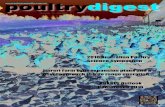

Poultry Digest February/March 2012

-

Upload

primary-media -

Category

Documents

-

view

255 -

download

5

description

Transcript of Poultry Digest February/March 2012

PrintPost Approved PP243096/00007 ISSN 1444-8041

Volume 27, Number 4

February/March 2012

New technologyfingerprints 37 different mycotoxins

in feed

Murphy’s CrossingFree Range Eggs –an evolving andsuccesful family

business

AustralianPoultryScienceSymposium2012

PoultryDigest

PDFebMar2012:PDFEBMAR09 5/04/12 4:27 PM Page 1

Vaxsafe® PM is a new product funded by the Australian Poultry CRCfor the Australian poultry farmer to help control Fowl Cholera.

This live vaccine o�ers signi�cant improvements in controlof Pasteurella multocida (PM) over previous vaccines.

Its broad protection means it is the �rst stop forPM control irrespective of what PM you have.

Brought to you by Bioproperties to help prevent blood from staining the wattle**Apologies to Henry Lawson

Phone (03) 9876 0567Fax (03) 9876 0556bioproperties.com.au

Vaxsafe PM

The new vaccine for Fowl Cholera

PDFebMar2012:PDFEBMAR09 5/04/12 4:27 PM Page 2

OFFICe aDDRess:7 Kerns Rd, Kincumber Nsw 2251Ph: (02) 4368 2220 Fax: (02) 4368 2260sUBsCRIPTIONs: aUsTRaLIa One year – $55.00*.send payment and full details to (subscritpions only): Primary Media, GPO Box 1846, sydney Nsw 2001New ZeaLaND One year – $a80. OTHeR COUNTRIes asia Pacific including thesubcontinent – One year: airmail – $a80; Rest of the world – One year: airmail – $a92. send payment in australian dollars. *australia subscription rate includes GsT.

CHaNGe OF aDDRess FOR sUBsCRIPTIONsONLy: send details, along with the old addresslabel, to GPO Box 1846, sydney Nsw 2001(subscriptions only).aLL MaTeRIaL COPyRIGHT (editorial and advertisements)and may not be reproduced without the written consent ofthe publishers. whilst every care is taken to ensure the accuracy of the contents of POULTRy DIGesT, the pulishersdo not accept any responsibility or liability for the material herein.

editorial enquiriesPeter Bedwell or Rosemary embery0419 235 288 or 0409 944 472

sales: Peter BedwellPhone: + 61 2 4368 2220Mob: 0419 235 288 or Mob: 0409 944 472Fax: + 61 2 4368 2260 email: [email protected]: www.primarymedia.com.au

POULTRy DIGesT consists of a bi-monthly manage-ment magazine and an annual industry review. Published by C D supplies Pty Ltd (aCN 091 560 557)

Production: Rosemary emberyemail: [email protected]

News

4 Australian Poultry Science Symposium 2012

The 23rd Australian Poultry Science Symposium (APSS) 2012, held on February19-22 at the University of Sydney Camperdown Campus, offered a record 250attendees a packed program and added new dimensions to a proven format.

18 10th Alltech APSS Breakfast

After an opening address by Alltech’s Business General Manager, Adam Naylor,the first speaker at the 10th Alltech Australian Poultry Science Symposium (APSS)Breakfast was Jorge Pena, Alltech’s Technical Manager who described the LatinAmerican commercial industry and that of Chile in particular.

32 BEC celebrates 25 years of successful operation

Brisbane based BEC Feed Solutions held a lunch on February 24 2012 at itsCarole Park facility for customers, suppliers, friends and staff to celebrate its 25thyear of operation.

10 COVeR sTORy Murphy’s Crossing Free Range eggs – an evolving and successful family business

Murphy’s Crossing Free Range Eggs, located at Wasleys in South Australia, is a successful family run business operated by Stephen and Trish Simpson. Originally thefarm was a conventional cage layer operation but has evolved into a free range configuration housing 10,000 hens in three sheds.

26 MaNaGeMeNT FeaTURe

Comparison of performance of commercial conventional and free range broilers

Comparisons of the performance of free range and conventionally housed broilerchickens are scarce. A new free range operation was recently established and an opportunity to compare its progressive performance with conventional broilers under similar management practices and nutrition was taken.

20 NUTRITION FeaTURe New technology fingerprints 37 different mycotoxins in feed

In view of changing weather and the changing volumes of grain and commodities traded internationally, mycotoxins are front of mind with many producers inAustralasia. There are more than 500 identified mycotoxins, yet until recently, the ability to test for mycotoxins has been limited to relatively few mycotoxins, and theaccuracy of some tests is considered by many to be only semi-quantitative at best.

Stephen Simpson, Murphy’s Crossing

February/March 2012Volume 27, Number 4

Contents

PoultryDigest

Vaxsafe® PM is a new product funded by the Australian Poultry CRCfor the Australian poultry farmer to help control Fowl Cholera.

This live vaccine o�ers signi�cant improvements in controlof Pasteurella multocida (PM) over previous vaccines.

Its broad protection means it is the �rst stop forPM control irrespective of what PM you have.

Brought to you by Bioproperties to help prevent blood from staining the wattle**Apologies to Henry Lawson

Phone (03) 9876 0567Fax (03) 9876 0556bioproperties.com.au

Vaxsafe PM

The new vaccine for Fowl Cholera

POULTRY DIGEST, February/March 2012 3

PRODUCT NEWS40 New solutions to old problems from OEC

PDFebMar2012:PDFEBMAR09 5/04/12 4:27 PM Page 3

4 POULTRY DIGEST, February/March 2012

News

The 23rd Australian Poultry ScienceSymposium (APSS) 2012, held onFebruary 19-22 at the University of SydneyCamperdown Campus, offered a record250 attendees a packed program and addednew dimensions to a proven format.

On Sunday 19, an informal AvianScience Forum held at RydgesCamperdown resulted in two thought provoking presentations from MamduhSifri (ADM Alliance Nutrition USA) andNan-Dirk Mulder, Rabobank Europe.

‘Future Challenges in the Poultryindustry – Biological and NutritionalResponse Limits’ was Mamduh’s topic.‘Crossroads for growth: changing commod-ity markets urge poultry industry tochange’, was the subject of Nan-Dirk’spaper.

Both presenters are absolutely at thetop of their game and the informal natureof the forum allowed for plenty of discussion before the drinks and snackswere served.

The evening set the tone for what wasto be a great symposium.

Judy O’Keeffe, President of the PoultryResearch Foundation (PRF) and AaronCowieson, Director of the PRF, opened theSymposion and SARDI’s Bob Hugheschaired the first session, ‘Free RangeCompared with Conventional PoultryProduction’.

There was no doubt about the factthat this subject was of vital interest – therewas hardly a spare seat in the WebsterTheatre as Birger Svihus from theNorwegian University of Life Sciencesdelivered his paper, ‘Gastrointestinal TractDevelopment: Implications for free rangeand conventional production.’

“By allowing birds access to an outdoorarea in free range poultry production, theywill be able to consume forage such asfibrous plant materials and grit stones.

“This will facilitate gizzard develop-ment potentially resulting in better nutri-ent utilisation and a bird more resistant toenteric diseases,” Dr Svihus said.

In summing up Dr Svihus pointed outthat, “birds (in free range production) willpossibly be stimulated to a more extensiveuse of the crop as an intermediate storageorgan, and that these changes could resultin improvements in nutrient utilisation.”

‘Nutritional immunity: Possible chal-lenges in free range production’, was thetopic prepared by Brooke Humphrey of

Cargill Animal Nutrition USA, but delivered by Eugeni Roura from theUniversity of Queensland.

“The objective of the study was to provide a basic understanding of nutritionalimmunology with a special emphasis onhow use of free range production systemsmay influence applicability of this approachto affect animal productivity and welfare,”Dr Ruora said.

Don Thomas from Massey UniversityNZ spoke next on the topic of ‘Influenceof whole wheat inclusion and pellet diameter on the performance and gizzarddevelopment of broilers’.

Berger Svihus got his second run of theday when he presented a paper prepared byAdam Sacranie of Nutreco Spain whosetravel plans were upset by Australia’s visarequirements.

“The effect of insoluble fibre and inter-mittent feeding on gizzard development,gut motility and performance in broilerchickens,” were the subjects of the study.

Tugrul Durali, a postgraduate studentat Sydney University, is studying the effectsof free-range production on broiler produc-tivity.

As farm manager at Red Lea Chickens,he is in a unique position to deal with thistopic as Red Lea has established new free-range broiler farms as well as expanding itsconventional tunnel ventilated fullyenclosed production.

His paper ‘Comparison of performanceof commercial conventional and free rangebroilers’, is run at length in this issue ofPoultry Digest.

The free range compared with conven-tional poultry production session continuedwith Paul Iji from University of NewEngland in the chair and the first invitedspeaker Juha Apajalahti from Alimetrics,Finland posed the question, ‘Does thecomposition of intestinal microbiota deter-mine or reflect feed conversion efficiency?’

