R-HPP-Chemical-processing-EN.pdf

-

Upload

kumar-saravana -

Category

Documents

-

view

11 -

download

0

Transcript of R-HPP-Chemical-processing-EN.pdf

-

Thermoplastics

High Performance Plasticsfor the Chemical Processing Industry

07/2013

-

2 | Rchling High-Performance Plastics

The Rchling Group is a global plastics group. With some7,300 on the workforce at 60 locations in 20 countries,Rchling today ranks internationally amongst the leadingenterprises in the field of plastics processing.

With their two divisions, High-Performance Plastics andAutomotive Plastics, the Group, with its companies onthe American, European and Asian continents, generatesan annual turnover of around 1.2 billion euros.

RchlingCompetence in plastics

The High-Performance Plastics business unit covers the range ofhigh-performance plastics within the Rchling Group. With world-widesubsidiaries as well as sales and distribution offices, the RchlingHigh-Performance Group has a leading position internationally inproducing and machining thermoplastics and composites for thecapital-goods industry.

The product range covers extruded, polymerised and pressed semi-finished products, such as round rods, flat rods and sheets, foils,tubes, extruded profiles, special polyamide cast parts, fibre-reinforcedplastics and machined finished components.

RchlingHigh-Performance Plastics

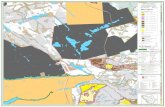

ContentPage

Areas of application ....................... 4 9 Tanks for storing liquids Galvanic plants Steel-pickling plants Water-treatment plants Exhaust-air cleaning plants Ventilation plants

Materials ......................................... 10 21 PE-HD PP PVC PVDF E-CTFE Polystone Safe-Tec C Foamlite

Full servicefor tank construction ................. 22 25 Welding rods U-profiles and square tubes RITA

Chemical resistance ................... 26 29Weather resistance ............................. 30Electrical conductivity ....................... 30Fire behaviour ....................................... 31

Quality assurance ........................ 32 34 Test methods

Our offer at a glance..............................35

-

Rchling High-Performance Plastics I 3

Thermoplastics have been implemented in the chemical industryas a material for tanks and plants for many decades now.

Ranking amongst the most important fields of activity are:

Tanks for storing liquids Galvanic plants Steel-pickling plants Water-treatment plants Exhaust-air cleaning plants Ventilation plants

The great benefit of thermoplastics in many of these applicationsis the high chemical and corrosion resistance. Depending onthe mechanical requirements, plant parts can be produced in all-thermoplastic or alternatively in composite material with a glass-fibre reinforced plastic (FRP) or steel as supporting material.

The plastics from Rchling High-Performance Plastics haveproven themselves in the above-mentioned fields of applicationover decades on end. They are characterised by outstandingchemical resistance, can be easily processed, and meetthe requirements of current guidelines and standards for theconstruction of chemical tanks and plants.

High Performance Plasticsfor the Chemical Processing Industry

Complete system

Rchling High-Performance Plastics has one of the largestproduct ranges for chemical-tank and plant construction.

We offer a complete system for your application comprisingsheet material, U and square profiles as well as welding rodsright up to the time-tested "RITA" tank calculation programme,as well as expert consultation in selecting the right material.

Furthermore, Rchling disposes of comprehensive databasesand long years of experience pertaining to the chemicalresistance of thermoplastics.

This prospectus will give you an overview of our competencefor the construction of chemical tanks and plants.

-

4 | Rchling High-Performance Plastics

Areas of applicationTanks for storing liquids

For application in tanks for storing liquids in chemical-tank and plant construction, plastics mustfulfill varying demands: Included here is resistance to thermal and chemical corrosion as well asstatic loading and depending on the set-up resistance to weathering influences.Rchlings wide product range offers just the right solution for practically any application.

Tank variants

Round tanks are mainly used for storingliquids. Round tanks can be made of sheetmaterial, in a strip winding process or ascomposite tanks. In all three cases, plasticsfrom Rchling are used, either for the tankas a whole, in the stripe winding process,for the cover and base, or as inliners incomposite tanks.The production of rectangular tanks iscomparatively more elaborate and thus moreexpensive, since, in most cases of rectangulartanks, steel reinforcements must be resortedto support the side walls and base.

Moulding compoundswith DIBt approval

In its engineering and testing principles forwater-pollution control, the German Institutefor Civil Engineering (DIBt) stipulates that forabove-ground tanks and tank parts made ofthermoplastics that are used for storing water-hazardous liquids, only sheets may be putto use which are manufactured of mouldingcompounds approved by the building authorities.

For this very reason, Rchling only usesmoulding compounds listed by the DIBt toproduce sheets and welding rods of the tankconstruction type Polystone G black B 100,Polystone G black B 100-RC as well asPolystone G blue B 100-RC.

UV resistance

Due to the fact that storage tanks are mainlynot set up inside buildings, but outside,UV resistance of the material used is also arequirement. The most effective way to protectmaterials, such as PE and PP, against UVdamage is adding carbon black. This is whymany tanks for outside storage of liquidsare black.

Polystone P homopolymer grey Storage tanks for olive oilPolystone G black B 100 Storage tanks forhydrochloric acid with a capacity of 80 m

Polystone G black B 100-RC Round tank

Polystone G blue B 100-RC Round tank Polystone P homopolymer greyMixing tank with a capacity of 25 m

-

Rchling High-Performance Plastics I 5

Areas of applicationGalvanic plants

Polystone E-CTFE GKInliner of a chromium-plating bath withglass-fabric lamination

Polystone P homopolymer grey undPolystone P homopolymer naturalDrums for a galvanic plant

Polystone P homopolymer naturalAnodisation basin for treating door handles

In galvanic plants, items are provided with ametallic coating in an electrochemical processin order to increase their corrosion resistance.Metals that are typically applied here are nickeland copper. Also falling under the category ofgalvano technique or electroplating are suchprocesses as chrome-plating machine parts,zink-coating nuts and bolts as well as anodicoxidation of aluminium parts (anodisation).

Due to the diversity of these chemical processes,various plastics from Rchling are used in galva-nic plants. Depending on the kind of applicationconcerned, the plastics must feature a hightemperature and chemical resistance.

This is why it is an absolute must to preciselyclarify the resistance of the selected plasticmaterial to the chemicals to be used at theworking temperature specified.Rchlings wide product range offers just theright solution for practically any application.

Polystone P homopolymer greyTank with yoke reinforcement for a galvanic plant

Polystone P homopolymer greyChromium-plating plant for car seat-belt clips

Polystone P homopolymer greyGalvanic plant for the treatment of aluminium parts

Polystone Phomopolymer greyTank for acopper-coating plant

Polystone P homopolymer greyGalvanic plant for the treatment of aluminium parts

-

6 | Rchling High-Performance Plastics

Areas of applicationSteel-pickling plants

Polystone P homopolymer greyTanks for a steel-pickling plant

Polystone P random-copolymer greyTanks for a stainless-steel-pickling plant

In the pickling process, cold-rolled steel bandsare rid of the scaling incurred on the surface bythe hot-rolling process.

In the last two decades, application of poly-propylenes in pickling tanks has been time-tested and is ever increasingly substitutingrubberised or brick lined steel tanks.

Typical process conditions insteel-pickling plants are: Medium: HCl 10 20 %temperature: 80 C 90 C

Medium: H2SO4 50 %temperature: up to 105 C

Typical process conditions instainless steel-pickling plants are: Medium: HF 10 % + HNO3 18 %temperature: 50 C 65 C

Due to these varying requirements, differentpolypropylene types are used. Differentiationis made between PP-H (polypropylene homo-polymer), PP-R (polypropylene random-copolymer)and PP-B (polypropylene block-copolymer).By reason of the high process temperatures,application of PP-H is preferred in steel-picklingplants, depending on the maximum temperaturewith an additional heat stabilisation asPolystone P homopolymer EHS(Extra Heat Stabilised).

