QAP for MS Pipes-Revised

-

Upload

vijay-chander-reddy-keesara -

Category

Documents

-

view

732 -

download

60

Transcript of QAP for MS Pipes-Revised

-

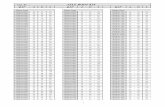

8/10/2019 QAP for MS Pipes-Revised

1/3

Name of Sub Project:

Date:

MEngineer

& TPI

1 RAW MATERIAL CONTROL

a. Chemical Critical Chemical Analysis1 per section or

lot

IS 10748 Gr. 3/ IS

3589IS 10748 Gr. 3/ IS 3589 MTC R R

b. Physical

1. Tensile Critical UTM1 Samples per

every 40 tonnes

IS 10748 Gr. 3/ IS

3589IS 10748 Gr. 3/ IS 3589 P R

2. Bend Test Critical UTMOne Sample per

Batch

IS 10748 Gr. 3/ IS

3589IS 10748 Gr. 3/ IS 3589 P R

c. Dimension Major Measuring

Instrument100%

IS 5504-1997 &

Customer

Specification if any

IS 5504-1997 &

Customer Specification if

any

P R

d. Surface Defect Major Visual 100% IS 3589/IS 5504 IS 3589/IS 5504 P R

2 PROCESS CONTROL

2.1 Pipe Forming Edge Milling & Forming Major Visual, Template,

Measurement

100% IS 5504:1997 IS 5504:1997 - W R

2.2Welding & NDT

Consumables

Chemical composition,

Mechanical

Properties and DPT

Materials

MajorVerification of batch

TCs100%

ASME Sec II part C

for weld wire & flux,

IS 3658:1999

& IS 814-1991 for

stick electrode

ASME Sec II part C for

weld wire & flux, IS 3658

:1999 for NDT materials

& IS 814-1991 for stick

electrode

MTC W R

2.3

WPS for SAW

Pipe manufacturingProcess

a) Determination of

welding Parameter

b) SAW pipemanufacturing process in

length of 5.0-12.2 Mtr.

Critical Mechanical Test 100% ASME Sec IX/PQR ASME Sec IX/PQR/WPS

WPS (MEIL/ QAQC/F-024) W R

2.4 Repair welding Repair of weld defects Critical Visual 100% IS 5504 :1997 IS 5504 :1997

Repair Rectification

report (MEIL/QAQC/F-

014)

W R

2.5 DPT Repaired Weld Defects Critical Visual 10%ASME Sec. V Article

6.0

ASME Sec. V Article

6.0

DPT report

(MEIL/QAQC/F-017)W R

2.6 End Preparation

a) Bevel end Outsideb) Root face.

C) End Flushing : ID &

OD 100mm from both

weld ends

CriticalVisual & Bevel

gauge100% IS 5504 :1997 IS 5504 :1997

Bevelling Inspection

report (MEIL/QAQC/F-

006)

W RW

3 FINAL INSPECTION & TESTING

a. Dimension CriticalMeasuring

Instrument100% IS 5504 : 1997 IS 5504 : 1997

Inspection Report

(MEIL/PR/F-010)W RW

Reference

DocumentsAcceptance Norms Format of Record

Agency

Remarks

Lab Report(MEIL/QAQC / F- 011)

Characteristics Check Category

Manufacturer's Register/

Report (MEIL/QAQC/F-

013)

HR Coils1.1

FOR MANUFACTURE OF SPIRALLY WELDED MS PIPES WITH INLINING & COATING PROCESSES , INSPECTION AND TESTING PLAN

Sl. No.Component /

MaterialType of Check

Quantum of

Check

-

8/10/2019 QAP for MS Pipes-Revised

2/3

MEngineer

& TPI

Reference

DocumentsAcceptance Norms Format of Record

Agency

RemarksCharacteristics Check CategorySl. No.Component /

MaterialType of Check

Quantum of

Check

b. Welding Critical Visual 100%

As per welding

practise (IS 816 & IS

822)

As per welding practise(IS 816 & IS 822)

Inspection Report(MEIL/PR/F-009)

W RW

c. Soundness of Weld Critical Ultrasonic

As per agreement

specififcations

(10% of Weld

Length)