“The importance of intestinal micro-biota for the performance of broiler chick-ens has been studied for decades,” he statedas he introduced his paper.

Robert Swick from University NewEngland revealed interesting research into‘The effect of litter material and dietaryfibre on gut development, gut microfloraand performance’.

“Results of trials indicated a perfor-mance benefit for dietary oat hulls inyoung broilers especially those reared on

australian Poultry science symposium 2012

1.Sonia Yun Liu, University of Sydney.2. Shokri Oramary, University ofQueensland. 3. Penelope Steer,University of Melbourne. 4. MichaelKidd, University of Arkansas, USA.

1

2

3

4

w

PDFebMar2012:PDFEBMAR09 5/04/12 4:27 PM Page 4

PDFebMar2012:PDFEBMAR09 5/04/12 4:27 PM Page 5

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 6

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 7

News

8 POULTRY DIGEST, February/March 2012

Nobilis®

For product enquiries contact Robin Anderson Mobile: 0424 197 640

For orders contact Customer Service Free Call: 1800 033 461 or Free Fax: 1800 817 414

MSD Animal Health91-105 Harpin Street, Bendigo East VIC 3550

Free Call: 1800 033 461www.msd-animal-health.com.au

PROTECTING YOUR

INVESTMENT Gumboro & ND VaccineEDS & ND Vaccine

Inactivated vaccine for the protection of IBD, EDS and Newcastle Disease.

paper litter,” he revealed.Ken Bafundo from Phibro Animal

Health USA spoke on the topic of‘Semduramicin and nutritional responses:the effects of protein source and concentra-tion’.

Stuart Wilkinson from the Universityof Sydney has long been associated withAPSS, making sure that presentations survived digital technology and appearedon the screen in the Webster Theatre.

Now he is at the other end of that verytechnology presenting his own research:‘Exploiting the calcium specific appetite ofbroilers’.

“In this research a group of 144 Cobb500 broilers were used to investigate ifmodern broilers can regulate calciumintake using choice feeding,” he said.

“The final paper of this session waspresented by Eduardo Serrao from theUniversity of Queensland in which hedescribed “small scale poultry productionin Timor-Leste”.

“Village chickens contribute a criticalsupply of protein to families in the country,”he said.

Wayne Bryden, University ofQueensland, in the chair for the First ShortCommunication Session: Nutrition, wasmerciless with the stopwatch as 15 speakersdelivered their five-minute papers.

That they achieved this on time is acredit to their skills in delivering conciseinformation in a small package.

The final paper of the day, The AvianTaste System was delivered by EugeniRoura, who in summing up currentresearch stated that, “taste receptor researchis far behind that being conducted inmammals”.

“A thorough validation of the sequenceand expression patterns of taste related aviangenes orthologous to those known in mam-malian systems is needed,” he concluded.

On the evening of the first full day ofAPSS, the Gourmet Barbeque WelcomeReception, apart from being an opportunityto enjoy good food, liquid refreshment,catch up with old friends and make newones, is the event which sees the introduc-tion of post graduate and masters students.

This year 26 students were introduced,some already well into their studies as wellas new faces. The Poultry CRC sponsorsthis event.

On February 21 the first session of theday was devoted to ‘Feed Additives:Mythbusters’ and Aaron Cowieson was inthe chair.

The first of the keynote speakers inthis session was Michael Kidd, University

of Arkansas, USA, and in his paper askedthe question ‘Feed additives mythbusters:how should we feed synthetic aminoacids?”

In summing up and in response to thisquestion he stated that, “from an environ-mental standpoint, the inclusion of eachsubsequent amino acid (L-isoleucine and L-arginine) into broiler diets allows for formulating closer to the bird’s require-ment, which reduces overages.

“This leads to a reduction in nitrogenpollution and a likely reduction in theamount of nitrous oxide produced, whichprovides a significant portion of the CO2

equivalence in greenhouse gases,” heexplained.

Michael Bedford from AB Vista UK inthe second of the keynote mythbusterspapers, spoke about ‘Enzymes in the spot-light’.

“Over the past twenty years the use ofenzymes has been refined in practice to thepoint that in most cases they are used successfully and with a good return oninvestment,” he said.

“However some grey areas remain intheir use and in the case of phytase therehas been the association of wet litter.

“Recent work suggests that the ‘wet lit-ter effect’ may be more due to the formula-tion changes made to accommodate theenzyme rather than the use of the enzymeper se,” he concluded.

Greg Siragusa from Danisco USA inhis paper ‘Modern Probiology – Direct fedmicrobials and the avian gut microflora’introduced his paper by stating that,“Direct fed microbials (DFM) – microor-ganisms, which when fed exert beneficialeffects on poultry performance, health andimmunity, routinely demonstrate efficacyin enhanced feed conversion and growthperformance that is comparable to subther-aputic antibiotic usage,” he said.

“The mechanistic basis of the probioticis largely unknown,” he added.

“In concluding his paper Greg Siragusastated that, “though used for over a centuryDFMs were frequently disparaged by skeptics.

“From these very humble beginningshas evolved a scientific foundation tounderstand the biological mechanisms andimprove the technology of probiotics forlivestock.

“Used properly, the efficacy of modernDFMs is rarely debated. Probiotics are notantibiotics: they are a different approach toachieve efficient poultry production.

“This author considers the myth that

v

1. Michael Bedford, AB Vista. 2. IanLean, SBScibus Australia. 3. Bob Pym(left) President WPSA with TrevorBagust, President WVPA. 4. GregSiragusa, Danisco USA.

1

2

3

CONTINUED ON PAGE 44 w

4

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 8

Nobilis®

For product enquiries contact Robin Anderson Mobile: 0424 197 640

For orders contact Customer Service Free Call: 1800 033 461 or Free Fax: 1800 817 414

MSD Animal Health91-105 Harpin Street, Bendigo East VIC 3550

Free Call: 1800 033 461www.msd-animal-health.com.au

PROTECTING YOUR

INVESTMENT Gumboro & ND VaccineEDS & ND Vaccine

INVESTMENTINVESTMENT Gumboro & ND VaccineEDS & ND Vaccine

Inactivated vaccine for the protection of IBD, EDS and Newcastle Disease.

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 9

10 POULTRY DIGEST, February/March 2012

Murphy’s Crossing Free RangeEggs – an evolving and successful family business

By PETER BEDWELL

South Australia and is still involved withthe farm that has evolved into a free rangeconfiguration housing 10,000 hens in threesheds and attached foraging paddocks.

Poultry Digest was introduced to theSimpson family and their innovative layerfarm by long time formulater of the hen’sdiets, Tina Grech, Animal Nutritionist atLienerts Australia, based at Roseworthy inSouth Australia.

Tina has supplied Murphy’s Crossingthrough its transition period to free rangeand worked with the business to obtainoptimum performance using a combinationof supplied materials and the farm’s owncrop production.

The Simpsons didn’t rush into freerange production.

“It was at least a five year process andStephen took much advice from SAARDI’sPhil Glatz whose research work in thepoultry industry is highly regarded,” Trishexplained.

A happy result of working with Philhas been that many students have been onthe farm when trials have been organised. w

Of the three sheds now in operationtwo are hoop barn designs, the first to gointo operation being an adaption of a com-mercially available shed supplied byJacksons of Murray Bridge and the second,a larger unit, was built by a local engineer-ing company Sharmans of Long Plains.

Started pullets, Hy-Line Browns, aresupplied by Scott Harley who representsHy-Line in South Australia. Stephen ishappy with both the performance of thehens and the service provided by Scott.

In the sheds the Jensen automated nestsystem has virtually eliminated any prob-lem with floor eggs, according to Stephen.A Big Dutchman chain feeder system delivers the diets and bell drinkers thewater.

With the move to free range camelower stocking densities in the shed andhoop barns and this, Stephen states, hasresulted in very low mortality rates.

The Simpsons have, by managing theirflocks, eliminated the need for antibioticuse with the exception of one outbreak ofspotty liver some time ago.

Hoop sheds are ideal for free rangehousing at Murphy’s Crossing.

Today Murphy’s Crossing FreeRange Eggs, located at Wasleys in SouthAustralia, is a successful family run businessoperated by Stephen and Trish Simpsonwith the help of sons Lachlan and Angus.

Originally the farm was a conventionalcage layer operation established back in1959 by Stephen’s father, John Simpson.

He set up the farm as an alternative todealing with miscreants as a policeman in

Unfortunately, Fowl Cholera has been a problem in many farms across Australia. But with Poulvac® iPabac® IV it doesn’t have to be.

P. multocida Types 1,3,4 & 3x4.

FOWL CHOLERA IS SCRATCHING ABOUT.

Pfi zer Australia Pty Ltd, 38–42 Wharf Road, West Ryde, NSW 2114. ABN 50 008 422 348. ® Registered Trademark of Pfi zer Australia. PAL0431/PD.