With medium mixtures causing stress crackssuch as HF-HNO3, Rchling recommends theapplication of the softer PP-R. Softer thermo-plastic material types can absorb the incurredstress more easily without stress cracks beingthus caused.Should it be intended to transport the plantsat temperatures below 5 C, PP-B offers greatbenefits over PP-H due to its high notchedimpact resistance, and it possesses toughnesseven at -30 C, while PP-H becomes brittle attemperatures below 0 C, whereby damageto the plant may easily be incurred duringtransport. PP-R still has good notched impactresistance at temperatures down to -20 Cas well.

There is only slight differentiation to be madebetween the three PP variants in their chemicalresistance. With the copolymers, diffusionrates are somewhat higher than with PP-H.Since 30 to 40 mm thick sheets are mostlyused for the tank walls for steel-picklingplants, diffusion plays here, however, only asubordinate role.

Polystone Pblock-copolymer greySteel-pickling plant

Polystone P homopolymer greySteel-pickling plant with a total length of 146 m

-

Rchling High-Performance Plastics I 7

Areas of applicationWater-treatment plants

Water treatment has great importance for the quality of lifeof people throughout the world. About two million people dieas a consequence of impure water every year, and on theglobal scale 884 million do not have adequate access toclean water.

The plastics used in water treatment must have a highdegree of purity for contact with drinking water and beparticularly chemical-resistant. Rchling offers one of thebiggest product ranges for water treatment: The plasticsused have good chemical resistance, possess the high purityrequired and fulfill the current standards and directive, aswell as have the necessary approvals available.

Typical fields of application include: Well construction Desalination plants Drinking-water tanks and linings Neutralisation plants Chemical water treatment Sewage purification plant construction

Drinking water approvals KTW W270 ACSPolystone G HD blue + +Polystone G black B 100 + + +

Apart from Polystone G HD blue and Polystone G black B 100,Polystone P materials can also be supplied with KTW approval(KTW Guideline = Guideline for the Hygienic Assessment of OrganicMaterials in Contact with Drinking water). Here, it is possible toapply correspondingly approved raw materials.

Polystone G HD blueLining of a drinking-water reservoir

Polystone P homopolymer greyWater purification tower of a beer brewery

Polystone P homopolymer greySmall sewage purification plant

Polystone G black B 100Industrial tanks for water treatment

Polystone G black B 100Back-flushing unit

Polystone P homopolymer grey

Polystone Gblack HD SKGFK-coated tanksfor purified water

-

8 | Rchling High-Performance Plastics

Areas of applicationExhaust-air cleaning plants

In order to minimise damage to health and the environmentthrough air-borne pollutants, there are different regulationsand directives in many countries to restrict the pollutantloads in emissions. This frequently makes waste-airpurification necessary.

Typical plants for waste-air purification are dropletseparators and gas scrubbers:

In droplet separators, upward exhaust air is conductedinto tanks through incorporated components. Here, the toxicsubstances are deposited onto these fittings as dropletsand collect in the lower part of the tank.

In gas scrubbers, the exhaust air is cleaned through aliquid supplied whereby the toxic substances collect in theliquid. Liquids typically used here are suspensions such asmilk of lime.The liquids and gases used for cleaning or the exhaust air tobe purified, such as SO2 and SO3 in flue-gas desulphurisationplants, are often severely corrosive. Thermoplastics areimplemented because of their special corrosion resistance.

Polystone P homopolymer greyExhaust-air treatment for odour removal

Ventilation plant with droplet separators made ofPolystone PVDF and Trovidur EC

Polystone PPs EL blackExhaust-air cleaning plant

Polystone P homopolymer greyExhaust-air scrubber

Polystone P copolymer greyExhaust-air treatment facility for odour elimination

-

Rchling High-Performance Plastics I 9

Areas of applicationVentilation plants

Removal of polluted air is an important challenge inbuildings and chemical plants. Both ventilator constructionas well as provision of air ventilation ducts and housingsfor plant parts are included in the field of ventilation plants.

Rchlings plastics are also used here on the basis of theirgood chemical resistance and outstanding processingproperties. Polystone PVDF is frequently implementedhere as an inliner for ducts made of glass-fibre-reinforcedplastics. Should the static, thermal and chemical loadpermit, complete plants are made of PE, PP or PVC.

Often, special requirements are also made on thematerials used in ventilation plants with regard to electricalconductivity and low inflammability. Polystone PPs is alow-inflammable polypropylene employed very frequentlyfor ventilation plants. If electrical conductivity of thematerials is additionally required, Rchling recommendsapplication of Polystone PPs EL black.

Polystone P homopolymer greyVentilator of a ventilation plant

Processing Polystone PPs greyfor a ventilation plant

Polystone G HD blackHousing of a ventilation plant

Polystone PVDF GKInliner in an air ventilation duct made of glass-fibre-reinforced plastic

Trovidur EC and Polystone PVDFVentilation plant

Polystone P homopolymer greyVentilation system for a glavanic plant

-

10 | Rchling High-Performance Plastics

MaterialsPolyethylene (PE-HD)

Molecular structure of polyethylene

Density (g/cm3)(natural)

Molecular weight(chain lengths)

Creep strength

PE-L(L)D< 0.93 (.94)

PE-MD 0.93...0,945

PE-HD> 0.945

not specifiedtyp. 50...200,000

not specified max. 300,000

... ...

PE 80 PE 100PE 63

Standard PE, extruded types

50.000...max. 500,000

If 300,000PE 300

Comparison of density

Polyethylene has the followingtypical properties: Low density High strength High elongation at break Application temperature rangefrom -50 C to +90 C

Good electrical insulation properties Very good chemical resistance Very low water absorption

The physical properties of PE are greatly depen-dent on the length of the molecular chains(molecular weight) and the structure of themolecules (crystallinity). As stated, the degreeof branching between the molecular chainsand the length of the side chains significantlyinfluence the level of crystallinity and densityof the polyethylene. An example of the effectsof these differences in terms of physical pro-perties can be seen by comparing PE-HD andPE-LD. PE-HD is produced when the polymeriza-tion occurs under low pressure allowing longerand less branched molecular chains to form,along with an increase crystallinity. This resultsin a relatively high elastic modules and

hardness. The situation is exactly the reversein the case of PE-LD. Consequently PE-LD hasa lower crystallinity leading to a lower elasticmodules, hardness and ultimate strength thanPE-HD. Additional to the higher crystallinity,PE-HD for chemical applications has normally ahigher molecular weight than PE-LD. This highermolecular weight results in more knots andeyes between the molecules. These formationshold the structure of the material even strongertogether increasing its toughness. In generalthe viscosity and the density of PE is measuredin order to assess what type of polyethylenehas been produced.

Types PE 80 and PE 100 used as standard inchemical tank and plant construction todaybelong to the Group PE 300 (PE-HD), the figures80 and 100 referring to the MRS Class. MRSstands for Minimum Required Strength anddescribes the minimum strength which amaterial must still possess in the long-term

failure test under internal hydrostatic pressureat 20 C after 50 years. A PE-HD will thereforebe rated in the MRS Class PE 80 if the strengthlies over 8 N/mm. If it is higher than 10, thematerial fufils the requirements of a PE 100.

Polyethylene has a simple molecular structure. CH2 segments are lined up in a simple form.Depending on the polymerization process however, polyethylene can be manufactured withdifferent densities. The different densities results from the number of cross branches between themain molecular chains. Further, the greater the number and length of the branches between thesechains the lower the crystallinity of the resulting material, and therefore, the lower the density.

H

. . . . . .

H H H H H

CC C C C C

HH H H H H

-

Rchling High-Performance Plastics I 11

MaterialsPolyethylene (PE-HD)

The raw materials for PE 80 and PE 100 materials used by Rchling are listed by the DIBt (German Institute for Civil Engineering),thus meeting the requirements defined by the DIBt for application in tank construction.

Requirements made on a PE 100 shown by means of thecreep-strength curves of DVS 2205, Part 1.A PE 100 should retain a minimum strength of 10 N/mm at aworking temperature of 20 C over a service life of 50 years.

