ppt geo syntitics

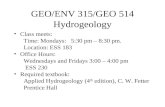

-

Upload

tooba-khalid -

Category

Documents

-

view

226 -

download

0

Transcript of ppt geo syntitics

-

8/7/2019 ppt geo syntitics

1/25

GRI-GT12 SpecificationNonwoven Geotextiles for Geomembrane

Protection

also called geomembrane cushions

weights 340-2000 g/m2 (10-60 oz/yd2)

silent on type of polymer

silent on virgin, rework or recycle

provides different puncture options

all values are MARV, except UV

-

8/7/2019 ppt geo syntitics

2/25

Regarding MARV

minimum average roll value accommodates variation in GT

properties

statistically its the -2 value procedure shown in next screens

-

8/7/2019 ppt geo syntitics

3/25

-

8/7/2019 ppt geo syntitics

4/25

SAMPLE

Field Sampling to Obtain

Average Roll Value

Roll

Width

1.0 m

S-1S-2

S-3

S-4

S-5S-6

S-7

XMD

MD

MD

1.0 m

SampleXMD

Rolllength

Take Specimens from above Sample

and Test as Required

-

8/7/2019 ppt geo syntitics

5/25

Roll NumberTestNumber 1 2 3 4 5 6

1

2

3

4

5

6

7Average =

643N

627

652

629

632

641

662641

627N

615

621

616

619

621

622620

637N

643

628

662

646

633

619638

642N

646

658

641

635

642

658646

652N

641

639

657

642

651

641646

637N

624

631

620

618

633

641629

This is MARV Value!

-

8/7/2019 ppt geo syntitics

6/25

Listed Properties

1. mass per unit area2. grab tensile strength and

elongation

3. trapezoidal tear

4. various puncture strengths

5. ultraviolet resistance

-

8/7/2019 ppt geo syntitics

7/25

1. Mass per Unit Weight

generally referred to as weight follows ASTM D5261

5 specimens across roll width

average value is determined

develop MARV to compare to spec

6-categories from 340-2000 g/m2

(10-60 oz/yd2)

-

8/7/2019 ppt geo syntitics

8/25

D5261Mass/Unit Areai.e., Weight

-

8/7/2019 ppt geo syntitics

9/25

2. Grab Tensile Response follows ASTM D4632

10 specimens MD & XMD across width

100 mm wide; gripped in center 25 mm

must avoid slippage or grip failure record maximum strength in kN (lb)

record elongation at max. strength

(/L) 100 = % elongation develop MARV for strength and

elongation and compare to spec

-

8/7/2019 ppt geo syntitics

10/25

D4632 - Grab Tensile Test(Evaluates Strength and Elongation at Failure)

-

8/7/2019 ppt geo syntitics

11/25

3. Trapezoidal Tear Strength

follows ASTM D4533

tear propagates from an initial cut

maximum value is recorded

10 specimens in MD and XMDacross roll width

take average value of lowest develop MARV and compare to

specification value

-

8/7/2019 ppt geo syntitics

12/25

D4533 - Trapezoidal Tear Strength(Evaluates the Maximum Value)

-

8/7/2019 ppt geo syntitics

13/25

4(a) Puncture (Pin) Strength

follows ASTM D4833 uses a 8 mm (5/16 in.) probe

15 specimens across roll width

take average value

develop MARV and compare to

specification value

-

8/7/2019 ppt geo syntitics

14/25

D4833 - Puncture (Pin) Strength(Evaluates Strength at Rupture)

-

8/7/2019 ppt geo syntitics

15/25

4(b) Puncture (Pyramid) Strength

follows ASTM D5494, Method B

uses a pyramid shape pointed probeon GT on metal substrate

contact made with underlyingsubstrate registering electric signal

10 specimens across roll width

take average value

develop MARV and compare to spec

-

8/7/2019 ppt geo syntitics

16/25

D5494 - Puncture (Pyramid) Strength(Evaluates Strength at Metal Base Plate Contact)

-

8/7/2019 ppt geo syntitics

17/25

4(c) CBR Puncture Strength

California Bearing Ratio (CBR) is a soil

strength test adopted for geosynthetics follows ASTM D6241 using the same device

probe is 50 mm (2.0 in.) diameter

container is 150 mm (6.0 in.) diameter

10 specimens across roll width

strength and deformation monitored take average value of each

develop MARV and compare to spec

-

8/7/2019 ppt geo syntitics

18/25

-

8/7/2019 ppt geo syntitics

19/25

CBR Relationships(a) for wide width strength

where

Tf = tensile force per unit width of fabric (kN/m),

Fp = puncture breaking force (kN), and

r = radius of the puncturing rod (m).

(b) for strain at failure

where

x = diagonal elongation of the geosynthetic at failure (m)

a = horizontal distance between the outer edge of the plunger and

the inner edge of the mold (m).

r/2FT pf =

( )100

a

axf

=

-

8/7/2019 ppt geo syntitics

20/25

Puncture Interrelationships

0

500

1000

1500

2000

2500

3000

0 10 20 30 40 50 60 70

CBR (5 x PIN)

Pyramid (2 x PIN)

Pin (Base)

Lb

0

500

1000

1500

2000

2500

3000

0 10 20 30 40 50 60 70

CBR (5 x Pin)

Pyramid (2 x Pin)

Pin (Base Value)

Lb

GT Mass (oz/yd2)GT Mass (oz/yd

2)

-

8/7/2019 ppt geo syntitics

21/25

5 Ultraviolet Resistance follows ASTM D4355 (Xenon Arc)

500 hours exposure

cycled at 90 min. light; 30 min. light

and water spray 50 mm strip tensile per D5035

5 MD and 8 XMD and values averaged

70% strength retained from original

-

8/7/2019 ppt geo syntitics

22/25

TypicalXenon Arc

Weatherometer

-

8/7/2019 ppt geo syntitics

23/25

Interior Chamber

of Xenon ArcWeatherometer

-

8/7/2019 ppt geo syntitics

24/25

-

8/7/2019 ppt geo syntitics

25/25