Agenda

1. Welcome & Introduction2. RGU OPTI – Foundry Resource Planning System

What makes foundries so special?3. RGU OPTI – Added Value for the foundry

1. Resourceplan – Basis for foundry specific calculation, the gateway between PPC and cost accounting

2. Tool/Pattern Management – integrated foundry-specific pattern management

3. OPTI.melt – a complete optimisation of the alloy usage with coverage of all logistical aspects

4. Disposition: the basis for capacity planning and Shop Floor Data Capture

5. Shop Floor Data Capture: All possibilities in a standardised solution

6. KPI & FIS – Consistent data for a homogenous reporting7. Post Calculation / Costing

19/05/2015 RGU OPTI - Cast in Software 2

Agenda

1. Welcome & Introduction2. Why FRP (Foundry Resource Planning) - Not just ERP?3. RGU Products

▪ RGU.OPTI▪ OPTI.MELT▪ OPTI.SAP

4. Resource plan – Basis for foundry specific calculation, the gateway between PPC and cost accounting

5. How RGU solutions works?6. Disposition: the basis for capacity planning and Shop Floor

Data Capture7. Shop Floor Data Capture: All possibilities in a standardised

solution8. KPI & FIS – Consistent data for a homogenous reporting9. Post Calculation / Costing

19/05/2015 RGU OPTI - Cast in Software 3

• Auto Design Online

▪ Auto Design Online brings world class foundries products & technology to Indian market, with the aim to upgrade Indian foundries with world class products

▪ We are the first company in India, to introduce foundry specific software to manage Foundry & it’s Resource planning – unique product!

▪ Team of expert engineers and foundry consultant, with vast experience in foundry, to provide the best sales & support our client deserves!

▪ Effective sales and support network across India

▪ We serve

▪ Sales & Support for our partner products

▪ Engineering Services – Casting gating system design & casting simulation

▪ Foundry consultancy – Cost reduction, Foundry management

▪ CAD-CAE design & services

Auto Design Online

19/05/2015 RGU OPTI - Cast in Software 4

• Auto Design Online – An Authorised Distributor of RGU GmbH, Germany

▪ Foundry Resource Planning Software packages

▪ RGU OPTI.Kompakt

▪ RGU OPTI.Melt

• Auto Design Online – An Authorised Distributor of C3P Engineering Software International Co., LIMITED, USA

▪ C3P develops complete Casting & Stamping simulation software packages

Auto Design Online - Partners

19/05/2015 RGU OPTI - Cast in Software 5

Cast Designer TM

Form Advisor TM

Geo Designer TM

• Founded in 1984 by German foundry experts with profound IT-knowledge

• 45 specialized employees with sole focus on the foundry industry

• Over a 120 pan-European installations and foundry projects

The RGU

19/05/2015 RGU OPTI - Cast in Software 6

• ERP - Enterprise Resource Planning“determines the corporate task to plan and steer resourceslike funds, assets, employees, machines, materials and ITas defined by company objectives in due time and tailored tosuit the market.“

Source: Wikipedia

• FRP - Foundry Resource Planning“determines the corporate task to plan, steer and

synchronize resources like funds, assets, employees,machines, materials, raw materials, scrap, pre-products,purchased products, external services, IT, logistics andquality assurance processes as defined by foundryobjectives in due time and tailored to suit the market.“

Source: RGU

19.05.2015 RGU - Cast in Software 9

The term “FRP“

19.05.2015 RGU - Cast in Software 10

Why “FRP“ – not just ERP?

ERP FRP = ERP + Resource plan + Production plan & control + QM +

Tool Administration

ProcessesWhy “FRP“ – not just ERP?

Foundry specific product structure− raw castings, treatment, cores, moulding sand− tools, mould boxes, pits− internal and external services (ESP)− casting and drawing history

Material data management− material demands− desired mixture, metallurgical

characteristic values− material test plans - variants− integrated resource and test planning

Material costing− as a material cost unit− melting book or with retrograde

accounting from the melting report− optimised calculation of the mixture

Linkage of product- & tool-data,pattern life-cycle− tool-variant part list

(pattern, core box, gravity dies..)− pattern state, changes, processes− control of downtime, life-cycles

Production planning and controlling− synchronising pattern, mould, cores, melt− pattern availability and pattern provision− tracing of castings− coordination of external services & providers

Calculation and pricing− surcharges (material, energy etc.)− price list, customer agreements− reference to item, gross & shipping weight,

charge− foundry specific planning formulas

19/05/2015 RGU OPTI - Cast in Software 11

FRP takes care of all Foundry specific requirements

19.05.2015 RGU - Cast in Software 12

General Manufacturing V/S Foundry market

Mechanical &ElectricalEngineeringFoundries

Most ERP software in the market are developed for g eneral manufacturing process, while RGU.OPTI developed for specific foundry segment, despite a niche market si ze!

General ERP

software

RGU.OPTI – FRP

13

What makes a casting so special?

• Geometry� size accuracy� surface

• methods� permanent/loast moulds� moulding line / hand

moulding

• raw materials� alloy, microstructure� mechanical properties

19.05.2015 RGU - Cast in Software

19.05.2015 RGU - Cast in Software 14

Work flow of general Mechanical engineering

In General mechanical manufacturing process workflow is�linear, continuous process chain – General ERP solutions aresuitable

19.05.2015 RGU - Cast in Software 15

Work flow of Foundry

In foundry processes are � non-linear, discontinuous process chains – demands for FRP solutions, not just ERP!

ProcessesProcess model (Example)

RM storage

Charge Preparation

Melting

Pattern Preparation or manufacturingMoulding

(includes stripping, curing, drying, etc)

Coating

Setting(Inserts, core, xWin)

Mould closing

Pouring

Cooling

Shake-out

Knock-off

Cleaning (Shot blasting/Fettling/Grinding)

Heat treatment

Finishing (painting, etc)

Storage/production(Inserts, core, xWin)

PackShipGoal =ship through

PPF/Ladle

1

2

Production operations in

scope:

Melting

Moulding

Core prod. & prep.