Requirements made on a PE 80 shown by means of thecreep-strength curves of DVS 2205, Part 1.A PE 80 should retain a minimum strength of 8 N/mm at aworking temperature of 20 C over a service life of 50 years.

Creep rupture curves according to DIN 8075by ISO TR 9080 (07.92) covered parts of the creep rupture curves

Years

Service life [h]

Comparisonstress[N/mm

2 ]

Creep rupture curves according to DIN 8075by ISO TR 9080 (07.92) covered parts of the creep rupture curves

Years

Service life [h]

Comparisonstress[N/mm

2 ]

-

Polystone G HD black

Polystone G HD black is high-density poly-ethylene. The material is characterized by a highchemical resistance, easy processing and food-stuff stability. Particularly the high chemicalresistance makes Polystone G HD black idealfor the use in the chemical processing industry.

Properties

Suitable for contact with food stuff Good chemical resistance Good UV resistant High resistance against stress cracking

12 | Rchling High-Performance Plastics

MaterialsPolyethylene (PE-HD)

Polystone G HD blackHousing of a ventilation plant

Polystone G black B 100

For the production of Polystone G black B 100only raw materials are used which are approvedfor tank building. The demands of the pipe gradePE 100 (MRS class) are met and are regularlymonitored by third parties.

Properties

Excellent weldability and processing properties High elongation at break, very suitable fortank building

Very good chemical resistance For vessels requiring a test certificate(controlled by SKZ, Wrzburg)

Approved in Germany for tanks requiringmandatory test certificates according to 19 WHG

High resistance against stress cracking(FNCT > 900 h)

Suitable for contact with drinking water(appoved to KTW, W270 and ACS)

Polystone G black B 100Storage tanks for sulfuric acid

Polystone G black B 100-RC

Polystone G black B 100-RC is a PE 100 withsignificant higher stress cracking resistance.Only raw materials are used which are approvedfor tank building.

Properties

High elongation at break, very suitabletank building

Good chemical resistance Approved in Germany for tanks requiringmandatory test certificates according to 19 WHG

High resistance against stress cracking(FNCT > 8760 h)

Polystone G black B 100-RCStorage tanks fr hydrochloric acid

Polystone G HD blue

Polystone G HD blue is ideal for applicationsin the drinking-water sector because of itscolour being similar to RAL 5015.

Properties

BfR/KTW approval W270 approval Suitable for contact with drinking water Good chemical resistance

Polystone G HD blueLining of a drinking water storage

-

Rchling High-Performance Plastics I 13

MaterialsPolyethylene (PE-HD)

Polystone G blue B 100-RC

Polystone G blue B 100-RC is a PE 100 withsignificant higher stress cracking resistance.Only raw materials are used which are approvedfor tank building.

Properties

High elongation at break, very suitable fortank building

Good chemical resistance Approved in Germany for tanks requiringmandatory test certificates according to 19 WHG

High resistance against stress cracking(FNCT > 8760 h)

Polystone G blue B 100-RCStorage tank with collecting tank

Polystone G EL black

Polystone G EL black is a very highlyconductive Polystone G material offeringexcellent long-term mechanical properties.

Properties

Electrically conductive UV resistant Easy processing Excellent weldability Good chemical resistance Almost no moisture absorption Excellent mechanical properties

Polystone G EL blackScrubber

Polystone G HD SK/GK black

Polystone G HD SK/GK black sheets arecoated on one side to enable bonding to othermaterials. The material used is either a polyesterstretch (SK) or, in the case of strongly diffusingchemicals and/or high temperature fluctuations,knitted glass fibre (GK). Polystone G HD GKblack offers especially high strength whenbonded and in composite construction.

Properties

Excellent weldability and processingproperties

High adhesion in a composite systemand so highly suitable for tank building

Good chemical resistance

Polystone G HD SK blackFRP lined tank for desalinated water

-

14 | Rchling High-Performance Plastics

MaterialsPolypropylene (PP)

Molecular structure of an isotactic polypropylene

The polypropylene is produced through thepolymerization of propylene. A laterally addedmethyl group (CH3 group) can be arranged diffe-rently in space. This results in PP products withdifferent properties, enabling polypropylene tobe differentiated on the basis of the followingcharacteristics:

Isotactic polypropylene:With this polypropylene, all CH3 groups areon the same side.

Syndiotactic polypropylene:With this polypropylene, the CH3 groups arealternately on different sides of the carbonchain in a regular sequence.

Atactic polypropylene:With these polypropylenes, the CH3 groupsare arranged randomly in space with respectto the main chain.

The semi-crystalline, isotactic polypropyleneis technically important, because only heredoes high crystallinity provide the technicallyrelevant properties. The Polystone P productsmanufactured by Rchling are made of isotacticpolypropylene.

Polystone P homopolymer grey

Polystone P homopolymer is extremelystrong and highly resistant to chemicals,corrosion and heat. These characteristics makePolystone P homopolymer grey the idealmaterial for chemical tanks and plants.

Properties

High strength Very high heat resistance Excellent weldability properties High chemical and corrosion resistance

Polystone P homopolymer greyScrubber

Furthermore polypropylen is differentiated in:

PP block copolymers

PP block copolymers are very tough thanks to anelastomeric component in the molecular chain(mostly ethylene-propylenerubber) and can beused at temperatures of up to approximately 30 C. However, the continuous usage tempera-ture is approximately 10 C lower comparedwith homopolymers.

PP homopolymers

PP homopolymers are highly crystalline poly-propylene types that, in contrast to copolymers,display greater hardness, stiffness and tensilestrength at room temperature. At temperaturesaround freezing point however, they undergoheavy embrittlement due to their molecularstructure.

Compared with polyethylene, thepolypropylene types are characterizedby the following differences: Lower density Greater rigidity and strength Higher melting temperature

(between 160 and 165 C) Greater dimensional stability in heat Polypropylene homopolymers are brittle

when cold, PP copolymers on the other handdisplay good impact strength

Good electrical insulation properties Lower oxidation resistance

HH H

HH

H

CC C

CC

C

CH3H H

CH3H

CH3

. . .

. . .

-

Rchling High-Performance Plastics I 15

MaterialsPolypropylene (PP)

Polystone P homopolymer natural

Polystone P homopolymer natural isextremely strong and highly resistant tochemicals, corrosion and heat.

Properties

High strength Very high heat resistance Excellent weldability properties High chemical and corrosion resistance

Polystone P homopolymer naturalAnodisation basin for treating door handles

Polystone PPs EL black

Its range of properties enables Polystone PPs ELto fulfil the requirements that are particularlyimportant for applications in potentially explosivelocations and for the protection of electroniccomponents against static discharges. For thisreason, Polystone PPs EL is particularly wellsuited for application in construction ofventilation devices.

Properties

Flame retardant Antistatic Electrically conductive

Polystone PPs EL blackScrubber

Polystone PPs grey

Polystone PPs grey is a flame retardantmaterial, especially suitable for ventilationsystems and equipment manufacture.

Properties

Flame retardant (B1) to DIN 4102 High rigidity Excellent weldability and processingproperties

Very high chemical resistance

Polystone PPs greyParts of a ducting system

Polystone P copolymer grey

Polystone P copolymer materials areoutstanding for their toughness at temperaturesdown to -30 C, as well as their high strengthand high chemical and corrosion resistance.Standard: block copolymer, randon copolymeron request.

Properties

High strength Very high impact resistance High heat resistance Excellent weldability High chemical and corrosion resistance

Polystone P block copolymer greySteel pickling line

-

16 | Rchling High-Performance Plastics

MaterialsPolyvinyl chloride (PVC)

Molecular structure of Polyvinyl chloride (PVC)

Polyvinyl chloride is a predominantly amorphousplastic with low crystalline components(approx. 5%). All chlorine atoms are statisticallydistributed on both sides of the C atoms (atacticarrangement with short syndiotactic segments).The chlorine content is approximately 56.7%.Depending on the manufacturing method, theraw material is handled as a mass (M-PVC),suspension (S-PVC) or emulsion (E-PVC) PVCwith fine grains.

