Poultry Digest April/May 2014

-

Upload

primary-media -

Category

Documents

-

view

252 -

download

12

description

Transcript of Poultry Digest April/May 2014

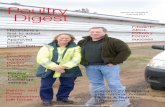

Free range layer farm plans for and survives major bush fire

poultrydigestApril/May 2014

www.primarymedia.com.au

PIX PREVIEWTrade Display 2014

First high efficiency EC fans trial a winner for Victorian broiler grower

PIX/AMC 2014 – a must attend event for growers and the poultry industry

Print Post Approved PP243096/00007 ISSN 1444-8041

Vaxsafe® PM is a new product funded by the Australian Poultry CRCfor the Australian poultry farmer to help control Fowl Cholera.

This live vaccine oers signi�cant improvements in controlof Pasteurella multocida (PM) over previous vaccines.

Its broad protection means it is the �rst stop forPM control irrespective of what PM you have.

Brought to you by Bioproperties to help prevent blood from staining the wattle**Apologies to Henry Lawson

Phone (03) 9876 0567Fax (03) 9876 0556bioproperties.com.au

Vaxsafe PM

The new vaccine for Fowl Cholera

PDJuneJuly2012:PDFEBMAR09 24/07/12 6:55 PM Page 2

poultrydigestwww.primarymedia.com.au

EDITORIAL & DESIGN

Features

News

ADVERTISING

SUBSCRIPTIONS

ENQUIRIES

EDITOR:JOURNALIST/PHOTOGRAPHERPRODUCTION EDITOR

Peter BedwellPhone: (02) 4323 0005Mob: 0419 235 288Email: [email protected]

OFFICE ADDRESS:22 George Street, East Gosford NSW, 2250Phone: (02) 4323 0005Mob: 0419 235 288Production: 0409 944 472Email: [email protected]

Poultry Digest consists of a bi-monthly management magazine and an annual industry review, Poultry Industry Yearbook.Published by C D Supplies Pty Ltd trading as Primary Media (ACN 091 560 557)

All material copyright (editorial and advertisements) and may not be reproduced without the written consent of the publishers. Whilst every care is taken to ensure the accuracy of the contents of POULTRY DIGEST, the publishers do not accept any responsibility or liability for the material herein.

AUSTRALIAOne Year - $55.00*NEW ZEALAND One Year - A$80OTHER COUNTRIESOne Year: Airmail - $A90Please send payment in Australian dollars.Send payment and full details to:22 George Street, East Gosford NSW, 2250*Australian subscription rate includes GST

Peter BedwellAlex Bedwell

Rosemary Embery

3

for the .This

of

*

VaThe new v

Page 10: First high-efficiency EC fans trial a winner for Victorian broiler growerPoultry Digest visited a trial shed of broiler grower Joe Buttigeig in Victoria, where a technical trial was completed to show and test the energy efficiency and reliability of the ebm-papst AgriCool shed ventilation system using high-efficiency EC fans.

Page 22: Free range layer farmer in Newcastle region plans for and survives major bush fire

Page 4: Australia risks ‘missing the boat for golden opportunity in agriculture’ report warns

Page 6: PIX/AMC 2014 – a must attend event for growers and the industry

Page 28: Has the poultry industry lost control of its destiny and where do we go from here?

Page 44: PIX Preview Trade Display 2014

April/May 2014

Back LtoR: Joe Colla (Agricultural Automation); Luke Colla (HmiElectric); Christopher Hauck (ebm-papst); Andy Walker (ebm-papst); Alexandra Gray (ebm-papst) Dr Simon Bradwell (ebm-papst). Front: Joe Buttigeig.

When bush fires tore through NSW in late 2013 one free range layer farm that was threatened was June and Kerry Fuller’s from Campvale in NSW.

NEWS

4

Australia risks ‘missing the boat for golden opportunity in agriculture’ report warnsAustralia risks missing ‘a golden opportunity’ to grow its agricultural sector, and addressing this requires a concerted and coordinated approach from all sector stakeholders, a new report on the competitiveness of Australian agribusiness has warned.

‘Agriculture in Focus 2014: Competitive Challenges’, by agricultural banking specialist Rabobank, said Australian agribusiness is facing mounting competitive threats throughout the supply chain, which require resolute and aligned action from industry and government.

The report, which examines Australia and New Zealand’s agribusiness sectors, identifies six key challenges affecting the competitiveness of Australia’s food and agribusiness industries, which are increasingly coming under threat from a growing group of highly-resourceful international competitors, including countries in South America, Eastern Europe and even Asia.

The report says the critical areas which need to be addressed as a matter of priority are: • rising production costs both on-farm and beyond farmgate • international market access • logistics infrastructure (in)efficiencies • regulatory pressures • capital constraints and • product innovation and development.

Rabobank General Manager Food & Agribusiness Research and Advisory Luke Chandler said “while the rising demand growth for food from our Asian neighbours remains a golden opportunity, Australia risks missing the boat without a more co-ordinated effort from industry and government in addressing these factors, which threaten to impact Australia’s future competitiveness in world export markets.

“Broadly speaking, while the competiveness of Australia’s food and agricultural sectors has generally compared favourably in a global context in the past – and this has underpinned our prominent role in global agribusiness markest – this situation is far from static,” he said.

“Many of Australia’s competitors in agricultural markets around the world

are investing heavily and becoming much more productive, and this is very much raising the bar for our agricultural industries.”

Mr Chandler said food and agriculture is becoming the subject of increased focus from governments around the world as the challenge of meeting the food needs of a growing and wealthier global population places pressure on farming enterprises.

“However, we need to realise that Australia is not the only agricultural exporter looking to capture this increasing demand,” he said. “Over the past decade highly-resourceful developing countries have begun to assume a greater role in the global export trade of food and agriculture products.

“The potential of countries in South America and Eastern Europe is obvious, but even some major food-importing countries and regions, such as China and the ASEAN-5 nations, are playing a greater role in shaping the export landscape.”

As opportunities to boost direct on-farm cost competitiveness become harder to realise in Australia, the report says, the nation’s food and agribusiness sector must look to broader factors to maintain its competitive edge.

Market access challenges The report notes, for example, the

pressing issue of improving Australia’s international market access, where the process of de-constructing trade barriers in foreign markets is proving to be “very complicated and drawn out”.

As a case in point, in the area of international market access for beef, the report says increased lobbying

from international competitors is risking Australia being left behind when it comes to global market access and trade relationships.

“Negotiating ‘most favoured nation’ status for Australia’s food and agriculture suppliers in key markets would ensure local suppliers aren’t needlessly being placed at a disadvantage to our competitors,” Mr Chandler said. “This includes prioritising the further seven Free Trade Agreements (FTAs) Australia currently has in progress, not including the FTA with Korea which is soon to be ratified. Including Korea, the countries involved in these FTAs account for 45% of Australia’s current trade.”

In addition, Australia’s beef industry must set itself apart by investing in strengthening relationships and knowledge exchange frameworks with their foreign counterparts.

“Clearly there is a fundamental need for industry to build even closer working relationships with counterparts in foreign markets through the greater exchange of technology and education, and sometimes investment downstream in the supply chain to provide greater reassurance around long-term supply,” Mr Chandler said.

Inefficiencies in logistics infrastructure

Addressing the inefficiencies in Australia’s logistics infrastructure is another priority in lifting the competitiveness of the agricultural sector, the report says.

“Higher on-farm costs and slowing productivity growth in many sectors in Australia relative to global peers have increased the importance of driving efficiencies in alternate parts of the supply chain,” said Mr Chandler.

“In the grain industry for example, strong infrastructure and quality improvements by our global competitors is exposing a relative lack of investment in Australian grain logistics infrastructure and the corresponding level of efficiency with which Australian grain reaches export markets,” he said.

“This requires commitment to a unified industry-wide, long-term strategy to invest in infrastructure improvement which involves unilateral

“The report indentifies six key challenges affecting the competitiveness of Australia’s food and agribusiness industries”

w

advert_AA_poultrydigest_A4_23.09.11.pdf 1 23/09/11 10:04 AM

Ph: (03) 5979 [email protected]

VictoriaAgriculturalAutomationPh: (03) 5979 1666

6

NEWS

PIX/AMC 2014 – a must attend event for growers and the poultry industryThe Poultry Information Exchange (PIX) has always been a vital event for all in the commercial poultry industry but the 2014 PIX is particularly important if only for the significant changes that have taken place since 2012.