Cleaning & Finishing

1

2

Machining

Core preparation

Core Production

Core Production

SleevesFilters,

…

Rejects + Feeding gates

3

4

4

3

19/05/2015 RGU OPTI - Cast in Software 16

ProcessesLinked continuous and discontinuous

Processes

melting,treatment

making the mixture

sand preparation

coremaking

mould

tool/pattern

management

mech. treatment

cleaningannealingexamine

...

pouring

ERP-system

orders

planning, controlling

19/05/2015 RGU OPTI - Cast in Software 17

raw casting

Synchronized continuous and discontinuous processes

Core-shop Pouring

Moulding sands

Patterns Melting, treating

Moulding Shotblastingfettling

HT

Machined casting

machining, testing

ESP

Packaging & dispatch

A huge variety of determining factors and parameters have influence on the quality of castings

Moulds/Coressands (humidity, hardness, coating,patternsfeeders/downsprues

Meltchem. analysis, temperature, densityindexinoculation, treatment

Pouring/HT

pouring time solidification HT, microstructure

Energy-intensive processes(ratio 65-85 %)

logistics

Half-finished andfinished parts, tracingof HU, provision of HU, packaging instr.

19.05.2015 18RGU - Cast in Software

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 20

1. RGU.OPTI – Perfect solution for small-mid scale foundries, takescare of all the foundry process right from query to dispatch.

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 21

2. OPTI.Melt – Makes your melting economical through optimummelt-runs combined with cost-effective material consumption,reduced re-alloying quantities, and shorten melt times.

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 22

3. OPTI.SAP – ALL IN ONE: The perfect solution for large scalefoundries who needs best of both.

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 24

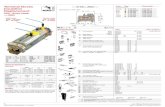

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

Tool

Core packages1200

PlanningResource Plan / Scheme

(Structure of the Part groups)Machined casting ready for dispatchMachined casting ready for dispatch16901690

Machined casting(Int ./ Ext.)Machined casting(Int ./ Ext.)16001600Fettled Raw casting ready for dispatchFettled Raw casting ready for dispatch15901590

Fettled Raw castingFettled Raw casting1500150014001400

Tool/Pattern0300

CoresCores11001100Sand recipesSand recipes10101010

Core patternsCore patterns02000200

Sand

Purchased coresPurchased cores11101110

blasting

Fettling

Inspection

HT

Moulding

Core setting

Pouring

Drilling

Lathing

ESP

1090

Inspection

Raw CastingRaw Casting

PackagingInstructions

1900

Packaging

Ready fordispatch

......

......

shooting

coating

......

glueing

......

Filters / Exothermics6024Liquid metal1300

Returns / Circuit1390Pouring specifications1414

19/05/2015 RGU OPTI - Cast in Software

......

25

19.05.2015 RGU - Cast in Software 26

Expanded Resource Plan(Treeview)

Shop operations

Purchasedparts

Pre-products

19.05.2015

PlanningMaster Data

Description of technical identifiers• 100 identifiers on head of resource plan• 24 class identifiers• 12 alphanummeric and• 24 numeric identifiers at part master data

All descriptions are available throughout the wholesystem and are linked between modules

• Product Planning• Purchasing• Pattern Management• Quality• PPC• MM

27RGU - Cast in Software

• All needed resources for a casting are mapped into a tree structure (moulding boxes, pits, cores, purchased parts etc., even externals services and all shop operations).

• SINGLE CLICK – for parts Calculations with an unmatched detail down to the last Cent and all necessary surcharges.

• New parts are created on the fly on the basis of similar parts.• Since every layer of the resource plan is a resource plan on

its own, each layer features different technical master data (cores have different parameters from moulds, from the patterns, from the melt and so on).

• Feedback data during production can be acquired according to the detail of the resource plan, even for multitask operations of workmen.

RGU OPTI - Cast in Software

PlanningThe Resource Plan: Advantages

19/05/2015 28

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 29

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 32

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

� Master data for process, product descriptions and all resources for the manufacture of the products

� Resource plan contains the time and quantity specifications for processes, workstations, equipment, assembly groups, pre-products and materials in the form of a task list with an integrated parts list.

� Calculation of production costs and pricing,� Capacity and workforce requirements planning� Quantities of purchasing materials required� Cost center accounting, controlling and cost object controlling

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 33

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

� Identifying the company’s KPIs and investment planning� Calculation of wages according to the remuneration model and

performance incentives.� Comprehensive material database linked with the material test plans� Integration of the tool management in which the available moulding

plates, core boxes, casting dies, mechanisms, etc. can be assigned according to the resource plan

� administration of the moulding box store, selection of suitable boxes� All specifications and cost elements are archived, so development

costs can be traced throughout the entire product lifecycle.

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 34

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

� Pre-configuration of part groups through all production stages of the cast part, including typical foundry formulae, classification characteristics for the different moulding and casting procedures,

� Administration of diagrams, documents, images, 3D data and simulation data

� User-defined formulation of surcharges and conversion to customer-dependent metal prices.

� Every change is documented, can be traced via the history function

RGU OPTI - Cast in Software

PlanningOPTI program mask: Resource plan

The gateway between PPC and cost-accounting

All shop operations (A) with default and hold times

All parts and half-finished products needed for production

Treeview

Instant cost-calculation and print-out

19/05/2015

Status of patterns, cores, drawings etc.