Poultry Health. Performance. Growth.

www.pfizeranimalhealth.com.au

For more information on Fowl Cholera or Poulvac® iPabac® IV,

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 10

w

Unfortunately, Fowl Cholera has been a problem in many farms across Australia. But with Poulvac® iPabac® IV it doesn’t have to be.

P. multocida Types 1,3,4 & 3x4.

FOWL CHOLERA IS SCRATCHING ABOUT.

Pfi zer Australia Pty Ltd, 38–42 Wharf Road, West Ryde, NSW 2114. ABN 50 008 422 348. ® Registered Trademark of Pfi zer Australia. PAL0431/PD.

Poultry Health. Performance. Growth.

www.pfizeranimalhealth.com.au

For more information on Fowl Cholera or Poulvac® iPabac® IV,

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 11

12 POULTRY DIGEST February/March, 2012

Though plenty of thought has goneinto the design and equipment in the shedsthemselves and the management of the Hy-Line Brown birds in a free range environ-ment, the Simpsons’ innovation in the pad-docks is a key element in the success andsustainability of Murphy’s Crossing FreeRange eggs now and into the future.

To create a better overall environment,remediation tree planting has been under-taken and with 400 hectares there is amplescope to grow mostly winter crops – barley,clover peas and triticale have all been successfully grown and now contribute significantly to the overall diets of the hens.

The availability of significant foddercreates opportunities for Tina Grech to puther experience and the capabilities ofLienerts to use in making the most of thefeed materials grown on the Simpson’sfarm.

“Though the hot dry summer monthssignificantly reduce the ability to grow fodder crops, the low moisture levelsreduce disease risk and this combined withan isolated biosecure farm location meanthere is little or no requirement for antibi-otics,” Tina points out.

“Also for consumer appeal of theMurphy’s Crossing Brand, issues likeantibiotic and GE free feed are significantfactors in feed formulation.

“We have to take factors like this intoconsideration and formulate diets that suita variety of housing systems from large cagelayer farms to alternative systems like theSimpson’s farm,” she added.

“Stephen has experimented with deepbanding fertiliser application on their pad-docks and it appears that this practice hasresulted in improved protein levels in theirgrain crops.

“We have developed diets based onthree different rations for the age groupsegregated flocks which are early lay, midlay and late lay, all based on Hy-Line speci-fications.

“Lienerts has an NIR facility in-housewhich greatly assists in the accuracy of ourlayer nutrition program,” Tina explained.

“Obviously in the case of the Murphy’sCrossing Free Range operation, we assumea valuable forage intake during the wintermonths from crops like barley and triticale,”she added.

Good shed design, winter forage cropsand good layer performance are obviouslyvital to the success of the Simpson’s freerange business but so too is their marketingstrategy.

Building the Murphy’s Crossing FreeRange brand through a simple but effectiveweb site and regular participation at grow-ers markets, has generated plenty of bothconsumer and retailer awareness in their

v

Top: Though paddocks offer little forage in summer, winter crops of barley and triticale offer variable diet opportunities. Centre: Hy-Line Brown age group segregated flocks. Above: Ability to deliver fresh eggs that suit consumer needsmeans a growing business.

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 12

Freecall 1800 649 231 w w w.ahs.dupont.com

Extensive investment to assess the safety of Virkon® S for humans

and animals means that operatives have no need for excessive personal

protection during biosecurity procedures. In many countries, Virkon® S

is approved for aerial misting over livestock and for use in drinking

water systems at a dilution of 1:200, and yet, it is proven to be deadly

to over 500 pathogens that can threaten the health of your livestock.

V IR K O N S. ®

©2011 DuPont. The DuPont Oval Logo, DuPont , The miracles of science and Virkon® are trademarks or registered trademarks of E.I. du Pont de Nemours and Company or its affiliates. All rights reserved.

You too can benefit from this wealth of experience by putting Virkon S at the heart of your on farm biosecurity

For your nearest distributor, contact Michael Pritchard M: 0407 764 850

or Lienert Australia P: 1800 649 231 www.lienerts.com.au

KIND TO STOCK & OPERATORS DEADLY TO PATHOGENS

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 13

14 POULTRY DIGEST, February/March 2012

For more information please contact: Potters Poultry, Willey Fields Farm, Willey,Rugby, Warwickshire CV23 0SQ UK Telephone: +44 (0)1455 553234 Fax: +44 (0)1455 [email protected]

locality and further afield.“About 25% of our production sells

through the markets and the rest we deliverto our retailers within 24 hours of lay,”Stephen explained.

“We do our own grading and packingon site and pride ourselves on quick turnaround resulting in the consumer beingable to enjoy fresh eggs – this is veryimportant to us,” he said.

Having tackled optimal shed designand the growth of fodder crops as well asoverall paddock improvement, the nexttask that has attracted Stephen’s interest issustainability.

“We pride ourselves on being able toproduce our eggs with minimal powerusage and we avoid water wastage.

“In the future I would like to look atthe possibility of being able to generate atleast some of our energy requirementsthrough solar cells and utilise our roofspace to harvest rain water.

“In the next 25 years I think that ener-gy and water use will be as significant toprotein production as feed costs have beenin the last two decades,” Stephen predicted.

So where will the Murphy’s CrossingBrand go next? Well like it or not, the areain which the farm is situated will soonbecome a major development area for newhousing.

Though WA and Queensland are mostoften mentioned as the states where growthis being propelled by the minerals andenergy boom, the South Australian econo-my will also be boosted by similar factors aswell as a growing industrial and hi-techcapability.

This means that in the not too distantfuture the Simpsons could be living inclose proximity to thousands of potentialnew customers.

With 400 hectares and plenty of accu-mulated experience the family is wellplaced to expand its business to meet possi-ble future needs in a sustainable and eco-nomically viable way that suits their brandmessage.

It’s not all work on the Simpson’s farm- the family has an interesting collection ofold military vehicles including a WW2Chevy Blitz.

But Trish’s passion is for old LandRovers and lurking in one of the machinesheds is a particularly rare, running andoriginal early Series 1 Landy that almostcertainly was originally acquired for workon the Snowy Mountains Hydro Scheme.

Subsequently it may have spent sometime in military use when South Australiawas host to UK atomic tests and missile tri-als in the fifties.

Trish plans to restore it to roadworthycondition without loosing its originality.

Top: It looks simple but a lot ofresearch with SAARDI went into setting up the free range operationhousing. Centre: Stephen Simpsonwith Lienerts’ Nutritionist Tina Grech.Left: John Simspon (left) set up theoriginal farm in 1959. It was convertedby Stephen (right) to free range.Above: WWII Chevy Blitz, one of anumber of historic vehicles on thefarm.

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 14

For more information please contact: Potters Poultry, Willey Fields Farm, Willey,Rugby, Warwickshire CV23 0SQ UK Telephone: +44 (0)1455 553234 Fax: +44 (0)1455 [email protected]@potterspoultrFax: +44 (0)1455 550593elephone: +44 (0)1455 553234 T

wickshire CV23 0SQ UK ar, WRugbyRugby, W,illeyilley,illey Fields Farm, W, Wyy, WPotters Poultr

For more information please contact: For more information please contact:

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 15

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 16

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 17

18 POULTRY DIGEST, February/March 2012

1. Adam Naylor, Alltech’s BusinessGeneral Manager made the openingaddress at the Alltech APSS Breakfast.2. Jorge Pena, Alltech’s TechnicalManager. 3. Andreas Kocher, Alltech’sAsia Pacific Regulatory Manager.

Michael Seidel (left) from LohmannTiezucht GmbH with Dr GregUnderwood.

Call for a quote: Etienne Misfud on Mob: 0428 481 811 or 0417 481 811 Office: (02) 4774 8764

Fax: (02) 4774 8415 Email: [email protected]

News

10th alltech aPss Breakfast

Lohmann Layers australia to launch in 2012Inghams phases out layer breederoperation

After an opening address by Alltech’s Business General Manager, Adam Naylor,the first speaker at the 10th AlltechAustralian Poultry Science Symposium(APSS) Breakfast was Jorge Pena, Alltech’sTechnical Manager who described theLatin American commercial industry andthat of Chile in particular.

“Chile is a country with a populationof 17 million which consumes 3.42 bilioneggs annually and 27.7 kg of chicken meatper person per anum,” Jorge said.

“The country’s poultry industry is challenged by exotic diseases such as AvianInfluenza, Newcastle Disease, andSalmonella – antibiotic use is vet only andit is a particulary sensitive issue as Chileexports to the EU,” he said.

“Use of Bio Mos instead of resorting toantibiotics during nine months of the yearwhen weather is a challenge in Chile,resulted in a mortality drop from a high inmale broiler birds of 12% to 5.34% and infemale birds of 5.34% to 3.71%,” he added

“On the topic of Actigen use in trials,FCR in broiler production was reducedfrom 1.92 to 1.81 while mortalities werereduced from 3.5% to 1.79%.

