Primeri Za BIM

-

Upload

vladimir-tijanic -

Category

Documents

-

view

227 -

download

0

description

Transcript of Primeri Za BIM

A CASE STUDY ON CONSTRUCTING 3D/4D BIM MODELS FROM 2D DRAWINGS AND PAPER-BASED DOCUMENTS USING A SCHOOL

BUILDING PROJECT

S. L. FAN1, S. C. KANG

2, S. H. HSIEH

3, Y. H. CHEN

4, C. H. Wu

5, J. R. JUANG

6

1 Assistant Professor, Tamkang University, Taipei, Taiwan

2 Assistant Professor, Taiwan University, Taipei, Taiwan

3 Professor, National Taiwan University, Taipei, Taiwan

4 Graduate student, National Taiwan University, Taipei, Taiwan 5 Undergraduate student, Tamkang University, Taipei, Taiwan

6 Undergraduate student, National Taiwan University, Taipei, Taiwan

Correspond to Prof. S.L. Fan ([email protected] )

ABSTRACT: Research efforts have demonstrated that building information modeling (BIM)

approaches hold significant potential for the construction industry. However, even though the

advantages are generally acknowledged, they are far from becoming standard practice. This research

presents a case study on constructing 3D/4D BIM models from 2D drawings and paper-based

documents using a typical nine-floor school research building. A 3D model was created from existing

2D drawings using BIM software and a construction schedule was re-constructed from existing

paper-based schedule documents to include the durations of and the relationships between activities.

The data of both applications were transposed separately onto a 4D simulation package. Reported are

the time taken and problems encountered in constructing the 3D/4D BIM model, and the approaches

employed to solve the problems. Our results show that 230 labor-hours were needed for the

construction of a 4163-element BIM model of the building (inclusive of the time for personnel

training). The results provide industry practitioners with some useful empirical data and documented

experiences for when applying BIM technologies to building projects.

Keywords: BIM, 4D simulation, Building construction, Case study

1. Introduction

Building information modeling (BIM) and 4D modeling have recently attained widespread attention in

the architectural, engineering and construction (AEC) industries[1,2,5]. Research efforts demonstrate

the BIM and 4D approaches provide a faster and more effective way of communicating information

between interested project parties and a better design which enables improved and innovative

solutions as well as many other benefits[1,3,6,7]. Numerous case studies have also been conducted

showing that use of BIM results in time and cost savings[1,2,3,8] by elimination of unbudgeted change

and unplanned change orders, cost estimation accuracy and time reduction, clash detections and

elimination of rework[1,2,3,8]. Some research adopts GIS and web-based technology [4,10] providing

an alternative to the existing 4D tools whereas other researches present solutions for creating time

schedules and 4D simulations based on data stored in a building model[7,9]. Nevertheless, current

planning processes in the construction industry are still mainly based on 2D drawings[1]. For a

construction managerr, with 2D drawings provided, redesigning a project using 3D modeling software

might be too large a jump. Therefore to construct 3D/4D BIM models from 2D drawings would be a

more practical choice. However with the time needed to construct 3D/4D BIM models from 2D

drawings being the main concern, constructors still struggle with applying the 3D/4D model

technology on their specific projects.

This research takes a nine-floor building as a case study to quantify the labor and time needed for

constructing 3D/4D BIM models from 2D drawings and paper-based documents. It provides

contractors useful empirical data for applying BIM technologies in building projects.

2. Case Project

The case study focuses on a typical research building of National Taiwan University. The project is a

precast concrete construction RC building possessing a seismic isolation system at the mid-story. This

building consists of an underground parking basement and nine floors with a total height of

approximately 41.4 m and a total floor area of 9686.44 m². The construction period was 6 months.

Figure 1 shows the project visualization and a photo taken on-site.

Figure 1 Project visualization (left) and a photo taken on-site (right)

There are two primary workflows involved:

2.1 2D to 3D

A 3D model was created from existing 2D drawings using standard BIM software called Revit

Architecture. The detailed workflows included setting up grid and level, and inputting each floor plan

to each level.

2.2 3D to 4D

A construction schedule was created from a paper-based schedule and provides durations of activities

and the relationships between activities using MS-Project without any information sharing from the

3D model. The data of the schedule and the 3D model were exported separately to a 4D simulation

package called Autodesk NavisWorks. This was followed by the linking of 3D objects to the activities

in the time schedule automatically and manually.

The aforementioned workflows were conducted by a graduate student and an undergraduate student of

the Computer-Aided Engineering Group at National Taiwan University and an undergraduate studying

construction management at Tamkang University in Taiwan. Each student was familiar with the

Windows operating system, yet all were beginners of BIM software.