Attached test plans

PatternManagementProduct structure (RP) and BOM of Pattern

variant 2

pattern (plate) 1

core box 1

lot parts

core box 2

template, apparatus

pattern (plate) 2

. . . . . . . .

pattern instalation

variant BOM

pattern (plate) 1

core box 1

lot parts

core box 2

template, apparatus

pattern (plate) 2

. . . . . . . .

raw casting master data

structured BOM in the resource plan

core shooting ...

core box

liquid iron/-metal

feeder, filter

cleaning, testing, . . . cleaning, testing, . . .

machined casting

desired mixture

core moulding sand

mixture

moulding sand

pattern

moulding, founding

treatment

cores/core package

19/05/2015 RGU OPTI - Cast in Software 36

Planning - PLAPlanning – Scope of work

19/05/2015 RGU OPTI - Cast in Software 39

� Possible scope of work for Planning� Cost Center:

• The Cost Centres of the production and the adjusted cost rates• Allocate different service types with their plan-cost rates

(prop/fixed/Setting-up/Wages)

� Operations:• Allocation-List of value (Target values per time/cycle, lot, item, ...)• Sequence of work in order to control Bookings• Bottleneck for the capacity calculation• Foundry specific formulas for cast weight, moulding sand

requirements etc. are pre-defined

� Activities:• Activities can be defined to describe operations in more detail. Each

operation can posses several activities, which are carried out within this operation.

Planning - PLAPlanning – Scope of work

19/05/2015 RGU OPTI - Cast in Software 40

� Possible scope of work for Planning� Materials:

• Material database the chemical and physical• Quality control plan & Standard• Technical Parameters

• Material group• Heat Treatment• Temperatures• Weld ability etc..

� Part Groups:• Production and offer parts• Tools/Pattern• Test Plans

� Costing Surcharges:

Planning - PLAPlanning – Scope of work

19/05/2015 RGU OPTI - Cast in Software 41

� Possible scope of work for Planning� Article Master/ Inventory Card:

• Material• Customer• Supplier• Drawing• Pattern• Product group• Commodity group• Additional values to describe to treatment grade of the product

� Resource Plan: The resource plan describes for production parts the cost and time frames of the necessary resources:

• Operations• BOM-articles• Tools/Pattern• Supplies

Planning - PLAPlanning – Scope of work

19/05/2015 RGU OPTI - Cast in Software 42

� Possible scope of work for Planning� Resource Plan continue..

• Purchase parts• Pre-products• Assemblies• Raw parts• Finished parts

� Costing• Standard programmed costing tool• Report costing (in standard version only)• Excel costing• Offer Costing• Order Costing• Post-Costing (by using the feedback reporting)• Semi-finished-/Finished-appraisals

Planning - PLAPlanning – Scope of work

19/05/2015 RGU OPTI - Cast in Software 43

� Possible scope of work for Planning� Evaluation and Reports:

• Bottleneck-Information (Configuration)• SeW-Information (Configuration)• Capacities• Shift-Model - History• Shift-Model - Overview• Bottlenecks• Capacity Utilization• Techn.-log. Order Overview Prod.-Lot• PPC Orders• Voucher Reports• Development of the Calls• Order Progress• Inventory-Info• Capacity Utilization Display

Planning - PLAPlanning – Scope of work

19/05/2015 RGU OPTI - Cast in Software 44

� Possible scope of work for Planning� Evaluation and Reports continues..

• Scrap, Scrap Rates• Tool Ready Positioning• Target Fettle-Performance (WS/Period)• Material Requirements• Voucher Reports• Serial-No.-Information• Inventories of Pre-Products• PDA-Key Figures (Diagrams)• Course of Voucher Reporting• Inventories at ESP• Melt-Information Batch, Melt-Information Date• Material Requisition• Aggregated Completion Reports• Shift Scheduling (Header)• Reservations (Bottlenecks/Calendar Week)• Sequence of Work-Inventory• Working Papers• QA-Labels

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 45

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 48

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

� Tool for the operative and strategic planning of your production� synchronies moulding, melting and casting processes� Both long and short term scheduling and capacity situations can be controlled

and monitored quickly and reliably� Check Tool availability, preparation and provisioning, and the availability of

moulding boxes and pits for mass castings� Coordinating moulding shop and core production, if necessary taking into

account pattern plate and core box allocations and combinations� Provision of liquid melt to several moulding shop areas in differing material

qualities

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 49

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

� Cycle time and planning including any cooling times needed� Continuity and capacity of cast finishing treatment, possibly with external

service providers� Forming heat treatment batches� Detailed planning in each production area - planning machine assignment to

control the production in the subsequent time-period, optimal sequences planning

� Ideal requirement for both typical series producers and jobbing producers� “Gantt diagrams” for clear scheduling and planning.

19/05/2015

PPC/Reporting

Shop Floor Reporting Process

Unfinished casting Finished CastingPre-product / Pattern

Preparation Coreboxes

Stock EntryStock Removal (Sand etc.)

Stock removal raw materialTransfer chem. Analysis

Melting Report

corescores

Preparation Patterns

Stock removal sand, feeders etc.Stock removal coresStock removal sand, feeders etc.

Begin MouldingBegin Moulding

stock removal meltgeneration testing order

Pouring

Pre-product

End Moulding

Finish goods report

Stock entry unfinished castingStock removal unfinished casting� fettling shop

Knock-out

Stock removal pre-finished productPackagingStock entry HU

Shipping (HU)

ApprovalApproval

Fettling shopSeparatingSeparatingfettlingfettlingshotblastingshotblastingQA reportingQA reporting

Rework

Generation of testing order

Stock entry

PackingPacking

DispatchStock entry

Machining ESP

Capture of testing data

Capture of measuring data

Machining

RGU OPTI - Cast in Software 50

19.05.2015 RGU - Cast in Software 51

PPCBottleneck Master Data

Capacities

Related shop operations

Parameters and time grades

19.05.2015 RGU - Cast in Software 52

PPCAutomated Disposition (Scheduling)

Resource Plan with times and quantities is scheduledautomatically against production bottlenecks and alreadyscheduled production orders until delivery date is either matchedor impossible to keep� Errors and warnings have to be reviewed by resp. employee

19.05.2015 RGU - Cast in Software 54

PPCPlanning/Load Melt-Shop

Demand for liquid melt correspondingto moulding plan

(example: 2 moulding lines)