The polymerization process of PVC

Mass polymerizationThe highest purity due to the low polymerizationadditive content. It is preferable to usemass polymerides where there are specialrequirements regarding the products purity.

Suspension polymerizationA frequently used method of radical polymeriza-tion. The carrier medium is normally water.The monomer that is barely soluble or insolublein water is dispersed in the carrier medium bystirring. The monomer droplet size is between0.01 and 3 mm diameter. The initiator is solublein the monometer, i.e. polymerization occurs inthe monomer droplet. The monomer dropletsare stabilized by a protective colloid.

Emulsion polymerizationIn emulsion polymerization, a little watersoluble monomer is emulsified in water andpolymerized with the aid of a water-solubleradical starter. The polymer chains that occurinitially in the aqueous phase come together.By diffusion of other monomers from thedroplets into the aqueous phase, the particlescan take up monomers and grow.

AdditivesSince PVC does not melt but would firstdecompose, additives must be mixed in beforeprocessing. A distinction is made betweenthermostabilizers (e.g. tin, calcium, zinc or leadstabilizers), lubricants (e.g. wax or fatty acidesters) and colour additives (e.g. titaniumdioxide, carbon black). Modifiers, auxiliaryagents, minerals, flame protection agents etc.are also mixed in so as to obtain particularproperties in a targeted manner. A recipe of

this type therefore contains at least 4 andfrequently up to 20 components. The powdermixture is heated up by friction in a hot mixer,during which some of the additives melt andpenetrate into the PVC grain or surround it.During a subsequent and fast cooling process,(cooling mixer), an easily pourable powderis produced that is now called dryblend andis either temporarily stored in silos or is sentdirectly for further processing.

The polyvinyl chloride types displaythe following properties: High mechanical strength, rigidity, hardness

(modulus of elasticity) Good chemical resistance Good electrical properties Self-extinguishing outside the flame Extremely low residual monomer content

(in the raw material

-

Rchling High-Performance Plastics I 17

Trovidur EN liner red

Trovidur EN liner red is a PVC-U speciallydeveloped for liner construction due to its highchemical resistance.

Properties

Normal impact strength High resistance to acids, lyes and saltsolutions

Meets the requirements for classificationin fire classes B1 to DIN 4102 up to4 mm thickness

Visually proper surface Easy processing, by welding, thermoformingand bondingTrovidur

EN liner redInliner for a storage tank

Trovidur EC

Trovidur EC is a plasticizer-free PVC withnormal impact strength.

Properties

Normal impact strength High resistance to acids, lyes and saltsolutions

Meets the requirements for classificationin fire classes B1 to DIN 4102 up to4 mm thickness

Self-extinguishing after removal of flame Easy processing, by welding, thermoformingand bonding

Trovidur ECDucting system with mist eliminators

Trovidur ET

Trovidur ET is a transparent, unplasticisedrigid PVC material especially suited forsafety equipment in machine and equipmentmanufacturing.

Properties

Normal impact strength RoHS-compliant High transparency Flame retardant, self-extinguishing afterremoval of flame

Good resistance against chemicals Easy processing, by welding, thermoformingand bonding

Trovidur ETSplash protection for rinsing tank in a clean room technology

Trovidur PHT

Trovidur PHT is a post-chlorinated PVC forchemical tank building.

Properties

Normal impact strength Uniform physical properties in all directionsof sheet thanks to the manufacturing process

Very high resistance to acids, lyes andsalt solutions

Flame retardant, self-extinguishing afterremoval of flame

Continuous operating temperatureup to 90 C

Problem-free processing, when welding,thermoforming and bonding

Trovidur PHTMist eliminator

Trovidur W 2000

Trovidur W 2000 is a soft PVC productparticularly suited for applications in thechemical industry.

Properties

Shore A approx. 85 Increased chemical resistance Tough and abrasion-resistant Excellent electrical insulation properties Excellent gluability Weldable and hot-formable

Trovidur W 2000Inliner in a steel tank

-

18 | Rchling High-Performance Plastics

MaterialsPolyvinylidenefluoride (PVDF)

Molecular structure of PVDF

PVDF (polyvinylidenefluoride) is a semicrystallinethermoplastic that belongs to the group offluorine polymers. The fluorine content is around59%. It can be created by both emulsion andsuspension polymerization. The products madeof Polystone PVDF that are manufactured byRchling are made via suspension polymerizati-on, as this method gives the polymerizate ahigher crystallinity and melting temperature.

Fluoroplastics are used in chemical engineeringdue to their good chemical resistance, mechani-cal properties and thermal stability. The strongbonding between the very electro-negativefluorine and the carbon is the reason for thehigh chemical resistance of PVDF.

Polystone PVDF

Polystone PVDF is a highly temperature-resistant, strong material.

Properties

High mechanical strength, stiffnessand tenacity

Relatively high temperature resistance(10 C to 150 C)

Outstanding resistance to acids Physiologically harmless Good resistance to abrasion Excellent sterilisability Flame retardant Excellent weldability

Polystone PVDFTank with collecting tank made of Trovidur EN grey

Polystone PVDF SK/GK

Polystone PVDF SK/GK sheets are backedon one side to enable them to be bonded withother materials. The material used for thecoating is either a polyester stretch (SK) or, inthe case of strongly diffusing chemicals and/orhigh temperature fluctuations, knitted glassfibre (GK). Polystone PVDF GK offers goodbonding properties e.g for composite tanks.

Properties

Excellent weldability and processingproperties

Especially firm adhesion in the compositesystem and therefore especially suitablefor container and plant construction

Especially high resistance to acids Very high heat resistance Excellent ageing properties

Polystone PVDF GKInliner of a chrom-plating bath

F

. . . . . .

H F H

C C C C

F H F H

-

Rchling High-Performance Plastics I 19

MaterialsEthylene chlorotrifluorethylene (E-CTFE)

Molecular structure of E-CTFE

Ethylene chlorotrifluorethylene is a partlyfluorinated thermoplastic.The fluorine content is higher compared toPVDF. Based on its chemical structure a 1:1 alternating copolymer of ethylene andchlorotrifluorethylene E-CTFE offers uniqueproperties.

The sheets manufactured by Rchling areproduced in a press or extrusion procedure.

Polystone E-CTFE SK/GK

Polystone E-CTFE SK/GK sheets are backedon one side to enable them to be bonded withother materials. The material used for thecoating is either a polyester stretch (SK) or, in thecase of strongly diffusing chemicals and/or hightemperature fluctuations, knitted glass fibre (GK).Polystone E-CTFE SK/GK offers good bondingproperties e.g for composite tanks.

Properties

Excellent chemical resistance againstnumerous chemicals e.g. acids and alkalis

Good electrical properties Flame retardant (UL 94 V0) Very high purity Very smooth surface

Polystone E-CTFEInliner of a chrom-plating bath

H

. . . . . .

H F F

C C C C

H H CI F

-

20 | Rchling High-Performance Plastics

MaterialsPolystoneSafe-Tec C

Polystone Safe-Tec C

Polystone Safe-Tec C is a multi-layer andgrained sheet which has a special non-skidsurface and at the same time high chemicalresistance.

Contact with chemicalsIt has been developed by Rchling especiallyfor bases and treads in chemical plant andtank construction. The sheet produced in thecoextrusion process is ideally suited for fieldswhere contact of the sheet with chemicalscannot be excluded, for example, in the vicinityof a plant for chemical surface treatment.

Properties Non-skid properties tested in accordancewith DIN 51097 Class A

High chemical resistance Surfaces and intersections can be weldedtogether (extrusion welding, hot-platebutt welding)

Almost no moisture absorption, thereforeno swelling

Simple processing

Chemical resistance Alkali solutions Salt solutions Organic acids Inorganic acids(excepting strongly oxidising acids)

Alcohol Water Oils

Applications Bases and treads in chemical plantand tank construction

Chemical industry Clean-room technology

PolystoneSafe-Tec CChemical-resistantand non-skid surface

Polystone Safe-Tec C is suitable for areas wherecontact with chemicals cannot be excluded

-

Rchling High-Performance Plastics I 21

Foamlite is the innovative plastic sheet withfoamed inner core. In the engineering phase,Rchling was, above all, concerned withweight reduction. Compared to a comparablecompact sheet, it offers a weight advantageof 30 percent.