In that year PIX combined with the Australian Milling Conference (AMC) and now in May 2014 these two important industry groups combine to again delivering a bigger and better trade exhibition as well as conference papers with greater depth and relevance to modern poultry production.

The combination of animal rights activism; consumer and social pressure groups and the immense power of our two big retailers, have fundamentally changed the production protocols for both broiler chicken meat and eggs.

There is little doubt that retailers would like to sell as much free range product as they claim consumers want, but this situation has been affected by the hard line attitude taken by the Australian Competition and Consumer Commission (ACCC) to both labeling and definition of ‘free range’.

This situation has lead to the creation of both RSPCA and now FREPA accredited broiler meat and eggs.

So rapid has been the expansion of ‘welfare friendly’ production that many in the industry are unsure about what it all means for them and the future of the industry.

Visitors to the combined PIX/

AMC 2014 will be spoilt for choice in the quality of speakers and the topics they cover as well as making sufficient time to visit the 130 plus stands in the exhibition hall so its worth planning ahead.

Go to the PIX/AMC 2014 website at www.pix.org.au and look at the programs for both events and then look at the exhibitors list to make sure you don’t miss the vast array of products, services and on-stand advice this event offers.

After the opening address and keynote speakers on Monday May 26, Philip Wilkinson from UK 2 Sisters Food Group will discuss UK experiences with real outcomes of more stringent welfare standards.

Philip was long experience in running not only a major chicken integrator business but in dealing with often conflicting supermarket requirements.

Next Heather Neil, head of the RSPCA (Australia) asks and answers the question, ‘Has the introduction of RSPCA standards improved chicken welfare?’

Next industry experts James Kellaway AECL traces his ‘Roadmap towards animal welfare standards – egg industry,’ and Vivien Kite, ACMF does the same for the broiler industry.

In the Concurrent Sessions (Arena 1B. chicken meat) the last speaker just before ‘beeroclock’ is Steve Teitzel, an experienced broiler grower whose

topic is ‘Retrofitting sheds to meet RSPCA standards’. This is definitely a topic broiler growers need to learn about.

For layer farmers, particularly those operating or considering free range production, Peter Scott (Scolexia), speaking in the ‘Egg –Food Safety – egg quality session (Room –MR 5.6) after lunch on the 26 reveals ‘Strategies for salmonella prevention on egg farms.’

In the Chicken Meat Biosecurity Session after morning tea on the May 27, Margaret McKenzie from Inghams Enterprises will speak about range control for disease management and she will be followed by FREPA board member and broiler grower Sandra Pegler on ‘Range management in practice’.

Peter Scott is also speaking on the following day in the session after morning tea (11.00am-12.30 am approximate) on ‘Minimizing the risk of avian influenza on free range (egg) farms’.

Of interest to innovators in the poultry sector will be speakers in the AMC program ‘Food and Feed for Asia: Combined feed and flour keynote session’ after lunch on May 26.

Professor Frank Dunshea from the University of Melbourne will speak on the topic of ‘Innovation and production of high value food products for China.

The following speaker Rob Cumine, Farm Manager for Coles supermarkets, reveals ‘What matters to consumers.’

input from government, supply chain operators and industry participants.”

‘Road map’ for future Mr Chandler says that while the

solution to the competitive challenges to Australian agriculture does not lie in any one direction, there is a ‘road map’ that can guide industries to build a more competitive and sustainable base for the sector into the future.

“While some competitive factors such as exchange rates and wage costs are beyond the sector’s control, many other issues can be successfully addressed through the concerted and coordinated action of industry and government institutions,” he said.

“There is no question that a food

and agriculture sector that has better access to global markets, ready access to capital, more efficient logistics infrastructure, higher value product and processes, a highly sustainable environmental impact, and more affordable production inputs will be better placed to capture the ‘Asian dining boom’.”

“However, the objective should not be for Australia to ‘feed the world’.

“The reality is Australia is not in a position to supply and compete in the high-volume markets,” Mr Chandler says. “Rather our focus needs to be on developing into high-value markets where we can compete on quality and other sought-after attributes where

consumers have the capacity to pay. Australia will not be the food bowl of Asia, but we can be the delicatessen.”

Rabobank group Executive Country Banking Australia Peter Knoblanche said Agriculture in Focus 2014: Competitive Challenges was the first in a series of reports the bank would be releasing which would examine the issues impacting the agricultural sector along the entire length of the supply chain.

“In our view it is vitally important that these issues are examined and addressed in order that our agribusiness sector can benefit and prosper in delivering a vital product to an increasingly hungry world,” he said.

v

With 95% accuracy in targeting the effective vaccination location in the egg,it’s obvious why Embrex® Inovoject® is the in ovo vaccination leader. These numbers make it even clearer: When vaccinating 1.5 million eggs in ovo,* Inovoject helps ensure that 1.425 million receive proper vaccination at the correct site of injection. Compared to the competition, that is 34% greater protection against disease challenge.1 Can you afford ineffective vaccination and disease risk in 510,000 birds per week?

Smarter is greater accuracy. Smarter is Embrex Inovoject.

For more information talk to Mark Bennett 0427 627 774.

DUAL-NEEDLE INJECTION TOOLING

*Based on assumed weekly volume of 1.5 million eggs injected.1 Williams CJ, Hopkins BA. Field evaluation of the accuracy of vaccine deposition by two different commercially available

in ovo injection systems. Poultry Science 2011; 90:223–226.

SMARTERIS RELIABLEVACCINATION.

© 2013 Zoetis Inc. All rights reserved. Zoetis Australia Pty Ltd 38–42 Wharf Road, West Ryde, NSW, 2114. www.zoetis.com.au 02/14 PAL1077

PAL1077_A_EmbxInovo_A4.indd 1 5/03/14 3:16 PM

Saves you money & maintenanceDimming LEDS

With an average life of 50,000 hours you don’t have to change a bulb in over 5 years when used 12 hours a day!

Bulbs pay for themselves in the first year. Available in White, Green & Blue colours.

Adaptors are available to convert our screw fitting to your bayonet fittings at low cost.

Dimmable from 1% to 100% using Normal dimmers.

Our LED’s are free from UV, Mercury and IR Radiation and are cool to touch resulting in cooler temperature in your sheds.

1 x 7 watt LED= 1 x 46 watt

incandescent bulb!

That’s an 85% reductionin energy use!

Pre-wired light fitting and wire

come in 100 metre rolls and with either 3, 4 or 6 metre spacing

24 months In-Shed Guarantee

Made in Israel for Poultry Sheds

OEC Head OfficePh: (07) 5429 2028

• Equipment You Can Trust

We can’t run your poultry farm for you to meet RSPCA standards, but we do have the range of equipment and expertise that can help you to get there. Bird perches and the winches that drive them, dry litter with Cubo floor drying fans and drinker nipples that don’t leak are all part of the solution.

Contact us now for information and assistance

OEC can help you to meet RSPLi

ghti

ng/C

ontr

ol RLED Light

Dimmer For Energy Saving LampsRotem Control and Management's new RLED provides effective and simple control over both LED and CFL/CCFL based lighting systems.

Featuring advanced TRIAC relays. the two channel digital light dimmer can be directly managed by a poultry house controller via 0-10 volt analog output or communication line {when using a Platinum Controller).

RLC-1LVLow Voltage Light Controller...If you don't have a controller then this will drive the dimmer to meet RSPCA requirements

Saves you money & maintenanceDimming LEDS

With an average life of 50,000 hours you don’t have to change a bulb in over 5 years when used 12 hours a day!

Bulbs pay for themselves in the first year. Available in White, Green & Blue colours.

Adaptors are available to convert our screw fitting to your bayonet fittings at low cost.

Dimmable from 1% to 100% using Normal dimmers.

Our LED’s are free from UV, Mercury and IR Radiation and are cool to touch resulting in cooler temperature in your sheds.

1 x 7 watt LED= 1 x 46 watt

incandescent bulb!

That’s an 85% reductionin energy use!

Pre-wired light fitting and wire

come in 100 metre rolls and with either 3, 4 or 6 metre spacing

24 months In-Shed Guarantee

Made in Israel for Poultry Sheds

OEC Head OfficePh: (07) 5429 2028

• Equipment You Can Trust

We can’t run your poultry farm for you to meet RSPCA standards, but we do have the range of equipment and expertise that can help you to get there. Bird perches and the winches that drive them, dry litter with Cubo floor drying fans and drinker nipples that don’t leak are all part of the solution.