Status pre-products (cores) andpatterns

PPCDetailed Planning / Shift Plan

continuous planning on base of scheduled production orders

generating of shift schedules(e.g. core shop, melting shop etc.)

free selection of data (filter) (i.e. machine related, material related, plate related, temperature related etc.)

production load reportper moulding plant andload of preceding and

subsequent processes

production load reportper moulding plant andload of preceding and

subsequent processes

Bedarf Flüssigeisen

0,0

0,5

1,0

1,5

2,0

2,5

3,0

3,5

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

Stunde

t/h

19/05/2015 RGU OPTI - Cast in Software 55

PPC/Info System

Utilisation OverviewBottlenecks

Capacity Charging Utilisationof the Bottlenecks concerning Calender Weeks

19/05/2015 RGU OPTI - Cast in Software 56

WiP Report

Overheads

Staff Time Distribution

Tool Ready Positioning

Circulation Report

Completion Report

Stock Dispatch

Stock Entry

Scrap Report

Presence Times

19/05/2015

PPC/Reporting

Shop Floor Reporting

Overheads

Staff Time Distribution

Tool Ready Positioning

WiP Report

Circulation Report

Completion Report

Stock Dispatch

Stock Entry

Scrap Report

Presence Times

RGU OPTI - Cast in Software 58

OPTI – Mobile

PPC/Reporting

Application example – mobile reporting

Scan shift plan position

Order data are read via w-lan fromthe OPTI-DB and the number ofpieces confirmed on-line

19/05/2015 RGU OPTI - Cast in Software 59

Planning - PLAProduction Planning & Control – Scope of Work

19/05/2015 RGU OPTI - Cast in Software 60

� Possible scope of work for Planning� Bottlenecks (BN):

• To determine the available capacities per week.• They deliver are the basis prerequisites to carry out the disposition /

scheduling of the production. • Already existing operations have to be allocated to bottlenecks if

they should be considered in the disposition.� Sequences of Work (SeW):

• Summary on the basis of a chaining of similar operations (e.g. Hardening, Tempering, Releasing, etc. belong to the sequence of work: Heat treatment) which are carried out in a delimited operational area.

• SeWs serve the progress and inventory monitoring, they have impacts to the WiP-reports and the booking routines of the system.

� Shift Models:• Within the shift models the valid shifts of the company like early

shift, day shift or night shift with the working times and break times are defined.

Planning - PLAProduction Planning & Control – Scope of Work

19/05/2015 RGU OPTI - Cast in Software 61

� Possible scope of work for Planning� Week Shift Model:

• Week shift models describe the shifts of individual company areas. They are allocated to the concerned bottleneck.

� Company Calendar:• The company calendar needs to be defined per week and shift

model. • These data are basically needed to calculate the capacities.

� Capacities:� Production Orders:

• Production orders are the basis for all activities and functionalities They can be recorded

• Manually• Automatically generated out of the customer order program in case of

make-to-order production• Automatically generated by the system in case of factory orders

• All statistical figures of the entire order including all production lots

Planning - PLAProduction Planning & Control – Scope of Work

19/05/2015 RGU OPTI - Cast in Software 62

� Possible scope of work for Planning� Assemblies:

• The assemblies maintain all lots belonging to the production order covering all structure levels. Usually this program is only used by the system and automatically maintained.

� Resource Loads:• Resource loads are generated by the disposition/scheduling of the

production• They are generated for operations/bottlenecks and material groups

if desired.• They contain the basis information concerning

• WiP-reporting• Utilisation of the production

� Auto-Disposition / Scheduling:• The scheduling of customer orders is carried out automatically by

using the order maintenance of the sales module. • The scheduling control parameters are handed over to the

disposition process. They are defined in a corresponding list of values:

Planning - PLAProduction Planning & Control – Scope of Work

19/05/2015 RGU OPTI - Cast in Software 63

� Possible scope of work for Planning� Auto-Disposition / Scheduling continue..

• Very early (Processing Scheduling with target delivery date)• Early (Processing Scheduling)• Normal A Customer (scheduling under consideration of capacities)• Normal B Customer (Scheduling with cumulative check of capacity

utilization)

• Cancellation of calls (possible if lots are not yet started to be produced)

• Increase of quantities (including labelling)• Generation of factory orders of stackable pre-products• Net requirements calculation• Scheduling possible on the basis of cumulated capacity utilizations• Labelling of orders (Status rules) with deliver dates deviation with

provided methods to schedule these orders manually

Planning - PLAProduction Planning & Control – Scope of Work

19/05/2015 RGU OPTI - Cast in Software 64

� Possible scope of work for Planning� Capacity Calculation:

• Using the data of the company calendar and the concerned parameter of the bottleneck the capacities are calculated by the system.

• Necessary up gradation/editing e.g. worker is ill in week x.� Print of Working Papers:� Work in Progress (WiP)-Reporting:

• The production shop floors report the progress of their workloads. • Produced good parts• Bad parts or parts that need to be reworked by stating the reasons• The area of serial-numbers belonging to the voucher if applicable• Overhead times that do not concern the production order like

waiting times, malfunctions, maintenance, etc.• In case of inspection operations the receiver of the produced parts

and the packaging containers• The PIN-numbers of the persons doing the work and responsible for

this voucher

Planning - PLAProduction Planning & Control – Scope of Work

19/05/2015 RGU OPTI - Cast in Software 65

� Possible scope of work for Planning� Scrap/Rejects-Reporting:� Circulation Reports:

• Monitor the progress of the production• Carry out the material bookings• Generate the Sequence of Work (SeW) balance

� Completion Reports:• The completion reports book the parts on stock and close the

vouchers and SeW balances of the concerned structure level.

� SeW Balance:• Using the SeW balances the system determines location and status

of an order within the entire production process in detail.• SeW balances can be kept for articles, orders, lots and circulation

reports.