“Actigen was developed on the basis ofour knowledge on yeast cell wall chemistryand the understanding of the interactionsof carbohydrates with key receptors in theintestine,” Jorge said.

“It is well established that any

production animal is faced with sub-clinicalchallenges, this challenge will lead to a pro-inflammatory immune response and ultimately a reduction in available nutrientsfor growth.

Up to 9% of dietary nutrients can berequired for the immune response.Dampening this pro-inflammatoryimmune response will make more nutrientsavailable for growth, hence permittinggrowth for the animal. This can mostnotabley be seen in a significant improve-ment in FCR.

“In summary Actigen effectively bindsbacteria with type-1 fimbriae. It is a naturalgrowth permitter developed and testedthrough the science of Nutrigenomics andit helps the animal to effectively utilisenutrients without compromising thedefences,” Jorge concluded.

Nigel Meads, Corporate AccountsManager Alltech NZ, spoke on the topicof mycotoxins in Australian and NZ live-stock production and his outline on Alltechinitiatives to deal with growing mycotoxinconcerns are covered in an article in thisissue of Poultry Digest.

Andreas Kocher, Alltech’s Asia PacificRegulatory Manager was the final speakerat the Alltech APSS Breakfast 2012 and hismain topic was catabolic reaction.

Catabolism refers to chemical reactionsresulting in the breakdown of more complexorganic molecules into simpler substances.

In a significant move for the Australianlayer industry, a new organisation headedup by Dr Greg Underwood with JoeWegryzyn as National Sales and MarketingManager will be officially launched at PIX2012.

Lohmann Layers Australia has signedan agreement with Lohman TiezuchtGmbH to distribute this leading geneticbrand in Australia.

“The launch of Lohmann Brown layerhens will offer the latest internationalgenetics to the Australian layer industry,”said Dr Underwood.

“The Lohman Brown is sold in morethan 100 countries and has proven perfor-mance in a variety of management systems,and especially in alternative and free rangeoperations,” he added.

This initiative comes at a time ofmajor change in the layer industry asInghams exits the sector and the trendtoward alternative production systems continues in 2012.

1

2

3

Ingham’s Enterprises has taken the decisionto phase out its Hisex Brown CommercialLayer Breeder operation during the remainder of the fiscal year 2012.

The Hisex customers have been advisedand the phase out is progressing smoothly.

Ingham’s Stockfeed (Layer Feeds) salesremain unchanged. Contact Joe Wegrzynfor any further enquiries 0407 261 922.

Business relationships are forged overmany years. Ingham’s Enterprises wishes tothank everyone for their ongoing supportand friendship in the past, and during thistime of change.

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 18

Call for a quote: Etienne Misfud on Mob: 0428 481 811 or 0417 481 811 Office: (02) 4774 8764

Fax: (02) 4774 8415 Email: [email protected]

R & E SHEDSBuilt to Last

• Over 20 years experience in building poultry and machinery sheds• All styles of sheds – conventional, free range and tunnel sheds• Well known reputation for fast and efficient erection time without compromising good quality workmanship

• As the owner of R&E Sheds, Etienne Misfud oversees the whole job fromstart to finish

• Repairs, extensions, insurance work to any existing sheds• All sheds can be customised to suit any clients’ needs• All structural steel work manufactured at R&E Sheds, so no delays on completion of the project

• No project too small or large• We travel to all areas of Australia and New Zealand• Fully licenced to build interstate or overseas

R & E SHEDS

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 19

20 POULTRY DIGEST, February/March 2012

• Located 12km from the major centre of Tamworth.• Six sheds on $ per metre square contract• 150,000 birds per batch @ 0.54 density• Substantial five bedroom home with magnificent views• Established trees and gardens surround home, inground pool and new paved entertaining area• Town water gives excellent safe water supply to farm and home• Three phase back up power system and back up water system• 3,000 cubic metres (1500T) of organic fertilizer for pastures• Facilities have had recent upgrades and are well maintained• Once in a life time opportunity to purchase such a sound investment• Suitable for owner operator or run under management

EXCELLENT CASH FLOW PAID MONTHLY*EXTREMELY HIGH RETURNS – LONG CONTRACTS*

This meat chicken farm has been held in the one family for its 36 yearsof operation. It is not often that such a sound and sustainable

investment like this becomes available for purchase.Don’t miss this opportunity to secure your future!

Offered for sale by way of expressions of interestclosing 5.00pm Thursday, April 19, 2012

Scott Waters: 0428 860 435Personalised Professional Service

www.cwrural.com.au

FOR SALELucrative Meat Chicken Farm

NUTRITION FEATURE

New technology fingerprints 37 different mycotoxins in feedBy NIGEL MEADS, Corporate Accounts Manager, Alltech New Zealand

In light of the changing climatic patterns and adverse weather in Australia,New Zealand and the rest of the world,producers are experiencing more difficultieswith mycotoxin contamination in rawmaterials.

In view of this changing weather andthe changing volumes of grain and commodities traded internationally, mycotoxins are front of mind with many producers in Australasia.

There are more than 500 identifiedmycotoxins, yet until recently, the ability totest for mycotoxins has been limited to relatively few mycotoxins, and the accuracyof some tests is considered by many to beonly semi-quantitative at best.

Mycotoxins can have negative conse-quences on the profitability of animal production operations. With recent poorharvest conditions throughout Australiaand New Zealand, it is clear that there is aneed for a wide ranging assessment technology to assist producers make decisions in the face of threat.

Recently in Sydney, representativesfrom the poultry industries in bothAustralia and New Zealand were given aninsight into the latest establishment of newtechnologies that will equip them withaccurate assessments of mycotoxins in theirfeedstuffs.

Traditional methodology has usedeither enzyme linked immune-suppressionassays (ELISA) or thin layer chromatogra-phy (TLC). Both these technologies havehad their limitations, potentially leading toan underestimation of toxicity in feed.

A new technology has been developedby Alltech, a company that is well poised todeliver breakthroughs in the area of myco-toxins. Having supported the research the-sis of 16 PhD and 19 Masters students, thecompany has over 60 peer reviewed articlespublished utilising both in vitro and invivo models.

Following on from a research programat its US bioscience centre, Alltech hasdeveloped exclusive methodologies to

analyse the presence of mycotoxins throughthe use of liquid chromatography doublemass spectrometry (LC-MS/MS) to finger-print mycotoxins both in raw materials andin feed.

Termed 37+, this new approach confersseveral advantages over other technologies;• up to 37 toxins are both identified andquantified in a single test.• the 37+ programme helps detect ‘maskedmycotoxins’ – mycotoxins joined to sugarmolecules that are otherwise missed by traditional methodology. This exposes amore accurate picture of the true toxicity ofthe feed. • rapid analysis, needing only a 16 minuterun time of the equipment, which meansresults are relevant.• Accurate to parts per billion, meaning nosecond guessing is required on the marginsof error.• 37+ can be done on complete feed.Traditional tests lose accuracy when testinga compound feed, now producers havemore flexibility in monitoring.• The 37+ programme allows for the iden-tification of the so called ‘silage’ mycotoxingroup. This is only the second testing facility in the world with this capacity, theother being a research laboratory inScandinavia.

The silage mycotoxins are unfortunately

mis-named. They appear in all feed types,not just silage. In fact, in a recent survey ofNorth American feeds and raw materials,25 from 72 samples had the silage myco-toxin group present, and of those, 21 samples were not silage.

To date, survey work completed inSouth Asia, North America and Europe hasturned up surprising findings.

One phenomenon was the presence ofmultiple toxins. In fact, over 60% of samples in North America containedbetween two and 10 toxins in a single sample.

At the time of writing, current surveywork has been commissioned and is under-way on the 2012 harvest of Australiangrains.

Work on the 37+ programme contin-ues, by constantly researching the futureexpansion of testing beyond 37 mycotox-ins, and with more facilities being estab-lished throughout the Asia Pacific region.

The 37+ programme forms one part ofa four pronged approach that collectivelymakes the Alltech Mycotoxin Managementprogram.

The presentation in Sydney of the 37+programme generated discussion on a topicthat is relevant to all animal producers.Different regional surveys conducted byAlltech show that mycotoxins are anunavoidable risk in animal production.

The 37+ programme offers an excitingnew level of quantification that will helpthe producers make the best decisions inthe face of challenge.

Nigel Meads, Alltech New Zealand.

POULTRY DIGEST Magazine

has moved. New number:

(02) 4368 2220 or

fax: (02) 4368 2260.

Mobile: 0419 235 288.

