QAP Volume -2

-

Upload

henrique-xavi-inesta -

Category

Documents

-

view

237 -

download

1

Transcript of QAP Volume -2

-

7/31/2019 QAP Volume -2

1/75

Third Party Qu

National Cyclone R(N

Revenue (D

Government o

National Cyclone R(N

Revenue (D

Government o

v

lity Audit(TPQA)

isk Mitigation ProjectRMP)) Department

Andhra Pradesh

isk Mitigation ProjectRMP)) Department

Andhra Pradesh

in jointnture with

-

7/31/2019 QAP Volume -2

2/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads

to Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

in

Joint Venture

with

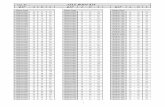

S.No Name of Test Page No.

Tests on Soil

1 Preparation of Dry soil samples for various Tests 1

2 Determination of Soil Gradation 4

3 Moisture Content of Soil

a. Sand Bath Method 5

b. Rapid Determination of Water Content with Alcohol Method 6

c. Rapid Determination of Water content with Infra Red LampTorsion Moisture Meter

6

d. Rapid Determination of Water content from Gas Pressuredeveloped by the Reaction of Calcium Carbide with the Free water

of the Soil

7

4 Tests for the Determination of Liquid Limit

a. Determination of Liquid Limit of Soil by Casagrandhe method 8

b. By Cone Penetration Method-One Point Method 9

5 Test for the Determination of Plastic Limit 10

6 Determination of Free Swell Index of Soils 11

7 Swell Pressure Test 12

8 Determination of Proctor Density

a. Standard Procter Test.(Light Compaction) 18

b. Modified Procter Test (Heavy Compaction) 20

9 Determination of Field Density and Dry Unit Weight By

a.Sand Replacement Method 20

b. Core Cutter Method for Field Density 22

c. Measurement of Density in place by Nuclear Density Gauge 22

10 Determination of California Bearing Ratio Value 23

Tests on Aggregates

11 Determination of Specific Gravity andWater Absorption of Aggregates

27

12 Determination of Moisture Content of Aggregates 28

13 Determination of Flakiness Index and Elongation Index Values 28

14 Determination of Aggregate Impact Value 30

15 Soundness test with Magnesium Sulphate 31

16 Soundness test with Sodium Sulphate 33

Tests on Bituminous Material

17 Determination of Penetration Value of Bitumen 37

-

7/31/2019 QAP Volume -2

3/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads

to Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

in

Joint Venture

with

18 Determination of Open Flash Point and Fire Point of Bitumen 39

19 Determination of Softening Point of Bitumen 39

20 Determination of Ductility of Bitumen 4021 Elastic Recovery Test 40

22 Determination of Rate of Spread of Binder 41

23 Binder Content test By Cold Solvent Extraction 41

Tests on Sand

18 Determination of Bulkage of Sand 43

19 Determination of Silt Content 43

20 Determination of Fineness Modulus 43

Tests on Bricks

21 Determination of Crushing Strength of Bricks 44

22 Determination of Water Absorption 45

Tests on Cement Mortar

23 Sand Mortar testing ( Mortar Jar Test ) 45

24 Consistency of Mortar 46

25 Water Retentivity of Mortar 47

26 Compressive Strength of Mortar 49

Test on Cement and Concrete

27 Initial and Final Setting Time of Cement 54

28 Soundness of Cement 55

29 Compressive Strength of Cement 56

30 Deleterious Materials and Organic Impurities 58

31 Crushing Strength of Coarse Aggregates 59

32 Petro graphic Examination 60

33 Alkali Aggregate Reactivity 63

34 Workability of Concrete by Slump Test 65

35 Workability of Concrete by Compaction Factor Test 66

36 Curing of Concrete 68

37 Schmidts Rebound Hammer Test 68

38 Ultra Sonic Pulse Velocity Test 69

39 Accelerated Curing Test of Concrete 69

40 Flexural Strength of Concrete 70

-

7/31/2019 QAP Volume -2

4/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

1in

Joint Venturewith

EgisInternational - Prcdemment- Ang

TESTS ON SOIL

1. PREPARATION OF DRY SOIL SAMPLES FOR VARIOUS TESTS

(IS: 2720 PART 1 1983)

SCOPE

This standard (Part I) covers the method of preparation of dry samples from the bulk soilsample received from the field for various laboratory tests.

APPARATUS

1 Wooden Mallet: For breaking soil clods.

2 Trays: For air drying of soil of suitable size and of non-rusting material.

3 Pulverizing Apparatus: Both mortar and rubber covered pestle or a mechanical deviceconsisting of a mortar and a power driven rubber covered pestle suitable for breaking up theaggregation of soil particles without reducing the size of the individual grains. Pestle andmortar made of soft wood may also be used.

4 Sampler: A suitable riffle sampler or sample splitter for quartering the samples (see IS:1607-1960 methods for dry sieving).

5 Sieves : Of sizes 75 mm, 63 mm, 37.5 mm, 19 mm, 13.2 mm, 9.5 mm, 6.7 mm, 4.75 mm,2.00 mm and 425 micron {seeIS: 460(part I)-1978 specification for test sieves: part I wirecloth test sieves (second division)}.

6 Drying Apparatus: a) Drying oven: Thermostatically controlled with interior of noncorroding material to maintain the temperature between 1050 to1100 C.

b) Other suitable drying apparatus.

7 Balance: a) Capacity 10 kg and min. sensitivity 100 g.b) Capacity 1 kg and min. sensitivity 1 gc) Capacity 250 g and min. sensitivity 0.01 g

Preparation of Samples for Tests

1 General: Soil sample as received from the field shall be dried in the air or in the sun. In wetweather, a drying apparatus may be used in which case the temperature of the sampleshould not exceed 60C.The clods may be broken with a wooden mallet to hasten drying.The organic matter, like tree roots and pieces of bark should be removed from the sample.Similarly, matter other than soil, like shells should also be separated from the main soil mass.A noting shall be made of such removals and their percentage of the total soil sample noted.When samples are to be taken for estimation of Organic content, lime content etc, totalsample should be taken for estimation without removing shells, roots etc.

2 Drying of the sample: The amount of drying depends up on the proposed tests to beconducted on the particular sample. The type, temperature and duration of drying of soilsamples for different tests are given in table-I. When oven is used for drying, the temperaturein the oven shall not exceed 110C (see note.). Che mical drying of samples should not beadopted for any tests.Note: Soils containing Organic or Calcareous matter should not be dried at temperature above 60C.

-

7/31/2019 QAP Volume -2

5/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

2in

Joint Venturewith

EgisInternational - Prcdemment- Ang

3 Degree of Pulverization: The big clods may be broken with the help of wooden mallet.Further pulverization may be done in pestle and mortar. The pulverized soil shall be passedthrough the specified sieve for the particular test and the soil retained on that sieve shall be

again pulverized for sieving, this procedure should be repeated until on further attempts atpulverizing very little soil passes through the specified sieve. Care should be taken not tobreakup the individual soil particles (see table-I).

Table I Quantity of Soil Sample Required for Conducting the Tests.(Clauses 3.2, 3.3 & 4.1)

S.

NOTEST

TypeTemperature and

duration of drying.

Amount of soilsample required

for test.

Degree ofPulverization

(IS Sieve size)

Refer topart of IS

2720.