Planning - PLAProduction Planning & Control – Scope of Work

19/05/2015 RGU OPTI - Cast in Software 66

� Possible scope of work for Planning� Evaluation and Reports:

• Bottleneck-Information (Configuration)• SeW-Information (Configuration)• Capacities• Shift-Model - History• Shift-Model - Overview• Bottlenecks• Capacity Utilisation• PPC Orders• Voucher Reports• Development of the Calls• Order Progress• Inventory-Info• Capacity Utilisation DisplayTechn.-log. Order Overview Prod.-Lot

Planning - PLAProduction Planning & Control – Scope of Work

19/05/2015 RGU OPTI - Cast in Software 67

� Possible scope of work for Planning� Evaluation and Reports continues….

• Scrap - Scrap Rates• Tool Ready Positioning• Target Fettle-Performance (WS/Period)• Material Requirements, Serial-No.-Information• Voucher Reports• Inventories of Pre-Products• PDA-Key Figures (Diagrams)• Course of Voucher Reporting• Inventories at ESP• Melt-Information Batch, Melt-Information Date• Material Requisition• Aggregated Completion Reports• Shift Scheduling (Header)• Reservations (Bottlenecks/Calendar Week)• Sequence of Work-Inventory• Working Papers• QA-Labels

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 68

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 70

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

� Prepare offers, processing orders, plan shipping and invoicing � Supports both trial and first sample, individual run schedule header and make

and- hold orders� Variety of logistical principles such as preview, firm order, consignment stores or

trading goods� Quick - up-to-date overview of all processes between the company - customer� Addresses and contact details, terms of delivery and payment are stored in the

customer master, with automatic currency adjustment depending on the country� Can be integrated with financing system, monitor customer credit limit

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 71

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

� Price calculation includes � Manufacturing costs, � Contribution margins � Target sales prices under consideration of raw material � Spare part surcharge policies and external services etc.

� price list functionality includes � Current material cost, e.g. daily rates aluminum and other metals. � Current excise price � Current metal and energy price agreements can be recorded individually

for each customer and material

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 72

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

� All prices are stored along with a validity date, and any changes are archived.� The preparation of offers of all of the departments Sales, Product Development

and Calculation, Tool Management/Construction and, if applicable, Purchasing.� The progress of different tasks is monitored with respect to their completion

dates, so that offer deadlines can be met.� Any changes in the course of negotiations with the customer are recorded and

follow-up dates are noted by the system for automatic reminders.

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 73

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

� Customer call-off orders communicated by EDI (Electronic Data Interchange) to make-and-hold orders are processed directly and are available without delay for production scheduling.

� Details of order confirmations, delivery notes, invoices and credit memos are also communicated to the customer by EDI.

� Any quantities or deadlines changes by customer, communicate directly to the Production Scheduling and Control. As these changes to quantities and deadlines are being recorded, the system checks their plausibility, e.g. � Have procurement transactions already been initiated? � Has production begun yet? � What are the current stock levels?

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 74

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

� When a shipping order is created, stock accounts are booked for the loading equipment and container for each shipment and customer

� Freight calculation is based on rate tables, with the distance to a delivery location and the quantities to be transported also influencing the freight costs

� Record of the commission rates for each sales representative is kept� Status of each Production order, its progress,stock levels, storage, dispatch etc.� An extremely useful management tool for quick overview of sales volume and

revenue according to customer and merchandise category, which is also linked to a profitability analysis for the item

� Report generation and online information system

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 75

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 78

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

� Integration of purchaser, supplier and store department� Master data saves usage and price units, as well as various parameters for

controlling the purchasing and technical specifications� Price list function, price conditions and delivery terms - easy to maintain� Automatic material requirements for BOM for generated scheduled orders or

can be entered manually, considering available stocks and minimum stock level requirements, batch order sizes, restocking times and the orders which have already been initiated

� The purchasing department is provided with an overview of the requirements at an early stage within the prescribed preview period so they can optimize order quantities from a cost and liquidity point of view.

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 79

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

� Evaluate the suppliers, based on delivery schedules, quality parameters as per company-specific rules defined.

� Send out delivery reminders and final demands according to various running levels, to preselect the form of communication (email, fax, print) and to save an original document with the order items

� Send enquiries to one or more suppliers to get the best price and quality goods� Incoming goods are entered in relation to the relevant orders� Incoming goods have to be checked to ensure they fulfil certain quality criteria

(visual inspection, condition of delivery and packaging correct etc.).� Provides the data for stock and proportionate production costs� Trace on real time basis flow and status of every item/material purchased

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 80

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

� Incoming supplier invoices are either entered directly upon receipt of the goods or checked against the respective incoming goods.

� Integration with finance or accounting software e.g. Tally or similar � OPTI Materials Management package is an efficient warehouse management

solution for all your products and pre-products, purchasing and stock materials including load carriers, containers, pallets etc.

� Receipt and issue postings derived from feedback messages sent from production as well as inventory and stock evaluations.

� Stock item management is a function which helps to manage articles in the warehouse using identity and batch numbers.

� Trace materials used in the current production and distribution chain

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 81

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 84

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

� Test planning for products throughout all the stages of manufacture, materials and processes.

� Test values, quality parameters and process requirements are monitored with relation to products and processes.

� Complaint Management deals with internal and external errors and complaints.� Test plans for purchasing materials, tools and equipment, also for machinery,

plant and test apparatus, even for environmental conditions and waste disposal facilities.

� Target and actual values for moulding material tests, sieve analyses or measurements of any process parameters such as temperature, moisture etc. can also be recorded.

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 85

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

� Maintain record of various quality test for each batch, test plan, sample etc.� chemical analyses,� mechanical values (tensile and bending test, notched bar impact test),� Hardness test,� Thermal treatment with the temperature� Profile and the corresponding parts,� Microstructure,� Non-destructive tests (ultrasound, magnetic particle inspection, dye

penetrant inspection),� Industrial radiography,� Dimensional tests.