New address: 7 Kerns Rd,

Kincumber NSW 2251

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 20

• Located 12km from the major centre of Tamworth.• Six sheds on $ per metre square contract• 150,000 birds per batch @ 0.54 density• Substantial five bedroom home with magnificent views• Established trees and gardens surround home, inground pool and new paved entertaining area• Town water gives excellent safe water supply to farm and home• Three phase back up power system and back up water system• 3,000 cubic metres (1500T) of organic fertilizer for pastures• Facilities have had recent upgrades and are well maintained• Once in a life time opportunity to purchase such a sound investment• Suitable for owner operator or run under management

EXCELLENT CASH FLOW PAID MONTHLY*EXTREMELY HIGH RETURNS – LONG CONTRACTS*

This meat chicken farm has been held in the one family for its 36 yearsof operation. It is not often that such a sound and sustainable

investment like this becomes available for purchase.Don’t miss this opportunity to secure your future!

Offered for sale by way of expressions of interestclosing 5.00pm Thursday, April 19, 2012

Scott Waters: 0428 860 435Personalised Professional Service

www.cwrural.com.au

FOR SALELucrative Meat Chicken Farm

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 21

22 POULTRY DIGEST, February/March 2012

On February 23 following APSS 2012, agroup of representatives from feed andpoultry producers in key Asian markets visited the Poultry Research Foundation atthe Camden Campus of the University ofSydney.

Following this the group proceeded toa Red Lea Chickens contract broiler farmat Marulan NSW.

The event was organized by Dr DavidCresswell, principal of Cresswell Nutritionand sponsored by AB Vista. The visitorsincluded representatives from Malaysia(Federal Flour Mill and GymtechFeedmill), Charoen Pokphand, (CP)Indonesia, AB Vista (Singapore &Thailand) and from Thailand, PNP,Sunfeed, Betagro, Topfeed, Thai Food,Varluaid, and CP.

Liberato Castro from Crown PacificBiotechnology, Singapore was also in thegroup.

At the Camden Campus Dr AaronCowieson, head of the Poultry ResearchFoundation and Dr Cresswell welcomedguests and after explaining the researchwork being undertaken by the research unitthe group was shown specific research

projects and visited the feed mill atCamden.

There was a lot of interest in Australianpoultry diets including the use of wholewheat and canola meal. In the SE Asianpoultry sector corn soy diets dominate butas corn costs rise other raw materials arenow more frequently being adopted indiets throughout the SE Asian poultry sectors.

After lunch at the Camden site visitorswere taken to the Marulen broiler farm runby Steve and Keely Lichtenberger whereSydney University post graduate researcherand Red Lea Farming Manager TugrulDurali explained typical features of a

News

asian representatives visit Poultry Research Foundation, Camden

modern Australian broiler farm.“Each of the six sheds has a Skov

computer system tunnel ventilation andhouse up to 45000 birds, “Tugrulexplained.

“Arne Overgard from Skov Australiajoined us for a brief explanation about theSkov tunnel computer system.

“Another reason for the visit was todiscuss wheat based diet and the benefits ofwhole wheat addition.

“We talked about broiler productionin Australia overall with a focus on wheatand sorghum based diets and specificallythe effect of whole wheat addition post pellet on GIT,” Tugrul concluded.

Top: The group at University of Sydney Camden Campus and (centre left)at the Marulen broiler farm belonging to Steve and Keely Lichtenberger.Centre right: Aaron Cowieson explains wheat and sorghum based diets atCamden feed mill. Right: Dr David Creswell (Creswell Nutrition), StuartWilkinson and Aaron Cowieson, Sydney University. Above: The Marulen 6shed farm has 45,000 birds per shed with Skov controllers.

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 22

POULTRY DIGEST, February/March 2012 23

Feed costs too high?

Danisco - more profit from lower feed costs

This is just one of the challenges that Danisco can help you solve.

When the pressure's on, turn to Danisco. As leaders in delivering the

greatest value from Avizyme, Porzyme, Grindazym and Phyzyme XP feed

enzymes and Betafin feed betaine, we are able to offer both the ingredients

and expert knowledge to help keep your feed costs to a minimum.

To find out more please contact your local distributorFeedworks, [email protected] Tel: 03 5429 [email protected] www.feedworks.com.au www.danisco.com/animalnutrition

Maintaining the integrity of the intestinal tract is one of the key drivers of bird performance, processing efficiency and food safety. That’s why poultry producers throughout the world look to Elanco Animal Health to protect their birds against coccidiosis and bacterial enteritis. Our range of quality premixes, supported by global expertise and cutting-edge diagnostic tools, improve the health and performance of millions of birds worldwide every day. For more information about how a customised intestinal integrity program can protect your profitability, call Elanco on 1800 226 324 or visit www.elanco.com.au

Elanco®, Maxiban®, Monteban®, Rumensin®, Surmax® and the diagonal colour bar are trademarks of Eli Lilly and Company. EAH12001

Safeguarding your profitability

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 23

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 24

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 25

26 POULTRY DIGEST, February/March 2012

MANAGEMENT FEATURE

Comparison of performance of commercial conventional

and free range broilersBy T. DURALI*, P. GROVES and AJ COWIESON

Comparisons of the performance offree range and conventionally housed broiler chickens are scarce.

A new free range operation was recentlyestablished and an opportunity to compareits progressive performance with conven-tional broilers under similar managementpractices and nutrition was taken.

Growth, mortality and feed conversionof eight paired batches of broilers from thesame breeder flocks and hatchery in a similar geographical location over 16months was compared.

Although the initial batch performanceof the free range sheds was similar to conventional, the free range performancedemonstrated a continuous decline, withslower growth, higher mortality and deteri-orating feed conversion efficiency overtime. The implications for the industryand consumer and the need to betterunderstand the reasons for this poorer per-formance are discussed.

IntroductionFarm animal welfare is an important

subject in higher income countries particu-larly in the EU, Switzerland, Canada,Australia, New Zealand and the USA especially for commercial poultry production.

It has been demonstrated that there is astrong relationship between Gross NationalIncome and Animal Welfare Legislation(Van Horne and Achterbosch, 2008).According to Bennett’s (1996) study, 21%of respondents were ‘very concerned’ andanother 60% were ‘concerned’ about thewelfare and mistreatment of farm animalsin food production.

Harper and Makatouni (2002) reportedthat the two main reasons behind the pur-chasing of free range products were animalwelfare and a perceived health benefit.

Consumers identify free range productsas more advanced than conventional prod-ucts in terms of health benefits.

Free range broiler production is in its

infancy in Australia but is growing rapidly.In the mid-1990s in Victoria, it was estimated that free range broiler productionper week was around 1000 birds, with totalbroiler production around 171,000 perweek (less than 1% of total broiler produc-tion) (Dixon, 2002).

In 2006, free-range broiler productionaccounted for 4% of total broiler produc-tion and today it is around 15% of totalbroiler production (ACMF, 2011).

Free-range broiler production is associ-ated with poorer bird performance, higher

feed conversion and higher mortality com-pared with conventional broiler produc-tion. This ‘performance gap’ is not wellunderstood but is thought to be as a resultof poorer digestive health, coccidiosis anddysbacteriosis challenge, nutritional inade-quacy and variable pasture consumption.

These performance challenges con-tribute to poor economic sustainability inthe industry.

It is the purpose of this paper todescribe performance of free-range andconventionally-reared broilers at the samelocation, under commercial productionconstraints.

Comparative benchmarking is animportant prerequisite to further exploratoryempirical or mechanistic research.

Materials and methodsTwo farms from the same geographical

area (1.5 km apart) were selected in orderto compare flock performance over time.Placements of day old chicks were synchro-nized as much as possible using the samedonor flocks.

Both farms received an identically formulated diet from the same feed milldiffering only in that the free-range dietdid not contain in-feed antibiotics as perthe requirements of Free Range Egg &Poultry Australia (FREPA, 2009). w

Table 1: Mortality rates by age and production system

ProductionSystem

Free Range

Conventional

P value <

RMSE

0-7 d.

1.262

1.032

0.06

0.2245

0-14 d.

2.025

1.482

0.01

0.3087

0-21 d.

2.806

1.798

0.001

0.3922

0-28 d.

3.819

2.180

0.001

0.7076

0-35 d.

5.281

2.893

0.01

1.2547

Differences between growth rates for each production system were significantonly from day 28-35, resulting in an interaction (P<0.01) between age andproduction system.

Tugrul Durali

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 26

POULTRY DIGEST, February/March 2012 27

w

That’s right - yet again, Fanquip have startled the Poultry industry with breakthrough technology, giving all Poultry Growers fi rst world ventilation at extremely competitive rates, along with signifi cant reductions in both energy and maintenance costs throughout the peak season.

Why not talk to Fanquip today to start revolutionising your input and to maximize valuable time spend on vital areas of farm ventilation and management?

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 27

28 POULTRY DIGEST, February/March 2012

MANAGEMENT FEATURE Dead birds were collected and recorded

daily. Birds on both farms were weighed at7, 14, 21, 28 and 35 days. Feed conversionwas calculated at the end of each batch foreach farm and corrected to 2.45 kg liveweight to be able to compare differentkilling age and final weights. Data wereentered into an Excel spreadsheet andexported to JMP v.8 (SAS Software).