(1) (2) (3) (4) (5) (6)

i Water content Oven. 24 h As given in table 2 -- Part 2

ii Specific GravityOven. 105 to 110

oC

24 h

50 g for fine grainedsoils

400g for fine,medium and coarse

grained soils

2 mm

part3/section 1

part3/section 2

iiiGrain sizeanalysis

Air Drying As given in table 3 -- part 4

iv Liquid Limit do 270g 425 micron part 5

v Plastic Limit do 60g do Do

viShrinkage

FactorsAir Drying 100g 425 micron part 6

vii

Compactiona) Light

Compactionb)Heavy

Compactionc)Constant Mass

do

do

do

6 kg(15 kg if soil issusceptible to

crushing)

do

2 kg

19 mm

19 mm

4.75 mm

part 7

part 8

part 9

viiiUn-confinedcompressive

strength.Oven 110

oC 5

oC 1 kg -- part 10

ixTriaxial

compression(Unconsolidated)

Do 1 kg / 5 kg -- part 11

xTriaxial

compression

(Consolidated)do do -- part 12

xi Direct ShearAir Drying/Oven

110o

5o

C1 kg 4.75 mm part 13

-

7/31/2019 QAP Volume -2

6/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

3in

Joint Venturewith

EgisInternational - Prcdemment- Ang

xii

Density Index

(RelativeDensity)

Oven, 105 to1100C

24 h

As per size ofparticle given below

75 mm 45 kg

37.5 mm 12 kg19 mm 12 kg9.5 mm 12 kg4.75 mm 12 kg

--Part

14

xiiiConsolidation

PropertiesAir Drying/Oven

110o

5o

C500g -- part 15

xiv CBR Air Drying 6 kg 19 mm part 16

xv PermeabilityOven, 105 to110

0C

24 h2.5 kg (100 mm dia)/ 5 kg (200 mm dia)

9.5 mm part 17

xviField Moisture

equivalentAir Drying 15 g 425 microns part 18

xviiCentrifugemoisture

equivalentDo 10 g do part 19

xviii Linear Shrinkage Do 450 g do part 20

xix

Chemical Testsa)Total Soluble

Solids

b)Organic Matter

c)CalciumCarbonate

d) Cat ionexchangecapacity

e)silicaSesquioxide ratio

f)pH value

g)Total solubleSulphates

Oven, 105 to1100C

24 h

Air Drying

Oven, 105 to1100C

24 h

do

do

do

do

10 g

100 g

5 g

80-130 g

15 g

30 g

30 g

2 mm

do

--

--

---

425 microns

--

part 21

part 22

part 23

part 24

part 25

part 26

part 27

xx Vane ShearAir Drying/Oven

110o

5o

C250 g -- part 30

xxiNegative Pore

Water PressureDo 1 kg / 5 kg -- part 35

xxiiPermeability of

Granular soils

Air Drying / Oven

110

0

C 5

0

C

1 kg / 5 kg -- part 36

-

7/31/2019 QAP Volume -2

7/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

4in

Joint Venturewith

EgisInternational - Prcdemment- Ang

xxiiisand equivalent

value110

oC 5

oC 1500 g 4.75 mm part 37

xxiv Direct Shear Air Drying up to 120 g above 4.75 mmpart 39/

section 1

xxv Free Swell Index Oven Dry 20 g 425 microns part 40

xxviSwellingPressure

Air Drying / OvenDry

2 kg 2 mm part 41

Quantity of Sample

1 The quantities of soil sample required for conducting various laboratory tests are given intable-I for guidance.

Note: - For actual quantities corresponding part of IS 2720 shall be referred.

2 When a smaller quantity has to be taken out of a bigger soil mass, representativesampling shall be done by quartering or riffling.

Note: - In the case of coarse gravel or gravelly soils, quartering by forming a cone shall not be done.The entire sample shall be thoroughly mixed and spread on a flat surface. The sample sospread shall be divided in to four quadrants and diagonally opposite quadrants mixed. Thisprocess shall be repeated till the desired quantity of sample is obtained.

Table 2 Quantity of sample required fordetermination of water content

Size of Particles morethan 90% passing

Minimum quantity of soilspecimen to be taken for the

test. Mass in Grams.

425 micron IS Sieve 25

2 mm IS Sieve 50

4.75 mm IS Sieve 200

9.50 mm IS Sieve 300

19 mm IS Sieve 50017.5 mm IS Sieve 1000

Depending upon the type, 100 to 200 g of the soil fraction passing the 2 mm IS Sieve will berequired for the determination of the distribution of particles below 63-micron size.

2. Determination of Soil Gradation

A. Dry Sieve Analysis

(for soil fraction retained on 4.75 mm sieve)

1. Prepare the sample by drying it in air or oven and bring it to room temperature.

Table 3 Quantity of Soil required for grain size analysis

Maximum Size ofMaterialPresent in Substantial

Quantities

Mass to betaken for Test.

mm Kg

75 60

37.5 25

19 6.5

13.2 3.5

9.5 1.56.7 0.75

4.75 0.4

-

7/31/2019 QAP Volume -2

8/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

5in

Joint Venturewith

EgisInternational - Prcdemment- Ang

2. Clean all the sieves to be used (40 mm, 25 mm, 20 mm, 10 mm, and 4.75 mm)

3. Weigh the required quantity of material from the prepared sample.

4. Place the sieves over a clean tray one over the other in the ascending order of size.

5. Shake the sieve with a varied motion, backwards and forwards, left to right, circular clockwiseand anti clockwise, and with frequent jerking, so that the material is kept moving over thesieve surfaces.

6. Do not force the material through the sieve by hand, except for sizes coarser than 20mm.

7. Break the lumps of fine particles, if any, with fingers against the side of the sieve.

8. Light brushing with a soft brush on the under side of sieve may be done to clear surface.

9. Find the individual weight of material retained on each sieve and record.

10. Calculate the percentage by weight of the total sample passing each sieve and report. Theresults in the prescribed form.

B. Wet Sieve Analysis

(for soil fraction passing 4.75 mm sieve and retained on 75 micron sieve)

1. Take a portion of the sample prepared by drying in oven and brought to room temperature.

2. Soak the sample in water and leave it for soaking overnight.

3. Wash out the finer fraction passing through 75 micron sieve.

4. Then dry it in oven for 24 hours and sieve the dry particles and find the percentage of soil

passing through each sieve and report the results in the prescribed form.

3. Moisture Content of Soil

a. Sand Bath Method

Purpose

The properties of soil like shear strength and compaction characteristics are greatlyinfluenced by its water content and the changes therein.

Procedure

1. Take an open vessel of 150 mm diameter containing sand filled (called as sand bath) to adepth of3 cm or more.

2. Take the required quantity of soil specimen in tray, crumbled and placed loosely andweigh (W1).

3. Place few pieces of white paper on the sample.4. Then keep the tray on the sand bath and heat it with stove. Drying takes place about 20

to 60 min, depending upon the type of soil. The white paper turns brown whenoverheating occurs.

5. Take tray out of the sand bath, once drying is over and cooled and weighed.6. Record the weight of the dried soil sample (W2).7. Calculate the percentage of moisture content using the formula:

Moisture content: [(W1-W2)/W2]* 100

-

7/31/2019 QAP Volume -2

9/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

6in

Joint Venturewith

EgisInternational - Prcdemment- Ang

Sample No Wt. of WetSoil (g) (W1)

Wt. of drySoil (g) (W2)

Loss of Water (g)(W1 W2)

Moisture Content (%)= [(W1-W2) /W2]* 100

b. Rapid Determination of Water Content with Alcohol Method

Purpose

It is a rapid method of determining the moisture content. Though less accurate, it is moresuitable as a field test.

Procedure

1. Clean the evaporating dish, dry and weigh (W1).2. Take appropriate quantity of soil specimen in the evaporating dish and weigh (W2).3. Pour methylated spirit over the soil at the rate of about one milliliter for every gram of soil

taken so that the soil is well covered.4. Work the methylated spirit well into the soil with the palate knife and break up any large

lumps of soil.5. Place the evaporating dish on a surface which will not be affected by heat and ignite the

methylated spirit. Stir the soil constantly with the spatula or knife taking care to see thatnone of the soil is lost.

6. After the methylated spirit has burnt away completely allow the dish to cool and weigh itwith the contents (W3).

Calculations

The percentage of water content shall be calculated as follows:

(W 2 W3)w = -----------------------

(W1 - W1)Where

W = water content presentW1 = mass of dish in gW2 = mass of dish with wet soil in gW3 = mass of dish with dry soil in g

c. Rapid Determination of Water content with Infra Red Lamp Torsion MoistureMeter

Procedure

1. Set the 100 percent scale division of the calibrated drum to align with the index mark withthe help of drive knob.

2. With the pan placed on the pivot check that the pointer is aligned with the index line andthe 100 percent scale division. If not, set the pointer with the help of initial setting knob.

3. Rotate the drum drive knob anti-clockwise and bring the 0 percent scale division in line

with the index mark, thus prestressing the wire through an amount equal to 100 percentscale division (this represents the amount of unbalance). The pointer will now be above

-

7/31/2019 QAP Volume -2

10/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

7in

Joint Venturewith

EgisInternational - Prcdemment- Ang

the index mark.4. Raise the lamp housing and carefully distribute the test material evenly on the sample

pan until the pointer returns to the index mark (approximately 25 g of the material will be

needed in one operation).5. Lower the lamp housing and switch on the infra red lamp with the help of the switchprovided on the left hand side. Insert the thermometer in its socket and bracket. Adjustthe control knob between 95 and 100 on the scale if it is desired that the temperature ofdrying is around 110C. The sample will now begin t o lose water and pointer will riseabove the index.

d. Rapid Determination of Moisture Content from Gas Pressure developed by theReaction ofCalcium Carbide with the Free Water of the Soil

PurposeThe purpose of this test is to determine the moisture content of soil quickly, without

having to wait forthe moisture to evaporate.