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 86

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

� Limiting and target values are monitored for every process tested and the observed values recorded. These may be numerical values, attributive evaluations, or any available documents in the testing or process stage (images, logs).

� There are a number of standard techniques for transferring test values from the testing apparatus or other systems. These include the exchange of files, database tables or online link-up of the data logging program.

� If test results are recorded manually, incorrect entries can be prevented using pre-set search functions for a test job, production messages etc.

� If mandatory tests are fail - block production & prevent shipping, or it can request approval by an authorized member of staff.

RGU.OPTIRGU Product

19/05/2015 RGU OPTI - Cast in Software 87

RGU.OPTI – Foundry Resource Planning Software

Product Planning

Production planning &

Control

Sales Purchase Quality Management

� It can also generate number of different basic messages, in particular delivery note and clearance for shipping, allow inspection certificates and test documents required

� Can generate automatic quality certificates which can be printed on multi-language forms, saved as pdf documents and can be sent by email.

� In case of any complaints, It defines which measures are to be taken, including whether it is necessary to freeze an item, a tool or parts of a batch, whereby approval for clearance is possible only by authorized staff. It can also generate reworking orders to remedy errors.

RGU.OPTIHow RGU.OPTI works? – Existing casting

19/05/2015 RGU OPTI - Cast in Software 89

SALE � Quantity – Purchase Order� Price� Delivery date� Quality standard� Other required details….

Product Planning

� Resource plan� Check availability/plan of

required resource, material,manpower and machines

� Availability of tool/pattern, core� Generate automatic material

demand for this purchase order� Final order confirmation, if

possible to meet all customerdemand and deadline

� 500 Pump housing� Deadline – 7 days� As per given QS

� 20 ton Ingot, 10 tonreturn circuit, 10 tonscrap required

� Total 50 manpowerrequired

� 14 shifts required� Auto generation of

required bill of material� All required resource ,

material, manpoweravailable, order confirm!

Example

RGU.OPTIHow RGU.OPTI works? – Existing casting

19/05/2015 RGU OPTI - Cast in Software 90

Detailed Production Planning

� Detailed week/shift planning� Manually or automatic allocation

of core machine, molding line,CNC machine, manpower foreach station/process

� Core production planning� Shift planning for melting, fettling� Automatic PO generation of

required resource sand, core,sleeve, ingot, scrap, filter,packaging and logistics...

� Planning for any externalservice, if any require

� Preparation for required qualitytests

� Planning and shift-manpowerallocation for heat treatment

WiP -Product control

� 500 Pump housing� 35 pumps/shift� 1050 cores on 2

machines, 5 workman in 8 shifts

� Daily required material demand for sand, filter, sleeve, core sand given to store

� DISA line 2 reserved for week 14 – 8 shifts

� Week 14 – 8 shifts 2 workman for melting, 4 for fettling, 3 CNC machine reserved

Example

RGU.OPTIHow RGU.OPTI works? – Existing casting

19/05/2015 RGU OPTI - Cast in Software 91

� WiP – Work in progressstatus/report manually day/shiftbasis entries of produced core,mould, machined parts etc.

� RGU can integrate/communicatewith mould lime, core m/c, CNCm/c to avoid manual entries

� Chemical composition readingfrom spectrometer

� Man machine capacity utilization� Rejection, machine breakdown,

overtime report/details� Real time basis tracking of on

going work mould line, m/c shop,quality or dispatch

� Quality test, heat treatmentstatus report

� Quality test certification

WiP -Product control

� 36 mould/shift in yesterday night shift

� Spectrometer test specimen has 0.8% carbon less then required, add 20KG Iron

� DISA line was on hold 2 hrs for maintenance

� Feedback-additional shift because downtime of DISA line

� CNC m/c is under utilization or over loaded

� One batch failed required hardness,

Example

Logistic

RGU.OPTIHow RGU.OPTI works? – Existing casting

19/05/2015 RGU OPTI - Cast in Software 92

Example

Quality Management

� Hardness test results, X-Rayresults and shrinkage leveldetails

� Quality certificate print/report

� In X-Ray method level 2 shrinkage observed

� Correction steps, if not acceptable

� Dispatched quantity record� Truck, transporter details

Logistics � 500 parts dispatch as per schedule

Sales � Invoice generation� Part acceptance certificate from

client

� Client approves the casting received

RGU.OPTIHow RGU.OPTI works? – Existing casting

19/05/2015 RGU OPTI - Cast in Software 93

� Required Packaging planning onorder confirmation

� Resource plan e.g. trollies,pallets, truck scheduling etc.

� Track of delivered goods� Shipping notes� Received goods notes

Logistic � 250 pumps dispatched in 2 days

� Received parts on client side

� 2 truck booked for week 14, Truck number, driving license record

Example

Sales � Received goods notes� Shipping notes� Invoice generation� Client quality test confirmation –

parts acceptance certificate� Coordination with finance for

payment

� Client received 500 pump parts

� Client approved and acceptance certificate

� Invoice and payment follow-up

Complaints/feedback

� Complaint/feedback from clientsif any

RGU.OPTIHow RGU.OPTI works? – New casting

19/05/2015 RGU OPTI - Cast in Software 94

SALE � New product inquiry� Price� Delivery date� Quality standard� Other required details….

Product Planning

� Resource plan for samplecasting

� BOM Material for pattern/mould� Schedule

� 1 week for 2D-3D &simulation

� 1 week for pattern/mould� 1 week for trial, quality test,

dispatch� 1 week buffer time

� Cost for sample casting

� New pump housing casting required

� GGG 40� Sample casting in 4

weeks

� Drafting-simulationengineer require forweek 14

� 2 CNC m/c required forpattern

� 3 pattern expert requirefor week 15

� Special raw materialrequired for melting toachieve require gradefor sample casting

Example

SALE � Order confirm for Sample casting

RGU.OPTIHow RGU.OPTI works? – New casting

19/05/2015 RGU OPTI - Cast in Software 95

Detailed Production Planning

� Detailed week/shift planning� Manually or automatic allocation

of core machine, molding line,CNC machine, manpower foreach station/process

� Mould/Core production planning� BOM for pattern/mould� Planning for melting, fettling� Automatic PO generation of

required resource sand, core,sleeve, ingot, scrap, filter,packaging and logistics...