3. Results

3.1 Errors Found in the 2D to 3D process

During the process of transposing 2D information into a 3D model, two types of errors were found:

1. Referencing Errors

Before transposing 2D information into the 3D model, a referencing error was found. Each floor plan

in the project consists of 3 files. The first file is a standard drawing frame for each drawing which

shows the basic information of the project. The second file is the structural drawing for that floor,

named S201 thru S2011 to refer to the structure for the basement, 1st floor, the floor in between 1st

floor and isolation floor, isolation floor, 2F and the floors above. The third file is a drawing for steel

ladders, elevators and curtain walls for that floor, named as Basement, 1F, 1MF (refers the floor in

between), isolation floor, 2F and the following floors.

In this project, the isolation floor which was not named is named as 2F and the original 2F is renamed

as 3F, and so on after the design drawing has been completed. The name of the 3rd files and the title in

each structure drawing were revised accordingly. However it results in an error in each floor plan

which linked these 3 files automatically using AutoCAD. For example, as shown in Table 1 and Figure

2, 2F floor plan links the file named “S204”(the structure drawing of isolation floor) with the file

named “Isolation Floor”( a file which doesn’t exist after revision of file names), and 3F floor plan

links the 2nd

file named “S205”(the structural drawing of 3F) with the file named “2F”(the drawing for

the elevators, curtain walls and steel ladders of isolation floor). Therefore before noticing this error,

many conflicts were found in each floor plan because of this miss link of files. The fourth column of

Table 1 shows the correct link which has been revised manually by the research team after realizing

this error.

Table 1 Referencing Error and the Revision

Link Before Revision After Revision

2F Floor Plan 1st File Drawing Frame Drawing Frame

2nd File S204 S204

3rd File Isolation Floor (File not found!) 2F

3F Floor Plan 1st File Drawing Frame Drawing Frame

2nd File S205 S205

3rd File 2F 3F

Figure 2 Drawing of 2F floor plan before and after revision

2. Drawings Conflicts

When incorporating 2D drawings into the 3D models, many drawing conflicts were found. As shown

in the left-hand image in Figure 3, the steel staircase which should be above the steel beam is

displayed under the steel beam; therefore a revision was necessary. The right-hand image shows the

revised drawing.

Figure 3 Drawing before and after revision

3.2 Problems encountered in the 3D to 4D process

Since there is no information sharing between the schedule and the 3D model, the names of the 157

activities in the time schedule of MS-Project do not match with the names of the 4163 elements in the

3D model of Revit. Therefore, after both the elements of 3D model and the activities of the schedule

are exported to Navisworks, there exists no automatically created link between them. Due to the large

number of elements in the 3D model, linking them manually to activities would be excessively

time-consuming. Therefore the team grouped the elements into 74 stages in Revit according the

schedule, and revised both files to make the name of each stage the same as the name of each activity.

The files were then exported to Navisworks. However another problem was encountered. There were

some activities in the schedule such temporary facilities and excavation for which matching elements

had not been built in the 3D model. The solution to this problem by the research team was to show the

location of the activity using colors and text to explain the task in the 3D model.

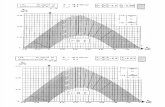

3.3 Time Spent

As shown in Tables 2 and 3, to construct a 4163-element BIM model and incorporate it with a

157-activity schedule required 230 labor-hours. This time included: 10 hours of Revit and 8 hours of

Navisworks training for the 3 students, 86 labor hours to transpose 2D information into the 3D model,

and 20 labor hours to establish a the 4D model. Clearly the process of moving from 2D to 3D takes

much more time than the process of moving from 3D to 4D, and customizing or modifying each

element takes about 2 labor hours on average.

Table 2 Details of the 4163-element of BIM model

Elements Quantity Remarks

Roofing Sheet and 1 7 Customized Elements,1

same Rain Awing element is

repetitively used to 161

places

Handrail for parking ramp 1

Parking Ramp 1

Disabled Ramp 3

Rain Awning 1

Ceilings 2 3973 Revit Built- in

elements

Curtain Wall Slabs 348

Curtain Wall Cells 193

Curtain Wall Frames 993

Handrails without Cast Panel 53

Floor Slabs 54

Stairs 25

Walls 1035

Equipments 2

Windows 183

Foundations 2

Columns 301

Frames 277

Beams 22

Joists 166

Girders 253

Line 11

Openings 2

Doors 51

Handrails with Cast Panel 23 1 Modified Built-in element

(adding cast panel to the

built in handrail element) is

repetitively used to 23

places

Total 4163

Table 3 Time taken in transposing 2D drawings to a 4D Model

Stages Workflows Time Taken

(man-hrs)

1. Training Personnel Training 18hrs*3=54 18hrs*3=54

man-hr

2. 2D to 3D

Setting up grid and level 1 2D to 3D

workflow

156man-hrs

Inputting each floor layout to each level 0.5

Building models with Revit built-in elements

(3973 places)

126

Customizing 7 elements

14

Building models with Customized

Elements (167 places )

2

Modifying 1 built-in element 2

Building models with modified built-in

elements (23 places)