Set up for Rapid Determination of Moisture Content

Procedure1. The apparatus required for the test includes one metallic pressure vessel with clamp

for sealing cup and a gauge calibrated in percentage water. One counterpoint

balance, a scoop for measuring calcium carbide and three steel balls of 12.5 mmdiameter and one steel ball of 25 mm diameter.

2. Set up the balance and place the sample in the pan till the mark on the balance armmass lines up with the index mark.

3. Unclamp the clamping screw to move the U-clamp off the cup. Lift off the cup. Cleanthe cup and the body.

4. Hold the body horizontally and gently deposit one level scoopful of calcium carbidehalfway inside the chamber. Then lay the chamber down without disturbing theabsorbent charge and transfer the soil weighed out as above from the pan to the cup.

5. Holding cup and chamber approximately horizontal bring them together, withoutdisturbing sample or absorbent, bring the U clamp round and clamp the cup tightlyinto place.

6. With the gauge downwards, shake the moisture meter up and down vigorously for 5

-

7/31/2019 QAP Volume -2

11/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

8in

Joint Venturewith

EgisInternational - Prcdemment- Ang

seconds, then quickly turn it so that the gauge is upwards, give a tap to the body ofthe moisture meter to ensure that all the contents fall into the cup.

7. Hold the rapid moisture meter downwards, again shake for 5 seconds, then turn it with

gauge upwards and tap. Hold for one minute. Repeat this for a third time. Once moreinvert the rapid moisture meter and shake up and down to cool the gas. Turn the rapidmoisture meter with the gauge upwards, and dial horizontal held at chest height whenthe needle comes to rest, take the reading. The readings on the meter are thepercentages of water on the wet mass basis.

8. Alternatively, the three smaller steel balls can be placed in the cup along with the soiland the larger one in the body along with the absorbent and seal up the unit as usual.Hold the rapid moisture meter vertical so that the material in the cup falls into thebody. Now holding the unit horizontally, rotate it for 10 seconds so that the balls arerolled round the inside circumference of the body. Rest for 20 seconds. Repeat therotation rest cycle until the gauge reading is constant (usually this takes 4 to 8 min).Note the reading as usual.

9. Finally release the pressure slowly (away from the operator) by opening the clampscrew and taking the cup out, empty the contents and clean the instrument with abrush.

10. Calculate the water content (w) on the dry mass from the water content (m) obtainedon the wet mass basis as the reading on the rapid moisture meter, as follows:

11.

m

W= ------------------ x 100 percent(100-m)

Where,

w = percent water content of the dry mass

m = percent water content of the wet mass

4. Test for the Determination of Liquid Limit

a). Determination of Liquid Limit of Soil by Casagrandhe method.

1. Take 120 gm of soil passing IS: 425 micron sieve.

2. Mix it with distilled water to form a paste.

3. Place a portion of the paste in the cup of the apparatus.

4. Level the specimen to half the cup.

5. Cut the paste with the standard grooving tool along the centre line.

6. Start rotating the handle at 2 revolutions per second.

7. Count number of blows till two parts of the sample comes into contact at the bottom of thegroove (along a distance of 12 mm).

8. Record the number of blows and determine m.c. of the sample taken near the closed groove.

9. Repeat the test by changing the m.c. so that number of blows to close the groove is from 35to 10.

10. Plot a graph between log (number of blows) and moisture content and fit a straight line.

-

7/31/2019 QAP Volume -2

12/75

-

7/31/2019 QAP Volume -2

13/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

10in

Joint Venturewith

EgisInternational - Prcdemment- Ang

Wc = moisture content of soil paste corresponding to penetration of Dand D = depth penetration of cone obtained in mm.

Report

1 The results of observations of the test shall be recorded suitably.

2 The liquid limit should be reported to the nearest whole number. The history of the soil sample,that is, natural state, air-dried, oven dried or unknown, the method used for the test and theperiod of soaking allowed after mixing of water to the soil shall also be reported.

5. Test for the Determination of Plastic Limit

Apparatus1 Porcelain Evaporating Dish about 12 cm in diameter.

OrFlat Glass Plate 10 mm thick and about 45 cm square or larger.IS: 2720 (Part 5) 1985

2 Spatula flexible, with the blade about 8 cm long and 2 cm wide.Or

Palette Knives two, with the blade about 20 cm long and 3 cm wide (for use with flat glassplate for mixing soil and water).

3 Surface for Rolling ground glass plate about 20 x 15 cm.4 Containers airtight to determine moisture content.5 Balance sensitive to 0.01 g.

6 Oven thermostatically controlled with interior of non-corroding material to maintain thetemperature between 1050C and 1100C.

7 Rod -3 mm in diameter and about 10 cm long.

Soil Sample A sample weighing about 20 g from the thoroughly mixed portion of the materialpassing 425 micron IS Sieve, obtained in accordance with IS: 2720 (Part I)-1983* shall be taken.When both the liquid limit and the plastic limit of a soil are to be determined, a quantity of soilsufficient for both the tests shall be taken for preparation of the soil. At a stage in the process ofmixing of soil and water at which the mass becomes plastic enough to be easily shaped into aball, a portion of the soil sample in the plastic state should be taken for the plastic limit test.

Procedure The soil sample shall be mixed thoroughly with distilled water in an evaporatingdish or on the flat glass plate till the soil mass becomes plastic enough to be easily moulded with

fingers. In the case of clayey soils, the plastic soil mass shall be left to stand for a sufficient time(24 hours) to ensure uniform distribution of moisture throughout the soil mass(See above Para).A ball shall be formed with about 8 g of this plastic soil mass and rolled between the fingers andthe glass plate with just sufficient pressure to roll the mass into a thread of uniform diameterthroughout its length. The rate of rolling shall be done till the threads are of 3 mm diameter. Thesoil shall then be kneaded together to a uniform mass and rolled again. This process of alternaterolling and the soil can no longer be rolled into a thread. The crumbling may occur when thethread has a diameter greater than 3 mm. This shall be considered a satisfactory end point,provided the soil has been rolled into a thread 3 mm in diameter immediately before. At no timeshall attempt be made to produce failure at exactly 3 mm diameter by allowing the thread toreach 3 mm, then reducing the rate of rolling or pressure or both, and continuing the rolling

without further deformation until the thread falls apart. The pieces of crumbled soil thread shall be

-

7/31/2019 QAP Volume -2

14/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

11in

Joint Venturewith

EgisInternational - Prcdemment- Ang

collected in an air-tight container and the moisture content determined as described in IS: 2720(Part II)-1973*.

Report

1 The observations of test should be recorded suitably.

2 The moisture content determined as above is the plastic limit of the soil. The plastic limit shall be determined for atleast three portions of the soil passing 425 micron IS Sieve. The average of the results calculated to the nearest wholenumber shall be reported as the plastic limit of the soil.

3 The history of the soil sample (that is, natural state, air-dried, oven dried or unknown) and theperiod of soaking allowed after mixing of water to the soil shall also be reported.

6. Determination of Free Swell Index of Soils

IS: 2720 (Part 40): 1977

1. Take two samples of dry soil. 10 gm each

2. Take two 100 ml graduated glass cylinders.

3. Pour the soil sample in each cylinder

4. Fill distilled water in one cylinder and kerosene in the other cylinder upto 100 ml marks.

5. Remove the entrapped air by gently shaking or stirring with a glass rod.

6. Leave the samples to settle and allow sufficient time (24 hours or more) for the soil samplesto attain equilibrium state of volume.

7. Read the final volume of soil in each cylinder.

8. Determine the differential free swell index Sd using the formula

Volume of soil in water - volume of soil in keroseneSd= x 100

Volume of soil in kerosene

9. If the value of Sd is 50 percent or more, the soil is expansive and not suitable for use asembankment fill material. (For EW-5(a))

Precautions1) Pour the soil specimen in both the graduated glass cylinder gently, so that no soil particle

remains stuck to the wall of the cylinder.2) Sufficient time should be given to both the soil specimen to attain the final equilibrium

position of volume without any future change in the soil volumes. This may take 24 hours ormore.

3) For highly swelling soils, the weight of soil specimen may be taken as 5g or cylinders of250ml. capacity may be used.