Production system and age were usedas leverage terms in a least square model toexplore the main effects of both and inter-actions between the two on body weightand mortality.

As FCR was only known for a wholebatch (not by age) the main effect of production system only was explored.Significance was set at P < 0.05 and wheredifferences existed means were separatedusing Tukeys HSD.

Results The effects of age and production

system on mortality rate and body weightare shown in Tables 1 and 2. There was asignificantly higher mortality for free-rangecompared with conventional production.Mortality rates for the first week did notdiffer between production systems.However mortality rates from the secondweek and thereafter were significantly different.

Differences in mortality especially inthe second week were mostly the result ofyolk sac infection. Antibiotic treatment isnot allowed in free range broiler produc-tion due to FREPA regulations. On theother hand, in a few batches, predatorattacks occurred (mostly chicken hawks),and resulted in high mortality due to pack-up in the free range broiler farm when freerange broilers had range access.

Discussion and conclusions That free range production systems

return poorer performance in broiler chickens has been previously observed.Weeks et al. (1994) showed that conven-tionally reared broilers had heavier (4.49 ±0.08kg) body weight than free range broil-ers (4.08 ± 0.08kg) at ten weeks of age.

This performance gap was attributed tothe fact that free range broilers performwalking, running and ground peckingbehaviours more often than conventionallyreared broilers and so the poor performancewas associated with increased activity.

The results of the study by Weeks et al.(1994) are comparable to the results presented herein where, at 35d, bodyweights of the conventional birds werearound 7.5% greater than their free-rangecounterparts (Table 2).

Extrapolating the results from the

v current study to the free range broilerindustry in Australia, the impact of thishigher FCR in free range production wouldcost around $8,000,000 per year. Further,the higher mortality in free-range systemsmay be indicative of stronger disease challenges and/or metabolic disorders.

Considerable demand exists for chickenmeat that has been produced under free-range systems and this is expected to growin the foreseeable future. This demand ispartially emotive and linked to anthropo-morphic interpretation of intensive animalpractice.

However, the performance gap is sub-stantial and may not be sustainable in thelong-term. The reasons for this perfor-mance gap are obscure and further researchis required to delineate the effects of theabsence of antibiotic growth promoters andthe effects of range access.

A greater appreciation for the challenges that free-range broilers face,whether immunological, nutritional orbehavioural, will allow more appropriateand strategic intervention by producers onone or all of these axes.

AckowledgementsThe authors gratefully acknowledge the

assistances of free range farm managersNoelene Lewis, Graeme Stewart and conventional farm owner Mark Attard. Thestudy could not have been conducted with-out the support of Red Lea Chickens andthe Poultry CRC.

References:ACMF (2011)http://www.chicken.org.au/page.php?id=6 Bennett RM, (1996) Animal Welfare, 5, 3-11. Dixon J, (2002) The Changing Chicken.University of New South Wales Press Ltd. Pp89-90. FREPA (2009)http://www.frepa.com.au/standards/meat-standards/ Harper GC, Makatouni A, (2002) BritishFood Journal, 104, 2887-299 Van Horne PLM, Achterbosch TJ, (2008)World’s Poultry Science Journal, 64, 40-52. Weeks CA, Nicol CJ, Sherwin CM, KestinSC, (1994) Animal Welfare, 3, 179-192.

*Tugrul Durali is a post graduate researcherat the University of Sydney, Camden Campusand this research for his PhD has been supported by the Poultry CRC.

He is also the Broiler Manager for RedLea Chickens and qualified as a vet inTurkey. He worked in the growing poultryindustry there before coming to Australia.

Table 2: Bird live weights by age

Table 3: Effect of production system on feed conversion rate and growth rate

ProductionSystem

Free Range

Conventional

P value <

RMSE

Production System

Free Range

Conventional

P value <

RMSE

FCR Corrrected to 2.45 kg

1.975

1.874

0.05

0.067

Age Corrrected to 2.45 kg(days)43.25

41.20

0.05

1.551

7 d.

151

156

NS

10.776

14 d.

398

419

NS

25.674

21 d.

803

816

NS

43.674

28 d.

1283

1318

NS

45.485

35 d.

1776

1917

0.001

65.129

FCR corrected to 2.45kg body weight was higher (P<0.05) in the free rangeproduction compared to the conventional production (Table 3). Growth ratewas significantly slower in the free range system than in the conventional production system. Birds in the free range production system required 2 moredays to reach 2.45 kg body weight than those in the conventional system.

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 28

POULTRY DIGEST, February/March 2012 29

Elanco®, Maxiban®, Monteban®, Rumensin®, Surmax® and the diagonal colour bar are trademarks of Eli Lilly and Company. EAH12002

Maintaining the integrity of the intestinal tract is one of the key drivers of bird performance, processing efficiency and food safety. Maxiban® from Elanco Animal Health helps to establish intestinal integrity during the first 28 days of feeding by protecting birds from coccidia. With two synergistic active ingredients, Maxiban improves weight gain and feed efficiency, reduces resistance potential and stimulates the immune system. For more information about how a customised intestinal integrity program using quality premixes from Elanco can protect your profitability, call 1800 226 324 or visit www.elanco.com.au

Intestinal integrity starts with Maxiban

Your savings box:Heat exchanger Earny. A hot tip for cool minds. Be in on the 60 percent cost reduction.

Big Dutchman International GmbH · Germany · Tel. +49-4447-801-0 Fax +49-4447-801-237 · [email protected] · www.bigdutchman.comBD Agriculture (Malaysia) Sdn. Bhd. · Tel. +60-3-33615555Fax +60-3-33422866 · [email protected] · www.bigdutchman.comAustralasian Agricultural Services Pty. Ltd. · Tel. +61-7-33960166Fax +61-7-33960266 · [email protected] Industries, Australia · Mobile +61-427601605 · [email protected] for Australia & New ZealandStephen Cadwallader · Mobile +61-417005462 (AUS)Mobile +64-21525942 (NZ) · [email protected]

Mike Mc Naught · Mobile +61-428271056 (AUS)Mobile +64-21893333 (NZ) · [email protected] for New ZealandLandmore Agri Ltd. · Mobile +64-276880317 · [email protected]

Exceptional efficiencyand fully automatic compressed-air cleaning

� Reduction of heating costs by up to 60 %

� Exchanger element made of special aluminium

� Fully automatic filter cleaning during the grow-out

� Easy-to-clean after the grow-out

� Intelligent process control

� Anti-freeze protection thanks to separate control of fresh and exhaust air

� Ready-mounted unit

� Suitable for old and new buildings

LAYER MANAGEMENT

BROILER MANAGEMENT

BREEDER MANAGEMENT

ENVIRONMENT CONTROL

EXHAUST AIR CLEANING

WASTE TREATMENT

PDFebMar2012:PDFEBMAR09 5/04/12 4:28 PM Page 29

30 POULTRY DIGEST, February/March 2012

How can the poultry industry keep up with the increasing demandfor poultry meat and also stay profitable in a world where trans-parency and sustainability are paramount?

Alltech’s 28th Annual International Symposium, held May 20 –23 in Lexington, Kentucky, aims to answer this question by lookingat solutions from the areas of nutrition and genetics, and fromhighly successful poultry regions in the world.

“Poultry meat has a fantastic reputation for being one of theworld’s healthiest and most versatile products. This has resulted in arise in global demand and also an increasing consumer focus onfood safety, animal welfare and environmental impact,” said NickAdams, co-chair of the poultry seminar.

“At this year’s Symposium the focus will be on maintainingconsumer confidence while sustaining profitability. Both are essential if this industry is to grow at the rate necessary to meetglobal needs.”

Poultry focussed session topics will include:• Smarter Feed Solutions to Start your Birds Better – The facts. • What do Birds Really Need? – The Brazilian perspective on realnutrient requirements, so different from ours. • Reaching New Limits – Genetic advances in poultry and the challenge for nutritionists. • Econometrics – Delivering more eggs by delivering the rightnutrients at the right time.

The 2012 Symposium will be the forum for more than 100presentations by industry experts.

Among the speakers at the poultry session will be Peter Ferket,North Carolina State University, USA; Osler Desouzart, ODConsulting, Planning and Strategy, Brazil; Gertrudes Corção,Universidade Federal do Rio Grande do Sul, Brazil and BillWilliams, Tegel Foods, New Zealand.

Looking to 2050’s burgeoning population, Alltech’s 2012Symposium will focus on ideas for better use of resources,improved business practices and natural nutritional solutions.

New in 2012, breakout sessions will include legal, marketing,information technology and designer food in addition to the popular aquaculture, beef, dairy, equine, poultry, pig, pet and regulatory-focused offerings.

The event is expected to draw more than 2,500 delegates fromaround the world making it the industry’s largest symposium. Tosecure your place at the 2012 Alltech Annual InternationalSymposium, visit www.alltech.com/symposium or contact [email protected].