Contact us now for information and assistance

OEC can help you to meet RSP

Lighti

ng/C

ontr

ol RLED Light

Dimmer For Energy Saving LampsRotem Control and Management's new RLED provides effective and simple control over both LED and CFL/CCFL based lighting systems.

Featuring advanced TRIAC relays. the two channel digital light dimmer can be directly managed by a poultry house controller via 0-10 volt analog output or communication line {when using a Platinum Controller).

RLC-1LVLow Voltage Light Controller...If you don't have a controller then this will drive the dimmer to meet RSPCA requirements

OECOECPty LtdPty Ltd• NSW Joe Vella 0418 965 369

• Bendigo Rod Ryan 0418 509 551

• A Team You Can Rely On

Poultry ShedsDust SuppressionAnd Cooling

Keep your floors dry with hot dry air already paid for...NEW OEC Cubo Floor Drying Fans.

The CUBO series air mixers or destratifiers are the perfect solution to retrofit any poultry house in order to reduce heat loss and maintain a more even temperature throughout the living area. CUBO technology does this by pulling the inaccessible hot air from the ceiling level and directing it in a 360 degree horizontal expulsion just above the floor. This creates a circular flow of air in the room as well as very even temperatures on all surfaces, including floor, walls, ceiling.

In addition, CUBO can be used to efficiently heat the air during circulation through various heating methods.

SPCA poultry shed standards! H

ea

t/D

ryin

g/P

erc

hin

g

Keeping your bird’s environment dry“No Drip” Plasson Drinker Nipples

CUBOCUBOHeat Mixer

• Widest range of flow rates• 100% of nipples leak tested during manufacturing• Highest grade plastic used for longevity• User friendly = Easy to service

Who else in Australia supplies as standard......

DRINKERMODEL

FEEDERMODEL

PERCHMODEL

OEC Bird Perch Winch1. Brake winch motor2. Motor / gearbox – sealed for life3. Remote up / down switch4. Emergency stop button5. 10 metres of wire rope6. 2 x 3.5” cast iron reduction pullies7. Built-in upper limit switch8. Mounting clamps9. Built to exacting German standards.

10

First high-efficiency EC fans trial a winner for Victorian broiler grower

consumption, increased air velocity, decreased mortality rate, improved bird spread and lower noise,” said ebm-papst Account Manager Christopher Hauck.

The trial was undertaken over the course of a whole batch (47 days) during Victoria’s summer in January and February 2014. The shed performance was compared to the neighbouring shed of exactly the same setup in which conventional, belt-driven AC fans using staging controls were used.

Poultry Digest had the chance to see the retrofit for themselves and to speak to both the fan manufacturer (ebm-papst) and controls developer (HmiElectric).

From this visit it was obvious that ebm-papst, HmiElectric and Agricultural Automation had together designed a completely new way of managing tunnel ventilation sheds.

“The use of ebm-papst EC fans

effectively halved the number of fans needed from 24 to 12,” said Christopher.

“The sidewall fans for minimum ventilation were no longer required, while the air velocity and bird comfort seemed to be improved.”

In discussions with the team they revealed that the entire shed ventilation is managed by speed controlling the EC fans using the existing controller with the addition of an interface.

Agricultural Automation and HmiElectric provided the installation, commissioning and programing of the fans, and hence ebm-papst and its partners were able to provide a turnkey solution to the grower.

The AgriCool shed ventilation system can be installed in any tunnel-ventilated shed.

“We chose Joe’s farm for this trial because it gave us four identical chicken broiler sheds which were

By ALEX BEDWELL

w

Poultry Digest recently visited a trial shed of broiler grower Joe Buttigeig in Victoria, where a technical trial was completed to show and test the energy efficiency and reliability of the ebm-papst AgriCool shed ventilation system using high-efficiency EC fans.

“The trial confirmed and exceeded expectations regarding lower power

ebm-papst A&NZ Managing Director Simon Bradwell and HmiElectric Director Luke Colla (right).

Nobilis® IBEFFICACIOUS TRUSTED RELIABLE Vaccine

Nobilis IB vaccine prevents Infectious Bronchitis disease in chickens.

S01

494/

00/1

113/

PD MSD Animal Health

91-105 Harpin Street, Bendigo East VIC 3550 Free Call: 1800 033 461www.msd-animal-health.com.au

For product enquiries contact Robin Anderson Mobile: 0424 197 640 Email: [email protected]

For orders contact Customer Service Free Call: 1800 033 461 Free Fax: 1800 817 414 Email: [email protected]

THE SCIENCE OF HEALTHIER ANIMALS

RR

A/M

SD

1499

9

12

built to the latest standard by shed manufacturer Eddy Dimech in 2010,” said Christoper.

He confirmed that the sheds are of a standard size, 170m in length by 17m in width and both sheds held 55,000 birds for the trial. All the trial sheds were fitted with power metering during the whole growing cycle and measurements of temperature and humidity were taken inside and outside.

One of the sheds was retrofitted with 1250mm high-efficiency, direct-drive, three-phase EC fan motors with in-built speed control from ebm-papst.

A motorised shutter system was supplied by Agricultural Automation which was fitted on the air intake side of the fan. The existing AgroLogic controller was supported by a control interface developed by HmiElectric, which converts the existing AgroLogic stage controls into a speed control signal for the EC fans.

In controlling these high efficiency EC fans via the HmiElectric EC fan interface controller, no side wall fans were needed, which reduced the total number of fans needed from 24 to 12.

“This interface is the linking part between the existing AgroLogic shed controller and the EC fans still enabling the use of the existing controller,” said Hmi Electric’s Luke Colla.

“This interface also controls the motorised shutter which opens as soon as the fans start operating and fully closes as soon as the fans stop running, thus allowing to fully insulate the shed while no fans are in operation.”

All the other sheds are controlled via AgroLogic climate controllers using conventional on/off operation (staging).

“Where a standard system would run four out of 16 fans at 100%, then gradually add on more fans, with the ebm-papst AgriCool system, it is possible to run all EC fans at 20% and then gradually increase speed of all fans, matching the exact air movement requirements at any given time,” said Luke.

This results in a significant reduction in energy usage as well as performance control.

The use of ebm-papst EC fans together with the interface comes with extensive safety and redundancy features. In case of controller failure or cable break, all shutters automatically open and all EC fans will run at a defined speed ensuring sufficient ventilation and cooling is provided to the livestock.

“ebm-papst EC fans are extensively protected against the harsh environment in poultry broiler sheds,” Christopher confirmed and said that special precautions have been undertaken to provide additional reliability and safety to the livestock.

1. High efficiency 50” direct drive fans by ebm-papst fiited to shed end wall. 2. ebm-papst shed in the foreground with control shed to the right. 3. The interface also controls the motorised shutter which opens as soon as the fans start operating.

v

3

1

2

The AgriCool Shed Ventilation Systems are high efficiency, high performance ventilation systems allowing for the optimum performance of broiler sheds. AgriCool will drive down the power consumption of sheds while optimising cooling, air circulation and control.

ebm-papst is a trusted performer, supplying local A&NZ markets for over 25 years.

AgriCool Shed Ventilation Systems

Destratification fans Stirring fans

ebm-papst A&NZ10 Oxford RoadLaverton North VIC 3026

Tel: 03 9360 6400 [email protected]

Meet us at

25-27 May

Gold Coast

Tunnel fans

2014 Agri Ad.indd 3 4/04/14 9:06 AM

w

The AgriCool Shed Ventilation Systems are high efficiency, high performance ventilation systems allowing for the optimum performance of broiler sheds. AgriCool will drive down the power consumption of sheds while optimising cooling, air circulation and control.

ebm-papst is a trusted performer, supplying local A&NZ markets for over 25 years.

AgriCool Shed Ventilation Systems

Destratification fans Stirring fans

ebm-papst A&NZ10 Oxford RoadLaverton North VIC 3026

Tel: 03 9360 6400 [email protected]

Meet us at

25-27 May

Gold Coast

Tunnel fans

2014 Agri Ad.indd 3 4/04/14 9:06 AM

system,” Luke added.He also said that he is confident

that even after three years of testing and measuring this new system, further efficiencies can still be achieved.

Christopher projects an efficiency increase of up to 60% for the next batch.

“I believe that our direct drive fans could be even more efficient, especially in the first two weeks of the test” he said. “We also had a water pump for the cool pads fail during a day which reached over 40 degrees C which caused the EC fans to run at full speed before anyone noticed.