A relation between differential free swell (%) and degree of expansiveness of soil is given below:

Differential free swell (%) Degree of expansiveness

< 20 Low

20-35 Moderate

35-50 High

-

7/31/2019 QAP Volume -2

15/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

12in

Joint Venturewith

EgisInternational - Prcdemment- Ang

> 50 Very High

If the degree of expansiveness of soil at a site is damageable to the structure to be constructedthere, it is recommended to take suitable measures for foundation design to the same. In such

cases, the foundation should be constructed under the supervision of a geotechnical engineer.

7. SWELL PRESURE TEST

CONSOLIDOMETER METHOD

1. APPARATUS AND EQUIPMENT

1.1 Consolidometer - A device to hold the sample in a ring either fixed or floating with porousstones (or ceramic discs) on each face of the sample. A consolidometer shall also providemeans for submerging the sample, for applying a vertical load and for measuring the change inthe thickness of the specimen gauge shall be rigid; the provision for fixing of the dial in no case

shall the dial gauge be fixed to a cantilevered arm. Suitable provision shall be made to enablethe dial gauge to be fixed in such a way that the dial gauge records accurately the verticalexpansion of the specimen.

1.1.1 Specimen Diameter-Thespecimen shall be 60 mm in diameter ( specimens of diameters50, 70 and 100 mm may also be used in special case ).

1.1.2 Specimen Thickness The specimen shall be at least 20 mm thick in all cases. However,the thickness shall not be less than 10 times the maximum diameter of the grain in the soilspecimen. The diameter to thickness ratio shall be a minimum of 3.

1 1.3 Ring -The ring shall be made of a material which is non-corrosive in relation to the soiltested. The inner surface shall be highly polished or coated with a thin coating of silicon greaseor with a low-friction material. The thickness of the ring shall be such that under assumedhydrostatic stress conditions in the sample the change in diameter of the ring will not exceed 003percent under the maximum load applied during the test. The ring shall have one edge beveledsuitably so that the sample is pressed into the ring with least disturbance. The ring shall beplaced with its cutting edge upwards in the consolidometer and clamped with a special clampwhich should in no way damage the sharp edge. The clamp should be made circular with centralhole equal in diameter of the porous stone and should be perfectly concentric with the sample.The ring shall be provided with a collar of internal diameter same as that of the ring and ofeffective height 20 mm. The collar shall rest securely on the specimen ring.

1.1.4 Porous Stones -The stones shall be of silicon carbide or aluminum oxide and of mediumgrade. It shall have a high permeability compared to that of the soil being tested. The diameter ofthe top stone shall be 0.2 to 0.5 mm less than the internal diameter of the ring. The thickness ofthe stone shall be a minimum of 15 mm. The top stone shall be loaded through a corrosion-resistant plate of sufficient rigidity and of minimum thickness 10 mm to prevent breakage of thestone. The loading plate & all have suitable holes for free drainage of water.

1.2 Dial Gauge - accurate to 001 mm with a traverse of at least 20 mm.

1.3 Water Reservoir - To keep the soil sample submerged.

1.4 Moisture Room - For storing samples and for preparing samples in climates where there is

likelihood of excessive moisture loss during preparation (optional).

-

7/31/2019 QAP Volume -2

16/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

13in

Joint Venturewith

EgisInternational - Prcdemment- Ang

1.5 Soil Trimming Tools -Fine wire-saw, knife, spatula, etc for trimming sample to fit into theinside diameter of the consolidometer ring with minimum disturbances.

1.6 Oven -thermostatically controlled oven with interior of non-corroding material to maintain thetemperature between 105 and 110C.

1.7 Desiccator -With any desiccating agent other than sulphuric acid.

1.8 Balance - sensitive to 0.01 g.

1.9Containers - forwater content determination.

2.PREPARATION OF TEST SPECIMEN

2.1 Preparation of Specimen from Undisturbed Soil Samples -

Thecontainer ring shall be cleaned and weighed empty. From one end of the undisturbed soilsample about 30 mm, or more if desired, of the soil sample, if desired shall be cut off andrejected. The specimen shall be cut off either from the undisturbed tube sample or from blocksample the latter.

Generally being more representative of the field conditions. In either case the consolidation ringshould be gradually inserted in the sample by pressing with hands and carefully removing thematerial around the ring. The soil specimen so cut shall project as far as 10 mm on either side ofthe ring. The specimen shall then be trimmed smooth and flush with the top and bottom of thering. Any voids in the specimen caused due to removal of gravel or limestone pieces, shall befilled back by pressing lightly the loose soil in the voids, care being taken to see that the

specimen is not affected. The container ring shall be wiped clear of any soil sticking to theoutside and weighed again with the soil. The whole process should be quick to ensure minimumloss of moisture and if possible shall be carried cut in the moisture room. Three representativespecimens from the soil trimming shall be taken in moisture content cans and their moisturecontent determined in accordance with IS : 2720 ( Part XI )-1973*.

2.2Preparation of Specimen from Disturbed Soil Sample? In case where it is necessary touse disturbed soil samples the soil sample shall b& compacted to the desired (field) density andwater content it1 a standard compaction proctor mould. Samples of suitable sizes are cut from itas given in 4.11.

NOTE1 - Since the swilling pressure of the soil is very much influenced by its initial water contentand dry density it shall be ensured that in the case of undisturbed soil samples, the specimenshall be collected from the field for test during the driest season of the year, namely, April, Mayand June, so that the swelling pressure recorded shall maximum.

In the case of remoulded soil samples, the initial water content shall be at the shrinkage limit orfield water content. SOthat the swelling pressure recorded shall be maximum.

NOTE 2 - The desiccated soil obtained from the field coupled with smaller thickness ofconsolidation ring make the undisturbed soil specimen always in danger of being disturbedduring trimming: hence great care shall be taken to handle the specimen delicately with the leastpressure applied to the soil.

-

7/31/2019 QAP Volume -2

17/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

14in

Joint Venturewith

EgisInternational - Prcdemment- Ang

PROCEDURE

3.1 Assembly

3.1.1 The porous stones shall be saturated. All surfaces of the consolidometer which are to beenclosed shall be moistened. The porous stones shall be saturated by boiling in distilled waterfor at least 15 minutes. The consolidometer shall be assembled with the soil specimen (in thering) and porous stones at top and bottom of the specimen, providing a filter paper rendered wet(What man No. 1 or equivalent) between the soil specimen and the porous stone. The loadingblock shall then be positioned centrally on the top porous stone.

3.1.2 This assembly shall then be mounted on the loading frame such that, the load whenapplied is transmitted to the soil specimen through the loading cap. The assembly shall be socentered that the load applied is axial.

3.1.3 In the case of the lever loading system, the apparatus shall be properly counterbalanced. Ifa jack with load measurements by platform scales is used as the loading systems the tare weightwith the empty consolidation apparatus, excluding those parts which will be on top of the soilspecimen, which rest on the platform shall be determined before filling the ring with the soil andthis tare weight shall be added to the computed scale loads required to give the desiredpressures at the time of loading the soil specimen.

3.1.4 The holder with the dial gauge to record the progressive vertical heave of the specimenunder no load, shall then be screwed in place and adjusted in such a way that the dial gauge isnear the end of its release run, allowing small margin for the compression of the soil, if any.

3.1.5 An initial setting load of 50 gf/cms (this includes the weight of the porous stone and the

loading pad) shall be placed on the loading hanger and the initial reading of the dial gauge shallbe noted.

3.1.6 The system shall be connected to a water reservoir with the level of water in the reservoirbeing at about the same level as the soil specimen and water allowed to flow in the sample. Thesoil shall then be allowed to swell.

3.2Procedure

3.2.1 The free swell readings shown by the dial gauge under the seating load of 5 kN/ms (0.05kg f/cm %) shall be recorded at different time intervals. For the purpose of record form 1 given inAppendix A shall be used and the total readings noted at total elapsed time since starting showntherein.

3.2.2 The dial gauge readings shall be taken till equilibrium is reached. This is ensured bymaking a plot of swelling dial reading UCMUS time in hours, which plot becomes asymptotic withabscissa (time scale). The equilibrium swelling is normally reached over a period of 6 to 7 days ingeneral for all expansive soils.

3.2.3 The swollen sample shall then be subjected to consolidation under different pressures asgiven in form 2 of IS2720 Part (XLI)-1977. Compression dial readings shall be recorded till thedial readings attain a steady state for each load applied over the specimen. The consolidationloads shall be applied till the specimen attains its original volume.