Apart from the low weight, the Foamlitesheet gains high mechanical stability throughits closed-cell structure.

For a host of applications, this offers distinctcost benefits through easier handling anddesign adaptations.

Foamlite P

With a density of 0.65 g/cm, Foamlite P isclearly lighter than a sheet made of compactpolypropylene with 0.915 g/cm.

Application in tank constructionWith its good mechanical properties andexcellent chemical resistance, Foamlite P isespecially tailored to application in chemicaltank and plant construction. Here, Foamlite Poffers cost benefits due to its low weight, forexample, as tank covers.

At the same time, Foamlite can be providedwith an "integrated hinge" by a 90 degree Vnotch being cut into the sheet surface. The highflexural-fatigue strength enables the sheet tobe bent up to 40,000 times without breaking.

Moreover, costs for accessories and theirassembly can also be saved on in manyapplications through the additional hingeeffect.

Easily weldableWhat is more, Foamlite P can be very easilywelded with other Foamlite P types inextrusion and high-speed hot-air/gas-weldingprocedures. Foamlite P can be drilled, sawn,cut and bolted with the usual tools as alsoused for wood.

Foamlite G

With a density of 0.70 g/cm, Foamlite G isover 30 percent lighter than compact polyethy-lene. A sheet 2,000 x 1,000 x 10 mm in size istherefore about 6 kilogrammes lighter. Thiscreates benefits in handling and dimensioningconstructions.

Suitable for moist and wet areasFoamlite G has a high surface quality,optionally smooth or grained, and can be pro-cessed very well. The very low water absorptionmakes Foamlite G particularly suitable forapplications in moist and wet areas. Theadditional UV-stabilised variant is availablefor outdoor applications.

MaterialsFoamlite

By cutting a V notch into the sheet surfacea hinge can be produced with Foamlite P

Foamlite P greyCover flaps over a galvanic tank

Foamlite P greyMobile hub of a galvanic line (installed)

Foamlite P greyMobile hub of a galvanicline prior to installation

-

Full service for tank constructionWelding rods

Welding rod

For nearly all sheets made of thermoplastics for use in construction of chemical tanks and plants,Rchling offers the corresponding welding rods.

22 | Rchling High-Performance Plastics

Bar 1000 mmmm Loose rollCoil mm mm

Polystone G HD blackPolystone G black B 100Polystone G black B 100-RCPolystone G HD bluePolystone G blue B 100-RCPolystone G EL black

Polystone P homopolymer greyPolystone P block copolymerPolystone P random copolymerPolystone PPs EL blackPolystone PPs grau

Polystone PVDF 1)

Polystone E-CTFE 1)

Delivery program welding rods PE / PP / PVDF / E-CTFE

Welding rods types include: Polystone G HD black Polystone G black B 100 Polystone P homopolymer grey Polystone P copolymer

Trovidur NL Trovidur EN liner red Trovidur EN Trovidur EC

Trovidur HT-X Trovidur PHT Polystone PVDF Polystone E-CTFE

Rchling supplies welding rods on rolls, coils oralternatively as bars with a length of 1 or 2 metres.

Properties Excellent weldability properties All common cross sections as perDVS 2211 available

Special products available on request

RS/2RS/3RS/4RS/5DK/80-4DK/80-4,3DK/80-5DK/80-6DK/80-7DK/90-5,7DK/70-7DK/90-5OS-5DR/80-5

Round DVS 2211

Triangle 80 DVS 2211

Triangle 90 DVS 2211Triangle 70 DVS 2211Triangle 90 specialOvalTriplet 90

2345

4,0 x 3,04,3 x 3,05,0 x 3,56,0 x 4,57,0 x 5,35,7 x 3,87,0 x 5,05,0 x 3,25,0 x 3,05,0 x 3,4

0,20,2

-0,3/+0,2-0,4/+0,2

0,30,30,30,30,4

-0,5/+0,1-0,3/-0,9

0,30,30,3

0,20,2

-0,3/+0,2-0,4/+0,2+0/-0,4+0/-0,4+0/-0,4+0/-0,4+0/-0,4+0/-0,4+0/-0,4+0/-0,40,3

+0/-0,4

3 kg3 kg3 kg3 kg3 kg3 kg3 kg3 kg3 kg3 kg3 kg3 kg3 kg3 kg

5 kg5 kg5 kg5 kg5 kg5 kg5 kg5 kg5 kg5 kg5 kg5 kg5 kg5 kg

3 kg3 kg3 kg3 kg3 kg3 kg3 kg3 kg3 kg3 kg3 kg3 kg3 kg3 kg

1) only available as 2 kg roll

Bar 1000 mmmm Bar 2000 mmLoose roll

Trovidur NL Trovidur EN liner redTrovidur ENTrovidur EC

Trovidur PHTTrovidur HT-X

Delivery program welding rods PVC

0,20,20,20,2

8 kg

3 kg3 kg3 kg3 kg

3 kg

3 kg

3 kg3 kg3 kg3 kg3 kg3 kg3 kg3 kg

Round DVS 2211

Triangle 80 DVS 2211

Triangle 90 DVS 2211

Double CoreTripletDK 100DK 200Profile aProfile b

S DMS:2S DMS:3S DMS:4S DMS:580-4,380-680-780-890-490-6

2345

3 x 3 x 4,34 x 4 x 65 x 5 x 76 x 6 x 8

3 x 3 x 4,34,7 x 4,7 x 6

6,1 x 3,15,0 x 3,55,55 x 3,06,45 x 3,457,0 x 3,05,5 x 2,5

mm

-

U-profile and square tubes

Prerequisites for the weldabilityof plastics

The prerequisites for the hot-plate butt weldingof PE80 and PE100 materials are describedin DVS 2207-1 (09.05) in accordance with DIN8074 and DIN 8075. Accordingly, "suitabilitywithin the hot-melt compound flow rateMFR 190/5 from 0.3 to 1.7 g/10 min or 0.2 to0.7 g/10 min can be assumed".

In DVS 2207-11 (08.08) describes the prere-quisites for the hot-plate butt welding ofPP-H, PP-B and PP-R materials accordingto DIN 8077 and DIN 8078. Accordingly,"suitability within the hot-melt compoundflow rate MFR 190/5 from 0.4 to 1.0 g/10 mincan be assumed. This range roughly corre-sponds to the hot-melt compound flow rateMFR 230/2.16 from 0.2 to 0.6 g/10 min".

In DVS 2207-15 (12.05), the prerequisites forthe hot-plate butt welding of PVDF materialsare described. Accordingly, "with density of1.7 to 1.8 g/cm, suitability can be assumedwithin the hot-melt compound flow rateMFR 230/2.16 from 1.0 to 25 g/10 min".

If the materials to be joined together meetthese prerequisites, it can be assumed thatthe two components can be welded together.

DVS 2207-1 continues: "With the hot-meltcompound flow rates deviating from this,verification of suitability can be conductedin the tensile-creep test in accordance withDVS 2203-4 and supplementary sheet 1."Should the hot-melt compound flow rates liein the above-mentioned ranges, verificationof suitability is therefore not necessary.The hot-melt compound flow rates for thethermoplastics manufactured by Rchlingfor chemical-tank and plant construction arespecified in the technical data sheets andfactory certificates.

PP-B welding rods for sheet materialmade of PP-H

Invariably arising in the area of welding seamsare small nicks which may lead, under un-favourable circumstances, to cracks in the tankmaterial. To minimise the danger of damage tothe tanks, a welding rods should be used thatis slightly notch-sensitive. This is why Rchlingrecommends the application of welding rodsmade of PP-B, including for welding togethersheet material made of PP-H. Rchling changedover their storage programme more than sixyears ago and offers the welding rods madeof Polystone P copolymer grey as standard.Regardless of that, delivery of welding rodsmade of Polystone P homopolymer grey isfurther possible.