“This means that the EC fans ended up using a lot more electricity than they

Left: overview of power data from AC abd EC ventilated broiler sheds. Below: Air velocity fancomparison.

Above: High efficiency EC fans are controlled via the HmiElectric EC fan interface. Right: Christopher Hauck from ebm-papst in the control room.

“The EC fans are equipped with stainless steel shaft, nuts and bolts, bearings sealed for life, galvanised rotor plus additional coating against corrosion,” said Christopher.

“The blades are of strong die-cast aluminium coated in black paint which is highly anti-corrosive, ensuring the fans’ performance even at high pressure and constant run-time.”

Christopher explained that because the fans have direct-drive motors (no belts, pulleys, tensioners etc.) there is no maintenance required throughout the fans’ lifetime.

He also explained that the ebm-papst fans have a higher air velocity. The 12 15inch ebm-papst fans have an air velocity of 3.4m/s compared to the 16 15inch standard belt driven fans which have an air velocity of 3.3m/s. He said that if they had used 12 15inch standard belt driven fans they would only have an air velocity of 2.8m/s. “That’s why we only need to run 12 of the 15 inch ebm-papst fans,” he said.

“The use of EC fans also resulted in a more stable temperature profile and even airflow throughout the shed. Airflow is adjusted constantly and steplessly, thereby enabling the controls system to react immediately and accurately to the ever-changing conditions in the shed.

“The birds in the ebm-papst shed were more evenly spread out as they got more even airflow with more even temperatures and there were no hot spots,” Christopher said.

He believes this provides a better growing environment which was also corroborated as the ebm-papst shed also achieved a marginally lower mortality rate.

Christopher Hauck explained that the conventional shed used 9576kWh of electricity compared to the ebm-papst shed which used 4615kWh, resulting in a saving of 4961kWh. This represents a 52% lower power consumption.

A comparison of both types of fans at the same air performance proves that the EC fan shows a huge increase in specific fan efficiency, namely 29.1 CFM/W (EC fan) and 14.6 CFM/W (belt-driven fan).

“The ebm-papst fans have soft starters, which means there is no in-rush of current which can possibly damage or overheat the electrical

v

14

would normally.”When talking about the cost of the

fans Christopher suggested that the turn around cost for retrofitting sheds is less than three years.

“However,” Luke said, “if the ebm-papst fans are installed into new sheds their ventilation system would almost cost the same as installing belt driven fans as less fans are needed and no cross fans need to be installed”.

To see the fans find out more information about the new tunnel ventilation system, ebm-papst, HmiElectric and Agricultural Automation will have stands at PIX. The Australian agent for ebm-papst fans is Agricultural Automation.

IMEXCO KNOWS THAT FARMERS NEED ALTERNATIVES

....so consumers can have choices

Don’t give up on your old shedsIMEXCO knows that farmers need alternatives.

We can help you to convert old sheds to free range and organicproduction for broilers or layers.

If it really is time to build new sheds, either for alternative layer systems or tunnel ventilated broiler sheds we can do

that too.

THERE’S NO FREE RIDE IN FREE RANGE

Imexco Australia Pty LtdLot 2, Winta Road, Tea Gardens, NSW 2324Tel: 02 4997 2045Fax: 02 4997 2085Email: [email protected]: www.imexcoinc.com

FAX: 0249972085 E

There can be capital equipment cost savings in convertingolder sheds to free range and organic production.

But to ensure these upgraded sheds reach their maximum potential, IMEXCO offers the best range of products proven inalternative systems in Europe and the US as well as Australia.

IMEXCO is price competitive with a full range of spares in stockfor the products we sell and others.

• Automatic nests • Egg collection • Egg packers• Feeders • Drinkers • Ventilation

ImexcoAdDPSFreeRange:Layout 1 23/04/14 1:17 PM Page 1

IMEXCO KNOWS THAT FARMERS NEED ALTERNATIVES

....so consumers can have choices

Don’t give up on your old shedsIMEXCO knows that farmers need alternatives.

We can help you to convert old sheds to free range and organicproduction for broilers or layers.

If it really is time to build new sheds, either for alternative layer systems or tunnel ventilated broiler sheds we can do

that too.

THERE’S NO FREE RIDE IN FREE RANGE

Imexco Australia Pty LtdLot 2, Winta Road, Tea Gardens, NSW 2324Tel: 02 4997 2045Fax: 02 4997 2085Email: [email protected]: www.imexcoinc.com

FAX: 0249972085 E

There can be capital equipment cost savings in convertingolder sheds to free range and organic production.

But to ensure these upgraded sheds reach their maximum potential, IMEXCO offers the best range of products proven inalternative systems in Europe and the US as well as Australia.

IMEXCO is price competitive with a full range of spares in stockfor the products we sell and others.

• Automatic nests • Egg collection • Egg packers• Feeders • Drinkers • Ventilation

ImexcoAdDPSFreeRange:Layout 1 23/04/14 1:17 PM Page 1

CRC NEWS

Poultry CRC project leader Dr David Cadogan, from CRC partner Feedworks, has recently submitted the final report for his project ‘Influence of betaine on embryo survival, hatchability and progeny performance’.

This was a two-part project investigating both the value of Danisco’s Betafin S1 as a feed additive in layers, and the effect of Betafin S1 on broiler breeders.

The presence of betaine enables microbes, plants and animals alike to be more resistant to temperature, osmotic, disease or environmental stresses.

As temperature variation and fluctuation does occur in commercial incubators, this raises potential issues for embryo development and survival. Impaired embryo development produces a considerable loss in broiler and layer performance and health.

The benefits of natural betaine supplementation have been investigated in other species, including humans. For example, Van Wettere et al. (2012) demonstrated that betaine significantly improves embryo survival in gestating sows by reducing blood homocysteine (a blood toxin) and reducing (temperature) stress on the sow.

Betaine is also an extremely good source of methyl groups, which are used to spare the amino acid methionine, increase carnitine levels and methylate DNA to maximise its integrity and gene expression.

The layer experiment was designed to investigate whether significant amounts of dietary natural betaine can accumulate in the eggs laid by commercial hens.

For broilers, the potential benefits of natural betaine supplementation was investigated in Ross 308 broilers, measuring the hatchability, percentage of chick culls and hatched weight under commercial conditions.

Hy-Line laying hens were offered either a control diet (zero betaine) and a treated diet (1000ppm of betaine) in a 6 week trial.

Overall results indicated the natural betaine supplementation significantly increased the betaine content of the eggs (P<0.001) from 0.46 mg/100g (control) to 1.37 mg/100g (treated), representing a 3 fold increase (equating to 0.91mg/100g).

However, this had no significant effect on other production parameters

of the laying hens (there was a numerical 2.4% increase in egg weight by the treated diets).

For broiler breeders the commercial evaluation of natural betaine was tested in 7000 Ross 308 broiler breeders, run in two blocks, with a partial crossover (one shed had both a control and a treated diet at different times) of treatments (control and betaine treated diets at 2000ppm of betaine).

The broiler breeders were 32 weeks of age, and were offered the control and treated diets for a period of 24 weeks. Results showed natural betaine significantly improved hatch rate from 84.75% to 86.89% (P=0.004), but had no effect on hatch weight or number of chick culls.

“A 2.5% improvement in hatch rate is worth approximately 1.5 cents per egg” said David, “and if 750,000,000 eggs are produced per annum to produce 600,000,000 broilers, then this

Natural betaine benefits broiler chicks

Dr David Cadogan (centre) with Professor Bob Swick and Mark Dunlop.

18

is worth approximately $11.3 million dollars to the broiler industry”.

It is also highly likely that natural betaine will also improve the hatch rate in layer, duck and turkey breeders. Additionally, increasing natural betaine to layer diets could also promote health benefit to egg consumers.

“The potential in-ovo effects of natural betaine in chick development and subsequent growth and carcass characteristics could be significant, and this strongly warrants further investigation” said David.

Currently, at a 2kg/tonne dose rate, betaine would cost between $9 and $10 per tonne to incorporate in breeder diets. Therefore, further research is necessary to assess the effects of lower (more cost effective) doses.

For further information on this project, or to request a copy of the Final Report, please contact the Poultry CRC [email protected]

Tesco cartons go plasticTraditional cardboard cartons are being replaced by plastic versions at Tesco in the UK.

Egg cartons made of pulp or cardboard are to be replaced by recyclable plastic packaging to save more than a million free-range eggs from going to waste every year after a successful trial by Britain’s biggest egg retailer.

