Power Transmission Shaft Irmydel Lugo Victor Molina Eladio Pereira.

-

Upload

kerry-simmons -

Category

Documents

-

view

214 -

download

0

Transcript of Power Transmission Shaft Irmydel Lugo Victor Molina Eladio Pereira.

Power Transmission Power Transmission ShaftShaft

Irmydel LugoIrmydel Lugo

Victor MolinaVictor Molina

Eladio PereiraEladio Pereira

PurposePurpose

To design a shaft that transmits 40 To design a shaft that transmits 40 HP of power.HP of power.

It will be designed for infinite life.It will be designed for infinite life. Also, it will be as light as possible Also, it will be as light as possible

(mass minimized)(mass minimized)

ApplicationsApplications

Electric motorsElectric motors TurbinesTurbines Automotive transmissionAutomotive transmission Manufacturing processesManufacturing processes

ConsiderationsConsiderations

The torque acting on the shaft is The torque acting on the shaft is fluctuating as the angular velocity fluctuating as the angular velocity changes.changes.

The shaft will have cross sections of The shaft will have cross sections of different diameters, which will make different diameters, which will make it more difficult to analyze it more difficult to analyze dynamically. dynamically.

ConsiderationsConsiderations

It was challenging to analyze all the It was challenging to analyze all the four possible most critical sections four possible most critical sections and the effect of the fluctuating force and the effect of the fluctuating force on them.on them.

The force is not changing sinusoidally, The force is not changing sinusoidally, but it is decreasing exponentially as but it is decreasing exponentially as the angular velocity increases.the angular velocity increases.

Force vs. RPMForce vs. RPM

Why is this Shaft Why is this Shaft Different?Different?

The design is relatively large, but it The design is relatively large, but it can be made smaller or bigger and it can be made smaller or bigger and it will work in the same way, as long as will work in the same way, as long as the proportions of diameters is kept. the proportions of diameters is kept. That makes it unique.That makes it unique.

This shaft will resist for an infinite life This shaft will resist for an infinite life and at the same time it will be and at the same time it will be economical.economical.

Principal ChallengePrincipal Challenge

Our biggest challenge with this Our biggest challenge with this project was finding the forces that project was finding the forces that were acting on the shaft, because were acting on the shaft, because they fluctuate with the revolutions they fluctuate with the revolutions applied (from 100 rpm to 3000 rpm)applied (from 100 rpm to 3000 rpm)

ChallengesChallenges

Another challenge was designing for Another challenge was designing for a light material, but at the same time a light material, but at the same time resistant to fatigue and deflection resistant to fatigue and deflection and to have infinite life. and to have infinite life.

Finding a material to cover our Finding a material to cover our requirements, but being economical requirements, but being economical at the same time.at the same time.

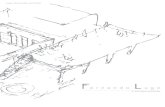

ShaftShaft

ShaftShaft

Design DetailsDesign Details

These calculations were made with 3000 RPMThese calculations were made with 3000 RPM

Design DetailsDesign Details

For the next step, we made a diagram show how the For the next step, we made a diagram show how the forces are applied at the point of the spur gear, we forces are applied at the point of the spur gear, we assumed the angle of attack for the teeth of the spur assumed the angle of attack for the teeth of the spur

gear is 20ºgear is 20º

StressesStresses

Section with diameter of 2 in:Section with diameter of 2 in:

StressesStresses

Section with diameter of 4.8 in:Section with diameter of 4.8 in:

StressesStresses

Section with diameter of 6 in:Section with diameter of 6 in:

Material Selection:Material Selection:

To minimize the mass we have to To minimize the mass we have to minimize the relation . minimize the relation .

.

Material Selection:Material Selection:

Amongst the best materials to be used are Amongst the best materials to be used are aluminum alloys, titanium alloys and steel. aluminum alloys, titanium alloys and steel.

Also the ceramic and carbon fiber alloys, but Also the ceramic and carbon fiber alloys, but due to the fact that the forces and stresses are due to the fact that the forces and stresses are so high, it is not recommendable to use them. so high, it is not recommendable to use them.

Aluminum 2024-T4 has the lowest ratio with 1.68Aluminum 2024-T4 has the lowest ratio with 1.68 Beta Titanium Alloy has a relation of 2.70 Beta Titanium Alloy has a relation of 2.70 1020 Steel has a relation of 2.85. 1020 Steel has a relation of 2.85.

DeflectionDeflection

The maximum deflection occurs at The maximum deflection occurs at wherewhere a a and and bb are the distances between are the distances between the applied force and the supports, where the applied force and the supports, where b > ab > a..

DeflectionDeflection

At this point the maximum deflection is At this point the maximum deflection is obtained by the following equation; where obtained by the following equation; where PP is 168.064lb, I is .78233 in^4 and L is 28 is 168.064lb, I is .78233 in^4 and L is 28 in. in.

DeflectionDeflection

We obtained the value of E for Al-2024 T-4 We obtained the value of E for Al-2024 T-4 (E = 10602 KSI), ASI-1020 (E = 29732 (E = 10602 KSI), ASI-1020 (E = 29732 KSI) and Ti-15Mo5Zr3Al (β titanium alloy) KSI) and Ti-15Mo5Zr3Al (β titanium alloy) (E = 10878 KSI).(E = 10878 KSI).

Calculating Safety FactorCalculating Safety Factor

Calculating Safety FactorCalculating Safety Factor

Calculating Safety FactorCalculating Safety Factor

Calculating Safety FactorCalculating Safety Factor

The safety factor was calculated by taking The safety factor was calculated by taking into consideration that we use infinite life into consideration that we use infinite life as a goal of the design. as a goal of the design.

The highest safety factor was obtained by The highest safety factor was obtained by titanium, followed by steel and aluminum titanium, followed by steel and aluminum respectively.respectively.

Weakness of Our Shaft

There is no curvature between the There is no curvature between the sections of different diameters (no sections of different diameters (no notch), so there are no stress notch), so there are no stress concentrations to make the shaft concentrations to make the shaft more resistant to fatigue fracture. more resistant to fatigue fracture.

ConclusionsConclusions

We learned what materials we should We learned what materials we should have in mind when designing a shaft.have in mind when designing a shaft.

We also learned that the safety factor is We also learned that the safety factor is different for each section of the different for each section of the component, so we should use the one component, so we should use the one of the most critical area. But we have to of the most critical area. But we have to analyze all the possible critical sections, analyze all the possible critical sections, even if it is very exhausting.even if it is very exhausting.