-

7/31/2019 QAP Volume -2

18/75

-

7/31/2019 QAP Volume -2

19/75

-

7/31/2019 QAP Volume -2

20/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

17in

Joint Venturewith

EgisInternational - Prcdemment- Ang

SWELLING PRESSURE TEST by CONSOLIDOMETER METHOD

Project: Dated:

Tested by:

1. Details of soils samplei) Locationii) Boring No.iii) Depthiv) Visual description of soilv) Liquid limit

Plasticity indexvi) Percentage of soil fraction below 0002 mm2. Details of soil specimen

i) Undisturbed or remoldedii) Specific gravity of the soil

NATURAL DENSITY MOISTURE CONTENT

Description Test-1 Test-2 Description before Test after Test

Weight of container- Weight of container /Ring + wet specimen + wet soil

Weight of container Weight of container +Dry Soil

Diameter of container Weight of containerInitial thickness of soil sample Weight of waterWet density in g/ml Weight of Dry soil

Dry density in g/ml Moisture content in percent

Date

Time of starting

Elapsed time in hours Swelling dial Reading0

0.514281216202436

48

-

7/31/2019 QAP Volume -2

21/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

18in

Joint Venturewith

EgisInternational - Prcdemment- Ang

607296

8. Determination of Proctor Density Test

Object and scope. The object of the experiment is to determine the relationship between watercontent and dry density of soil using Standard Proctor Test (light compaction) or Modified ProctorTest (heavy compaction), and then to determine the optimum water content and thecorresponding maximum dry density for a soil. The test also covers the determination ofrelationship between penetration resistance and water content for the compacted soil.

(a) Light Compaction (Standard Proctor Test)

Materials and Equipment. (i) Cylindrical metal mould of capacity 1000cc, with an internal

diameter of 1000.1 mm and an internal effective height of 127.30.1 mm, or mould of capacity2250 cc, with an internal diameter 1500.1 mm and an internal effective height of 127.30.1 mm,each mould fitted with a detachable base and a removable extension (collar) approximately 60mm high (ii) Metal rammer, 50 mm diameter circular face, weighing 2.6 kg and having drop of310 mm (iii) Steel straight edge (iv) 20 mm and 4.75 mm IS sieves (v) Balances, 10 kg capacitysensitive to 1 g, and 200 capacity sensitive to 0.01 g (vi) Thermostatically controlled oven (105 1100C) (vii) Water content containers (viii) Mixing equipment, such as mixing pan, spoon, trowelspatula etc. (ix) Measuring cylinder of glass, 100 ml capacity (x) Sample extruder (optional).

Test Procedure1. Take about 18 Kg of air dried sample for 1000 cc mould (40 Kg for 2250 cc mould). Sieve thesoil through 20mm and 4.75mm IS Sieves and calculate the ratio of fraction passing 20mm IS

Sieve and retained on 4.75mm IS Sieve. Use 100mm dia mould if percentage retained on4.75mm sieve is less than 20 and 150mm dia if soil percentage retained on 4.75mm sieve ismore than 20. Discard the soil retained on 20mm sieve. Add enough water to bring its watercontent to about 7 per cent (sandy soils) or 10 percent (clayey soils) less than the estimatedoptimum moisture content. Keep this soil in an air tight container for about 20 hours, for maturing.

2. Clean the mould and fix it to the base. Take the empty mass of the mould and the base,nearest to 1 g.

3. Attach the collar to the mould. The inside of the mould may be greased thoroughly.

4. Mix the matured soil thoroughly. Take out about 2 kg of the soil and compact it in the mould

in three equal layers, each layer being given 25 blows from the rammer weighing 2.6 kg droppingfrom a height of 310 mm, if 1000 ml mould is used. If however, the 2250 ml mould is used, about5 kg of soil should be taken and should be compacted in three equal layers, each layer beinggiven 56 blows from the rammer weighing 2.6 kg dropping from a height of 310 mm. The blowsshould be uniformly distributed over the surface of each layer. Each layer of compacted soilshould be scored with a spatula before putting the soil for the succeeding layer. The amount ofsoil used should be just sufficient to fill the mould leaving about 5 mm to be struck off when collaris removed. Find the penetration resistance of compacted soil, using the Proctors needle.

5. Remove the collar, and cut the excess soil with the help of a straight edge. Clean the mouldfrom outside, and weigh it to the nearest gram. Eject out the soil from the mould, cut it in themiddle and keep a representative soil specimen for water content determination.

-

7/31/2019 QAP Volume -2

22/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

19in

Joint Venturewith

EgisInternational - Prcdemment- Ang

6. Repeat steps 4 and 5 for about five or six times, using a fresh part of the soil specimen andafter adding higher water content than the proceeding specimen.

Fig.a Fig.b

Tabulation of observations: The observations are tabulated as illustrated in Table below.

Table: Data and Observation Sheet for Proctors Test (Light Compaction)

Determination No. 1 2 3 4 5 6 7

(a) Density

Mass of mould + compacted soil (g)

6607 6644 6723 6795 6837 6842 6829

Mass of mould (g) 4944 4944 4944 4944 4944 4944 4944

Mass of compacted soil (g) 1663 1720 1779 1851 1893 1898 1885

Bulk density () g/cm3 1.76 1.82 1.88 1.96 2.00 2.01 1.99

Dry density (d) g/cm3 1.55 1.57 1.58 1.64 1.63 1.62 1.58

(b) Water content Container No. 23 94 8 9 159 71 10

Mass of container + wet soil (g) 45.3 59.9 38.8 52.2 46.8 45.6 44.9

Mass of Container + dry soil (g) 42.5 54.7 36.2 47.4 42.2 41.3 40.2

Mass of water (g) 2.8 5.2 2.6 4.8 4.4 4.3 4.7

Mass of container (g) 22.5 22.9 22.5 22.6 23.1 22.9 22.5Mass of dry soil (g) 20.0 31.8 13.7 24.8 19.3 18.4 17.7

Water content (w) (%) 13.9 16.3 18.8 19.4 22.8 23.4 26.6

Calculations: 1. The dry density of the compacted soil is calculated as follows:

d = (1+w)

A curve showing the relationship between dry density and water content is plotted. The watercontent corresponding to the maximum dry density is found from the curve. For the datatabulated above, the optimum water content is found to be 20% corresponding to maximum drydensity of 1.64 g/cm3. The corresponding dry unit weight = 1.64 x 9.81 = 16.09 kN/m3.

2. The voids ratio for each determination is found from the equation:

-

7/31/2019 QAP Volume -2

23/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

20in

Joint Venturewith

EgisInternational - Prcdemment- Ang

e = G w - 1d

3. On the same plot, a curve is drawn between penetration resistance and water content (Fig. b).

(b) Heavy Compaction (Modified Proctors Tests)The equipment required for the heavy compaction test is the same as that required for the lightcompaction except that the rammer has a falling mass of 4.89 kg and has a drop of 45 cm. Thesoil is compacted in five equal layers, instead, of three. Each layer is given 25 blows of therammer if the 1000ml mould is used and 56 blows if 2250cc mould is used.

9. Determination of Field Density and Dry Unit Weight By

a). Sand Replacement Method

Object and scope. The object of the test is to determine the dry density of natural or

compact soil, in-place, by the sand replacement method.Materials and equipment: (i) Sand pouring cylinder of about 3 liter capacity, mounted

above a pouring cone and separated by a shutter cover plate and a shutter, (ii) Cylindricalcalibrating container, 10 cm internal diameter and 15 cm internal depth, fitted with flangeapproximately 5 cm wide and about 5 mm thick (iii) Glass plate, about 45 cm square and 1 cmthick, (iv) Metal tray with a central circular hole of diameter equal to the diameter of the pouringcone, (v) Tools for excavating hole, (vi) Balance accurate to 1 g, (vii) Container for water contentdetermination, (viii) Clean, closely graded natural sand passing the 1mm IS Sieve and retainedon the 600-micron IS Sieve.

Test Procedure

(A) Determination of mass of sand filling the cone

1. Fill the clean closely graded sand in the sand pouring cylinder up to a height 1 cm below the

top. Determination the total initial mass of the cylinder plus sand (M1). This total initial massshould be maintained constant throughout the tests for which the calibration is used.

2. Allow the sand of volume equivalent to that of the excavated hole in the soil (or equal to thatof the calibrating container), to run out of cylinder by opening the shutter. Close the shutterand place the cylinder on glass plate.