Act now to save 20% on registration through April 14.

NEWS

Balancing profitability and comsumer demands at alltech’s 28th International symposium

If you would like to advertise in the PIX Preview

edition of POULTRY DIGEST Magazine

call (02) 4368 2220 or Mobile: 0419 235 288.

Email: [email protected]

PDFebMar2012:PDFEBMAR09 5/04/12 4:29 PM Page 30

POULTRY DIGEST, February/March 2012 31

Poultry

Equipment

......aatt iitt’’ss bbeesstt

54 King Street,

Clifton, Q, 4361.

Tel: 07 46973344

Fax: 07 46973532

Email: [email protected]

Broiler Equipment

Breeder Management

Alternate Egg systems

Ventilation

www.stockyardindustries.com

DDiissttrriibbuuttoorrss ooff::

NEWS

Potters Poultry International was recentlyawarded the Manufacturers Seal ofApproval by the American HumaneAssociation for their bird welfare friendlyAviary the Avitier 125-4 + Avinest.

Potters has been making and design-ing aviary systems for more than 22 yearsand this is the latest in the design basedon work carried out on their own farmsand customers around the World.

The Seal was presented to Potters atthe IPE 2012 in Atlanta recently by KathiBrock – Senior Director and Will GillisTechnical Co coordinator for the FarmAnimal Program.

“We are extreamly pleased to achievethe high standards set by the AmericanHumane Association for equipment andwe see this as an endorsement of theresearch we have done in producing aunique, welfare friendly multi-tier systemand nest boxes,” said Mike Button,Export Manager for Potters Poultry

International. “With the changing market to

welfare friendly systems in America we look forward to working further with the industry and AmericanHumane.

Go to [email protected] formore information on these products.

Auspac Ingredientshas appointedHarun Rashid

American Humane Association awardsSeal of Approval to Potters Poultry

AusPac ingredientshas appointedHarun Rashid asManager –TechnicalServices.

Harun qualifiedas a Veterinarian(DVM, 2002) inBangladesh.

After gradua-tion he worked forSquare Pharmaceuticals Ltd (2004 –2009) in the department of VeterinaryTechnical Services and ProductManagement.

He then joined Rivalea (Australia)Pty Ltd (2009 – 2011) where he had theopportunity to work in a large integratedpig production system.

Harun remained at Rivalea until hisenrolment in Veterinary Science atCharles Sturt University.

Overall he has seven years of solidexperience working in intensive poultryand pig production.

LtoR: Justin Potter, Mike Button of PottersPoultry with Kathi Brook and Will Gillis ofAmerican Humane Association.

PDFebMar2012:PDFEBMAR09 5/04/12 4:29 PM Page 31

32 POULTRY DIGEST, February/March 2012

Brisbane based BEC Feed Solutions held a lunch on February 24th2012 at its Carole Park facility for customers, suppliers, friends andstaff to celebrate its 25th year of operation.

Originally established as Brisbane Export Company, an exporttrader of rural commodities, mainly to Europe and Asia, back in1985, the company quickly developed into a domestic supplier.

Richard Reeder one of the founder members of the original andon-going enterprise, described the early days when 3 family groupswith an investment of $10,000 each.

“Our slender resources taught real fiscal diligence as we grew thebusiness,” he said.

“We sent out 8000 letters, got 400 replies which we converted to20 customers in an era when the phone and telex where, apart fromthe mail, the main means of communication.

“Having achieved the original goal of establishing an export ori-ented company the partners were bought out and the businesschanged into a domestic feed supply organization,”Mr Reeder said.

“In 1988 a premix blending facility was established at Carole Parkto be an adjunct to the development and expansion of the feed ingre-dient and additive product portfolio: further expansion took placewhen we acquired an adjacent property and opened a new office andwarehouse facility in 1998.

“Our manufacturing operation was rebuilt in 2005 and thisnot only modernised and greatly increased our production capacitybut enabled us to implement process control and state of the artconcepts that further tightened our quality assurance and auto-mated traceability.

“We aimed to achieve QA systems that would satisfy pharma-cutical rather than feed industry standards,” he said.

“In 2007 we acquired the Adisseo Australia premix and addi-tive business in Carole park and in 2009 this site was designated adedicated non-medicated site, making it the only premixing facility in Australia with this feature.

“Now with a staff of more than 50, many of whom have beenwith us since early days we have developed a business that by giving good service, has grown along with the growers we supply,”Mr Reeder explained.

“Tony Reynolds our finance officer, for instance, has beenwith us for 22 years.

“Our growth through the last 25 years has not been withoutits challenges, including merging companies and a period in thelate 1980s when interest rates hit 23%.

“Every so often we have had to focus on why we are here andhow we intend to face the future, “he said.

“We could not have got to where we are without the help ofour suppliers, consultants, and yes- our bank.

Brett Antonio, the current Managing Director of BEC FeedSolutions said that “Richard Reeder’s optimistic outlook on life

SWEEPS ALL TYPES OF FLOORS:

HANDLES WITH EASE:

KEY BENEFITS:

• Dirt/Clay• Stabilised Rock

• Cement• Various Broom types

to suit floor types

• Square Corners• Uneven Surfaces • Pot Holes

• Corrugated Surfaces • 3600 Around Posts

• Easy Operation• Low Maintenance• Full Parts Backup

• 12 Months Warranty

www.kisstech.com.au

NEWS

BeC celebrates 25 years of successful operation

CONTINUED ON PAGE 43 w

Richard Reeder left) and Brett Antonio, current ManagingDirector of BEC Feed Solutions.

PDFebMar2012:PDFEBMAR09 5/04/12 4:29 PM Page 32

POULTRY DIGEST, February/March 2012 33

A reliable and cost ef fective Betaine

RUTH CONSOLIDATED INDUSTRIES (AUST) PTY LTDUnit 5, 7-9 Kent Road, Mascot NSW 2020 Australia

Telephone: +61 2 9667 0700 • Fax: +61 2 9669 0430Web: www.rci.com.au • Email: [email protected]

Distributed by: National Feed Solution • please phone 02 9609 7922

Lienert Australia • please phone 1800 649 231

fost efost effceliable and A r

etainee Btivecffeceliable and

etaineeliable and

usAienert Leed tional FaN

www:beW+:enohpeleTK9-7,5tinUSNOCHTUR

ase phone 1800 649 231 alia • pletrusase phone 02 9609 7922olution • pleSeed

: yed btributisD

r@ofni:liamE•ua.moc.icr.w216+:xaF•00707669216

202WSNtocsaM,daoRtneKTSUA(SEIRTSUDNIDETADILOS

ase phone 1800 649 231 ase phone 02 9609 7922

ua.moc.icr034096692

ailartsuA02DTLLTYTP)T

Distributed by:

National Feed Solutions • please phone 02 9609 7922

RUTH CONSOLIDATED INDUSTRIES (AUST) PTY LTD

Unit 5, 7-9 Kent Road, Mascot NSW 2020 Australia

Telephone: +61 2 9667 0700 • Fax: 61 2 9669 0430

Web: www.rci.com.au • Email: [email protected]

PDFebMar2012:PDFEBMAR09 5/04/12 4:29 PM Page 33

34 POULTRY DIGEST, February/March 2012

NEWSCommercial free range broiler farm sold for $3.06 million

Colliers International Rural & Agribusinesshas sold a quality commercial free rangebroiler farm located approximately 58 kilo-metres north of Adelaide near Mallala for$3,060,000 and in a separate transaction,the former ‘Pro Poultry’ chicken processingplant at Tailem Bend for $300,000.

“The free range broiler farm known as‘Banero’ was being marketed online onlywhen an approach was made by a motivatedprivate buyer,” said Jesse Manuel, Rural &Agribusiness Executive at ColliersInternational.

He said there is increasing activity inthe general market place for poultry industryassets and most of this is occurring off-market or with limited marketing.

“As well as existing producers andagribusiness funds, there are several partiesfrom outside the industry looking at invest-ment in the sector.”

Mr Manuel said Banero Broiler Farm isa quality chicken grow-out complex whichcurrently operates as a free range farm andcomprises a total land area of approximately50.49 hectares.

“The broiler operation consists of sixclimate controlled tunnel sheds and is contracted to Baiada Poultry, Australia’slargest chicken meat processor.

“This is a significant commercial farm-ing operation, modern compared to manyother broiler farms recently offered to themarket and well located within close prox-imity to Baiada’s processing facility,” hesaid.

“This was an opportunity to secure aproperty with an instant cash flow with agood balance of lifestyle and business.”

In a separate transaction, Mr Manuelsaid the former ‘Pro Poultry’ property wassold to a local investor for $300,000 afterbeing offered for sale late last year.

The property is located approximately100 kilometres east of Adelaide at TailemBend and comprises a site area of approxi-mately 45,980sq m.

“The improvements were constructedover 2006 to 2007 and designed to processup to 50,000 birds (chickens) per week,”he said.