Polystone U-profile and square tubes areproduced from the same moulding compo-und, as the corresponding welding rod and

the sheets. This ensures identical materialproperties and best processing propertiesfor the complete tank.

Rchling High-Performance Plastics I 23

Tank with Polystone P grau profiles

Delivery program U-profiles and square tubes

Minimum edge radius 0.5 mm. Other colours and dimensions on request.Not all dimensions and types available ex stock.1) not available ex stock

Colours: black, grey L 5000 mm mm s mm

U-profile

Square tubes

U01 49 46 4U02 49 72 4U04 49 112 4U05 49 132 4U06 69 72 4U07 69 92 4U08 69 112 4U09 69 132 4U11 69 153 4U12 90 92 4H01 35 35 2H03 35 35 3H05 35 35 4H07 50 50 4H11 60 60 4H12 68 68 3H14 52 52 2,5

S

S

Rchling offers a complete system for: Polystone G HD black Polystone G black B Polystone G black B 100 Polystone P homopolymer grey Polystone P copolymer Polystone PVDF

Properties High chemical resistance Long service life Excellent weldability and processingproperties

Polystone P homopolymerPolystone P copolymer 1)

Polystone PVDF 1)

Polystone GPolystone G black B 1)

Polystone G black B 100 1)

-

Full service for tank constructionRITA3 Tank calculation program

Rchlings Integrated Tank Building Assistant

The user interface of the tank calculation program wasdesigned along the lines of the well-known Microsoftoffice applications, thus enabling even beginners tofamiliarise themselves quickly with the use of theprogram.

Technical drawings support the user to enter the tankdimensions correctly.

The RITA software enables manually complicated calculations for rectangular or cylindrical thermoplastic tanks to be performed in a fewseconds and the designing of tanks to be optimised with ease. The calculation bases for the program are based on the internationallyrecognised DVS Guideline 2205. The program also offers a means of designing tanks beyond the scope of the DVS 2205 Guideline.

Earthquake protection

Cylindrical tank calculated withRITA for installation in a Germanearthquake zone

Round tanksDesign variants

For the first time RITA offers a means of dimensioning tanks in conformity to the new supplementary sheets to DVS guideline 2205 witha conical and sloping bottom. At the same time the skirt and supporting structure for the bottom are calculated.

Where tanks are to be installed inareas of seismic activity, verificationof earthquake protection isincreasingly being required forthem. Now RITA offers a meansof designing and anchoringcylindrical, flat-bottomedtanks so as to make themearthquake-resistant.

24 | Rchling High-Performance Plastics

-

Rectangular tanksDesign variants

Various design variants are possible for rectangular tanks:

without reinforcement with all-round reinforcementwith edge reinforcement with yoke reinforcement with cross-ribbing

List of steel profilesFor reinforced tanks the user of the program can choose from an extensive list of U-, I-, L-, IPE-, IPB- and hollow profiles.The list always shows just those steel profiles which meet the static requirements for the tank to be calculated.

Yoke reinforced rectangular tank calculated using RITA

Rchling High-Performance Plastics I 25

TV-tested

Before a new program version isreleased, the calculations done withthe program are checked by TV Nord[Technical Inspection Agency North] inaccordance with a specification previouslyset. In individual cases the results are alsosafeguarded by means of FEM analyses.

Special serviceIn case of any queries about the installation of thesoftware, support is available by email free of charge from

over the telephone atsupport telephone number +49 4103 12117-21Mondays to Thursdays from 9 a.m. until 5 p.m.and Fridays from 9 a.m. until 1 p.m.

If you have any queries about theoperation, functionality or purchase of RITA3.1,please [email protected]

The calculations in RITA are based on the guideline DVS 2205.This is published in the pocket book "DVS Technical Codes onPlastics Joining Technologies" available from DVS Media AGhttp://www.dvs-media.eu/

chec

ked 2

012

Voluntary Test

accordingto test specification ST

WK-K

U1.

02/0

9.11

-

26 | Rchling High-Performance Plastics

Chemical resistance

Chemical resistance

A mutual influence may result when a plastic comes intocontact with other materials such as air, gas, water andnatural chemical substances. Whilst solid materials do notusually cause any change in the plastics apart from possibleabrasions and the removal of low molecular additives(such as plasticisers), even water in the strict sense of theword has an influence. This is all the more sowith liquidchemicals. Reversible and irreversible changes may becaused, particularly in conjunction with heat and light, theextent of such changes increasing with the length ofexposure.

It follows that the major factors determining resistanceto chemicals are temperature, period of exposure, concentra-tion and aggressiveness of the medium. It should be addedthat materials react differently to such influences, dependingon whether they are at rest or under stress, i.e. whether amechanical load is imposed at the same time.

Behaviour of metals exposed to chemicals

In metals, the fact that the atoms are closely packed inthe crystal structure means that penetration of the liquidor gas molecules is virtually excluded, except at the crystalboundaries. For this reason, the metal is attacked, orcorroded, by chemical or etectro-chemical processes virtuallyonly at those places which come into direct contact withthe corrosive medium, i.e. only at the surfaces of the metal.

If the reaction products (oxides, sulphides, chlorides orother metal salts) are soluble or easily carried away, themetal surface is laid bare time after time to react againwith the corrosive until no metal is left. It is simple toestablish the concomitant loss of weight and, from thereduction in the cross section, to arrive at a figure forthe loss of strength.

Behaviour of plastics exposed to chemicals

In polymers, however, the methods of attack are completelydifferent. The intermolecular attractions (van der Waalsforces) are far smaller in polymers than in metals (1/100 to1/1000). This makes the spaces between the large,awkwardly shaped and only mattedor convolutedmoleculechains of the thermoplastics under consideration here solarge that the comparatively tiny gas and liquid moleculescan easily permeate and fill them. This means that theinfluence brought to bear on the plastics is no longer limitedto the coated surface but occurs throughout their depth andthus represents a much more differentiated process.

When considering the effect of attacking media on plastics,it is possible to differentiate between those media whichact physically and those which act chemically.

Chemically active media

Immediately during the absorption into the surface of theplastic, chemically active media cause chemical reactionsto occur with the molecules of the plastics and with anyadditives (pigments, stabilisers etc.) that might be present.The chemical attack leads to oxidation, chain breakageor cross-linking. These lead to irreversible changes in thetarget materials.

Physically active media

This is not necessarily the case with media having aphysical mode of action. After absorbtion into the surface,they spread into the plastic and occupy the free spacesbetween macromolecules and into microscopic defectsand cavities, leading to swelling.

The liquids and gases used in exhaust-air cleaning plants areoften severely corrosive. Thermoplastics are used here becauseof their special corrosion resistance.

-

Rchling High-Performance Plastics I 27

Chemical resistance

Essential influences on the chemical resistance

In order to access the resistance of a material to the effectsof chemicals, it is important to remember that it is depen-dent on many factors. The essential factors of influence onthe chemical resistance of materials are

The temperature The period of exposure The mechanical stress The concentration of the medium

Influence of the temperature

Since all the chemical and physical processes affectingresistance develop faster as the temperature increases,clearly, as a rule, the resistance decreases to a greaterof lesser extent as the temperature rises. Consequently,this behaviour can also be used to predict the long-term behaviour. If there are results for immersion tests attemperatures which are higher than that desired, then thebehaviour during long-term exposure at the desired lowertemperature can be estimated from these results.

Influence of the period of exposure

As a rule, chemical resistance falls as the period of exposureincreases. By way of departure, this rule does not apply tothose media which do not chemically attack the plastic andhave only limited solubility in the plastic when in contactwith the plastic at the specified temperature. As the massincreases over the course of time the limited solubility isindicated by the occurrence of a degree of saturation.If this saturation value is relatively low, as with, for exam-ple, construction materials and the medium water and itslow concentration solutions of salts, acids and bases, thenthe plastic is chemically resistant to such media since itscharacteristics do not change significantely, even aftermany years of exposure.