3

3. 2D to 3D Error

Correction

External reference error 2

Drawings referencing error 5.5

4. 3D to 4D Exporting 3D model from Revit to

NavisWorks

5 3D to 4D

workflow

20 man-hrs

Generating schedule with given durations of

activities and the relationships between

activities using MS-Project and exporting the

schedule from MS-Project to Navis Work

4

Linking of 3D objects to the activities in the

time schedule automatically and manually

1

5. 3D to 4D

Problem Solution

Establishing Stages in Revit and exporting to

NavisWorks

8

Revise the activity name in MS project 0.5

Linking of 3D objects to the activities in the

time schedule automatically and manually

1.5

Total 230

4. Lessons Learnt

The three main lessons learnt during this study are as follows.

4.1 Systematical Naming of Drawing Files

It is recommended that participants adopt an identical and systematical naming convention for

drawing files. One method would be to have all files named using 5 digits, where the first digit refers

to the type of the drawing, and other four digits refer to the specific location ID. This is preferable over

naming the drawings according to the locations, in order to avoid the referencing errors that occurred

in the studied case.

4.2 Information Sharing

As shown in 3.2, without information sharing, the names of the elements and the names of activities in

the schedule will not be identical. Therefore it is recommended that the personnel establishing the

construction of the 3D model should consult the scheduler before building the model, and set up an

identical rule for naming activities/stages, so that when incorporate the 3D model and the schedule

into a 4D software package, the automatic linking function provided by the 4D software can function.

4.3 BIM Element Library

As shown in 3.3, each modified or customized element takes on average two hours of labor time. This

is very time-consuming when compared with the two minutes for each built-in element. Therefore it is

recommended that the developers store the elements built in each project so that they can be shared

between projects. Such a BIM-element library would reduce the time for building the customized

elements.

5. Conclusions

This research presents a case study on constructing 3D/4D BIM models from 2D drawings and

paper-based documents using a typical nine-floor building. This study reported the time taken and the

problems encountered in constructing the 3D/4D BIM model, and the approaches employed to solve

the problems. Two hundred and thirty hours of labor were needed to construct a 4163-element BIM

model and incorporate it with a 157-activity schedule for the nine-story building studied (including the

time for personnel training). The results provide contractors some useful empirical data for estimating

the time needed to construct a 3D/4D model from 2D drawings and paper-based documents; it also

provides constructors with some documented experiences learnt from this case study.

References

1. Azhar, S., Hein, M., and Sketo, B. (2008). “Building Information Modeling (BIM): Benefits,

Risks and Challenges”. Proceedings of the 44th ASC Annual Conference (on CD ROM), Auburn,

Alabama, April 2-5, 2008.

2. Bonsang Koo, and Martin Fischer, “Feasibility Study of 4D CAD in Commercial Construction”

Journal of Construction Engineering and Management, Vol. 126, No. 4, July/August 2000, pp.

251-260.

3. Fischer, M. & Kunz. J. 2004. The Scope and Role of information Technology in Construction.

Invited Paper, Journal of Construction Engineering and Management, Japanese Society of Civil

Engineers, accepted for publication.

4. Julian H. Kang, Stuart D. Anderson and Mark J. Clayton, “Empirical Study on the Merit of

Web-Based 4D Visualization in Collaborative Construction Planning and Scheduling” Journal of

Construction Engineering and Management, Vol. 133, No. 6, June 2007, pp. 447-461.

5. Roorda, D., and Liu, M. K. (2008). “Implementation of Building Information Modeling (BIM)

on the Renovation of the Art Gallery of Alberta in Edmonton, Alberta,” Proceedings of 18th

Analysis and Computation Speciality Conference, Vancouver, Canada. April 24-26.

6. Schwegler, B. R., Fischer, M., O’Connell, J. M., Hanninen R., & Laitinen J. 2001. Near-

Medium- and Long-Term Benefits of Information Technology in Construction. CIFE Working

Paper #65, July, 2001.

7. Sheryl Staub-French, Alan Russell and Ngoc Tran, “Linear Scheduling and 4D Visualization”

Journal of Computing in Civil Engineering, Vol. 22, No. 3, May/June 2008, pp. 192-205.

8. Timo Hartmann, Ju Gao, and Martin Fischer “Areas of Application for 3D and 4D Models on

Construction Projects” Journal of Construction Engineering and Management. Volume 134, Issue

10, pp. 776-785 (October 2008).

9. Tulke, J., Hanff, J., 2007. 4D CONSTRUCTION SEQUENCE PLANNING – NEW PROCESS

AND DATA MODEL. 24th International Conference on Information Technology in Construction,

Maribor.

10. V. K. Bansa and Mahesh Pal “Generating, Evaluating, and Visualizing Construction Schedule

with Geographic Information Systems” Journal of Computing in Civil Engineering, Vol. 22, No.

4, July/August 2008, pp. 23-242.