� Planning for any externalservice, if any require

� Preparation for required qualitytests

� Planning and shift-manpowerallocation for heat treatmentWiP – Sample

casting

� 3 CNC machine occupied for week 15

� 2 Pattern maker occupied for week 15

� PO generated as per BOM for Mould, core, scrap, other material

Example

RGU.OPTIHow RGU.OPTI works? – New casting

19/05/2015 RGU OPTI - Cast in Software 96

� WiP – Track actual status ofwork in progress sample casting

� Chemical composition readingfrom spectrometer

� Quality test, heat treatmentstatus report

� Quality test certification forproduct approval

� Rework on mould/pattern, if anyrequire

� Save the possible tried variousgating system design model,drawing , pattern details, results

WiP –Sample casting

� During machining, some shrinkage has been found, rework on gating system design

� After pattern modification, another trial requires

� Hardness value of sample casting is below customer requirement

Example

Quality Management

� Hardness test results, X-Rayresults and shrinkage leveldetails

� In X-Ray method level 2 shrinkage observed

� Correction steps, if not acceptable

RGU.OPTIHow RGU.OPTI works? – New casting

19/05/2015 RGU OPTI - Cast in Software 97

� Sample casting dispatch� Various reports, Sample casting

cut sections, quality test dispatch

Logistics � Sample casting dispatch on time

Example

Sales � Sample casting approval andacceptance certificate

� Pattern/mould approval� Invoice generation

� Client approves the sample casting for mass production

If client confirms the order for mass production, f urther steps will be followed in RGU as explained earlier for “Existin g Parts”

MES / ERPIntegrated Order Processing

19/05/2015 RGU OPTI - Cast in Software 99

• The best part about RGU is, it can be integrated wi th other existing ERP/Accounting software, if require. However independent RGU is still a preferable choic e for most small and mid scale foundries.

• Our expert engineers are well verse with technology and skill to integrate the software for two way flo w of communication.

• Integration with standard finance, accounting software e.g. Tally, BAAN etc.

• RGU team is capable to deal with any level of detai led customization, if foundry requires. That too at any level right from query to dispatch.

MES / ERPIntegrated Order Processing

Disposition Process ControllingSales/ Purchase

Prices, Quantities, Dates

Customer OrdersCustomer OrdersFrame OrdersFrame OrdersCalls / EDICalls / EDI

OC

Generation P-Order Resource plan / Item MasterWorking Program, Bill of Material,Pattern/Tools, Resources

Bill of pattern/ToolWorking Program

Bill of pattern/ToolWorking Program

Date–Confirmation

Targets

Quality Management

Test Certificates

Quality ManagementPlanning of Tests,Test- and Process ValuesTest Certificates

Orders on Hand

Orders on Hand

Needs ( Feeder, ESP ...)Prices, Quantities, Dates

Auto – Mat. Needs

Shipping NotesShipping NotesInvoicesInvoicesCredit NotesCredit Notes

Certificates

Evaluation of the actual timesPost-Costing

Detailed Planning

Combination

Detailed Planning(Week/Shift)Machine Utilisation, Order, BatchesCombination

DispositionDisposition of Production LotsScheduling, DispatchingConfirmation Delivery-DateLists, Work papers

Material ManagementMaterial ManagementESP

Mould Facilities...

WiP-ReportingAuto(BDE / MDE)Core Shoot.-M.Mould Facilities...

Interfaces

WiP-ReportingManuallyPrint PapersPieces, Times...

Incoming GoodsIncoming Goods

Stock exits (retrograd)Stock entriesStock exits (retrograd)Stock entries

DemandsPurchase OrdersPurchase Orders

Finance

19/05/2015 RGU OPTI - Cast in Software 100

19.05.2015 RGU - Cast in Software 103

Evaluations/Info SystemFIS - Bottleneck survey

Integrated Foundry Info System (FIS) - Web access to mission-critical information and management cockpits

Evaluations/Info SystemKPI: Daily Report

MOULD004/00 Daily Report 2012-11-09 / 17:02

Selektion : 2012-01-05

(for Management Opratives)

Production data Unit Day Month Year

05.01 01.2012 2012

Production good parts tons 1947 14652 14652

Dispatched castings tons 1867 13856 13856

Rejects w/o return % 4,5 4,24 4,24

Rejects w/ return % 4,5 4,67 4,67

Downtime moulding lines % 26.0 14,58 14,58

FTE / good parts h/ton 3,50 3,46 3,46

Yield % % 70 67 67

Good parts / Moulding line operation time tons/h 20,79 21,34 21,34

No. of moulds on moulding line pieces 12563 51227 51227

No. of moulds on moulding line Cycle/h pieces 260 245 235

No. of moulds on moulding line A Cycle/h pieces 112 85 85

No. of moulds on moulding line B Cycle/h pieces 240 212 212

No. of moulds on moulding line C Cycle/h pieces 240 234 234

No. of moulds on moulding line D Cycle/h pieces 153 159 159

electric power / melt KWH/ton 732 728 728

gas / melt KWH/ton 0 0 0

Employee FTE 240 240 240

Employee temporary staff / ESP FTE 12 12 12

Employee on vacation FTE 15 0 0

Employee ill % 4,0 4,0 4,0

Vacation % 6,3 6,3 6,3

Absence % 3 2 2

Stock level finished parts tons 28598

Stock level half-finished parts tons 13567

Stock level total tons 42165

Stock level finished parts consignment stock tons 0 0 0

19/05/2015 RGU OPTI - Cast in Software 109

19/05/2015 RGU OPTI - Cast in Software

Evaluations/Info System

FIS - Online InfoInquiries Overview

112

19/05/2015 RGU OPTI - Cast in Software

Evaluations/Info System

FIS - Online InfoInquiry Tracking

114

19/05/2015 RGU OPTI - Cast in Software

Evaluations/Info System

FIS - Online InfoCompany Calendar

115

19/05/2015 RGU OPTI - Cast in Software

Evaluations/Info System

FIS - Online InfoProduction Schedule (Cores)

116

PlanningPost Calculation / Costing

Output via Excel Output via Printer

19/05/2015 RGU OPTI - Cast in Software 117

OPTI.meltMaterial & Melt Management

19/05/2015 RGU OPTI - Cast in Software 119

� Delivers extensive melt process planning for all melt and treatment stepsat charge, ladle and casting levels.