Tesco’s free-range eggs are currently sold in pulp cartons so if an egg breaks in transit, it can seep through the box and damage packs beneath.

But the supermarket has trialled a recyclable plastic packaging made from old drinks bottles. When an egg breaks, the seepage can be contained in one pack.

Tesco has trialled the new 12-egg packaging in nearly 200 stores. Tesco is the UK’s largest egg retailer, selling around 1.3 billion eggs every year.

Spokesman Lee Gray said: “We know that plastic packs reduce food waste – now we have a pack that will reduce food waste and offer customers a more environmentally friendly packaging solution.”

av i a g e n . c om AN AVIAGEN BRAND

The superior growth of the Ross® 308 offers you greater efficiency and the ability to move birds

sooner, leading to enhanced profitability. The superior broiler performance of the Ross 308 is

supported by a knowledgeable, experienced regional technical team who resides in your market

and understands the conditions experienced by you and your production teams. The Ross 308 is

backed by an industry-leading investment and R&D program that is yielding the fastest rate of

genetic progress and creating unequalled value for you.

Visit aviagen.com/Ross-308 to view our new 2013 Management Handbook and learn even more

about how to manage our birds and enable your future success.

LESS FEED. LOWER FCR.

AGEN-997-11/13GG-ROSS-LESS-210mmx297mm-LO.indd 1 11/27/13 10:08 AM

Fully experienced in all aspects of poultry shed design and construction

Fully licenced throughout Australia

Highest quality workmanship and materials

No project too large

Competitive prices

Reliable honest and friendly advice

Flexible design which can be adapted to meet any client needs and shed size Flexible design which can be adapted to meet any client needs and shed size

R&DG SandayTunnel Ventilated Shed Specialists

OVER 40 YEARS EXPERIENCE

Call Ron Now 0404 489 573

www.RDGSanday.com

100% Australian Owned

100% Australian Designs

100% Australian materials

100% Australian, fullstop!

Don’t be misled by companies claiming to be Australian but use overseas materials!

The ORIGINAL designer and builder of the

GENUINE CLEAN SKIN SHEDwith no exposed trusses, columns or internal bracing

Fully experienced in all aspects of poultry shed design and construction

Fully licenced throughout Australia

Highest quality workmanship and materials

No project too large

Competitive prices

Reliable honest and friendly advice

Flexible design which can be adapted to meet any client needs and shed size Flexible design which can be adapted to meet any client needs and shed size

R&DG SandayTunnel Ventilated Shed Specialists

OVER 40 YEARS EXPERIENCE

Call Ron Now 0404 489 573

www.RDGSanday.com

100% Australian Owned

100% Australian Designs

100% Australian materials

100% Australian, fullstop!

Don’t be misled by companies claiming to be Australian but use overseas materials!

The ORIGINAL designer and builder of the

GENUINE CLEAN SKIN SHEDwith no exposed trusses, columns or internal bracing

22

By PETER BEDWELL

Free range layer farm in Newcastle region plans for and survives major bush fire

When bush fires tore through NSW in late 2013, it was the Blue Mountains region that got most of the media coverage. However other locations like the Newcastle region also experienced horrendous fires as temperatures soared to record levels and huge fires burnt out of control.

One of the farms that found itself threatened by a massive fire was the two shed free range layer farm run by June and Kerry Fuller who have operated the Campvale NSW farm since 1985, firstly as a broiler farm for Steggles, but today the operation is a 10,000 birds per hectare free range layer farm.

They produce for Free Range Egg Farms operated by Ray Leach and Poultry Digest ran a story on this interesting enterprise in its Feb/March edition.

Go to www.primarymedia.com.au, latest issues and open the Feb/March issue. The story is on page 34.

The farm was originally built as a layer operation so it has returned to its original purpose, firstly as a larger capacity free range operation and more recently converted to 10,000 bph protocols that are consistent with Free

Range Egg Farm’s ‘ecoeggs’ brand.“Our hens have at least eight hours

a day access to the range areas that consist of both natural and improved pastures,” Ray explained.

“All our ‘ecoegg’ farms provide an average maximum of 10 hens per square metre or less in the sheds and an average maximum of one bird per square metre or less on the range areas during daylight hours.

“In our experience there are rarely more than 50% of the birds on the range at any time so the effective load on pasture is around .5 hen. /m2,” he added.

The location of the farm, next to an area of state forest, offers isolation and some biosecurity advantages but at the penalty of having fires risk on the doorstep.

On the night of October 17, 2013 that risk turned to harsh reality when w

Background trees behind June Fuller and her birds show how close to disaster the farm came.

CleanOxide 75 The ultimate waterpurification system

Also Distributors for BioWish

or phone Natural Water Solutions:Barrie Weir - 0409 928 820

For further information, please contact:[email protected]

Benefits• Lower mortality (Saves Money)• Increased weight ($$)• CleanOxide 75 keeps drippers Clean and free from blockages (Saves Money)• Clean Oxide 75 is 100% bio-degradable.• Clean Oxide 75 is a sustainable, environmentally friendly product. • Clean Oxide 75 removes biofilm slime from water tanks and pipes.• Clean Oxide 75 Oxidizes iron & manganese. • Clean Oxide 75 removes foul odours from water. • Clean Oxide 75 is 10 times more powerful than chlorine.• Clean Oxide 75 does not contain free chlorine.• Micro-organisms do not develop resistance to Clean Oxide 75.

Successful poultry farming demand that measures are taken to control the introduction and spread of infectious agents. CleanOxide 75 is a unique product for sanitising water to assist in the prevention and transmission of disease.

Natural Water Solutions Clean Oxide 75 is 99.9 % pure Chlorine Dioxide

Natural Water Solutions CleanOxide 75 is the most cost effective chlorine dioxide system available.

The NWS CleanOxide purification system is very easily set up & self-managed.

www.nwsolutions.com.au

a huge fire took hold in the adjacent forest.

The Fullers, being experienced farmers who had lived and worked in their environment over many years, were aware of the risks and had planned accordingly.

“Power outages are frequent in this area at the best of times and we knew if fire took hold one of the first things to go would be mains electricity supply so we have always invested in well maintained back up generators with plenty of capacity,” Kerry said.

“The power requirements for the farm, feeders, stirrer fans, and the water pump for drinker lines, are relatively low, but what we have is a big power surplus for our high capacity water pumps.”

The strategy the Fullers had developed was to run high pressure irrigation hose over critical areas of the sheds and other farm infrastructure including the family home on the property.

Knowing the speed with which bush fires travel through the area the plan was, when alerted to fire, to start the powerful pumps and flood rooves, ramps and walls and thoroughly soak the ground around the shed.

The other problem faced by the Fullers was that in all probability when fire approached they would be forced by authorities to evacuate.

On the day of the big fire at least they got some warning and with the pumps going flat out all critical areas of the farm got well watered.

As Kerry predicted, an early casualty as the fire took hold was the mains power supply but by switching to the stand-by generator system they still got plenty of water spread around before being forced to leave the property at 7.00 pm.

Having done the best they could to secure the property it was soon to be time for another piece of interesting technology to take over.

ChookCam, an innovation developed by the Free Range Egg Farms enterprise, primarily to allow consumers to actually watch the birds using their range and surroundings, continued to operate as the fire approached.

By 9.30 pm the fire had raged to the boundary fence of the Fuller’s property but the pumps and the Fuller’s plan worked.

Though the flames came to within a few metres of the sheds, they and almost all their hens survived and so did the valiant little ‘ChookCam’ located less than 10 metres from the inferno and it recorded the whole event.

When the Fullers returned the next day, though the farm had survived, just over 100 hens had perished, probably from the radiant heat at the end wall w

v

of the shed nearest the fire in adjacent bush.

With almost all their precious livestock intact and their farm and house saved and the generators still operating the next concern was fuel.

The power was still out and with fires still burning in the area it was likely to be out for some time.

Critical was the diesel fuel supply for the generators. The Fullers were okay but a few hundred metres down the road Paul Maskey, who runs a farm supplying pullets to amongst other farmer, the Fullers, and other growers in the Free Range Egg Farms Group, was after two days without power, running low. Roads were still closed so options were limited.

Fortunately the Fullers boat, which

runs on diesel power and has generous tanks, which were full, donated fuel to keep the generators running. It took two and half days before power was restored.

When Poultry Digest visited the Fullers farm with Ray Leach in March all was back to normal.