3. Open the shutter and allow the sand to run out. Close the valve when no further movement of

sand is observed. Remove the cylinder carefully. Weigh the sand collected on the glasssurface. Its mass (M2) will give the mass of sand filling the pouring cone. Repeat this step atleast three times and take the mean mass (M2). Put the sand back into the cylinder, to havethe same constant mass (M1).

(B) Determination of bulk density of sand

1. Determine the volume (V) of the calibrating container by filling it with water full to the brimand finding the mass of water. This volume should be checked by calculating it from themeasured internal dimensions of the container.

2. Place the sand-pouring cylinder concentrically on the top of the calibrating container, after

being filled to constant mass (M1). Open the shutter and permit the sand to run into the

-

7/31/2019 QAP Volume -2

24/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

21in

Joint Venturewith

EgisInternational - Prcdemment- Ang

container. When no further movement of sand is seen, close the shutter. Remove the pouringcylinder and find its mass (M3) to nearest gram.

3. Repeat step (2) at least thrice and find the mean mass M3. Put the sand into the sand-

pouring cylinder.

(C) Determination of dry density of soil in-place

1. Expose about 45 cm square area of the soil to be tested and trim it down to level surface.Keep the tray on the level surface and excavate a circular hole of approximately 10 cmdiameter and 15 cm deep and collect all the excavated soil in the tray. Find the mass (M) ofthe excavated soil.

2. Remove the tray, and place the sand-pouring cylinder, so that the base of the cylinder

concentrically covers the hole. The cylinder should have its constant mass M1. Open the

shutter and permit the sand to run into the hole. Close the shutter when no further movementof the sand is seen. Remove the cylinder and determine its mass (M4).

Keep a representative sample of the excavated soil for water content determination.

Tabulation of observations. The observations are tabulated as illustrated in Table 3.10.

TABLE 3.10 Data and Observation Sheet for Determination of DryDensity by Sand Replacement Method

(a) Determination of Mass of sand in the cone1. Mass of sand (+cylinder) before pouring M1 10550 g2. Mean mass of sand in cone M2 445 g

(b) Determination of bulk density of sand3. Volume of calibrating container V 1000 ml4. Mean mass of sand (+cylinder) after pouring M3 8655 g5. Mass of sand filling calibrating container = M1 - M3 - M2 1450 g6. Bulk Density of sand S =1450 / 1000 1.45 g/cm

3(c) Bulk density of soil

7. Mass of wet soil from the hole M 2234g8. Mass of sand (+cylinder) after pouring in the hole M4 8512g9. Mass of sand in the hole = M1 - M4 - M2 1593g10. Bulk density of soil() = 2234 / 1593 X 1.45 2.03 g/cm

3

(d) Water content determination

11. Container No 1112. Mass of container + wet soil 62.48 g13. Mass of container + dry soil 57.76 g14. Mass of container 21.43 g15. Mass of dry soil 36.33 g16. Mass of water 4.72 g17. Water content (w) Ratio 0.13

18. Dry density d =__ _2.03_1+w 1+0.13

1.8 g/cm3

Reference to Indian standard: IS: 2720-1974 (Part XXVIII) by sand replacement method):

-

7/31/2019 QAP Volume -2

25/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

22in

Joint Venturewith

EgisInternational - Prcdemment- Ang

b). Core Cutter Method for Field Density

Field density can be determined by core cutter also. The method can be used

successfully whenever soil conditions permit pushing of cutter for sampling and taking itout in the laboratory without much disturbance. This is briefly described as under:-

1. Measure the inside dimensions of the cutter and calculate its volume.2. Weigh the cutter without dolly.3. Remove loose soil from the site.4. Place the dolly over the cutter and ram it gently into the soil till about one cm of the dolly

protrudes above the surface.5. Dig out the cutter containing the soil extruding from the ground.6. Remove the dolly and trim off any soil extruding from the ends.7. Weigh the cutter full of soil and keep a representative sample for water content

determination

8. Calculate the dry density of the soil by knowing its weight, volume and water content.

Determination of Field Density of Soil (Core Cutter Method)

S.No Observation 1 2 31 Volume of Core Cutter = V cm2 Weight of empty Core cutter = W g3 Weight of Core Cutter + Wet Soil = W g4 Weight of Wet Soil = W - W g5 Bulk Density Y = W1 - W

------------------- g/cm3V

6 Container No.7 Weight of Container + Soil Sample = W2 g8 Weight of Container after oven drying = W3 g9 Moisture Content = W2 W 3 g10 Weight of empty Container = W4 g11 Weight of Dry Soil = W3 W4 g12 Percentage of Moisture Content W2 W 3

w = ------------------x 100 %W3 W 4

13 Dry Density = 100Yd = --------------------x Yb g/cm3

100 + m

c). Measurement of Density in place by Nuclear Density Gauge

Purpose

This is a quick method of determining the in-situ density of soil which is based on the radiation.

Procedure

For this test special equipment which measures in place density using gamma radiation isused. Gauge usually contains a small gamma source (about 10mCi) such as Cesium 137 onthe end of a retractable rod.

-

7/31/2019 QAP Volume -2

26/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

23in

Joint Venturewith

EgisInternational - Prcdemment- Ang

Gamma rays are emitted from the source which interacts with electrons in the surroundingmaterial. Density of material is then correlated to the number of gamma rays received by thedetector. The following procedure is used for measuring the density of soil.

1. Make the surface even by using a guide plate or any other suitable equipment. 2. Make a hole by pounding a steel rod with a similar diameter to that of gauges

retractable rod. The hole should be at least 50mm deeper than the intended depth ofmeasurement.

3. Nuclear Density Gauges normally operate in two modes.I. Direct TransmissionII. Back Scatter

For measuring the density of soil, set the Equipment to Direct Transmission Mode.4. Lower the source rod into the hole. Set the handle to the depth position required. 5. Read the detector count on the panel. Use the calibration chart provided by the

manufacturer to obtain density of material.

6. It may be noted that the detector count is inversely proportional to the density of thesurrounding material.

7. The Nuclear Density Gauges are calibrated at the factory. Since the source materialundergoes decay, it needs to be calibrated from time to time in accordance with theprocedure given by the manufacturer.

Nuclear Density Gauge

10. Determination of California Bearing Ratio Value As per IS: 2720 (Part-16) -1979

1. Concept and Significance

California Bearing Ratio (CBR) test originally developed by California Division ofHighways (U.S.A) is one of the most commonly used methods to evaluate the strength ofsubgrade soil for design of pavement thickness. CBR value as defined by IS: 2720 (Part XVI)-1979 is the ratio of the force per unit area required to penetrate a soil mass with a circularplunger of 50 mm diameter at the rate of 1.25 mm/minute, to that required for correspondingpenetration of a standard material. Standard load is that load which has been obtained fromtests on a crushed stone whose CBR value is taken to be 100 per cent. The ratio is usuallydetermined for penetration of 2.5 mm and 5.0 mm. The results of this test cannot be related

-

7/31/2019 QAP Volume -2

27/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

24in

Joint Venturewith

EgisInternational - Prcdemment- Ang

accurately with fundamental properties of the material but are useful in design of flexiblepavements.

2. Objective

To determine the California Bearing Ratio of the subgrade soil.

3. Apparatus

The apparatus as per IS: 2720 (Part XVI) 1979 comprises of the following:

(i) Mould. A metallic cylinder of 150 mm internal diameter and 175 mm height; provided witha detachable metal extension collar 50 mm in height. It also has a detachable perforatedbase plate of 10 mm thickness. The perforations in the base plate do not exceed 1.5 mm

in diameter.(ii) Steel cutting collar, which can fit flush with the mould.

(iii) Spacer disc. A metal disc of 148 mm diameter and 47.7 mm in height.

(iv) Surcharge weights: One annular metal weight and slotted weights each of 2.5 kg and 147mm in diameter with a central hole 53 mm in diameter.

(v) Dial gauges. Two dial gauges reading to 0.01 mm.

(vi) IS Sieves of sizes 47.5 mm and 20 mm.

(vii) Penetration plunger. A metallic plunger having a diameter of 50 mm and at least 100 mmlong.

(viii) Loading machine with a capacity of at least 5000 kg and equipped with a platform thatcan move vertically at a rate of 1.25 mm/min.

(ix) Miscellaneous apparatus like mixing bowl, straight edge, scales, soaking tank, dryingoven, filter paper, dishes and calibrated measuring jar.

Procedure

Preparation of test specimen.