Influence of mechanical stresses

Many materials, including plastics, exhiibit stress cracking,as a result of the conditions of use. Cracks can appear inthe material as a result of subjecting a plastic to tensileloading in air which exceeds a certain stress or extensionbut is, however, lower than ist apparent yield point in theaccelerated test. Such cracks, which sometimes do notappear for many years, are known as stress cracks.

The stresses which cause such cracks are either internalstresses caused by the processing conditions or externalstresses as a result of external mechanical loading or acombination of the two. Simultaneous exposure to certainchemical media can, under certain circumstances, drasticallyreduce the time before cracking occurs. This phenomenonis known as environmental stress cracking (ESC) or simplystress cracking. Stress cracks can completely penetratethe wall of a plastic part and thus create fracture surfacesor they may stop as soon as they come into contact withregions of sufficiently low stresses or extensions ordifferent material structures.

Part of a tankshowing stresscracks

There is no straightforward and unambiguous explanationwhich covers all cases of stress cracking. It is known, forexample, that polar liquids, aqueos solutions of surface-activesubstances or distilled oils can cause stress cracking if aplastic part is exposed to them and, at the same time, hashigh internal stresses or for example, is subject to tensileor flexural stress. Without testing a medium beforehand, it isnot possible to say whether it causes stress cracking or not.

-

28 | Rchling High-Performance Plastics

Chemical resistance

water Ewater E testing medium Ftesting medium F

lg (service life) t

tF tE

lg(te

stst

ress

)

lg(te

stst

ress

)

lg (service life) t

E

F

Diagrammatic representation forcalculating the time-related fCRtfactors from the long term failuretest on polyolefin pipes usingwater and attacking media.

Diagrammatic representation forcalculating the stress-related fCRfactors from the long term failuretest on polyolefin pipes usingwater and attacking media.

Chemical resistance tables of the DIBt

Corresponding reduction factors, which are published, for example, inthe media lists of the German Institute for Civil Engineering (DIBt) canbe derived from these chemical-resistance factors. These lists containdata about the most common media used in chemical-tank and plantconstruction which can be referred to for selecting material for a tankor plant. Over and above this, Rchling has extensive databases andexperience regarding the chemical resistance of thermoplastics.

For this reason, when questions arise concerning the chemicalresistance of thermoplastics, Rchling recommends contacting ourexperts, and has set up an e-mail address specifically for this:

To be able to provide information about resistance and to make a materialrecommendation, our application engineers need the following data:

Designation, concentration and precise composition of the medium Temperature of the medium(are temperature fluctuations to be expected?)

Data concerning the exposure time(constantly in case of a storage tank)

It should be further stated as to whether the material is to be used for anall-thermoplastic tank or as inliner. Ideally, a design of the tank or planthas already been determined, so that any stress occurring in the materialcan be taken into due consideration.

Determination of the chemical reduction factors

For the dimensioning of full thermoplastic tank the permissiblestress is calculated in accordance with DVS 2205 part 1from the strength coefficient.

In order to obtain quantifiable information about theinfluence of a medium on the plastics strength and thuson the design of tanks and plants, long-term failure testingunder internal hydrostatic pressure is carried out onpipes, in which the usual water filling is replaced by thecorresponding medium. A comparison of the long-termperformance of the same pipe with a water filling enablesthe chemical-resistance factors (fCR) to be determined.

Definition of the chemical resistance

At the planning stage of tanks, plants and equipmentsthe resistance of the plastic against the attacking mediumto be stored or used in the process has to be evaluated.Classification of the materials into three levels is widely used.

Resistant:The material is generally regarded as suitable.

Partly resistant:The material is attacked by the medium, although it maybe used under certain conditions. More extensive testingmay be required.

Not resistant:The material is generally regarded as unsuitable.

Immersion test

This three level classification is based on immersion testingaccording to DIN 16888 or ISO 4433 in which sections of theplastic and test pieces are immersed in an unstressed statein the attacking medium.The relative change in mass and the changes in characteri-stics in the tensile test are adopted as the assessment critia.The period of exposure for this test ranges from 28 to112 days.The immersion test is only of limited suitability for gaininginformation with regard to the applicability of a plastic forchemical tank and plant construction, as the test pieces areexposed to the effect of the attacking medium whilst freefrom external stress. The immersion test is sufficient toassess PVC-U and PP liners (liner/UP-GF) since the liner isable to withstand extensions of not more than 0,1 to 0,2 %from the UP-GF component.

Influence of the concentration

In the case of solutions of two media, one of which attacksthe plastic under consideration whilst the other is inert,the chemical resistance of the particular plastic generallydecreases as the proportion of the aggressive medium inthe neutral medium increases, as for example, in the caseof mixtures of sulphuric acid and water.

-

Rchling High-Performance Plastics I 29

Chemical resistance

Critical media

All those media are designated "critical media" in media lists40 of the DIBt (issue September 2011), which possess a che-mical reduction factor A2 in excess of 1.4 for an assumedservice life of 25 years.

Generally valid as "critical media" for PE-HD is the following:

Medium Concentration

Chlorine water (Cl2*H2O) all

Potassium hypochlorite(KOCl, active chlorine 150 g/l)

Sodium hypochlorite(NaOCl, active chlorine 150 g/l)

Nitric acid HNO3 53 %

Sulfuric acid H2SO4 96 %

In earlier issues of the DIBt media lists, reduction factors forthese media were stated. However, due to isolated damage,the responsible committee resolved on removing them mediafrom the tables. Here, the applicability of PE-HD for tanksfor storing "critical media" should examined by an expert ineach case. A list of corresponding experts is available fromthe DIBt.

For applications with "critical media", Rchling recommendsin many cases the application of PVC or PVDF as the inlinerof a GFRP and steel tank alternatively to application ofPE-HD as all-thermoplastic tank.

Permeation behaviour

All attacking media penetrate into the plastic to a certainextent. Calculations for permeating attacking media whichpenetrate through the plastic at high diffusion rates withoutnoticeable changing its charachteristics require specialtests. Such substances can damage adjacent objects whenthey seep through the external surface of the tank or pipewall. Permeation must be taken into account particularlywith composite materials. In such cases, the resistance ofboth the inner liner which is in direct contact with theattacking medium and the outer casing (e.g. GRP or steel)must be specified.

The comparatively high degree of water vapour permeabilitygains significance in the case of composites of PVDF witha less permeable material. Thus, for example, the waterpermeability of a GRP layer of the same thickness is clearlylower. Consequently, there may be no voids or cavities inthe interfae layer between the PVDF and GRP or in theadjacent GRP composite. Otherwise, it may be affected bycondensation and, as a consequence of the created osmoticpressure, the liner can become detached causing blisteringor damage to the GRP. A suitable resin should be selected inorder to prevent the permeation of water vapour. Normal UPresin tends to saponify in the presence of water vapour andincreased temperatures.

Inliner of Trovidur EN liner redfor a storage tank

FRP-tank with inliner made fromTrovidur EN liner red

-

30 | Rchling High-Performance Plastics

Weather resistance

Electrical conductivity

Weather resistance

Materials like PE or PP that are subjected to sunlightoutdoors for an extended period, physical/chemicalprocesses are initiated particularly by the UV componentof the sunlight and under the influence of the oxygen inthe air. The results are:

Discoloration (often yellowish) Embrittlement (loss of toughness) Loss of mechanical properties

The processing methods and thickness of the moldedpart have a major influence on the degradation mechanism.Internal stresses and thin walls speed up UV-relateddegradation. However, this applies only to unstabilized PEor PP. Our own experiments have shown that UV damagecan be prevented by the use of additives.

If appropriately stabilized and/or with UV absorbers,PVC semi-finished products achieve service lives of overten years without any significant change to their rangeof properties. A low degree of chalking of the weather-exposed surface is also crucial to this protection, and isthe main reason why no dark colors are appropriate.