The nearby bush was still blackened as a testament to the severity of the fires but the paddocks had recovered their pasture and production was running along perfectly.

June reflected on the events of the October 17, 2013 and their narrow escape.

“We understand consumer concern for animal welfare and why they like the idea of free range, but there’s a lot more to running a layer farm than just looking

1. Kerry Fuller, experienced layer farmer. 2. Paul Maskey, neighbour and supplier of pullets in the area. 3. Six months after the fire the range has recovered. 4. Chookcam recorded the fire at its closest on October 17, 2013.

24

1 2

3

4

Highly effective againstAvian Influenza including H7

26

v after the range, which we do.“Apart from maintaining all the

equipment vital to looking after the hens in the sheds which is where they spend most of their time, we have to make sure predators and vermin are kept away from the property.

“Every night I walk the sheds to make sure all the birds are okay. It’s a vital task and I must admit I do talk to the birds as well as keeping a close eye on them – you have to know your birds.

“We do keep a graph for monitoring the performance of the flock, but a lot of managing the birds comes from intuition and long experience,” June said.

On its website The Australian Egg Corporation Ltd states that ‘it believes all egg production systems have their own advantages and disadvantages in relation to hen welfare.

“Recent scientific research undertaken by the University of Sydney demonstrated that hen stress levels are similar across cage, barn and free range environments, with the key determinants on hen welfare being hen husbandry not the system used,” a view that reinforces June’s belief in looking after her hens.

The Fullers birds, Hy-Line Browns, are supplied by Paul Maskey from down the road and they are allowed out onto the range at 25 to 26 weeks of age and stay in lay until around 78 weeks.

Paul, who has been a pullet grower since 1979 and supplies birds as far away as the Queensland border, has a preference for the Hy-Line Brown bird.

“Apart from other attributes which make the bird adaptable to alternative rearing systems, he believes that the breed is “less prevalent to feather pecking”.

As a matter of history the Hy-Line business was started in 1953 by Ray Leach’s father.

The business model for Ray Leach’s Free Range Egg Farms is interesting in that it is based on the contract grower system that has been a key factor in the success of the broiler industry in Australia.

“We want to attract experienced farmers from either the broiler or layer sector to our business model: we can take the uncertainty that seems to be prevailing in the commercial poultry industry at present, out of a growers life,” he said.

“We have supply contracts from the major retail groups and know that our business of supplying eggs that consumers want has plenty of potential to grow.”

On the question of barn laid as an option to satisfy consumer demand and supermarket ‘cage free ‘policy Ray agrees that this production model will grow, maybe to 25% or even 30% of the overall market.

“This will mean considerable investment on the part of growers to move from cage to barn laid but we offer assistance in financing the shift to more sustainable and commercially viable production,” Ray said.

“There is certainly confusion over egg labeling and who is going to be selling what in the future.

“The ACCC’s intervention over labeling, associated stocking density issues and prosecutions of egg suppliers, certainly hasn’t been of any real help to consumers who may have less choice over what egg products they buy rather than more,” Ray said.

“The policies of retailers and the ACCC have certainly contributed to shortages on supermarket shelves right now and this situation will get worse before it improves,” he predicted.

“At Free Range Egg Farms we have the industry and marketing experience to adapt to what the market wants and we can help growers adapt their operations to supply that demand be it free range or barn laid based,” Ray concluded.

1. Flooding the sheds with high volume pumps using generator power saved the sheds and hens. 2. The Chookcam not only survived the blaze but recorded it.3. Ray Leach, MD of Free Range Egg Farms, with the much sought after eggs from the Fullers farm.4. Nest boxes and egg collection system is from Vencomatic.

1

3

4

2

I N T E R N A T I O N A L

TM LEADING SUPPLIERS OF cage free POULTRY EQUIPMENT

I N T E R N A T I O N A L

TM

www.avinest.com

Long life, strong and stable flexible design - maximises stocking density

Rack & Pinion lifting floor with original AstroturfProbably the strongest and most stable available

Potters Poultry, Willey Fields Farm, Rugby, WarwickshireCV23 0SQUnited Kingdom

Ph: +44 1455 553234Email: [email protected]

MULTI-TIER AVIARYfor free-range and barn systems

NESTING SYSTEMS

SLATS SINGLE AND TWO TIER NESTSFOR LAYERS AND ALL bREEDERS

21573 Potters Modifications to Aus ad no highlight.indd 1 21/11/12 11:38:06

28

NEWS

Has the poultry industry lost control of its destiny and where do we go from here?

Big retail and even smaller shops all seem to want one type or another of what is seen by consumers as being welfare friendly poultry products.

This means free range or more recently, RSPCA approved broiler meat and either free range or barn laid eggs.

The poultry industry in its efforts to meet what retailers required has attracted the attention of the consumer regulator, the ACCC, which has undertaken numerous prosecutions for what it regards as misleading labelling against broiler meat producers, duck meat growers and free range egg farmers.

There is little doubt that both extreme animal rights groups and consumer action groups like ‘Choice’ as well as social action organisations like ‘Get Up’ have encouraged regulators in their efforts.

Given that big retailer policy demands ‘welfare friendly’ poultry products and the ACCC is unwilling to allow larger commercial operations to label their products as being ‘free range’ as in the case of 10,000 bird per hectare free range layer farms, the move to RSPCA approved farms by growers and integrators was an obvious one.

At least the RSPCA broiler code allows for the operation of enclosed sheds, which though the code presents complications for growers, it at least offers good levels of biosecurity if care is taken to observe well proven and sensible measures to prevent the entry and spread of disease on farms.

If the ACCC sticks to its stated intention to favour free range layer farms with populations on range of 1500 hens per hectare or less, there are dangers with this path that would not be

obvious to the consumer action groups and politicians who decry ‘factory farmers’.

All free range layer farms, whatever the stocking density, pose a greater biosecurity threat than enclosed production methods like cage or barn laid.

If consumer pressure continues to generate a big market for free range products and the ACCC only allow low stocking density farms to label their product as being ‘free range’, the logical result will be an explosion in the number of small free range poultry operations.

The lower returns from small farms will inevitably in most cases result in the use of less sophisticated equipment like nesting systems and grading/packing equipment.

Unless extraordinary care from these small scale farmers is taken that could result in more ‘floor’ eggs or damaged eggs ending up in the hands of consumers.

So the risk is two fold – from the farms themselves greater exposure to avian disease risk, particularly from diseases like avian influenza and from substandard eggs – salmonella.

In pointing out some of these risks potentially posed by small scale free range layer farms, Poultry Digest recognizes that there are many well run

free range operations like the Rohde family farm reported on in the Feb/March issue and the free range farm featured in his issue.

Both these operations are run by farmers with not only years but generations of experience in livestock management. No, the risk may arise when inexperienced ‘lifestyle farmers’ with little of no intensive livestock experience jump into a gap in the market created by the joint actions of retailers and regulators.

But the consumer, we are told, only cares for ‘natural products’ and what they see as conditions they favour despite the fact that more than half a century of scientific experience has developed an industry that delivers cheap and safe food.

That industry, driven by regulators and retailers, is now being forced to abandon the lessons of long scientific research and expertise.

When disease strikes it will not be the fault of the tireless regulators or the retailers whose policies only offer welfare friendly product but ‘factory farmers’ who Australia’s media love to criticise.

In past issues Poultry Digest has pointed out that one of the real problems the industry faces is the wealth of Australian consumers who are prepared to pay up to 50% more for essentially the same product produced in sometimes more hazardous and less efficient conditions.

If, in the future our economy that has stayed strong (while in Europe, the US and elsewhere on the globe economies tanked as a result of the GFC), should fall into recession with the inevitable rise in unemployment and overall wealth generation the willingness to spend considerably more of ‘animal welfare friendly’ products may change.

This has occurred in the UK, where many of the executives in big retail, gained their experience.

You don’t need to hire a focus group so beloved of both politicians and big retailers to discover that in the last few months Australia has lurched to the right.

Though the swing against Labour and the Greens was pretty universal it was particularly sharp in the outer

By PETER BEDWELL

“The consumer, we are told, only cares for ‘natrual products’ and what they see as conditions they favour despite the fact that more than half a century of scientific experience has developed an industry that delivers cheap and safe food”

w

felice anch’io.

Since 1972 on the Market, Since 2004 on your Market CMC Industries, Leading in Load Solutions

www.cmcindustries.com

www.