� Delivers accurate charge composition and post charge compositions byoptimizing the usage of materials, especially expensive metals andferroalloys.

� Enables preliminary costing to be carried out, calculating the requirements for scrap, alloying materials and metals

� Provides online support for the smelter, reduces melt times significantly and thus increases melt capacity

� Reduces energy consumption per ton and supports energy management at the point of highest consumption, which in turn leads to considerable cost savings

� Starting with the calculation of an optimal charge composition, all the steps of the melting process are recorded, documented and then made available for detailed evaluation

OPTI.melt

Material designations

Designation 2(Norm 2, customer)

Designation 1 (Norm / Standard)

Ident-No. sort of meltIdent-No. circuitCost schedule mateirial/circuitStandard-test plan Material groupWelding specCutting data processing

Material

Test values and properties

Target values for material

Test groups,Test conditions, Test values

Test plan– Norm 2

Test plan – Norm 1

Annealing specificationAnnealing specification

Structure examiniation

Charpy, hardness

Tension / bending test

Chem. analysis

Norms, specifications,...(describing objects as graphic, Word, Excel, ...)

Price agreement / validity

Price list(Daily prices)

Price basis, customer

Target composition, multistep if applicable, base iron, treatment

circuit

Pig iron

Scrap

Ferrous alloys,...

Energy

Coke

Melting

Structure of the material data

19/05/2015 RGU OPTI - Cast in Software 120

19.05.2015 RGU - Cast in Software 121

OPTI.meltResource Plan of liquid melt

The liquid melt is a pre-product, so it hasist own part-ID

Specification on raw materials, Scrap, curcuit, energy and melt-shop operations

122

OPTI.meltAlloy Definition incl. Target Analysis

Target analysis with defaults for batchpre- and post-calculation

Formulas für batchcomposition

Linkedpricelists

Material-Id.Nr. circuit, swarf

Identifier and testplanper variant

ID-Nr. Ofmaster dataliquid melt

Alloyparameters

19.05.2015 RGU - Cast in Software

OPTI.meltPlanned costs for molten melt

Planned production costs per ton – basis planned internaltransfer price

19/05/2015 RGU OPTI - Cast in Software 123

Calculation of the charge composition

Optimisation model for the most cost effective use of materials

(non-linear, simplex)

• With / without considering the raw material stocks

• Relation charge / furnace or standard composition

Options

OPTI.melt

•circuit types, chips•Materials group•Formula

Alloy/melt

Restrictions e.g..Proportion of scrap, totals

Target & limiting valuesChemical analysis

Usable raw material groups

Melt specifications

•Price depreciation factor•Classification scrap/circuit•Type of inventory mgmt.

Raw materials

Stock total/Per storage location,Pieces

Actual analysis

Allocation of raw material groups

•Compulsory specification•Desoxidation •Suitable material•limitations

Alloy specificationFor material usage

Alloy – Raw Materials – charge composition

19/05/2015 RGU OPTI - Cast in Software 124

OPTI.meltMelt report with charge- and rebatching calculation

19/05/2015 RGU OPTI - Cast in Software 126

RGU-SAPRGU OPTI.SAP - All In One

19/05/2015 RGU OPTI - Cast in Software 128

Integrated quantity and value flows

Foundries’ specific requirements

Integration solution

The integration platforms are SAP-PI and RGU-OI (OPTI Interface), in which the data is exchanged via HTTP protocol in XML format.

RGU-SAPRGU OPTI.SAP - All In One

19/05/2015 RGU OPTI - Cast in Software 129

SalesSD

Materials ManagementMM

ControllingCO

Financial AccountingFI

Product planning,Resources plan

Materials master/ Parts master

Master Data

Net requirements calc.

Sales Order

Purchasing/procurement

Scheduling

Detailed planning

Needs,

deliverylots

Planned

orders

Quantities

–deliveryconfirm

ationP

rod.-orders

Needs

Purchased

articles

Tools management

Quality management

PDA / MDEControl station function

RückmeldungenFeedback

Dispatch/invoicing

Production order/ Cost collector

Stock levels

Feedback

quantities/times

(arrivalfinal product

RGU-SAPRGU OPTI.SAP - All In One

19/05/2015 RGU OPTI - Cast in Software 130

RGU-SAP datacommunication, avoids multiple entries and efforts

RGU.OPTI � SAP SAP � RGU.OPTI

� Master data such as accountsreceivable, creditors, costrates/tariffs, personnel

� Material masters of sales goods (orOPTI managed) purchased material

� Customer orders/delivery plans,requirements

� Goods receipt by third party agent� Delivery note and stock levels

� Resources planning (work schedule, parts list) and parts masters of preliminary products

� Scheduled production lots as production orders

� Service notification, inward and outward stock movements including retrograde bookings

� Dispatch notification or dispatch preparation to third party agent)

� Working papers, production planning, tools management QS/QM

� Inspection certificates

Contact usThank You for Your Attention!

Auto Design Online: Authorized Distributor of RGU GmbH

Website: www.auto-design-online.com

Email: [email protected]

Contact Person: Mr. Bhushan Bhatt

Mobile: +91-9824247774