PVDF and E-CTFE possess excellent resistance toweathering influences and require no additives forUV stabilization. Even years of weathering tests onunmodified PVDF and E-CTFE have caused nosignificant changes to the mechanical properties.

Polystone G HD blackHousing of a ventilation plant ona hall roof. Here, good weatherresistance is absolutely essential.

The electrically conductive materialsPolystone G EL black and Polystone PPs ELblack manufactured by Rchling come to usein chemical-tank and plant construction.They have a specific volume resistance andsurface resistance of

-

Rchling High-Performance Plastics I 31

Fire behaviour

Fire behaviour

The flammability of plastics is often a technical problemand an obstacle to their use. Various testing methods areused for the fire behavior classifications. In DIN 4102, thematerials are divided up into flammable and non-flammable.In their standard versions, Polystone G and P belong tothe normal inflammable plastics. Through the addition offlame protection agents, Polystone PPs falls into Class B1(flame retardant).

According to this standard, all Trovidur materials arecategorized by definition as at least self-extinguishingoutside the flame (B2). The classes are:

B1 flame retardant B2 normally inflammable B3 highly inflammable

Polystone PVDF on the other hand is slightly inflammableand is self-extinguishing following removal of the ignitionsource. In addition, only a small amount of smoke isproduced when PVDF is burned. Basically two testingmethods are employed to assess flammability.

In the test as defined by ISO 4589, it is determined howmuch oxygen must be available to a plastic so that itcatches fire and continues to burn. The oxygen index definesthe concentration of oxygen (vol. %) in a nitrogen/oxygenmixture that is required in order to sustain combustion.

In this test, the values for PVDF are significantly higher thanthose for the polyolefines. Another assessment of the firebehavior is the test in accordance with UL 94 (UnderwritersLaboratories). In a test carried out on a 0.8 mm sample,PVDF achieved the best possible categorization of VO.Absolutely no flame formation was observed. PVDF remainsconsistent and does not flow.

B2 HBB2 HBB1 V2B1 V0B1 V0B1, 14 mm V0, 5VB1, 14 mm V0B1, 13 mm V0B1, 14 V0, 5V V0B2 HBB2 HBB2 HB

Materials DIN 4102 UL 94Polystone G (PE-HD)Polystone PPolystone PPsPolystone PPs EL blackPolystone PVDFTrovidur ENTrovidur ETTrovidur NLTrovidur ECTrovidur PHTPolystone Safe-Tec CFoamlite PFoamlite G

There are high requirements made on fire behaviour particularlywhen plastics are used for ventilation plants.

Fire behaviour ofPolystone- and Trovidur materials

-

32 | Rchling High-Performance Plastics

Quality assuranceTest methods

Damage to a tank or plant, in which highlyaggressive chemicals are stored, may haveserious consequences for persons and theenvironment. For this very reason, highrequirements are made on the thermoplasticsused in chemical-tank and plant construction.

In Rchlings laboratories more than 700 stan-dards are available. Over 350 tests could beconducted at the various locations.

They include:

FTIR (Fourier Trans-formations InfraRed)

Bending angle FNCT DSC/OIT Determination of impact

resistance High-voltage tests up to

200 000 Volt Weathering tests Wear tests Mechanical tests from plus 200 C

down to minus 100 C Electronic colour measurement

-

Rchling High-Performance Plastics I 33

Quality assuranceTest methods

The most important testing procedures for the application of plastics in chemical-tank andplant construction are described below:

FNCT (Full Notch Creep Test)

The FNCT is used by Rchling to determine the resistance of our plastic materialsagainst slow crack growth.The test specimen is provided with an all-round full notch and suspended in awetting agent solutionat 80C to 95C under tensile stress.

Dimension of specimen: 10 x 10 x 100 mm, applied tensile stress: 4 5 MPa

The longer the time until a fracture of the specimen the better the resistance of thematerial against slow crack growth.

Stress cracks Specimen with all-round full notch

test bodies

weight-arm

test weight

measuring gauge

testing medium

The test rig is similar to other tensile creep tests

time/min

Typical diagram of a OIT analysis Insertion of a specimen into the measuring cell Samples in the automatic sample changer

angular point

crystallinity

temperature

area

Typical diagram of a DSC analysis

DSC/OIT

Two complete procedures in one device. DSC (Differential Scanning Calometry) OIT (Oxidation Induction Time)

Computer supported analysis unit

Measuring of the difference between the heat flow of aspecimen being examinted and the heat flow of a referencematerial as a function of temperature and/or time.

Required specimen mass: Less than 10 milligrammes!

-

34 | Rchling High-Performance Plastics

Quality assuranceTest methods

Determination of impact resistance

For the determination of the impact resistance of our materials a notchedspecimen is subjected in an impact fixture with the ends on two buttresses toimpact stress using the swing hammer.The impact energy and the sample cross section must be harmonized to eachother so that the sample either breaks or is pulled through the buttresses.

The impact work absorbed during the breakage is measured, referred the thespecimens initial cross section. The result is given in kilojoules per squaremeter kJ/m.

Device for the determination of the impact resistance Test set-up the determination of the impactresistance

Geometry of the sample

Bending angle

One of the most important test methods for the determination of thequality of welded joints is the bend test.Using a specified ram geometry and a defined distance between theaxes the bend angle is determined as the difference between the initialangle and the final angle when either a fracture occurs or a crack in thespecimen is visible.

The bend angle, the ram displacement while bending and the fractureappearance provide a guide to the ductility of a welded joint and hencethe weld quality.

Bending angle diagram

Bending angle

sample thickness

Minimum bending angle for PE-HD (PE 80, PE 100)according to DVS 2203-1 supplement 3

View into the heated tool butt welding machine Determination of the bending angle

-

ProdukteProdukteProdukteProdukteProdukte

Material

Extruded sheets

Compressionmoulded sheets

Round rods

Profiles

Welding rods

Our offer at a glance

*skived sheets

Rchling High-Performance Plastics I 35

PE, PP, PVDF, E-CTFE PVC

Polystone G HD blackPolystone G black B 100Polystone G black B 100-RCPolystone G HD bluePolystone G blue B 100-RCPolystone G EL blackPolystone G HD SK blackPolystone G HD GK blackPolystone P homopolymer greyPolystone P block copolymer greyPolystone P random copolymer greyPolystone P homopolymer naturalPolystone PPs EL blackPolystone PPs greyPolystone PVDFPolystone PVDF SKPolystone PVDF GKPolystone E-CTFEPolystone E-CTFE SKPolystone E-CTFE GKPolystone Safe-Tec CFoamlite PFoamlite G1.000 x 1.000 mm2.000 x 1.000 mm2.440 x 1.220 mm3.000 x 1.500 mm4.000 x 2.000 mms 1-50 mm2.000 x 1.000 mm3.000 x 1.250 mm4.000 x 2.000 mm6.000 x 1.000 mm6.000 x 2.000 mm6.000 x 2.500 mms 8 100 mms 1 8 mm* 8 300 mm

1.000 mm2.000 mm2.150 mm

extruded

Trovidur NLTrovidur ENTrovidur EN liner redTrovidur ECTrovidur ETTrovidur PHTTrovidur W 2000

2.000 x 1.000 mm2.440 x 1.220 mm3.000 x 1.500 mm4.000 x 2.000 mm

s 1-6 mm1.000 x 1.000 mm2.000 x 1.000 mm2.440 x 1.220 mm

s 1 100 mm

8 300 mm1.000 mm2.000 mm

-

Rchling Engineering Plastics KG

Rchlingstr.149733 Haren/GermanyTel. +49 5934 701 - 0Fax +49 5934 701 - [email protected]

Rchling Engineering Plastics KG

Standort/Site TroisdorfMlheimer Str. 26Geb. 11553840 Troisdorf/GermanyTel. +49 2241 4820 - 0Fax +49 2241 4820 [email protected]

Rchling Sustaplast KG

Sustaplast-Str. 156112 Lahnstein/GermanyTel. +49 2621 693 - 0Fax +49 2621 693 [email protected]

www.roechling.com

grafikdesign.1209092/ro/GB