Welcoming Visitors at Pix Brisbane

25,28 May 2014

Apollo Generation 2: The New Catching Generation

On the market since 1972. On your market since 2004.

CMC Industries, Leading in Load Solutions

www.cmcindustries.com

Welcoming visitors at PIX

May 25-28 2014

30

suburban populations of our large cities.Many consumers may be getting

just a little fed up with inner city over remunerated baby boomer elites telling them what to buy and how to behave as consumers.

Ex-Labour PM Paul Keating famously described such groups when they incurred his displeasure as ‘chardonnay swilling socialists’ and ‘Balmain basket weavers’.

Without doubt the animal rights groups and social activists that may influence the directions of our regulators, derive a significant proportion of not only their influence, but also their revenue from these ‘urban elites’.

So what to do? In simple terms the supermarkets

which control 75% of Australia’s retail spend will only in the future sell ‘cage free eggs’, which in terms of our production systems means either free range or barn laid – a concept not readily understood by consumers.

The ACCC has basically stated that it will be unwilling to sanction free range labeling of eggs on farms with stocking densities of 1500 birds per hectare or less.

To satisfy demand for free range eggs even before the supermarkets declared their ‘cage free ‘ policies would not have been possible by relying on supplies from farms of 1500 bph or less- so does that mean the alternative is for current cage production to convert to barn laid?

That would involve significant expense that to be for producers viable would, ultimately, have to be passed on to the consumer.

The options are simple – abandon cage layer systems in favour of barn laid, which is what has happened in Europe or continue with cage layers and find a path to consumers other than the two big retailers who have stated that they will no longer sell the product.

Another approach would be to persuade regulators to adopt a policy towards free range that allows for production system densities that recognize the need for commercial realities in production scale.

The key for the cage layer system which may still account for the majority of egg sales is take a message to at least half the market for eggs is that their choice in what to buy is being resisted by supermarkets supported by fringe groups and their political allies who believe they know better.

So our corporate regulator and consumer action groups like Choice and

Get Up have, through their efforts to obstruct not only high density free range operations, but also by campaigning against cage layer production, actually reduced consumer choices.

And in the process ensured that all consumers will ultimately pay more for eggs!

What about the broiler industry? There the free range debate has been overtaken by the almost universal move by integrators towards RSPCA broiler codes.

Adopted by some of the smaller players initially, now both Baiada and Inghams appear to have recognised retailer pressure and joined up.

This development has the advantage of consumer and supermarket support but comes at a cost to production efficiency.

Will the prices charged for RSPCA broiler code products by big retail provide enough margin for integrators to

compensate growers for lower stocking densities and more labour input?

If so, there are clear advantages beyond consumer acceptance to the RSPCA poultry codes – they provide an additional impediment to imports of chicken meat beyond the current disease prevention protocols that keep our industry free of uncooked chicken meat imports.

However, as always with chicken meat cost is the key. The primary reason that chicken is the most consumed meat in Australia is that it is cheaper than all its competitors like beef, lamb and pork. If it looses that

edge it is in danger of loosing its market pre-eminence.

It is worth asking the question – why is beef and lamb so much more expensive than chicken? This is an industry that still requires feed and infrastructure costs that are higher than those faced by the red meat industry at least.

The answer – exports! Why should beef and lamb

producers accept less for their product than they can get from overseas markets like Japan and Korea?

Maybe a lesson for the chicken meat producers there!

New Zealand, a country with higher energy and feed costs than Australia, is successfully exporting at least a quarter of its production into key markets in Asia like Hong Kong, Macau and parts of mainland China.

Not only has this made the New Zealand industry more profitable, it has driven up prices in the domestic market. It is probably no secret that much of Ingham’s profits in recent times derive from their New Zealand operations (including feed mills).

Speaking at the ABARES Outlook Conference held in Canberra recently, key Rabobank executive Berry Martin identified Africa and Australia as the only two major areas of landmass able to expand crop production to satisfy the demand that will be created by Asian middle classes increasing meat consumption.

By Asia – we mean China primarily! That market doesn’t appear, at this

stage anyway, to care that much about animal welfare production systems.

The primary concerns will be food safety, availability, and of course cost.

Australia has the potential to satisfy those key criteria but only if we continue to use every advantage that science and technology has delivered to our efficient production systems.

By all means in the short term address the current needs of our pampered consumers but we must remember that in the end our industries strengths are low cost, safety, and a tasty healthy ever-available product. Jeopardise any of those criteria and ‘welfare friendly production’ wont be any help to us.

In fact we could turn the moral arguments pushed by the urban elites on their head, (and the organisations that support them) and show that our prime concern is to help feed the world in a era of growing shortage rather than satisfy the views of noisy minorities and the regulators.

NEWS

“The options are simple – abandon cage layer systems in favour of barn laid, which is what happened in Europe, or continue with cage layers and find a path to consumers other than the two big retailers who have stated they will no longer sell the product.”

v

2 HMTBa to 1 metal coordinate covalent bonds

C

CCC

C

C

C

C

C

C

S

SO

O

O

O

O

O

Higher Bioavailable Chelated Trace Minerals

Enhanced immunityReduced oxidative stressImproved progeny bonedevelopment

®MINTREX and are trademarks of Novus International, Inc.,and are registered in the United States and other countries. ©2010 Novus International, Inc.All rights reserved. 2001-10-14057 EI

Novus Nutrition Pty LtdTop Floor, 103 Victoria Rd, Drummoyne, NSW 2047Tel: 02 9719 1466 • Fax: 02 9719 1463www.novusint.com • [email protected]

Only MINTREX can supply producers with a source of organic trace minerals and methionine activity in one package. After delivering its trace mineral to the point of absorption, the HMTBa ligand contained within MINTREX becomes available for conversion to L-Methionine, representing an important added value.

EnvironmentSustainability

Meat & Carcass

Improved bone developmentstrengthImproved tissue integrityReduced mineral excretion

32

HEALTH FEATURE

Evaluation of different protections of butyric acid on performane and egg characteritics of White Leghorn layer hens

T he present study was

conducted to determine the effect of supplementing the diet of hens with different forms of butyric acid on performance (feed efficiency (FE), egg production (EP)), egg quality (egg weight (EW), egg mass (EM), shell weight (SW), shell thickness (ST) and egg density (ED)) and digestibility of energy and protein.

The treatments were: sodium butyrate protected with palm stearine (SBP) and calcium butyrate (CB). Two thousand four hundred ninety 38-week old White Leghorn (BV 300) laying hens were use in this experiment.

They were housed in 30 identical pens, each containing 83 birds, and 10 pens were used per treatment. The hens were fed with diets (168 g CP and 10.88 MJ ME / kg). Both forms of butyrate were included at same dosage of butyric acid (280 g / mT) for a period of 16 weeks.

Responses were compared with an unsupplemented treatment. The pooled data of four periods (16 weeks) indicated that incorporation of butyrate in both forms in layer diet did not influence (P > 0.05) EP, FI, FE, EW, EM, SW or ST. However, ED improved significantly (P < 0.05) in groups fed both forms of butyrate compared to those fed control diet without butyrate. The improved ED might be due to non-significant (P > 0.05) increase in shell thickness in layers fed both forms of butyrate.

Supplementation of SBP significantly improved the digestibility of energy (P < 0.001) and protein (P < 0.005) compared to those fed the control diet or diet supplemented with CB. The percentage of eggs produced by SBP (84.04%) was higher than control (83.43%) and CB (83.14%) groups without significant differences. Similarly, feed intake to produce a unit EM in SBP (2.191 g) was lower than

those fed other two diets (2.236 and 2.247 g). Livability in SBP (96.2%) was higher than control and CB (95.8 and 94.8%, respectively). Haugh unit score was higher for SBP group compared with Control and Calcium butyrate (73.58, 72.25, 71.83) with non significant effect (P > 0.05).

Digestibility of energy and protein improved significantly in SBP compared to those fed the other two diets. From the obtained data it can be concluded that supplementation of the diet with sodium butyrate protected with fat increases eggshell quality, nutrient digestibility and layer production when compared to the control.

IntroductionConventionally, antibiotic or

chemical growth promoters are used as a tool to reduce pathogen count in the gut in commercial poultry, which also enhances feed efficiency (Jin et al., 1997).