1 Preparation of Undisturbed Specimen

Fit to the mould, the steel cutting edge of 150 mm internal diameter. Push the mould into theground as gently as possible till the mould is full of soil. Remove the soil from sides and bottom.Trim the excessive soil from top and bottom.

2 Preparation of Remoulded Specimen

Remoulded samples are prepared such that the dry density obtained from proctor compactiontests, the water content of remoulded samples is either the optimum water content or the fieldmoisture as the case may be, the remoulded sample are compacted either statically ordynamically. The test material should pass 20mm IS sieve and retained on 4.75mm IS sieve. Ifcoarser material is retained on 20mm sieve, it should be discarded and an equal amount ofmaterial retained on 4.75mm sieve and passing through 20mm sieve should be replaced.

3 Statically Compacted Specimen

(i) Calculate the amount of soil required such that it fills the mould (excluding collar) at the

desired density after compaction.

-

7/31/2019 QAP Volume -2

28/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

25in

Joint Venturewith

EgisInternational - Prcdemment- Ang

(ii) Calculate the amount of water to be added to give desired water content.

(iii) Mix the soil thoroughly with water.

(iv) Fix the extension collar to the mould and clamp it to the base plate.

(v) Fix the mould with soil, gently pressing it with hands so that it does not spill out of themould.

(vi) Place a coarse filter paper over the leveled soil surface and then insert the space disc.

(vii) Place the assembly on the pedestal of compression machine and compact the soil untilthe top of the spacer disc is flush with the top of the collar.

4 Dynamically compacted specimen

(i) Sieve the material through 20 mm IS sieve

(ii) Take about 4.5 kg or more of representative sample for fine grained soils and about 5.5kg for granular soils in a mixing pan.

(iii) Add water to the soil in the quantity such that the moisture content of the specimen iseither equal to field moisture content or OMC as desired.

(iv) Mix together the soil and water uniformly.

(v) Clamp the mould along with the extension collar to the base plate.

(vi) Place the coarse filter paper on the top of the spacer disc.

(vii) Pour soil-water mix in the mould in such a quantity that after compaction about 1/5th ofthe mould is filled

(viii) Give 56 blows with the rammer weighing 2.6 kg dropping through 310 mm in three layers(light compaction) or 4.89 kg dropping through 450 mm in 5 layers (heavy compaction)evenly spread on the surface.

(ix) Scratch the top layer of compacted surface. Add more soil and compact in similar fashion.Fill the mould completely in five layers.

(x) Remove the extension collar and trim off the excess soil by a straight edge

(xi) Remove the base plate, spacer disc and the filter paper and note down the weight ofmould and compacted specimen.

(xii) Place a coarse filter paper on the perforated base plate.

(xiii) Invert the mould containing compacted soil and clamp it to the base plate.

5. Testing the Specimen

(i) Place the mould containing the specimen, with base plate in position, on the testingmachine.

(ii) Place the annular weight of 2.5 kg on the top surface of soil.

(iii) Bring the penetration plunger in contact with soil surface and apply a load of 4 kg so thatfull contact between soil and plunger is established. This should be taken as zero load.

(iv) Place the remainder surcharge weight so that total surcharge weight equals to 5 kg.

(v) Set the reading of dial gauges to zero.

(vi) Apply load so that penetration rate is 1.2 mm per min. Record the load at penetration of0, 0.5, 1.0, 1.5, 2.0, 2.5, 4.0, 5.0, 7.5, 10.0 and 12.5 mm. The maximum load has to berecorded if it occurs at less than 12.5 mm.

(vii) Collect about 20 to 50 g of soil to determine the water content

-

7/31/2019 QAP Volume -2

29/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

26in

Joint Venturewith

EgisInternational - Prcdemment- Ang

6. CBR Test on Soaked Specimen

To perform CBR test on soaked specimen, the sample excluding base plate and spacer disc is

weighed. A filter paper is placed on the sample with a perforated plate on it. Over it a surchargeweight 2.5 or 5 kg is placed and the sample is soaked in water tank for 4 days. The sample isthen allowed to drain off water in a vertical position for about 15 minutes. The sample is weighedagain to calculate the percentage of water absorbed. It is then tested following the normalprocedure.

7. Computation of Test Results

(i) Plot the load penetration curve with the load as ordinate and penetration as abscissa.Sometimes the initial portion of the curve is concave upwards due to surface irregularities. Insuch a case apply a correction. Draw tangent at the point of greatest slope. The point wherethis tangent meets the abscissa is the corrected zero reading of penetration.

(ii) From the curve, determine the load value corresponding to the penetration value at which theCBR is desired.

(iii) Compute CBR value as follows:Test load corresponding to chosen penetration (PT)

CBR value = x 100Standard load for the same penetration (PS)

Usually the CBR value is calculated for 2.5 mm and 5 mm penetration. Generally theCBR value at 2.5 mm penetration will be greater than that at 5 mm and in such a case the formeris taken for design purposes. If the 5 mm value is greater the test is repeated, if the same resultsfollow, the CBR value corresponding to 5 mm penetration is adopted for design purposes.

Table: Standard Load for Different Penetration Values

Penetrationmm

Unit standardload kg (f)/cm

2

Total standardkg(f)

2.5 70 1370

5.0 105 2055

7.5 134 2630

10.0 162 3180

12.5 183 3600

-

7/31/2019 QAP Volume -2

30/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

27in

Joint Venturewith

EgisInternational - Prcdemment- Ang

Note: The test must always be performed on remoulded sample of soils in the laboratory. Where everpossible the test specimen should be prepared by Static Compaction but if not possible Dynamic methodmay be used as an alternative. In-Situ tests are not recommended for design purpose as it is not possibleto satisfactorily simulate the critical conditions of dry density and moisture content in the field.

11. Determination of Specific Gravity and

Water Absorption of Aggregate

1. Wash a sample of aggregate of not less than 2000 gm to remove dust. Drain and place thesample in the density basket.

2. Immerse the basket in water at a temperature of 22C to 32C with at least 5cm cover ofwater above the top of the basket.

3. Immediately after immersion, remove the entrapped air from sample by lifting the basket25mm above the base of the tank and allow it to drop 25 times, at the rate of one drop persecond.

4. Keep the basket and aggregates completely immersed in water for 24 `/~ hours thenweigh in water at temperature of 22C to 32C (W 1).

5. Remove the basket and aggregates from water and allow to drain for few minutes.

6. Empty the aggregates from basket and return the empty basket into water.

7. Jolt the basket 25 times and weigh in water

8. Gently dry the surface of the aggregate by wiping with cloth. Spread the aggregates.expose to atmosphere but away from direct sunlight till they appear dry.

9. Take the weight of surface dry aggregates (W3).

10. Place the aggregates in oven at a temperature of 100C to 110C for 24 1/2 hours.

11. Remove the aggregates in oven, cool in air and weigh (W4).

12. W4i) Sp. Gravity = ----------------------

W3 - (W1 W2)

W4ii) Apparent Sp. Gravity = ----------------------

W3 - (W1 W2)

W3 W4iii) Water absorption (Percent of dry weight) = ---------------- X 100

W4

13. Report results in Form GB - 5.

-

7/31/2019 QAP Volume -2

31/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

28in

Joint Venturewith

EgisInternational - Prcdemment- Ang

12. Determination of Moisture Content of Aggregates

1. Clean the container thoroughly

2. Dry it and termine its empty weight (W1) with lid.3. Take the required quantity of the aggregate sample in the container and place it loosely

inside the container.4. Close the container and determine its weight (W2)

5. Keep the container with the lid removed in an oven maintained at a temperatureof 110C 5C for 24 hours.

6. After drying remove the container and allow it to cool to room temperature.

7. Determine weight of the dry sample with lid (W3)

8. Calculate the water content in percentage using the formula.W2 W3

W = ---------------- X 100W2 W3

9. Report the results in the prescribed Form.

Moisture Content of Aggregates

13.Determination of Flakiness Index and Elongation Index Values

Concept and Significance:Flakiness Index of an aggregate is the percentage by weight of particles in it whose least

dimension (thickness) is less than three fifths (3/5

th

) of their mean dimension. The test is notapplicable to sizes smaller than 6.3mm.