IS 4260 IS 4260Ultrasonic Test Report

(MEIL/QAQC/F-015)W W

d. Mechanical Test CriticalRoot & Face Bend

Test

Sampling as per

IS 4711IS 5504-1997 IS 5504-1997

Inspection Report

(MEIL/QAQC / F- 011 )W W

e. Hydraulic Pressure

Test for Pressures as per

agreement specifications

Critical

Hydraulic Pressureat manufacturer's

work at

a)15 kg/cm2

& b) 22 kg/cm2

100% IS 5504 : 1997 IS 5504 : 1997Inspection Report

(MEIL/QAQC / F- 005)W W

4 INNER LINING & OUTER COATING

1. Dimension MajorMeasuring

Instrument100% IS 3589-2001 IS 3589-2001 W RW

2. Surface Defect Major Visual 100% IS 3589-2001 IS 3589-2001 W RW

a. Chemical Critical Chemical AnalysisOne Sample

forevery 200Bags

IS 269 / IS 8112 / IS

12330

IS 269 / IS 8112 / IS

12330Suppliers MTC W R

b. Physical

1. Fineness do By Sieve do do do Lab Report W R

2. Standard Consistency do Lab Test do do do Lab Report W R

3. Setting Time Initial,

Finaldo Lab Test do do do Lab Report W R

4. Soundness do Lab Test do do do Lab Report W R

5. Compressive Strength do Lab Test do do do Lab Report W R

a. Delitereous Material Major Lab Test 1 per batch IS 3589 / IS11906 IS 3589 / IS11906 Lab report W R

b. Soundness do do do do do do W R

c. Specific Gravity do do do do do do W R

d. Grading & Size do do do do do do W R

4.4

Weld Mesh for

outer Coating &

Inside MS Rings

Dimension Minor Measuring

Instrument

100%

As per customer

specification IS:

1566

Wire Mesh Size:

50x50x3.0 mm, & Inside

6mm dia MS Rings 04

nos. at each end of the

pipe

Suppliers MTC W R

4.5 Water Suitability of Water for

Concrete WorksMajor Lab Test Once in a Year IS 456/IS 3589 IS 456/IS 3589 Lab TC W R

a. Mix Design Major Measurment 1 Per Batch IS 1916:1989

Outer Cement Mortar

ratio : 1:3, Inner Cement

ratio: 1:2

W R

Aggregate(Sand)4.3

Inspection of

Welded Pipes3.1

Cement4.2

Pipes4.1

Manufacturer's Register/

Report (MEIL/QAQC / F-

007 )

Manufacturer's Register/

-

8/10/2019 QAP for MS Pipes-Revised

3/3

MEngineer

& TPI

Reference

DocumentsAcceptance Norms Format of Record

Agency

RemarksCharacteristics Check CategorySl. No.Component /

MaterialType of Check

Quantum of

Check

b. Cube Strength Critical CompressiveStrength

3 Per Batch

IS 784

Purchaser'sSpecification &

IS 3589 / 2001

IS 784

Purchaser'sSpecification &

IS 3589 / 2001

W R

4.7

Outside & Inside

CoatingCoating thickness

Major Thickness guages/

vernier caliper100% IS 3589: 2001

Gunneting thickness:

30mm, Inlining thickness

: 12 mm, Cut back :

150 mm,

Manufacturer's Register/

Report (MEIL/QAQC / F-

007 )W RW

4.8 Curing Proper curing Critical

1. Visual

2. Co-relating with

cube strength

100% IS 3589 : 2001 IS 3589 : 2001 W RW

5 FINAL INSPECTION & TESTING

a. Surface Defects Major Visual 100%IS 3589 : 2001 &

IS 5504 : 1997

IS 3589 : 2001 & IS

5504 : 1997W W

b. Dimension Major

Measuring

Instrument &

Gauges

100%IS 3589 : 2001 &

IS 5504 : 1997

IS 3589 : 2001 & IS

5504 : 1997W RW

c. Marking Major Visual 100%IS 3589 : 2001 &

IS 5504 : 1997

IS 3589 : 2001 & IS

5504 : 1997W W

6 SEALING & STAMPING

6.1Stenciling IA

StampLegibility of Stamp Major Visual 100% - - Test Reports W W

Samplesinspected by

TPI are

double

stamped

5. Stenciling with the lettering - APMDP - KAKINADA is to be marked on the Finished MS Pipes

Approved By

Signature:

Name:

Designation:

Fabricated , Lined

& Coated Pipe5.1

4. MS Pipe 1540mm OD/1040mm OD x 8mm thickness, Outer Coating 30mm thk Cement Mortar (CM 1:3) with Wire Mesh 50x50x3mm, Inlining 12mm thk Cement Mortaar (CM:1:2) using 4 No. of 6mm Dia. MS Rings

1. Reviwed items may be randomly witnessed by the concerned if necessary.2. All measuring instruments and testing equipmenets shall be calibrated periodically and put up for verification to Third Party Inspection Agency.

3. Legend: M: Manufacturer, TPI: Third Party Inspection, R; Review, W: Witness, RW: Random Witness (10%),V: Verify

Report (MEIL/QAQC / F-

007 )

Manufacturer's Register/

Report (MEIL/QAQC / F-

007 )

4.6

Coating Mix

![QAP Summary [R]](https://static.fdocuments.in/doc/165x107/577cc1221a28aba7119253d1/qap-summary-r.jpg)