But, the use of antibiotics as routine feed additives are being discouraged due to consumer concerns about the safety and possible threat of developing drug resistant pathogenic bacteria (Leeson, 2007) by consuming poultry products from such practices. Several alternate approaches like the use of essential oils (Lee et al., 2004), probiotics (Panda et al., 2003; Rama Rao et al., 2004), and organic acids (Panda et al., 2009), are suggested to maintain optimum gut health in lieu of chemical or antibiotic growth promoters in avian diets.

Butyric acid, an organic acid, is known to play a vital role in the development of the gut membrane (Mallo et al., 2012) and reduce the population of harmful bacteria in the chicken gut. Butyric acid is, however, a corrosive liquid, so, in order to facilitate its use in animal nutrition, it is transformed into a salt (amongst other transformations and mixes). The

efficiency of butyric acid predominantly depends on the salt into which it has been transformed.

Butyrate salts have very different solubilities, being much higher for the sodium butyrate, 115 g /1000 ml, than for the calcium butyrate, 6 g /1000 ml (Mallo et al., 2012).

The liberation of the butyrate anion into the intestinal lumen, and the transformation of that anion into butyric acid or its direct absorption by the enterocytes, can be controlled with adequate protection. As calcium butyrate solubility is very low, it allows a slow release of the butyrate anion into the intestinal lumen; while sodium butyrate requires a physical protection(given by vegetable fat) in order to ensure the slow release of active principle.

This experiment was conducted to compare the addition of two presentations of butyric acid (sodium butyrate protected with palm stearine, SBP and calcium butyrate, CB) in layer diets on egg production (EP), feed efficiency (FE), egg mass (EM), egg weight, egg shell quality, Haugh unit score and digestibility of energy and protein.

Materials and methodsA total of 2490 White Leghorn (BV

300, Babcock) laying hens (38 weeks of age) were distributed equally among 30 replicates (four bird colony cages – 83 birds per replicate).

The cages were on an elevated platform in an open-sided poultry house (ambient temperature range 23-39.2°C). A control diet (CD) containing 10.88 MJ ME and 168 g CP/kg was prepared. The CD was supplemented with two forms of butyric acid (sodium butyrate protected with palm stearine, SBP and calcium butyrate, CB) independently to provide a uniform dose of butyric acid (280 g/T). The CD without butyric acid supplementation was fed to another

By M. PUYALTO, S.V. RAMA RAO AND J.J. MALLO*

w

New South Wales: PATARKER PTY LTD,Tel. 0247325520, E-mail: [email protected]

Queensland: FARMMARK P/L LIVESTOCK EQUIPMENT,Tel. 0732796599, E-mail: [email protected]

Victoria: RYAN-RYTE ENTERPRISES PTY LTD,Tel. 0397825515, E-mail: [email protected]

Western Australia: METROWEST AUTOM. & CONTROL PTY LTD,Tel. 0894704343, E-mail: [email protected]

ROXELL® Tel. +32 50 72 91 72, E-mail: [email protected]

TM

Wellness for hensOptimal comfort and animal welfare.Careful egg handling.Labor saving, solid and durable.

www.roxell.com

© Ro

xell –

Roxe

ll is a

regis

tered

trad

emar

k of R

oxell

– K

oozii

r™ –

EI -

04-2

014

Automatic community nest for broiler breeders and commercial layers.

Superior egg quality !Superior egg quality !

NEW!

Poul Digest Koozii 04-14.indd 1 3/03/14 16:05

34

HEALTH FEATUREgroup to compare the performance of layers fed diets with and without butyric acid. Each diet was offered ad libitum to ten replicates from 38 - 54 weeks of age.

Eggs were collected twice daily to record daily egg production (EP) and quantity of feed consumed to produce an unit egg mass (feed efficiency – FE). Average egg weight (EW), egg density (ED), egg breaking strength, shell weight and shell thickness were recorded on all the eggs produced during the last 3 days of each period (28 d interval). Egg mass (EM) was calculated by multiplying the average EW and EP percent and expressed as g per bird per day.

During period 4, a 3-day metabolic trial was conducted (six replicates per treatment) after 7 day adaptation period to study the apparent digestibility of energy and protein by the total excreta collection method. The data of all 4 periods were pooled and subjected to a one way analysis of variance (Snedecor and Cochran, 1980).

Results and discussion

The pooled data of 4 periods (16 weeks) indicated that incorporation of butyrate in both forms in diet did not influence (P > 0.05) EP, FI, FE, EW, EM, SW or ST. However, ED improved significantly (P < 0.05) in groups fed both forms of butyrate compared to those fed the CD without butyrate.

The improved ED might be due to non-significant (P > 0.05) increase in shell thickness in layers fed both forms of butyrate. Haugh unit score was not affected (P > 0.05) by treatments in the present study. The percentage of eggs produced by SBP (84.04) was higher than control (83.43) or CB (83.14) groups without significant differences. Similarly, feed intake to produce a unit EM in SBP (2.191 g) was lower than those fed other two diets (2.236 and 2.247 g). Livability in SBP (96.2 %) was higher than CD and CB (95.8 % and 94.8 %, respectively) fed groups.

Supplementation of SBP significantly improved the digestibility of energy (P < 0.001) and protein (P < 0.005) compared to those fed the CD or CB supplemented diet. The improvement in layer performance observed in this study could be due the beneficial role of protected sodium butyrate.

The calcium butyrate (CB) was found to be ineffective in improving these parameters. Supplementation of sodium butyrate was reported to enhance the development of intestinal

epithelium (Mallo et al., 2010) and reduce pathogenic bacteria count in chicken intestine (Van Immerseel et al., 2005; Fernandez-Rubio et al., 2009).

Though the majority of layer performance parameters showed improvements with SBP supplementation compared to the control group, the difference did not reach significance, which may be due to dose of the organic acid included in the current study.

The non-significant improvement in layer production parameters observed in SBP fed groups in the present study may partly be due to the beneficial effects associated with optimum gut development (Mallo et al., 2012) and possible reduction in pathogen count in the intestine (Rama Rao et al., 2004). From the obtained data it can be concluded that sodium butyrate protected with fat is more effective than calcium butyrate, as it increases eggshell quality, nutrient digestibility and layer production.

SBP sodium butyrate protected with palm stearine, CB calcium butyrate, EP egg production, FI feed intake, FE feed efficiency, EW egg weight, EM egg mass, SW shell weight, ST shell thickness, ED egg density, BS egg breaking strength, HU Haugh unit scoreReferences:Fernández-Rubio C, Ordóñez C, Abad-González J, Garcia-Gallego A, Honrubia P, Mallo JJ & Balaña-Fouce R (2009) Poultry Science 88: 943-948. Jin LZ, Ho YW, Abdullah N & Jalaludin S (1997) World’s Poultry Science Journal 53: 351-368.

Lee KW, Everts H, Kappert HJ, Wouterse H, Frehner M & Beynen AC (2004) International Journal of Poultry Science 3: 608– 612.Lesson S (2007) Nutritional Abstracts and Reviews 71: 1-5. Mallo JJ, Balfagón A, Gracia MI, Honrubia P & Puyalto M (2012) Journal of Animal Science 90: 227–229. Mallo JJ, Gracia MI, Sanchez J, Honrubia P & Puyalto M (2010) XIIIth European Poultry Conference Proceedings, pp. 171-738. Mallo JJ, Puyalto M & Kis I (2012) International Poultry Scientific Forum Proceedings, Abstract 328. Panda AK, Reddy MR, Rama Rao SV & Praharaj NK (2003) Tropical Animal Health and Production 35: 85-94. Panda AK, Rama Rao SV, Raju MVLN & Shyam Sunder G (2009) Asian Australian Journal of Animal Sciences 22: 1026-1031. Rama Rao SV, Reddy MR, Raju MVLN & Panda AK (2004) Indian Journal of Poultry Science 39: 125-130. Snedecor GW & Cochran WG (1980) Statistical Methods, Oxford and IBH Publishing Company, New Delhi, India. van Immerseel F, Boyen F, Gantois I, Timbermont L, Bohez L, Pasmans F, Haesebrouck F & Ducatelle R (2005) Poultry Science 84: 1851-1856.

*NOREL S.A. Jesús Aprendiz 19, 1º A, 28007, Madrid, Spain; [email protected] * Project Directorate on Poultry, Rajendranagar, Hyderabad 500 030, IndiaThis article was recently presented at Australian Poultry Science Symposium and published with permission.

v

CRC NEWS

36

Waste to energy – the potential of BiodigestionWith many limits in efficiency being reached within poultry production parameters, producers are looking at further cost savings via incremental gains.