Object

To determine the flakiness of coarse aggregate sample

Apparatus

1. Balance should have an accuracy of 0.10% of the weight of test sample

2. Metal gauge confirming to IS 2336 (Part I) 1977

3. I.S Sieves 63mm, 50mm, 40mm , 31.5mm ,25mm,20mm,16mm, 12.5mm , 10.0mm and6.3mm.

Procedure

1. The sample has to be carefully and properly sieved.

2. Nine fractions are to be collected with the following specifications:

Passing through I.S Sieve Retained on I.S Sieve60 mm 50 mm50 mm 40 mm40 mm 31.5 mm

31.5 mm 25 mm25 mm 20 mm

-

7/31/2019 QAP Volume -2

32/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

29in

Joint Venturewith

EgisInternational - Prcdemment- Ang

20 mm 16 mm16 mm 12.5 mm

12.5 mm 10 mm10 mm 6.3 mm

3. Every Piece of each fractional sieve shall be gauged for a minimum thickness with thehelp of the ISI gauge or in bulk using a set of sieves having standard elongated slots.

4. Thus, each fraction is to be separated into 2 parts: One consisting of pieces which passthrough the corresponding slot in the standard gauge and the other consisting of pieceswhich do not pass through the corresponding slot in the standard gauge.

5. Each part is separately weighed. Sum of both the weights gives the total weight of eachfraction.

Observations and Calculations:

F l a k i n e s s I n d e xWt.of fraction of the sample

S.No PassedThrough

RetainedOn

Weight ingms

ThicknessGauge

Wt.of fractionPassing throughThickness gauge

in gms

Allowable Percentage

1. 63.0 50.0 4030 63.0 - 50.0 3832. 50.0 40.0 11820 50.0 - 40.0 12173. 40.0 25.0 21880 40.0 - 25.0 2341

Total 37730 3941

Flakiness Index:( 3941/37730) x 100 = 10.44 % Not >15 %ELONGATION INDEX: Elongation Index is weight of elongated particles divided by total non-

flaky Particles.

The gauge length would be 1.8 times the mean size of aggregate. For an aggregate passingthrough 50mm sieve but retained on 40mm sieve, the mean size is 45mm and limit for the lengthof 45, works out to be 1.8 x 45 = 81mm.

Elongation Index

S.NoWeight ofNon-flakymaterial

Length GaugeWt. of Fraction

Retained onAllowable PercentageLength gauge in gms

1. 3647 63.0 - 50.0 1262. 10603 50.0 - 40.0 2733. 19539 40.0 - 25.0 676

Total 33789 1075

Elongation Index = 1075 x 100(37730-3941)

= 1075/33789 x 100 = 3.18.

Flakiness + Elongation Index = 10.44 + 3.18 = 13.62 % (Not > 30%)

The Flakiness Index shall be less than 35% for coarse aggregates for concrete works(Clause.1007 of MOST Specification.)

The Flakiness Index shall be less than 25% for stone chipping.

The Combined Flakiness and Elongation Indices shall be less than 30% for combined mix

aggregates (bituminous works)

-

7/31/2019 QAP Volume -2

33/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

30in

Joint Venturewith

EgisInternational - Prcdemment- Ang

14. Determination of Aggregate Impact Value

1. Concept and Significance.

The property of a material to resist impact is known as Toughness. Due to movement ofvehicles on the road the aggregates aresubjected to impact resulting in theirbreaking down in to smaller pieces. Theaggregates should therefore have sufficienttoughness to resist their disintegration dueto impact. This characteristic is measuredby impact value test. The aggregate impactvalue is a measure of resistance to suddenimpact or shock, which may differ from itsresistance to gradually applied

compressive load.

2. ObjectiveTo determine the impact value of

the road aggregate

3. Apparatus

1. Testing Machine

2. Cylindrical steel cup

3. Metal Hammer

4. Tamping rod

5. Balance.

4. Procedure

The test sample consists of Aggregate size 10.0mm to 12.5 mm .The aggregates should

be dried by heating at 100-110 C for a period of 4 hours and cooled.

1. The Aggregates passing through 12.5mm sieve and retained on 10.0mm sieve comprises the

test material.

2. Pour the aggregates to fill about just 1/3rd depth of measuring cylinder.

3. Compact the material by giving 25 gentle blows with the rounded end of the tamping rod.

4. Add two more layers in similar manner, so that the cylinder is full.

5. Strike off the surplus aggregates.

6. Determine the net weight of the aggregates to the nearest gram (W1).

7. Raise the hammer until its lower face is 380mm above the surface of the aggregate sample inthe cup and allow it to fall freely on the aggregate sample. Give 15 such blows at an intervalof not less than one second between successive falls.

-

7/31/2019 QAP Volume -2

34/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

31in

Joint Venturewith

EgisInternational - Prcdemment- Ang

8. Remove the crushed aggregate from the cup and sieve it through 2.36mm IS sieve until nofurther significant amount passes in one minute. Weigh the fraction passing the sieve to anaccuracy of one gram (W2). Also weigh the fraction retained on the sieve.

9. Note down the observations in the pro-forma and compute the aggregate impact value.10. The mean of two observations, rounded to the nearest whole number is reported as the

aggregate Impact value.

5. Precautions.

In the operation of sieving the aggregates through 2.36mm sieve the sum of weights of fractions

retained and passing the sieve should not differ from the original weight of the specimen by more

than one gram.

6. Record of Observations and Calculations.

15. Soundness with Magnesium SulphatePurpose

To see if the aggregate disintegrates by saturated solutions of Magnesium Sulphate. It indicatessoundness against weathering action.

Acceptance Criterion

The average loss of weight after 5 cycles should not exceed 18% when tested with magnesium

sulphate.

Procedure

1. Prepare the saturated solution of Magnesium Sulphate by adding sufficient quantities ofsalt into water at a temperature of 25 to 30oC. The solution may be cooled to 27+1oC.and kept at that temperature at least for 48 h before use.

2. Prepare the samples as given below:Fine AggregateA fine aggregate for the test shall pass through 10 mm IS Sieve. The sample shall be ofsuch a size that it will yield not less than 100g of each of the following sizes, which shall

be available in amount of 5% or more expressed in terms of the following sieves:

Passing IS Sieve Retained on IS Sieve600 micron 300 microns1.18 mm 600 micron2.36 mm 1.18 mm4.75 mm 2.36 mm10 mm 4.75 mm

Coarse Aggregate

Coarse Aggregate for the test shall consist of materials from which sizes finer than 4.75 mmhave been removed. The sample shall be of such a size that it will yield not less than the

-

7/31/2019 QAP Volume -2

35/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

32in

Joint Venturewith

EgisInternational - Prcdemment- Ang

following amounts of the different sizes which shall be available in amounts of 5% or more.

Size - Square hole sieve Yield

10 mm to 4.75 mm 300 g20 mm to 10 mm 1000 g

Consisting of12.5 mm to 10 mm 33 percent20 mm to 12.5 mm 67 percent40 mm to 20 mm 1500 g

Consisting of25 mm to 20 mm 33 percent40 mm to 25 mm 67 percent

63 mm to 40 mm 3000 g

Consisting of50 mm to 40 mm 50 percent63 mm to 50 mm 50 percent

80 mm and larger size by 20 mm

Spread in sieve size, each fraction 3000 g.

3. Wash the sample and dry to the constant weight at 105oC to 110oC. Separate intodifferent sizes as shown above by sieving to refusal. Weigh out the samples and keep

them in separate containers.4. Immerse the samples in prepared solutions of Magnesium Sulphate for not less than 16 h

and not more than 18 h in such a manner that the solution covers them to a depth of atleast 15 mm.

5. Cover the container to reduce evaporation and maintain the solution at a temperature of27+1oC.

6. Remove the sample after the immersion period and allow it to drain for 15+5 min. Place itin the drying oven at a temperature of 105o to 110oC; and dry it to a constant weight

Repeat a number of cycles and determine the loss of weight of specimen after each cyclein Accordance with the procedure given below.

7. After the magnesium sulphate solution has been removed, each fraction of the sampleshall be dried to constant weight at 105 oC to 110 oC and weighed. Fine aggregates shallbe sieved over the same sieve on which it was retained before the test and coarseaggregate over the sieve shown below for the appropriate size of particle.

Size of Aggregate Sieve used to Determine Loss

63 mm to 40 mm 31.5 mm

40 mm to 20 mm 16 mm

20 mm to 10 mm 8 mm

-

7/31/2019 QAP Volume -2

36/75

-

7/31/2019 QAP Volume -2

37/75

Third Party Quality Audit for Construction of Cyclone Shelters, Roads to

Cyclone Shelters & Habitations, Bridges and Culverts under NCRMPQuality Control Tests

34in

Joint Venturewith

EgisInternational - Prcdemment- Ang

Prepare the samples as given below:

2. Fine Aggregate