According to Mr Manuel, Australia’spoultry industry continues to emerge as akey sector for property investors as globaldemand for poultry products helps to driveindustry growth.

If you would like to advertise in the

PIX Preview edition of POULTRY

DIGEST Magazine

call (02) 4368 2220 or

Mobile: 0419 235 288.

Email: [email protected]

Jesse Manuel from Colliers International

PDFebMar2012:PDFEBMAR09 5/04/12 4:29 PM Page 34

POULTRY DIGEST, February/March 2012 35

Gameco (NSW) P/L161 Parramatta Rd,

Auburn NSWContact: Mar tyn Templeton

(02) 9648 5856Email:

Gameco Livestock Equipment Supplies

Gasolec G12 Radiant Space Heater42 megajoules per hour capacityApproved for use with natural gas & LPGAGA 7718 to AS4565–2004Specially designed to give even heat distribution to a diameter up to 12 metres

Poultry Farm Sales & Valuations Colliers International Rural & Agribusiness is

a market leader in the sale and valuation of

poultry assets.

Our team has extensive knowledge and

experience in Australia’s poultry sector

representing industry participants and investors in local and global markets.

Contact one of our independent specialists for a

confidential discussion.

Sales Valuations

Jesse Manuel Phil Schell Alex Thamm Nick Cranna

0421 550 242 0418 809 849 0409 595 415 0421 709 915

BROILER FARMS FOR SALE

Dublin Broiler Farm, SA Lethbridge Broiler Farm, Vic

www.colliers.com.au

Poultry Farm Sales & V

Poultry Farm Sales & V

Poultry Farm Sales & V

Poultry Farm Sales & V

aluations Poultry Farm Sales & VPoultry Farm Sales & Valuations

aluations

aluations

Colliers

market a

poultry assets.

team Our

experience

Rural International

the in leader market

poultry assets.

extensive has team

Australia’in experience

Agribusiness & Rural

valuation and sale

knowledge extensive

poultry s Australia’

is Agribusiness

of valuation

and knowledge

sector

representing investors in local and global markets.

Contact one of our independent specialists for a

industry representing investors in local and global markets.

Contact one of our independent specialists for a

confidential discussion.

poultry

participants industry investors in local and global markets.

Contact one of our independent specialists for a

confidential discussion.

and

Contact one of our independent specialists for a

Sales

aluationsVValuations

BROILER F

ARMS FOR SALE BROILER F

ARMS FOR SALE

Jesse Manuel Phil Schell

0421 550 242 0418 809 849

.colliers.com.au www

Jesse Manuel Phil Schell

0421 550 242 0418 809 849

.colliers.com.au

Thamm Nick Cranna Alex

0409 595 415 0421 709 915

Thamm Nick Cranna

0409 595 415 0421 709 915

PDFebMar2012:PDFEBMAR09 5/04/12 4:29 PM Page 35

36 POULTRY DIGEST, February/March 2012

News

Santrev, one of Australia’s leading poultryhouse builders, is well on the way to meet-ing the tight build timelines at theIngham’s South Australia Hamley Bridgebreeder complex.

The 4 farms at the complex will bemore than tripled in capacity and are dueto be completed in the middle of the year;bringing the monumental project of building new sheds and refurbishing theold sheds to a close.

Farm number one was completed ontime and within budget in November withthe first batch of breeders having beenplaced.

Steve Buckley, Inghams Breeder ServicePerson said “the Santrev team has beenmaking excellent progress.

“We have very tight timelines for allfour farms.

“Santrev has been fantastic, working onthree farms simultaneously with up to 80

GRIFCO WINCHES - THERE IS NO EQUIVALENT!

DON’T RISK IT! SPECIFY GRIFCO FOR ALL YOUR SHED WINCHING

MUSCLE

A GENUINE

4

4

100% Australian manufactured with comprehensive 2 year warranty

Super accuratelaser cut frame

– 6mm

K1045 high strength directional shaftTwin self aligning

bearing blocks

$20 million of productliability insurance

1 HP (750W) Grifcodesigned electric motor

Built in limits

Australianmade

reduction box

Genuine

GRIFCO

products

15 Dell Rd, West Gosford NSW 2250 Ph (02) 4323 3877 Fax (02) 4323 3882 Mob 0417 311 225

Email: [email protected] Website www.chamberlainanz.com.au

Full factory supportAustralian

made

santrev has Inghams breeder complex on course

Interior of shed number one at Hamley Bridge breeder complex with Jansen nestsytems and packers, Skov controllers and drinkers and mini-vents from FarmMark.

PDFebMar2012:PDFEBMAR09 5/04/12 4:29 PM Page 36

POULTRY DIGEST, February/March 2012 37

men across the sites. Our CEO KevinMcBain inspected the first farm and wasvery impressed”.

Santrev Director, Garry Sanday who isoverall construction manager, made thedecision to relocate to live near the site forthe duration of the project to ensure therewas hands-on, experienced control, underwhich the project is thriving.

“This project is very important toInghams and to us and we wanted to makesure that we delivered on all our undertak-ings and build a world class breeder facilityto support Inghams in South Australia,”Garry said.

“Santrev was selected by Inghamsbecause of our outstanding success indesigning and bringing large and complexdevelopment projects on time and withinbudget,” Garry said.

“The current success of the project hasnot come without setbacks, but any con-cerns have and will continue to be metwith lasting enthusiasm.”

“There has been some interesting issuesto solve, for instance, the conversion of theexisting breeder sheds to full tunnel,extending them and marrying in the oldwith the new as well as planning for thefull conversion to automated egg collection, packing and storage,” Garrycontinued.

“This is contained within the require-ments of a fully biosecure, shower in/show-er off facility.”

“The redeveloped complex will safe-guard Ingham’s fertile egg production forthe state into the future.

“In an ever more frequent role, Santrevwas engaged as the prime contractor allowing Inghams to only have to deal withone supplier.

“This meant that Santrev took on overall responsibility for all the sub-contractors and equipment suppliers,”Garry said.

“We have worked closely with Inghamsto ensure we are delivering a facility thatwill perform and be reliable for now andwell into the future at high efficiency.

“Products specified include Jansen nestsystems and packers and VDL chain feeders and feed pans supplied through ourexisting arrangements; SKOV controllersand drinkers and mini-vents suppliedthrough FarmMark.

“This will be a facility to rival any ofthe best in the world and we at Santrev arevery proud to be a part of it”.

News

Jabiru Gold Natural and Synthetic Pigment blends.

“The Producers No. 1 Choice for Uniformity of Quality Yolk Colours”

Jabiru Gold Natural Liquid PigmentsJabiru Gold Natural Dry PigmentsJabiru Gold blend of Natural and Synthetic pigmentsboth in liquid and dry formJabiru Natural Red pigment in liquid and dry formJabiru Natural Yellow pigment in liquid and dry formJabiru Red 10% Synthetic Canthaxanthin in liquid formJabiru Astaxanthin 10% dry for Aquatic pigmentationCommercially Proven Throughout AustraliaProducers No 1 Choice for Yolk PigmentationEfficacious, and Highly Stable in dry and liquidsNon Toxic, and easy to include into your layer and broiler rationsSpecialised Multi Filling Liquid Applicators available on requestThe most cost effective way to pigment egg yolks andbroilers

Ray Beazleigh,Jabiru Agribusiness Pty Ltd ABN. 17 117 945 141

PO Box 83, Bowral NSW 2576Telephone 02 4861 5325 Mobile 0418 201 629Fax (02) 4861 1410 E-mail [email protected]

w

w

w

w

w

w

w

w

w

w

w

w

w

PDFebMar2012:PDFEBMAR09 5/04/12 4:29 PM Page 37

38 POULTRY DIGEST, February/March 2012

News

PIX 2012 running from 20-23 May 2012 at the Gold CoastConvention Centre features the trade show with more than 100exhibitors booked for the event.

“This is by far he biggest trade show ever put on for the poultry and stockfeed industries in Australia and in fact twice thesize of PIX 2010 (the first to be held at the Gold CoastConvention Centre).

“In fact, the trade show has come to be seen as a must doevent for suppliers to the poultry industry,” said Rod Jenner,President of the PIX organizing committee.

The Tunnel Ventilation Workshop on Wednesday 23rd May2012 is back by popular demand.

Run by Mike Czarick with Brian Fairchild (University ofGeorgia US), the one day tunnel ventilation management work-shop is aimed at meat chicken growers, though some sections willbe useful to egg producers.

“Mike and Brian will lead discussion about getting the mostfrom your equipment, understanding your flock’s requirements,managing ventilation in various climatic scenarios and innovationin shed design,” revealed Rod.

“In the past this event has been booked out so it is importantto book as soon as possible (www.pix.org.au/program/workshops)to ensure a place,” Rod added.

During the two days of PIX/AMC 2012, a number of freeworkshops will be conducted, covering areas such as breeder management, hatchery management and disease investigation allrun by leaders in their field